Unlock Superior Camshaft Performance with Advanced Materials and Treatments

Camshafts Technology Background And Goals

In this report, you will explore the potential of advanced materials and surface treatments in enhancing the performance of camshafts. This involves analyzing the current state of camshaft technology, identifying key challenges, and evaluating promising solutions.

Camshafts play a crucial role in controlling the opening and closing of engine valves, directly impacting engine efficiency and power output. Improving their performance through material advancements and surface modifications can lead to reduced friction, increased durability, and better overall engine performance. The report will delve into the latest developments in high-strength alloys, coatings, and surface treatments that can address issues such as wear resistance, fatigue life, and thermal stability.

Camshafts Market Demand Analysis

- Market Size and Growth

Provide an overview of the current market size for camshafts, including the total revenue and unit sales. Analyze the projected growth rate and market potential over the next 5-10 years, considering factors like increasing vehicle production, demand for high-performance engines, and the adoption of advanced materials. - Application Segments

Identify the key application segments driving the demand for camshafts, such as passenger vehicles, commercial vehicles, motorsports, and aftermarket replacements. Discuss the specific requirements and trends within each segment that influence camshaft design and performance. - Regional Dynamics

Analyze the regional distribution of camshaft demand, highlighting major manufacturing hubs and consumer markets. Discuss the impact of factors like emission regulations, fuel efficiency standards, and consumer preferences on regional demand patterns. - Competitive Landscape

Provide an overview of the major players in the camshaft market, including OEMs, tier-1 suppliers, and aftermarket manufacturers. Analyze their market shares, product offerings, and competitive strategies to gain insights into the competitive dynamics. - Emerging Trends and Drivers

Identify the key trends and drivers shaping the future demand for camshafts, such as the adoption of variable valve timing systems, downsizing and turbocharging of engines, and the increasing focus on reducing emissions and improving fuel efficiency.

Camshafts Technology Status And Challenges

- Material Advancements

Exploring new materials like advanced alloys, ceramics, and composites for improved strength, wear resistance, and thermal stability. - Surface Engineering

Investigating surface treatments like nitriding, coatings, and texturing to enhance surface properties and reduce friction. - Manufacturing Techniques

Evaluating advanced manufacturing processes like precision casting, forging, and machining for better dimensional accuracy and surface finish. - Design Optimization

Utilizing computational tools and simulations to optimize camshaft design for improved performance and durability. - Tribological Studies

Analyzing friction, wear, and lubrication mechanisms to develop strategies for reducing frictional losses and extending component life.

Camshafts Current Technical Solutions

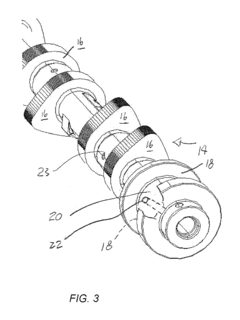

01 Camshaft Profile Optimization

Optimizing camshaft profile, including cam lobe shape, lift, and timing, can improve engine performance, fuel efficiency, and emissions through advanced design techniques and simulations.- Camshaft Profile Optimization: Optimizing camshaft profile, including cam lobe shape, lift, and timing, can enhance engine performance, fuel efficiency, and emissions through advanced design techniques and simulations.

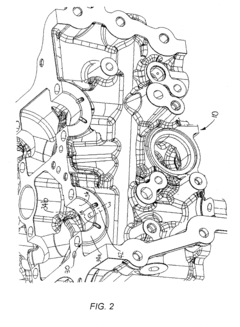

- Variable Valve Timing Systems: Variable valve timing systems, hydraulically or electrically actuated, allow adjusting intake and exhaust valve timing for better engine performance across different operating conditions.

- Advanced Camshaft Materials and Coatings: Using lightweight alloys, ceramic coatings, and diamond-like carbon coatings for camshafts can improve wear resistance, reduce friction, and enhance durability.

- Improved Camshaft Manufacturing Processes: Precision casting, forging, or machining processes can enhance camshaft quality, ensuring accurate dimensions, surface finish, and structural integrity.

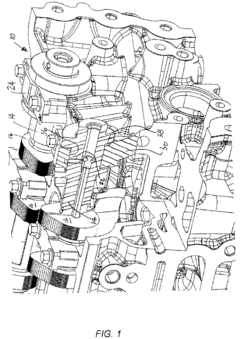

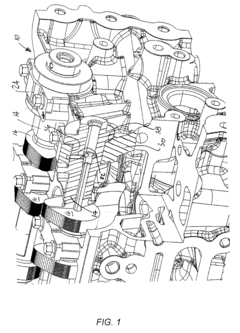

- Optimized Camshaft Drive Systems: Optimizing camshaft drive systems, including timing chain, gears, or belt, can improve reliability, reduce noise and vibration, and enhance overall engine performance.

02 Variable Valve Timing Systems

Variable valve timing systems, hydraulically or electrically actuated, allow adjusting intake and exhaust valve timing for better engine performance across different operating conditions.Expand Specific Solutions03 Advanced Camshaft Materials and Coatings

Using lightweight alloys, ceramic coatings, and diamond-like carbon coatings for camshafts can improve wear resistance, reduce friction, and enhance durability.Expand Specific Solutions04 Improved Camshaft Manufacturing Processes

Improved manufacturing processes, such as precision casting, forging, and machining, can enhance camshaft quality, ensuring accurate dimensions, surface finish, and overall durability.Expand Specific Solutions05 Optimized Camshaft Drive Systems

Optimizing camshaft drive systems, including timing chain, gears, and tensioners, can reduce noise, vibration, and wear, leading to improved engine performance and reliability.Expand Specific Solutions

Camshafts Main Player Analysis

BorgWarner, Inc.

GM Global Technology Operations LLC

Camshafts Key Technology Interpretation

- The camshaft system includes surface-piercing lubricant distribution channels formed in the bulkhead thrust surfaces to provide enhanced lubrication for the camshaft thrust surfaces.

- The camshaft system uses a cost-effective through bore type of bearing system for mounting the camshaft, while promoting long life and robustness of the camshaft thrust bearing system.

- The lubricant supply passage provides lubricant to the camshaft through the surface-piercing lubricant distribution channels, improving lubrication without adding significant cost.

Camshafts Advanced Materials Benefits Analysis

The exploration of advanced materials for camshafts is pivotal in enhancing their compression ratios and overall performance. Traditional camshafts, typically made of cast iron or steel, face limitations in weight and durability. The integration of advanced materials such as titanium alloys and carbon fiber composites has shown promising improvements. These materials offer high strength-to-weight ratios, which are crucial for reducing inertia and enhancing fuel efficiency. Through the use of innovative manufacturing techniques like additive manufacturing and advanced forging methods, these materials can be tailored to achieve specific mechanical properties.