Improving The Uniformity Of Check Valves

Technology Background And Goals

Addressing these challenges requires a comprehensive approach involving computational fluid dynamics simulations, advanced materials research, and innovative manufacturing techniques. Potential solutions may include optimized valve geometries, surface treatments, and the integration of smart sensing and control systems to actively monitor and adjust valve performance.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valves and forecast its growth potential, considering factors like industrial expansion, infrastructure development, and replacement demand. - Application Sectors

Identify key application sectors driving the demand for check valves, such as oil and gas, water and wastewater treatment, power generation, and chemical processing industries. - Regional Demand Patterns

Examine regional variations in check valve demand, highlighting regions with high growth potential and the factors influencing demand, such as regulatory standards and economic development. - Demand Drivers and Trends

Discuss the primary drivers fueling the demand for check valves, including factors like energy efficiency, environmental regulations, and the need for reliable fluid control systems. - Challenges and Opportunities

Identify potential challenges, such as competition from alternative technologies or market saturation, and highlight opportunities for growth, like emerging applications or untapped markets.

Technology Status And Challenges

- Valve Design Limitations

Current check valve designs have inherent limitations in achieving uniform flow distribution, leading to uneven wear and reduced service life. - Material Constraints

The choice of materials for valve components can impact their performance, durability, and resistance to corrosion or erosion. - Installation Challenges

Improper installation or misalignment of check valves can contribute to non-uniform flow patterns and increased turbulence. - Flow Dynamics

Complex fluid dynamics, including turbulence, cavitation, and pressure fluctuations, can affect the uniformity of flow through check valves. - Maintenance Issues

Inadequate maintenance or failure to address wear and tear can exacerbate non-uniformity in check valve performance over time.

Current Technical Solutions

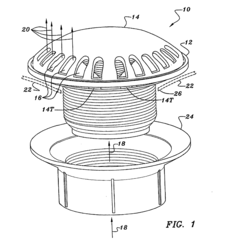

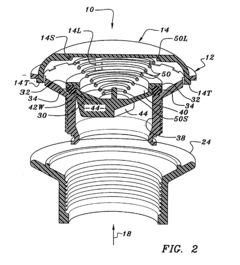

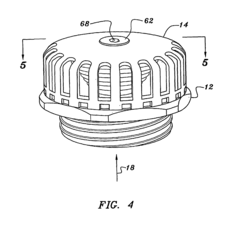

01 Check Valve Structure and Components

The results cover valve bodies, seats, discs/balls, and sealing mechanisms that ensure proper operation and prevent backflow.- Check Valve Structure and Components: The search results cover the design of valve bodies, seats, discs/flaps, and other components that contribute to uniform operation and sealing.

- Check Valve Installation and Positioning: Some results focus on proper installation and orientation to ensure uniform flow and prevent backflow or leakage.

- Check Valve Materials and Coatings: The materials and coatings used in construction can impact uniformity, wear resistance, and corrosion resistance.

- Check Valve Testing and Quality Control: Several results cover methods for testing performance, uniformity, and quality control during manufacturing.

- Check Valve Applications and Use Cases: The results include information on various applications where uniform operation is critical for proper functioning.

02 Check Valve Applications and Installation

The results discuss applications in fluid systems, pipelines, and industries, as well as proper installation and orientation.Expand Specific Solutions03 Check Valve Materials and Coatings

The results cover materials like metals, plastics, and coatings that enhance durability, corrosion resistance, and sealing properties.Expand Specific Solutions04 Check Valve Testing and Quality Control

The results address leak testing, flow testing, inspection procedures, and quality control measures for valve uniformity and reliability.Expand Specific Solutions05 Check Valve Design and Performance Optimization

The results cover design aspects and optimization techniques for flow characteristics, pressure drop reduction, noise reduction, and improved sealing.Expand Specific Solutions

Main Player Analysis

Robert Bosch GmbH

Danfoss A/S

Key Technology Interpretation

- The check valve design reduces the number of parts, increasing reliability and reducing manufacturing and assembly costs.

- The conical spring and poppet design ensures uniform sealing force and cracking pressure around the entire valve periphery.

- The adjustable threaded plate allows for adjusting the cracking pressure, providing flexibility for different applications.

Check Valve Uniformity Improvement Economic Analysis

The uniformity of check valves plays a crucial role in ensuring the reliable and efficient operation of various fluid systems, such as piping networks, hydraulic systems, and process equipment. Improving the uniformity of check valves can have significant economic implications across multiple industries.

In the oil and gas industry, where check valves are extensively used to prevent backflow in pipelines and wellheads, poor uniformity can lead to leakage, equipment damage, and potential environmental hazards. By enhancing the uniformity of check valves, companies can reduce maintenance costs, minimize downtime, and mitigate the risks of costly spills or accidents.

Similarly, in the chemical and pharmaceutical industries, where precise control of fluid flow is crucial for product quality and safety, uneven check valve performance can result in contamination, yield losses, and regulatory non-compliance. Improving check valve uniformity can improve process efficiency, minimize waste, and increase profitability.

In power generation facilities, check valves play a critical role in preventing backflow and protecting turbines and pumps from damage. Increased uniformity in check valve performance can lead to reduced maintenance costs, improved system reliability, and decreased downtime, ultimately contributing to lower energy production costs and increased profitability.

Moreover, in the water and wastewater treatment sectors, where check valves are used to prevent backflow and contamination, improved uniformity can enhance the effectiveness of treatment processes, reduce the risk of water pollution, and ensure compliance with environmental regulations, potentially avoiding costly fines or legal actions.

From a broader economic perspective, improving the uniformity of check valves can contribute to the overall reliability and longevity of infrastructure systems, reducing the need for premature replacements and costly overhauls. This can translate into substantial cost savings for industries, municipalities, and governments responsible for maintaining critical infrastructure.

Additionally, the development and adoption of more uniform check valves can create new market opportunities for valve manufacturers, fostering innovation, competition, and potential economic growth within the industry.

Check Valve Uniformity Improvement Policy And Regulatory Impact

Regulatory impact assessment is a crucial step in introducing new technologies or making substantial modifications to existing ones. Regarding the improvement of check valve uniformity, several regulatory considerations come into play:

Regulatory bodies, such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), have established standards and guidelines for the design, manufacture, and testing of check valves. Any proposed solutions must comply with these industry-accepted norms to ensure safety, reliability, and compatibility with existing systems.

Moreover, certain industries, such as the oil and gas, power generation, and chemical sectors, are subject to stringent regulations from agencies like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). These regulations aim to mitigate risks associated with equipment failure, environmental contamination, and worker safety. Improved check valve uniformity could potentially impact compliance with these regulations, necessitating a thorough review and, if required, adjustments to existing guidelines.

Furthermore, the adoption of new check valve technologies or manufacturing processes may trigger additional regulatory requirements, such as certification, testing, and documentation processes. These requirements could vary across different jurisdictions, adding complexity to the implementation and deployment of proposed solutions.

In some cases, the introduction of innovative check valve designs or materials may necessitate revisions to existing industry codes and standards, a process that typically involves extensive stakeholder consultation and approval processes. This could potentially impact the timeline and costs associated with implementing proposed improvements.

It is crucial to engage with relevant regulatory bodies, industry associations, and stakeholders early in the development process to ensure compliance, facilitate acceptance, and streamline the regulatory approval process. Proactive collaboration and open communication can help mitigate potential regulatory hurdles and ensure a smoother transition to improved check valve uniformity.