Improving The Wear Resistance Of Check Valves

Technology Background And Goals

Comprehensive research is needed to evaluate the effectiveness of these approaches under various operating conditions and to develop cost-effective solutions tailored to specific applications. Collaboration between material scientists, engineers, and end-users is crucial for achieving breakthroughs in this area.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valves and projected growth rates, considering factors like industrial expansion, infrastructure development, and replacement demand. - Application Sectors

Identify key application sectors driving demand, such as oil and gas, power generation, water and wastewater treatment, and chemical processing industries. - Regional Demand Patterns

Examine regional variations in demand, highlighting areas with high growth potential and factors influencing market dynamics, like regulatory environments and economic conditions. - Competitive Landscape

Assess the competitive landscape, including major players, their market shares, and strategies for capturing demand in different segments. - Emerging Trends

Discuss emerging trends shaping the market, such as the adoption of advanced materials, demand for compact and lightweight designs, and the integration of smart technologies.

Technology Status And Challenges

- Valve Wear Mechanisms

Erosion, corrosion, cavitation, and abrasion are the primary wear mechanisms affecting check valves. - Material Limitations

Conventional valve materials like carbon steel and stainless steel have limited wear resistance, leading to frequent replacements. - Harsh Operating Conditions

High temperatures, pressures, and flow rates in industrial applications accelerate valve wear and degradation. - Sealing Challenges

Maintaining effective sealing under varying conditions is a significant challenge, leading to leakage and performance issues. - Design Constraints

Valve design limitations, such as complex geometries and flow patterns, can contribute to localized wear and erosion.

Current Technical Solutions

01 Wear-Resistant Structure

The check valve structure incorporates wear-resistant materials, coatings, or surface treatments on components to reduce friction and wear.- Wear-Resistant Structure: The check valve structure incorporates wear-resistant materials or coatings on components like the valve seat and disc to reduce friction and enhance durability.

- Self-Cleaning Mechanism: These valves feature a self-cleaning mechanism, such as reverse flow flushing or wiping elements, to prevent debris accumulation and associated wear.

- Wear-Resistant Sealing Elements: The design includes specialized gaskets or seals made from materials like PTFE or wear-resistant polymers to prevent leakage due to wear over time.

- Wear-Resistant Valve Seat and Disc: The valve seat and disc are constructed with wear-resistant materials or coatings, like ceramics or stellites, to enhance durability and reduce wear from repeated opening and closing.

- Wear-Resistant Guide and Support Components: The valve stem, guide bushings, and other support components are designed with wear-resistant materials or coatings to ensure smooth operation and reduce wear.

02 Wear-Resistant Sealing Mechanisms

The sealing mechanisms employ specialized sealing materials, geometries, or arrangements to minimize wear on sealing surfaces and ensure proper sealing.Expand Specific Solutions03 Wear-Resistant Materials

The check valve construction utilizes wear-resistant metals, alloys, or composite materials to withstand prolonged use and minimize wear.Expand Specific Solutions04 Wear-Reducing Design

The valve design features streamlined flow paths, optimized geometries, or features that minimize turbulence and flow-induced wear.Expand Specific Solutions05 Wear Monitoring and Maintenance

Techniques like sensors, diagnostic tools, or periodic inspections are employed to monitor and detect wear, allowing for timely maintenance and replacement.Expand Specific Solutions

Technology Main Player Analysis

FANUC Corp.

Husky Injection Molding Systems Ltd.

Key Technology Interpretation

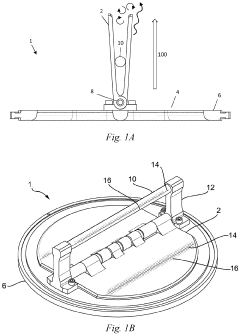

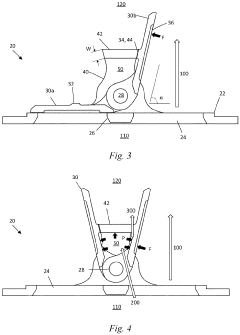

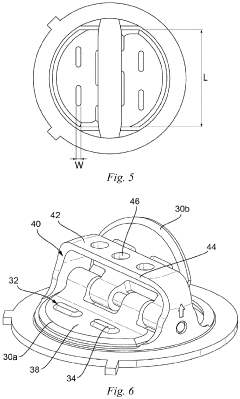

- Conformal contact surfaces: the provision of relatively large contact areas due to the conformal contact surfaces allows for the even distribution of stress between the flappers and stop elements. this reduces wear and tear on the components, especially during percussive opening of the valve. the use of conformal contact surfaces ensures that the stress is evenly distributed, preventing localized wear.

- Bumpers and adjacent openings: the inclusion of bumpers and adjacent openings in the valve design facilitates smooth opening and closing of the valve. these elements help reduce fluttering and percussive opening events, which can cause wear and damage to the contact surfaces. by minimizing these events, the valve can have a longer lifespan and reduced maintenance requirements.

- Static stop element: the provision of a static stop element with contact surfaces configured to be stationary (e.g. non-resilient) further prevents positional fluctuations of the flapper when in the open position. this additional stationary stop element further reduces wear on the contact surfaces and the pin of the hinge. the use of a static stop element ensures that the flapper remains in a fixed position, preventing any unwanted movement that could cause wear.

- Synergistic effect: the combination of conformal contact surfaces, bumpers, and static stop elements that are configured to remain stationary (rather than bend or flex in use) provides a synergistic effect. this ensures that wear on the contact surfaces is minimized, preventing wear on the pin of the hinge and reducing wear on the contact surfaces themselves. by preventing wear, the valve can have a longer lifespan and require less maintenance, resulting in cost savings for the organization.

Technology Environmental Impact

Improving the wear resistance of check valves is crucial for extending their lifespan and minimizing maintenance requirements, contributing positively to environmental sustainability. Enhanced wear resistance reduces the frequency of valve replacements, thereby decreasing the demand for raw materials and energy associated with manufacturing and transporting new valves. This reduction in material usage directly translates to a lower carbon footprint and conserves natural resources.

Additionally, by improving the durability of check valves, industries experience fewer leaks and failures, which not only supports operational efficiency but also prevents potential environmental hazards associated with fluid leaks. This aspect is particularly significant in industries dealing with hazardous substances, where leaks could lead to soil or water contamination. The improved performance of check valves contributes to sustainable industrial practices by minimizing the risk of environmental pollutants.

Moreover, adopting advanced materials or coatings to enhance wear resistance often involves using substances with longer life cycles and potentially recyclable components. This shift towards more sustainable material science aligns with global efforts to reduce industrial waste and promote the circular economy. As industries invest in research and development of these technologies, they contribute to a broader reduction of the industrial sector's environmental impact, paving the way for greener operational protocols.

In conclusion, integrating wear-resistant technologies in check valves not only supports technical and economic objectives but also aligns with environmental goals by reducing waste, conserving resources, and preventing pollution. Such innovations reinforce the industry's commitment to sustainable development and responsible resource management.