Integrating Advanced Sensors Into Check Valves

Technology Background And Goals

This report aims to provide a comprehensive overview of the technological landscape surrounding the integration of advanced sensors into check valves. This includes tracing the historical evolution of sensor technologies, identifying key milestones and breakthroughs, and projecting future development trajectories. The analysis will shed light on the current state of the technology, pinpointing existing technical challenges and bottlenecks that impede seamless sensor integration. Additionally, it will explore potential innovative pathways and solutions that could pave the way for more sophisticated and efficient sensor-valve systems, unlocking new capabilities and applications across various industries.

Market Demand Analysis

The market demand for advanced check valves with integrated sensors is driven by several key factors:

1. Increased focus on asset integrity and reliability: Industries such as oil and gas, power generation, and chemical processing are placing greater emphasis on ensuring the integrity and reliable operation of critical equipment, including check valves. Advanced sensors can provide real-time monitoring of valve performance, enabling predictive maintenance and reducing the risk of unplanned downtime.

2. Stringent regulatory requirements: Regulatory bodies are imposing stricter safety and environmental standards, particularly in industries handling hazardous materials or operating in harsh environments. Advanced check valves with integrated sensors can help operators comply with these regulations by providing accurate data on valve performance and enabling timely maintenance or replacement.

3. Digitalization and Industry 4.0: The trend towards digitalization and the adoption of Industry 4.0 principles is driving the demand for smart, connected devices that can generate data for analysis and optimization. Advanced check valves with integrated sensors can be seamlessly integrated into digital ecosystems, enabling remote monitoring, data-driven decision-making, and improved operational efficiency.

4. Cost optimization: While advanced check valves with integrated sensors may have higher upfront costs, they can provide long-term cost savings through reduced maintenance costs, extended equipment lifespan, and minimized downtime. This cost optimization potential is particularly attractive in capital-intensive industries with high operational costs.

5. Harsh and remote environments: Many industries operate in harsh or remote environments, where manual monitoring and maintenance of check valves can be challenging or hazardous. Advanced check valves with integrated sensors can provide remote monitoring capabilities, reducing the need for on-site inspections and enabling proactive maintenance planning.

6. Aging infrastructure: In many industries, aging infrastructure and equipment pose significant challenges. Advanced check valves with integrated sensors can help extend the lifespan of existing assets by providing real-time condition monitoring and enabling timely interventions.

Overall, the market demand for advanced check valves with integrated sensors is driven by the need for increased reliability, safety, compliance, cost optimization, and operational efficiency in various industries, particularly those operating in challenging environments or with aging infrastructure.

Technology Status And Challenges

- Valve Design Limitations

Current check valve designs face challenges in integrating advanced sensors due to size constraints, harsh operating environments, and compatibility issues with sensor materials. - Sensor Integration Challenges

Embedding sensors within valve bodies or components requires careful consideration of factors like temperature, pressure, vibration, and chemical resistance to ensure reliable sensor performance. - Signal Transmission Issues

Transmitting sensor data from within the valve to external monitoring systems can be problematic due to interference, signal attenuation, and the need for robust, leak-proof connections. - Power Supply Constraints

Powering sensors within check valves is challenging, as traditional wired power sources may not be feasible, and battery life can be limited in harsh environments. - Data Processing and Analysis

Effective utilization of sensor data requires advanced algorithms and computational resources for real-time analysis, fault detection, and predictive maintenance.

Current Technical Solutions

01 Fluid Flow Control

Integrating sensors with check valves to monitor and control fluid flow parameters like flow rate, pressure, temperature, or fluid composition, allowing for precise regulation and feedback in fluid systems.- Fluid Flow Control: Integrating sensors with check valves to monitor and control fluid flow parameters like rate, pressure, temperature, or composition, enabling precise regulation, feedback, and real-time adjustments in fluid systems.

- Leak Detection: Sensor integration with check valves for detecting leaks or abnormal conditions by monitoring parameters like pressure, flow rate, or fluid levels, helping maintain system integrity and prevent fluid loss.

- Reverse Flow Prevention: Sensors integrated with check valves to detect and prevent reverse flow, triggering valve closure when backflow is detected, protecting equipment and fluid sources from damage or contamination.

- System Diagnostics: Integrating sensors with check valves for comprehensive system diagnostics and monitoring, gathering data on parameters like pressure, temperature, flow rate, and valve position, enabling predictive maintenance, fault detection, and performance analysis.

- Process Automation: Sensor integration with check valves to facilitate process automation in fluid systems, using sensor data to control and automate valve operations for precise flow regulation, batch processing, or recipe-based fluid handling without manual intervention.

02 Leak Detection

Sensor integration with check valves for detecting leaks by monitoring parameters like pressure drops or flow irregularities, enabling prompt identification, maintenance, and prevention of fluid losses or environmental hazards.Expand Specific Solutions03 Valve Condition Monitoring

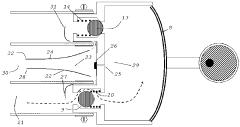

Integrating sensors with check valves to monitor valve condition and performance by tracking parameters like position, wear, or vibrations, allowing for predictive maintenance and preventing failures in critical fluid systems.Expand Specific Solutions04 Flow Direction Detection

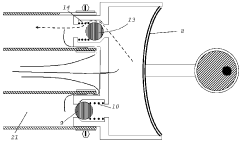

Equipping check valves with sensors to detect the direction of fluid flow, ensuring proper valve functioning, preventing backflow, and providing valuable data for system diagnostics and troubleshooting.Expand Specific Solutions05 Remote Monitoring and Control

Integrating sensors with check valves to enable remote monitoring and control of fluid systems, transmitting sensor data wirelessly or through communication networks for centralized management of distributed fluid systems.Expand Specific Solutions

Technology Main Player Analysis

Robert Bosch GmbH

Continental Automotive Systems, Inc.

Key Technology Interpretation

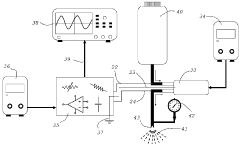

- A method for inspecting the operation of check valves and their subcomponents in real-time and during operation using low-cost electrodes inserted in a minimally invasive way.

- The electrical signals from the electrodes are proportional to the instantaneous performance of the valves, allowing real-time monitoring and evaluation.

- The use of a reference electrode allows synchronization of electrical signals in multiple valve systems, enabling comprehensive monitoring of complex systems.