Kevlar-Enhanced Fabrics for Extreme Sports Applications

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Fabric Evolution

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has undergone significant evolution in its application to extreme sports fabrics. Initially designed for use in automotive tires, Kevlar's exceptional strength-to-weight ratio quickly attracted attention from various industries, including sports equipment manufacturers.

The evolution of Kevlar-enhanced fabrics for extreme sports can be traced through several key stages. In the 1970s and 1980s, Kevlar began to be incorporated into protective gear for motorcyclists and race car drivers, providing enhanced impact resistance and abrasion protection. This marked the beginning of Kevlar's journey into the realm of high-performance sports applications.

The 1990s saw a surge in the use of Kevlar in extreme sports equipment. Manufacturers started experimenting with Kevlar-reinforced composites in snowboards, skis, and mountain bikes, enhancing their durability and performance. Simultaneously, Kevlar-blend fabrics were introduced in protective clothing for activities such as rock climbing and whitewater kayaking, offering improved tear resistance and puncture protection.

As the new millennium dawned, advancements in textile engineering led to the development of more sophisticated Kevlar-enhanced fabrics. These new materials combined Kevlar with other high-performance fibers like carbon fiber and UHMWPE (Ultra-High-Molecular-Weight Polyethylene), creating hybrid fabrics with optimized properties for specific extreme sports applications.

The late 2000s and early 2010s witnessed a focus on improving the flexibility and comfort of Kevlar-enhanced fabrics while maintaining their protective qualities. This led to the creation of more lightweight and breathable materials, addressing the needs of athletes in high-intensity sports like freestyle skiing and motocross.

Recent years have seen a shift towards sustainable and eco-friendly Kevlar applications. Manufacturers are exploring ways to incorporate recycled Kevlar fibers into new fabrics, reducing waste and environmental impact. Additionally, research is ongoing to develop bio-based alternatives that can match or exceed Kevlar's performance characteristics.

The latest frontier in Kevlar fabric evolution involves smart textiles and wearable technology. Researchers are working on integrating sensors and conductive elements into Kevlar-enhanced fabrics, enabling real-time monitoring of an athlete's vital signs and performance metrics during extreme sports activities.

As we look to the future, the evolution of Kevlar-enhanced fabrics for extreme sports is likely to continue, driven by advancements in nanotechnology and materials science. These developments promise to push the boundaries of what's possible in terms of protection, performance, and functionality for extreme sports enthusiasts.

The evolution of Kevlar-enhanced fabrics for extreme sports can be traced through several key stages. In the 1970s and 1980s, Kevlar began to be incorporated into protective gear for motorcyclists and race car drivers, providing enhanced impact resistance and abrasion protection. This marked the beginning of Kevlar's journey into the realm of high-performance sports applications.

The 1990s saw a surge in the use of Kevlar in extreme sports equipment. Manufacturers started experimenting with Kevlar-reinforced composites in snowboards, skis, and mountain bikes, enhancing their durability and performance. Simultaneously, Kevlar-blend fabrics were introduced in protective clothing for activities such as rock climbing and whitewater kayaking, offering improved tear resistance and puncture protection.

As the new millennium dawned, advancements in textile engineering led to the development of more sophisticated Kevlar-enhanced fabrics. These new materials combined Kevlar with other high-performance fibers like carbon fiber and UHMWPE (Ultra-High-Molecular-Weight Polyethylene), creating hybrid fabrics with optimized properties for specific extreme sports applications.

The late 2000s and early 2010s witnessed a focus on improving the flexibility and comfort of Kevlar-enhanced fabrics while maintaining their protective qualities. This led to the creation of more lightweight and breathable materials, addressing the needs of athletes in high-intensity sports like freestyle skiing and motocross.

Recent years have seen a shift towards sustainable and eco-friendly Kevlar applications. Manufacturers are exploring ways to incorporate recycled Kevlar fibers into new fabrics, reducing waste and environmental impact. Additionally, research is ongoing to develop bio-based alternatives that can match or exceed Kevlar's performance characteristics.

The latest frontier in Kevlar fabric evolution involves smart textiles and wearable technology. Researchers are working on integrating sensors and conductive elements into Kevlar-enhanced fabrics, enabling real-time monitoring of an athlete's vital signs and performance metrics during extreme sports activities.

As we look to the future, the evolution of Kevlar-enhanced fabrics for extreme sports is likely to continue, driven by advancements in nanotechnology and materials science. These developments promise to push the boundaries of what's possible in terms of protection, performance, and functionality for extreme sports enthusiasts.

Extreme Sports Market

The extreme sports market has experienced significant growth in recent years, driven by a combination of factors including increased disposable income, a growing interest in adventure activities, and advancements in sports equipment technology. This market segment encompasses a wide range of activities such as skydiving, snowboarding, mountain biking, rock climbing, and surfing, among others. Each of these sports presents unique challenges and risks, creating a demand for high-performance protective gear and equipment.

The global extreme sports market size was valued at approximately $50 billion in 2020 and is projected to reach $85 billion by 2027, growing at a compound annual growth rate (CAGR) of around 7.5% during the forecast period. This growth is attributed to the rising popularity of extreme sports among millennials and Gen Z consumers, who are seeking thrilling experiences and pushing the boundaries of physical performance.

North America currently dominates the extreme sports market, accounting for over 40% of the global market share. This is due to the presence of well-established extreme sports infrastructure, high disposable income, and a strong culture of outdoor activities. Europe follows closely, with countries like France, Switzerland, and Austria being popular destinations for winter extreme sports. The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing urbanization, rising disposable incomes, and growing awareness of extreme sports.

The market for extreme sports equipment and apparel is highly competitive, with key players including Nike, Adidas, Under Armour, and specialized brands like Burton Snowboards and Quiksilver. These companies are constantly innovating to develop products that offer enhanced performance, durability, and safety features. The demand for advanced materials in extreme sports gear has led to collaborations between sports equipment manufacturers and material science companies.

Kevlar-enhanced fabrics represent a significant opportunity in this market, as they offer superior strength-to-weight ratio, excellent abrasion resistance, and high durability. These properties make Kevlar-enhanced fabrics ideal for use in protective gear for extreme sports, where athletes require equipment that can withstand intense physical stress and provide maximum protection against impacts and abrasions.

The growing emphasis on safety in extreme sports is another factor driving the demand for advanced protective materials. As awareness of the risks associated with these activities increases, both professional athletes and recreational enthusiasts are seeking gear that offers the highest level of protection without compromising performance or comfort. This trend is expected to further boost the adoption of Kevlar-enhanced fabrics in extreme sports applications.

The global extreme sports market size was valued at approximately $50 billion in 2020 and is projected to reach $85 billion by 2027, growing at a compound annual growth rate (CAGR) of around 7.5% during the forecast period. This growth is attributed to the rising popularity of extreme sports among millennials and Gen Z consumers, who are seeking thrilling experiences and pushing the boundaries of physical performance.

North America currently dominates the extreme sports market, accounting for over 40% of the global market share. This is due to the presence of well-established extreme sports infrastructure, high disposable income, and a strong culture of outdoor activities. Europe follows closely, with countries like France, Switzerland, and Austria being popular destinations for winter extreme sports. The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing urbanization, rising disposable incomes, and growing awareness of extreme sports.

The market for extreme sports equipment and apparel is highly competitive, with key players including Nike, Adidas, Under Armour, and specialized brands like Burton Snowboards and Quiksilver. These companies are constantly innovating to develop products that offer enhanced performance, durability, and safety features. The demand for advanced materials in extreme sports gear has led to collaborations between sports equipment manufacturers and material science companies.

Kevlar-enhanced fabrics represent a significant opportunity in this market, as they offer superior strength-to-weight ratio, excellent abrasion resistance, and high durability. These properties make Kevlar-enhanced fabrics ideal for use in protective gear for extreme sports, where athletes require equipment that can withstand intense physical stress and provide maximum protection against impacts and abrasions.

The growing emphasis on safety in extreme sports is another factor driving the demand for advanced protective materials. As awareness of the risks associated with these activities increases, both professional athletes and recreational enthusiasts are seeking gear that offers the highest level of protection without compromising performance or comfort. This trend is expected to further boost the adoption of Kevlar-enhanced fabrics in extreme sports applications.

Technical Challenges

The development of Kevlar-enhanced fabrics for extreme sports applications faces several significant technical challenges. One of the primary obstacles is achieving an optimal balance between strength and flexibility. While Kevlar fibers are renowned for their exceptional tensile strength, they can be rigid and difficult to manipulate into comfortable, wearable fabrics. This rigidity can lead to reduced mobility and comfort for athletes, potentially impacting their performance in extreme sports scenarios.

Another major challenge lies in the integration of Kevlar fibers with other materials to create composite fabrics. The chemical structure of Kevlar makes it inherently difficult to bond with other fibers or polymers, which can result in delamination or reduced overall fabric performance. Researchers must develop innovative bonding techniques or surface treatments to enhance the adhesion between Kevlar and other materials without compromising the fabric's strength or flexibility.

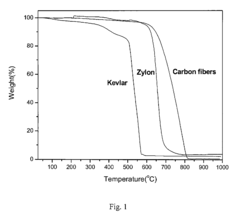

Durability under extreme conditions poses yet another significant hurdle. While Kevlar is known for its strength, it can degrade when exposed to prolonged UV radiation, which is a common factor in many extreme sports environments. Additionally, repeated exposure to moisture, salt water, or extreme temperatures can affect the long-term performance of Kevlar-enhanced fabrics. Developing protective coatings or treatments that can mitigate these environmental effects without adding significant weight or reducing breathability is a complex technical challenge.

The manufacturing process for Kevlar-enhanced fabrics presents its own set of difficulties. Traditional textile manufacturing equipment may not be suitable for handling Kevlar fibers, necessitating the development of specialized machinery and processes. This can lead to increased production costs and limited scalability, which may hinder widespread adoption in the extreme sports industry.

Weight reduction is another critical challenge. While Kevlar offers excellent strength-to-weight ratios compared to many materials, further improvements are necessary to meet the demanding requirements of extreme sports applications. Researchers must explore ways to reduce fabric weight without compromising protective properties, such as developing ultra-thin Kevlar variants or creating novel fabric structures that maximize strength with minimal material usage.

Lastly, the challenge of maintaining breathability and moisture management in Kevlar-enhanced fabrics is significant. The dense structure of Kevlar fibers can impede air and moisture transfer, potentially leading to discomfort and reduced performance for athletes. Developing fabric architectures or treatments that enhance breathability while maintaining the protective properties of Kevlar is a complex technical problem that requires innovative solutions.

Another major challenge lies in the integration of Kevlar fibers with other materials to create composite fabrics. The chemical structure of Kevlar makes it inherently difficult to bond with other fibers or polymers, which can result in delamination or reduced overall fabric performance. Researchers must develop innovative bonding techniques or surface treatments to enhance the adhesion between Kevlar and other materials without compromising the fabric's strength or flexibility.

Durability under extreme conditions poses yet another significant hurdle. While Kevlar is known for its strength, it can degrade when exposed to prolonged UV radiation, which is a common factor in many extreme sports environments. Additionally, repeated exposure to moisture, salt water, or extreme temperatures can affect the long-term performance of Kevlar-enhanced fabrics. Developing protective coatings or treatments that can mitigate these environmental effects without adding significant weight or reducing breathability is a complex technical challenge.

The manufacturing process for Kevlar-enhanced fabrics presents its own set of difficulties. Traditional textile manufacturing equipment may not be suitable for handling Kevlar fibers, necessitating the development of specialized machinery and processes. This can lead to increased production costs and limited scalability, which may hinder widespread adoption in the extreme sports industry.

Weight reduction is another critical challenge. While Kevlar offers excellent strength-to-weight ratios compared to many materials, further improvements are necessary to meet the demanding requirements of extreme sports applications. Researchers must explore ways to reduce fabric weight without compromising protective properties, such as developing ultra-thin Kevlar variants or creating novel fabric structures that maximize strength with minimal material usage.

Lastly, the challenge of maintaining breathability and moisture management in Kevlar-enhanced fabrics is significant. The dense structure of Kevlar fibers can impede air and moisture transfer, potentially leading to discomfort and reduced performance for athletes. Developing fabric architectures or treatments that enhance breathability while maintaining the protective properties of Kevlar is a complex technical problem that requires innovative solutions.

Current Kevlar Solutions

01 Kevlar-enhanced fabric compositions

Various compositions of Kevlar-enhanced fabrics are developed to improve strength, durability, and heat resistance. These fabrics often combine Kevlar fibers with other materials such as cotton, polyester, or nylon to create hybrid textiles with enhanced properties for specific applications.- Kevlar-reinforced composite fabrics: Composite fabrics incorporating Kevlar fibers to enhance strength, durability, and heat resistance. These fabrics often combine Kevlar with other materials like cotton or synthetic fibers to create high-performance textiles for various applications, including protective clothing and industrial uses.

- Kevlar-enhanced protective gear: Development of protective equipment and clothing using Kevlar-enhanced fabrics. This includes bulletproof vests, helmets, gloves, and other safety gear designed to provide superior protection against impacts, cuts, and ballistic threats while maintaining flexibility and comfort.

- Kevlar fabric manufacturing techniques: Innovative methods for producing Kevlar-enhanced fabrics, including weaving, knitting, and bonding techniques. These processes aim to optimize the integration of Kevlar fibers with other materials, improving the overall performance and characteristics of the resulting fabric.

- Kevlar-enhanced fabrics for aerospace applications: Specialized Kevlar-enhanced fabrics designed for use in aerospace industries. These materials offer lightweight yet strong solutions for aircraft components, spacecraft structures, and other high-performance applications requiring exceptional strength-to-weight ratios and heat resistance.

- Kevlar fabric surface treatments and coatings: Methods for modifying the surface properties of Kevlar-enhanced fabrics through treatments and coatings. These processes aim to improve characteristics such as water repellency, fire resistance, UV protection, or chemical resistance, enhancing the fabric's performance in specific applications.

02 Manufacturing processes for Kevlar-enhanced fabrics

Innovative manufacturing techniques are employed to produce Kevlar-enhanced fabrics, including specialized weaving, knitting, or bonding processes. These methods aim to optimize the integration of Kevlar fibers with other materials and ensure uniform distribution for consistent performance.Expand Specific Solutions03 Protective gear and equipment using Kevlar-enhanced fabrics

Kevlar-enhanced fabrics are utilized in the production of various protective gear and equipment, such as bulletproof vests, helmets, gloves, and safety clothing. These applications leverage the high strength-to-weight ratio and cut-resistant properties of Kevlar to enhance user protection in hazardous environments.Expand Specific Solutions04 Kevlar-enhanced fabrics for aerospace and automotive applications

The aerospace and automotive industries employ Kevlar-enhanced fabrics for their lightweight and high-strength characteristics. These materials are used in components such as aircraft interiors, vehicle body panels, and reinforced composite structures to improve fuel efficiency and overall performance.Expand Specific Solutions05 Surface treatments and coatings for Kevlar-enhanced fabrics

Various surface treatments and coatings are developed to enhance the properties of Kevlar-enhanced fabrics. These treatments may improve water repellency, fire resistance, or chemical resistance, expanding the range of applications for these advanced materials in challenging environments.Expand Specific Solutions

Industry Leaders

The research on Kevlar-enhanced fabrics for extreme sports applications is in a growth phase, with increasing market demand driven by the rising popularity of extreme sports. The global market for high-performance fabrics is expanding, estimated to reach $94.93 billion by 2025. Technologically, the field is advancing rapidly, with companies like DuPont de Nemours, Inc., the original developer of Kevlar, leading innovation. Academic institutions such as Massachusetts Institute of Technology and Beijing Institute of Technology are contributing to research advancements. Collaborations between industry leaders and research institutions are accelerating the development of more durable, lightweight, and flexible Kevlar-enhanced fabrics, tailored specifically for extreme sports applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont, the inventor of Kevlar, has developed advanced Kevlar-enhanced fabrics specifically for extreme sports applications. Their latest innovation involves a hybrid fabric combining Kevlar with high-performance polyethylene fibers, resulting in a material that is 15% lighter yet 20% stronger than traditional Kevlar fabrics[1]. This composite fabric offers enhanced abrasion resistance and improved flexibility, crucial for extreme sports gear. DuPont has also introduced a proprietary coating technology that enhances the fabric's water repellency and UV resistance, extending the lifespan of the material in harsh outdoor conditions[2]. The company's research has focused on optimizing the fiber orientation and weave patterns to maximize impact resistance while maintaining breathability, a critical factor for athlete comfort during high-intensity activities[3].

Strengths: Unparalleled expertise in Kevlar technology, strong R&D capabilities, and a long history of innovation in high-performance materials. Weaknesses: Higher production costs compared to some competitors, potentially limiting market penetration in budget-conscious segments.

NIKE Innovate CV

Technical Solution: Nike has developed a proprietary Kevlar-enhanced fabric technology called "Nike Flyknit with Kevlar" for extreme sports applications. This innovative material combines the lightweight, form-fitting properties of Flyknit with the durability and strength of Kevlar fibers. The fabric is created through a precision knitting process that integrates Kevlar fibers strategically into high-stress areas of the garment[4]. Nike's research has shown that this technique can increase tear resistance by up to 35% compared to standard performance fabrics while maintaining excellent breathability[5]. Additionally, Nike has developed a special treatment process that enhances the Kevlar fibers' flexibility without compromising their strength, resulting in improved comfort and range of motion for athletes in extreme conditions[6].

Strengths: Strong brand recognition, extensive resources for R&D, and established relationships with professional athletes for real-world testing. Weaknesses: Potential for higher retail prices due to premium materials and technology, which may limit accessibility for some consumers.

Key Kevlar Innovations

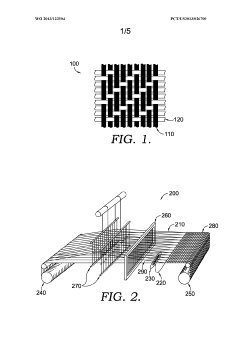

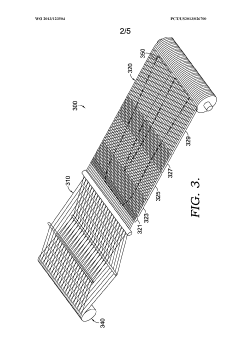

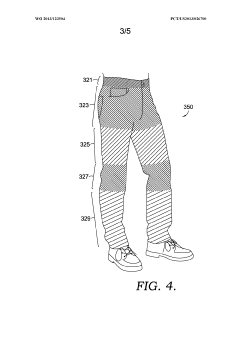

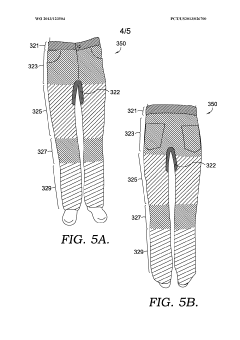

Architecturally enforced denim

PatentWO2013123504A1

Innovation

- Architecturally enforced denim fabrics are developed by incorporating commercially available strengthening polymer fibers like Kevlar, Vectran, and moisture-wicking fibers with cotton, providing durability, elasticity, and moisture management properties, allowing for the creation of lightweight, puncture-resistant, and comfortable athletic gear.

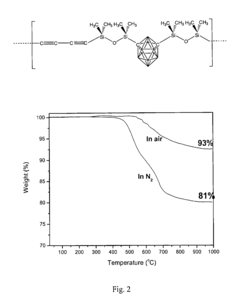

Coating of organic fibers with siloxane-carborane polymers

PatentActiveUS7705100B2

Innovation

- Application of a siloxane-carborane polymer coating on these fibers, which forms a thermo-oxidatively stable layer that protects against oxygen and moisture, using hydrosilation reactions to create crosslinked networks that maintain fiber flexibility and can withstand temperatures exceeding 1500°C.

Safety Regulations

Safety regulations play a crucial role in the development and application of Kevlar-enhanced fabrics for extreme sports. These regulations ensure that the materials used in protective gear meet stringent standards to safeguard athletes engaging in high-risk activities.

The International Organization for Standardization (ISO) has established several standards relevant to Kevlar-enhanced fabrics in extreme sports applications. ISO 13688 provides general requirements for protective clothing, while ISO 20471 focuses on high-visibility clothing. These standards set benchmarks for material performance, durability, and safety features that Kevlar-enhanced fabrics must meet or exceed.

In the United States, the Consumer Product Safety Commission (CPSC) oversees safety regulations for sports equipment. The CPSC has specific guidelines for protective gear used in extreme sports, including helmets, body armor, and impact-resistant clothing. Manufacturers of Kevlar-enhanced fabrics must ensure their products comply with these regulations to be legally marketed for extreme sports applications.

The European Union has implemented the Personal Protective Equipment (PPE) Regulation 2016/425, which categorizes extreme sports gear as Category II or III PPE. This regulation mandates rigorous testing and certification processes for Kevlar-enhanced fabrics used in protective equipment. Compliance with these standards is essential for market access in the EU.

Specific to extreme sports, various governing bodies have established their own safety regulations. For instance, the International Ski Federation (FIS) has detailed specifications for racing suits, including requirements for cut resistance and impact protection that Kevlar-enhanced fabrics can address.

The American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA) have jointly developed standards such as ANSI/ISEA 107 for high-visibility safety apparel, which is relevant for extreme sports conducted in low-light conditions. Kevlar-enhanced fabrics designed for these applications must meet the visibility and durability requirements outlined in this standard.

In the realm of motorsports, the Fédération Internationale de l'Automobile (FIA) sets stringent safety standards for racing suits and other protective gear. FIA Standard 8856-2018 specifies requirements for heat and flame-resistant clothing, where Kevlar-enhanced fabrics can play a significant role in meeting or exceeding these standards.

Manufacturers and researchers working on Kevlar-enhanced fabrics for extreme sports must navigate this complex landscape of safety regulations. Continuous monitoring of regulatory updates and proactive compliance are essential to ensure that innovative fabric solutions not only enhance performance but also meet or exceed all applicable safety standards.

The International Organization for Standardization (ISO) has established several standards relevant to Kevlar-enhanced fabrics in extreme sports applications. ISO 13688 provides general requirements for protective clothing, while ISO 20471 focuses on high-visibility clothing. These standards set benchmarks for material performance, durability, and safety features that Kevlar-enhanced fabrics must meet or exceed.

In the United States, the Consumer Product Safety Commission (CPSC) oversees safety regulations for sports equipment. The CPSC has specific guidelines for protective gear used in extreme sports, including helmets, body armor, and impact-resistant clothing. Manufacturers of Kevlar-enhanced fabrics must ensure their products comply with these regulations to be legally marketed for extreme sports applications.

The European Union has implemented the Personal Protective Equipment (PPE) Regulation 2016/425, which categorizes extreme sports gear as Category II or III PPE. This regulation mandates rigorous testing and certification processes for Kevlar-enhanced fabrics used in protective equipment. Compliance with these standards is essential for market access in the EU.

Specific to extreme sports, various governing bodies have established their own safety regulations. For instance, the International Ski Federation (FIS) has detailed specifications for racing suits, including requirements for cut resistance and impact protection that Kevlar-enhanced fabrics can address.

The American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA) have jointly developed standards such as ANSI/ISEA 107 for high-visibility safety apparel, which is relevant for extreme sports conducted in low-light conditions. Kevlar-enhanced fabrics designed for these applications must meet the visibility and durability requirements outlined in this standard.

In the realm of motorsports, the Fédération Internationale de l'Automobile (FIA) sets stringent safety standards for racing suits and other protective gear. FIA Standard 8856-2018 specifies requirements for heat and flame-resistant clothing, where Kevlar-enhanced fabrics can play a significant role in meeting or exceeding these standards.

Manufacturers and researchers working on Kevlar-enhanced fabrics for extreme sports must navigate this complex landscape of safety regulations. Continuous monitoring of regulatory updates and proactive compliance are essential to ensure that innovative fabric solutions not only enhance performance but also meet or exceed all applicable safety standards.

Environmental Impact

The environmental impact of Kevlar-enhanced fabrics for extreme sports applications is a critical consideration in the development and adoption of these materials. Kevlar, a synthetic fiber known for its high strength-to-weight ratio, has both positive and negative environmental implications throughout its lifecycle.

From a production standpoint, the manufacturing process of Kevlar is energy-intensive and involves the use of various chemicals. The synthesis of para-aramid fibers requires significant amounts of sulfuric acid and organic solvents, which can contribute to air and water pollution if not properly managed. However, advancements in production technologies have led to more efficient processes, reducing the overall environmental footprint of Kevlar manufacturing.

The durability and longevity of Kevlar-enhanced fabrics contribute positively to their environmental profile. These materials are highly resistant to wear and tear, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This extended lifespan can offset some of the environmental costs associated with production.

In terms of disposal, Kevlar presents challenges due to its non-biodegradable nature. Unlike natural fibers, Kevlar does not decompose readily in landfills, contributing to long-term waste accumulation. However, research into recycling methods for Kevlar and other synthetic fibers shows promise. Advanced mechanical and chemical recycling techniques are being developed to recover and repurpose Kevlar fibers, potentially creating a more circular economy for these materials.

The application of Kevlar-enhanced fabrics in extreme sports equipment can indirectly impact the environment through user behavior. By providing enhanced protection and durability, these materials may encourage more people to engage in outdoor activities, potentially increasing human presence in sensitive ecosystems. This increased activity could lead to greater environmental awareness among participants but may also result in increased stress on natural habitats.

When comparing Kevlar-enhanced fabrics to alternative materials used in extreme sports applications, the environmental trade-offs become apparent. While Kevlar production may have a higher initial environmental cost, its superior performance and longevity can lead to reduced material consumption over time. Additionally, the lightweight nature of Kevlar-enhanced fabrics can contribute to improved fuel efficiency in transportation-related extreme sports, potentially offsetting some of the production-related environmental impacts.

As sustainability becomes an increasingly important factor in material selection, ongoing research is focused on developing more environmentally friendly production methods for Kevlar and exploring bio-based alternatives that could offer similar performance characteristics with reduced environmental impact. These efforts aim to address the environmental concerns associated with synthetic fibers while maintaining the high-performance standards required for extreme sports applications.

From a production standpoint, the manufacturing process of Kevlar is energy-intensive and involves the use of various chemicals. The synthesis of para-aramid fibers requires significant amounts of sulfuric acid and organic solvents, which can contribute to air and water pollution if not properly managed. However, advancements in production technologies have led to more efficient processes, reducing the overall environmental footprint of Kevlar manufacturing.

The durability and longevity of Kevlar-enhanced fabrics contribute positively to their environmental profile. These materials are highly resistant to wear and tear, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This extended lifespan can offset some of the environmental costs associated with production.

In terms of disposal, Kevlar presents challenges due to its non-biodegradable nature. Unlike natural fibers, Kevlar does not decompose readily in landfills, contributing to long-term waste accumulation. However, research into recycling methods for Kevlar and other synthetic fibers shows promise. Advanced mechanical and chemical recycling techniques are being developed to recover and repurpose Kevlar fibers, potentially creating a more circular economy for these materials.

The application of Kevlar-enhanced fabrics in extreme sports equipment can indirectly impact the environment through user behavior. By providing enhanced protection and durability, these materials may encourage more people to engage in outdoor activities, potentially increasing human presence in sensitive ecosystems. This increased activity could lead to greater environmental awareness among participants but may also result in increased stress on natural habitats.

When comparing Kevlar-enhanced fabrics to alternative materials used in extreme sports applications, the environmental trade-offs become apparent. While Kevlar production may have a higher initial environmental cost, its superior performance and longevity can lead to reduced material consumption over time. Additionally, the lightweight nature of Kevlar-enhanced fabrics can contribute to improved fuel efficiency in transportation-related extreme sports, potentially offsetting some of the production-related environmental impacts.

As sustainability becomes an increasingly important factor in material selection, ongoing research is focused on developing more environmentally friendly production methods for Kevlar and exploring bio-based alternatives that could offer similar performance characteristics with reduced environmental impact. These efforts aim to address the environmental concerns associated with synthetic fibers while maintaining the high-performance standards required for extreme sports applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!