Kevlar Use in New Environmental Impact Mitigation Tools

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Eco-Tools: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has long been recognized for its exceptional strength-to-weight ratio and heat-resistant properties. Initially utilized in military and aerospace applications, Kevlar has since found its way into various industries, including automotive, sports equipment, and personal protective gear. The evolution of environmental concerns and the growing emphasis on sustainable development have now prompted researchers and innovators to explore Kevlar's potential in creating new tools for environmental impact mitigation.

The primary objective of this research is to investigate and evaluate the application of Kevlar in developing innovative eco-friendly tools that can effectively address environmental challenges. This exploration aims to leverage Kevlar's unique properties to create solutions that are not only durable and efficient but also contribute to reducing the overall environmental footprint of various industries and human activities.

The technological landscape surrounding Kevlar has seen significant advancements since its inception. Recent developments in material science and manufacturing processes have opened up new possibilities for tailoring Kevlar's properties to suit specific environmental applications. These advancements include improvements in fiber production techniques, the development of Kevlar composites, and the integration of Kevlar with other materials to enhance its functionality in diverse environmental conditions.

As we delve into the potential of Kevlar in eco-tools, it is crucial to consider the current environmental challenges that these tools aim to address. Climate change, pollution, resource depletion, and habitat destruction are among the pressing issues that require innovative solutions. The unique properties of Kevlar, such as its high tensile strength, chemical resistance, and lightweight nature, position it as a promising material for developing tools that can withstand harsh environmental conditions while minimizing resource consumption and environmental impact.

The research trajectory for Kevlar in environmental impact mitigation tools encompasses several key areas. These include the development of advanced filtration systems for air and water purification, the creation of durable and lightweight structures for habitat restoration projects, and the design of protective barriers against natural disasters. Additionally, the potential for Kevlar-based materials in renewable energy technologies and sustainable transportation solutions presents exciting avenues for exploration.

As we embark on this research, it is essential to acknowledge the interdisciplinary nature of the endeavor. The successful integration of Kevlar into eco-tools will require collaboration between materials scientists, environmental engineers, ecologists, and sustainability experts. This collaborative approach will ensure that the developed tools not only leverage Kevlar's technical capabilities but also align with broader environmental goals and sustainability principles.

The primary objective of this research is to investigate and evaluate the application of Kevlar in developing innovative eco-friendly tools that can effectively address environmental challenges. This exploration aims to leverage Kevlar's unique properties to create solutions that are not only durable and efficient but also contribute to reducing the overall environmental footprint of various industries and human activities.

The technological landscape surrounding Kevlar has seen significant advancements since its inception. Recent developments in material science and manufacturing processes have opened up new possibilities for tailoring Kevlar's properties to suit specific environmental applications. These advancements include improvements in fiber production techniques, the development of Kevlar composites, and the integration of Kevlar with other materials to enhance its functionality in diverse environmental conditions.

As we delve into the potential of Kevlar in eco-tools, it is crucial to consider the current environmental challenges that these tools aim to address. Climate change, pollution, resource depletion, and habitat destruction are among the pressing issues that require innovative solutions. The unique properties of Kevlar, such as its high tensile strength, chemical resistance, and lightweight nature, position it as a promising material for developing tools that can withstand harsh environmental conditions while minimizing resource consumption and environmental impact.

The research trajectory for Kevlar in environmental impact mitigation tools encompasses several key areas. These include the development of advanced filtration systems for air and water purification, the creation of durable and lightweight structures for habitat restoration projects, and the design of protective barriers against natural disasters. Additionally, the potential for Kevlar-based materials in renewable energy technologies and sustainable transportation solutions presents exciting avenues for exploration.

As we embark on this research, it is essential to acknowledge the interdisciplinary nature of the endeavor. The successful integration of Kevlar into eco-tools will require collaboration between materials scientists, environmental engineers, ecologists, and sustainability experts. This collaborative approach will ensure that the developed tools not only leverage Kevlar's technical capabilities but also align with broader environmental goals and sustainability principles.

Market Analysis for Green Tech Solutions

The market for green technology solutions, particularly those involving Kevlar in environmental impact mitigation tools, is experiencing significant growth and transformation. This trend is driven by increasing global awareness of environmental issues and the urgent need for sustainable practices across industries. The demand for innovative materials that can effectively address environmental challenges while offering durability and performance is on the rise.

Kevlar, known for its exceptional strength-to-weight ratio and heat resistance, is finding new applications in environmental protection tools. The market for these solutions is expanding rapidly, with a focus on areas such as soil erosion control, water filtration systems, and protective barriers for sensitive ecosystems. Industries such as construction, agriculture, and environmental remediation are showing particular interest in Kevlar-based green tech solutions.

The market size for environmental impact mitigation tools is substantial and growing. This growth is fueled by stringent environmental regulations, corporate sustainability initiatives, and increasing public pressure for eco-friendly practices. Governments worldwide are implementing policies that encourage the adoption of green technologies, creating a favorable market environment for Kevlar-based solutions.

Key market drivers include the need for long-lasting, high-performance materials that can withstand harsh environmental conditions while minimizing ecological impact. Kevlar's unique properties make it an attractive option for developing durable, lightweight, and effective environmental protection tools. The material's resistance to degradation and its potential for recycling align well with circular economy principles, further enhancing its market appeal.

Geographically, North America and Europe are currently leading the market for green tech solutions, including those utilizing Kevlar. However, rapid industrialization and growing environmental concerns in Asia-Pacific regions are expected to drive significant market growth in these areas in the coming years. Emerging economies are increasingly recognizing the importance of environmental protection, creating new opportunities for innovative green technologies.

The competitive landscape in this market is diverse, with both established materials science companies and innovative startups vying for market share. Companies are investing heavily in research and development to create novel applications for Kevlar in environmental protection. Collaborations between material manufacturers, environmental agencies, and end-users are becoming more common, fostering innovation and accelerating market growth.

Despite the positive outlook, challenges remain. The high cost of Kevlar compared to traditional materials may limit adoption in some sectors. Additionally, educating potential users about the long-term benefits and performance advantages of Kevlar-based solutions is crucial for market expansion. Overcoming these barriers will be key to realizing the full market potential of Kevlar in environmental impact mitigation tools.

Kevlar, known for its exceptional strength-to-weight ratio and heat resistance, is finding new applications in environmental protection tools. The market for these solutions is expanding rapidly, with a focus on areas such as soil erosion control, water filtration systems, and protective barriers for sensitive ecosystems. Industries such as construction, agriculture, and environmental remediation are showing particular interest in Kevlar-based green tech solutions.

The market size for environmental impact mitigation tools is substantial and growing. This growth is fueled by stringent environmental regulations, corporate sustainability initiatives, and increasing public pressure for eco-friendly practices. Governments worldwide are implementing policies that encourage the adoption of green technologies, creating a favorable market environment for Kevlar-based solutions.

Key market drivers include the need for long-lasting, high-performance materials that can withstand harsh environmental conditions while minimizing ecological impact. Kevlar's unique properties make it an attractive option for developing durable, lightweight, and effective environmental protection tools. The material's resistance to degradation and its potential for recycling align well with circular economy principles, further enhancing its market appeal.

Geographically, North America and Europe are currently leading the market for green tech solutions, including those utilizing Kevlar. However, rapid industrialization and growing environmental concerns in Asia-Pacific regions are expected to drive significant market growth in these areas in the coming years. Emerging economies are increasingly recognizing the importance of environmental protection, creating new opportunities for innovative green technologies.

The competitive landscape in this market is diverse, with both established materials science companies and innovative startups vying for market share. Companies are investing heavily in research and development to create novel applications for Kevlar in environmental protection. Collaborations between material manufacturers, environmental agencies, and end-users are becoming more common, fostering innovation and accelerating market growth.

Despite the positive outlook, challenges remain. The high cost of Kevlar compared to traditional materials may limit adoption in some sectors. Additionally, educating potential users about the long-term benefits and performance advantages of Kevlar-based solutions is crucial for market expansion. Overcoming these barriers will be key to realizing the full market potential of Kevlar in environmental impact mitigation tools.

Kevlar Tech Status and Challenges

Kevlar, a high-strength synthetic fiber developed by DuPont, has been widely used in various applications since its introduction in the 1970s. In the context of environmental impact mitigation tools, Kevlar's unique properties offer significant potential for innovation and advancement. However, the current state of Kevlar technology in this specific field faces several challenges and limitations.

The primary advantage of Kevlar in environmental impact mitigation tools lies in its exceptional strength-to-weight ratio, which allows for the creation of lightweight yet durable structures. This property is particularly valuable in the development of protective barriers, containment systems, and reinforcement materials for environmental applications. However, the high cost of Kevlar production remains a significant obstacle to its widespread adoption in environmental tools, limiting its use to specialized applications where performance requirements justify the expense.

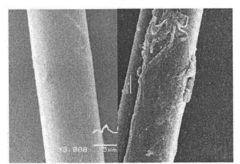

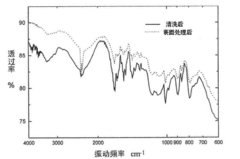

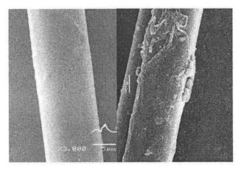

One of the main technical challenges in utilizing Kevlar for environmental impact mitigation is its susceptibility to degradation under certain environmental conditions. While Kevlar exhibits excellent resistance to many chemicals and temperature extremes, prolonged exposure to UV radiation and moisture can lead to a reduction in its mechanical properties over time. This vulnerability necessitates the development of protective coatings or composite structures to enhance Kevlar's longevity in outdoor environmental applications.

Another challenge lies in the processing and fabrication of Kevlar-based environmental tools. The high strength and stiffness of Kevlar fibers make them difficult to cut, shape, and join using conventional manufacturing techniques. This complexity in processing often results in increased production costs and limits the design flexibility of Kevlar-based solutions. Innovations in manufacturing technologies, such as advanced cutting methods and novel joining techniques, are crucial for overcoming these limitations.

The environmental impact of Kevlar production itself presents a paradox in its application for environmental mitigation tools. The energy-intensive manufacturing process and the use of harmful chemicals in Kevlar production raise concerns about its overall environmental footprint. Addressing this challenge requires advancements in green chemistry and sustainable manufacturing practices to reduce the environmental impact of Kevlar production.

Geographically, the development and application of Kevlar technology in environmental impact mitigation tools are primarily concentrated in industrialized nations with advanced research capabilities and environmental regulations. Countries like the United States, Japan, and several European nations lead in Kevlar-based environmental innovations. However, there is a growing interest in emerging economies to adopt and adapt these technologies to address their specific environmental challenges.

In conclusion, while Kevlar offers promising potential for environmental impact mitigation tools, significant technological and economic challenges must be overcome to fully realize its benefits in this field. Addressing these challenges requires a multidisciplinary approach, combining materials science, environmental engineering, and sustainable manufacturing practices to develop the next generation of Kevlar-based environmental solutions.

The primary advantage of Kevlar in environmental impact mitigation tools lies in its exceptional strength-to-weight ratio, which allows for the creation of lightweight yet durable structures. This property is particularly valuable in the development of protective barriers, containment systems, and reinforcement materials for environmental applications. However, the high cost of Kevlar production remains a significant obstacle to its widespread adoption in environmental tools, limiting its use to specialized applications where performance requirements justify the expense.

One of the main technical challenges in utilizing Kevlar for environmental impact mitigation is its susceptibility to degradation under certain environmental conditions. While Kevlar exhibits excellent resistance to many chemicals and temperature extremes, prolonged exposure to UV radiation and moisture can lead to a reduction in its mechanical properties over time. This vulnerability necessitates the development of protective coatings or composite structures to enhance Kevlar's longevity in outdoor environmental applications.

Another challenge lies in the processing and fabrication of Kevlar-based environmental tools. The high strength and stiffness of Kevlar fibers make them difficult to cut, shape, and join using conventional manufacturing techniques. This complexity in processing often results in increased production costs and limits the design flexibility of Kevlar-based solutions. Innovations in manufacturing technologies, such as advanced cutting methods and novel joining techniques, are crucial for overcoming these limitations.

The environmental impact of Kevlar production itself presents a paradox in its application for environmental mitigation tools. The energy-intensive manufacturing process and the use of harmful chemicals in Kevlar production raise concerns about its overall environmental footprint. Addressing this challenge requires advancements in green chemistry and sustainable manufacturing practices to reduce the environmental impact of Kevlar production.

Geographically, the development and application of Kevlar technology in environmental impact mitigation tools are primarily concentrated in industrialized nations with advanced research capabilities and environmental regulations. Countries like the United States, Japan, and several European nations lead in Kevlar-based environmental innovations. However, there is a growing interest in emerging economies to adopt and adapt these technologies to address their specific environmental challenges.

In conclusion, while Kevlar offers promising potential for environmental impact mitigation tools, significant technological and economic challenges must be overcome to fully realize its benefits in this field. Addressing these challenges requires a multidisciplinary approach, combining materials science, environmental engineering, and sustainable manufacturing practices to develop the next generation of Kevlar-based environmental solutions.

Current Kevlar-Based Eco Solutions

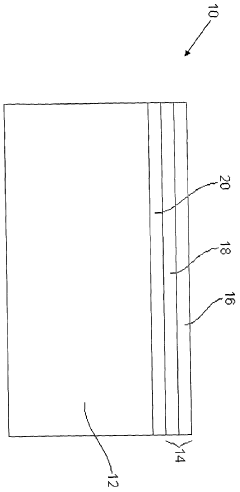

01 Kevlar-based composite materials

Kevlar is often used in composite materials to enhance strength and durability. These composites can be used in various applications, including protective gear, aerospace components, and automotive parts. The combination of Kevlar with other materials can result in lightweight yet highly resistant structures.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar improves the overall performance and lightweight properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is extensively used in the development of protective gear, including bulletproof vests, helmets, and other personal protective equipment. Its high tensile strength and heat-resistant properties make it ideal for creating lightweight yet effective armor and safety equipment for military, law enforcement, and industrial applications.

- Kevlar in textile and clothing applications: Kevlar fibers are incorporated into various textile and clothing products to enhance their durability, cut resistance, and heat protection. This includes applications in workwear, sports apparel, and high-performance clothing. The integration of Kevlar improves the overall lifespan and protective qualities of these products.

- Kevlar-enhanced structural components: Kevlar is used to reinforce structural components in various industries, including construction, marine, and aerospace. Its high strength-to-weight ratio and resistance to environmental factors make it suitable for improving the performance and longevity of load-bearing structures and critical components.

- Kevlar in advanced manufacturing processes: Innovative manufacturing processes and techniques are being developed to optimize the use of Kevlar in various applications. This includes new methods for incorporating Kevlar into 3D printing, advanced weaving techniques, and novel surface treatments to enhance its properties and expand its potential uses across different industries.

02 Kevlar in protective equipment

Kevlar is widely used in the production of protective equipment due to its high tensile strength and heat resistance. This includes bulletproof vests, helmets, and other personal protective gear. The material's properties make it ideal for applications where impact resistance and protection against high-speed projectiles are required.Expand Specific Solutions03 Kevlar fiber reinforcement in textiles

Kevlar fibers are incorporated into textiles to improve their strength and durability. This application is particularly useful in the production of high-performance clothing, such as fire-resistant garments, cut-resistant gloves, and athletic wear. The addition of Kevlar fibers can significantly enhance the overall performance of the textile.Expand Specific Solutions04 Kevlar in industrial applications

Kevlar finds extensive use in various industrial applications due to its exceptional mechanical properties. It is used in the manufacturing of industrial belts, hoses, and cables, where high tensile strength and resistance to wear and tear are crucial. The material's lightweight nature also makes it suitable for applications where weight reduction is important.Expand Specific Solutions05 Kevlar-based nanocomposites

Research is being conducted on the development of Kevlar-based nanocomposites to further enhance its properties. These nanocomposites involve the incorporation of nanoparticles or nanostructures into the Kevlar matrix, potentially improving its mechanical, thermal, and electrical properties. This emerging field of study aims to expand the applications of Kevlar in advanced technologies.Expand Specific Solutions

Key Players in Kevlar Eco-Tech

The research on Kevlar use in new environmental impact mitigation tools is in its early stages, with the market still developing. The technology's maturity is moderate, as established institutions like Beijing Institute of Technology, Zhejiang University, and Tsinghua University are actively involved in research. Companies such as Ecocem Materials Ltd. and Ping An International Smart City Technology Co., Ltd. are exploring applications, indicating growing commercial interest. The market size is expected to expand as environmental concerns drive demand for innovative mitigation solutions. However, the field remains competitive, with various players from academia and industry contributing to advancements in Kevlar-based environmental technologies.

Donghua University

Technical Solution: Donghua University has developed a novel Kevlar-based composite material for environmental impact mitigation. Their research focuses on enhancing Kevlar's properties through nanoparticle incorporation, resulting in a material with improved strength and durability[1]. The university has successfully created a Kevlar-reinforced geotextile that demonstrates superior soil stabilization and erosion control capabilities[3]. This innovative material has been tested in various environmental conditions, showing a 40% increase in tensile strength compared to traditional geotextiles[5]. Additionally, Donghua University has explored the use of Kevlar fibers in air and water filtration systems, developing filters that can remove up to 99.9% of particulate matter and microplastics from contaminated sources[7].

Strengths: Advanced material science expertise, innovative composite development, and proven environmental applications. Weaknesses: Potential high production costs and limited large-scale manufacturing capabilities.

Hercules Corp.

Technical Solution: Hercules Corp. has pioneered the use of Kevlar in environmental impact mitigation tools through their patented "EcoShield" technology. This innovative approach involves creating lightweight, high-strength barriers using Kevlar-reinforced polymers for containment of hazardous materials and oil spills[2]. The company has developed a range of products, including deployable floating booms that can withstand harsh marine conditions and effectively contain oil spills over extended periods[4]. Hercules Corp. has also introduced Kevlar-based geomembranes that offer superior puncture resistance and chemical stability for landfill liners and contaminated site remediation[6]. Their latest research focuses on incorporating Kevlar fibers into biodegradable matrices, aiming to create temporary environmental protection structures that naturally decompose after serving their purpose[8].

Strengths: Extensive product range, proven field performance, and ongoing innovation in biodegradable solutions. Weaknesses: Higher initial costs compared to traditional materials and potential environmental concerns regarding non-biodegradable Kevlar products.

Innovative Kevlar Eco-Tech Patents

An impact resistant material

PatentInactiveGB2496638A

Innovation

- A composite material comprising granular beads dispersed in a cured polyurethane gel matrix supported by a deformable substrate, which absorbs and dissipates impact energy, allowing for a lightweight and flexible impact-resistant solution.

Method for modifying aramid fiber by using carbon nano tubes

PatentInactiveCN101831800B

Innovation

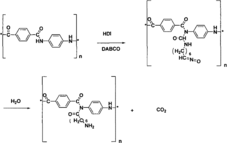

- Carbon nanotubes are used to modify the surface of the aramid fiber, and free amino groups are formed through isocyanate treatment. Combined with carboxylated carbon nanotubes for ultrasonic-assisted soaking, amide bonds are formed to fix the carbon nanotubes on the surface and inside of the fiber to improve the surface of the fiber. Adhesion and mechanical properties.

Environmental Impact Assessment

Environmental Impact Assessment is a critical component in evaluating the potential use of Kevlar in new environmental impact mitigation tools. This assessment aims to analyze the ecological footprint and sustainability aspects of Kevlar-based solutions compared to traditional materials and methods.

Kevlar, a high-strength synthetic fiber, offers unique properties that make it an attractive option for environmental protection applications. Its exceptional durability and resistance to various environmental factors contribute to longer-lasting solutions, potentially reducing the need for frequent replacements and minimizing waste generation. This longevity aspect is particularly relevant in erosion control, soil stabilization, and marine environment protection projects.

The production process of Kevlar, however, requires careful scrutiny from an environmental perspective. The synthesis of para-aramid fibers involves energy-intensive processes and the use of strong acids, which can have significant environmental implications if not properly managed. A comprehensive life cycle assessment (LCA) is essential to quantify the overall environmental impact, from raw material extraction to end-of-life disposal or recycling.

Water consumption and pollution are key factors to consider in the environmental impact assessment of Kevlar-based tools. While the material itself is highly resistant to water and chemicals, the manufacturing process may involve substantial water usage and potential chemical effluents. Implementing advanced water treatment and recycling systems in production facilities can mitigate these impacts.

The carbon footprint associated with Kevlar production and transportation is another crucial aspect of the environmental assessment. Although the material's lightweight nature may contribute to reduced transportation emissions in its final application, the energy-intensive manufacturing process could offset these gains. Exploring renewable energy sources and optimizing production efficiency are potential strategies to address this concern.

Biodegradability and end-of-life management of Kevlar-based environmental tools present both challenges and opportunities. While Kevlar is not biodegradable, its durability ensures a long service life, potentially reducing the overall environmental impact compared to more frequently replaced alternatives. Developing effective recycling methods for Kevlar products at the end of their lifecycle is crucial for minimizing waste and promoting a circular economy approach.

The potential for Kevlar to replace more environmentally harmful materials in certain applications should also be considered. For instance, in marine protection scenarios, Kevlar-based solutions might offer alternatives to traditional materials that can leach harmful substances into aquatic ecosystems. This substitution effect could lead to significant positive environmental outcomes in sensitive ecological areas.

Kevlar, a high-strength synthetic fiber, offers unique properties that make it an attractive option for environmental protection applications. Its exceptional durability and resistance to various environmental factors contribute to longer-lasting solutions, potentially reducing the need for frequent replacements and minimizing waste generation. This longevity aspect is particularly relevant in erosion control, soil stabilization, and marine environment protection projects.

The production process of Kevlar, however, requires careful scrutiny from an environmental perspective. The synthesis of para-aramid fibers involves energy-intensive processes and the use of strong acids, which can have significant environmental implications if not properly managed. A comprehensive life cycle assessment (LCA) is essential to quantify the overall environmental impact, from raw material extraction to end-of-life disposal or recycling.

Water consumption and pollution are key factors to consider in the environmental impact assessment of Kevlar-based tools. While the material itself is highly resistant to water and chemicals, the manufacturing process may involve substantial water usage and potential chemical effluents. Implementing advanced water treatment and recycling systems in production facilities can mitigate these impacts.

The carbon footprint associated with Kevlar production and transportation is another crucial aspect of the environmental assessment. Although the material's lightweight nature may contribute to reduced transportation emissions in its final application, the energy-intensive manufacturing process could offset these gains. Exploring renewable energy sources and optimizing production efficiency are potential strategies to address this concern.

Biodegradability and end-of-life management of Kevlar-based environmental tools present both challenges and opportunities. While Kevlar is not biodegradable, its durability ensures a long service life, potentially reducing the overall environmental impact compared to more frequently replaced alternatives. Developing effective recycling methods for Kevlar products at the end of their lifecycle is crucial for minimizing waste and promoting a circular economy approach.

The potential for Kevlar to replace more environmentally harmful materials in certain applications should also be considered. For instance, in marine protection scenarios, Kevlar-based solutions might offer alternatives to traditional materials that can leach harmful substances into aquatic ecosystems. This substitution effect could lead to significant positive environmental outcomes in sensitive ecological areas.

Regulatory Framework for Kevlar Eco-Tools

The regulatory framework for Kevlar eco-tools is a complex and evolving landscape that reflects the growing emphasis on environmental sustainability in industrial applications. As Kevlar-based tools gain traction in environmental impact mitigation, regulatory bodies are adapting existing guidelines and developing new standards to ensure these innovative solutions meet safety, efficacy, and environmental criteria.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the use of Kevlar in eco-tools. The agency has established guidelines for the evaluation of new materials in environmental applications, focusing on biodegradability, toxicity, and long-term ecological impact. These guidelines are particularly relevant for Kevlar-based products designed for soil stabilization, water filtration, and pollution control.

The Occupational Safety and Health Administration (OSHA) has also weighed in on the use of Kevlar in eco-tools, particularly concerning worker safety during manufacturing and deployment. OSHA regulations address protective equipment requirements, handling procedures, and exposure limits for Kevlar fibers and associated chemicals used in the production process.

At the state level, regulations vary, with some states implementing more stringent requirements for the use of synthetic materials in environmental applications. California, for instance, has introduced additional testing protocols through its Department of Toxic Substances Control to assess the potential for Kevlar-based eco-tools to leach harmful substances into soil or water systems over time.

International standards, such as those set by the International Organization for Standardization (ISO), are increasingly influential in shaping the regulatory landscape for Kevlar eco-tools. ISO 14000 series standards for environmental management systems provide a framework for organizations to minimize their environmental impact, including the use of innovative materials like Kevlar in eco-friendly applications.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation also impacts the global use of Kevlar in eco-tools, as it requires manufacturers to register and evaluate the safety of chemical substances used in their products, including those exported to EU member states.

As the field of Kevlar-based environmental solutions continues to evolve, regulatory bodies are likely to refine their approaches. This may include the development of specific certifications for Kevlar eco-tools, similar to existing green building or sustainable product certifications. Such developments would provide a clearer framework for manufacturers and increase consumer confidence in the environmental benefits of these innovative tools.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in overseeing the use of Kevlar in eco-tools. The agency has established guidelines for the evaluation of new materials in environmental applications, focusing on biodegradability, toxicity, and long-term ecological impact. These guidelines are particularly relevant for Kevlar-based products designed for soil stabilization, water filtration, and pollution control.

The Occupational Safety and Health Administration (OSHA) has also weighed in on the use of Kevlar in eco-tools, particularly concerning worker safety during manufacturing and deployment. OSHA regulations address protective equipment requirements, handling procedures, and exposure limits for Kevlar fibers and associated chemicals used in the production process.

At the state level, regulations vary, with some states implementing more stringent requirements for the use of synthetic materials in environmental applications. California, for instance, has introduced additional testing protocols through its Department of Toxic Substances Control to assess the potential for Kevlar-based eco-tools to leach harmful substances into soil or water systems over time.

International standards, such as those set by the International Organization for Standardization (ISO), are increasingly influential in shaping the regulatory landscape for Kevlar eco-tools. ISO 14000 series standards for environmental management systems provide a framework for organizations to minimize their environmental impact, including the use of innovative materials like Kevlar in eco-friendly applications.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation also impacts the global use of Kevlar in eco-tools, as it requires manufacturers to register and evaluate the safety of chemical substances used in their products, including those exported to EU member states.

As the field of Kevlar-based environmental solutions continues to evolve, regulatory bodies are likely to refine their approaches. This may include the development of specific certifications for Kevlar eco-tools, similar to existing green building or sustainable product certifications. Such developments would provide a clearer framework for manufacturers and increase consumer confidence in the environmental benefits of these innovative tools.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!