Optimizing The Flow Dynamics Of Check Valves

Technology Background And Goals

A thorough understanding of the market dynamics is crucial for determining the viability and potential success of any technological solutions aimed at improving check valve flow performance. This analysis will shed light on the specific market needs, customer requirements, and potential adoption barriers that must be addressed to ensure successful commercialization.

Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valve products and services, including the breakdown by industry sectors and geographical regions. Estimate the projected growth rate and future market potential based on factors like industrial expansion, infrastructure development, and regulatory changes. - Key Demand Drivers

Identify the primary factors driving the demand for check valves, such as the need for efficient fluid control, prevention of backflow, and compliance with safety regulations. Examine how these drivers vary across different applications and industries. - Application Analysis

Evaluate the demand for check valves across various applications, including oil and gas, chemical processing, water and wastewater treatment, power generation, and others. Highlight the specific requirements and challenges associated with each application. - Emerging Trends

Discuss emerging trends that could impact the demand for check valves, such as the adoption of new materials, the integration of smart technologies, and the emphasis on energy efficiency and sustainability. - Competitive Landscape

Analyze the competitive landscape, including the market share and positioning of major players. Identify potential opportunities for new entrants or disruptive technologies that could reshape the market dynamics.

Technology Status And Challenges

- Valve Design Limitations

Current check valve designs face challenges in optimizing flow dynamics, leading to issues like water hammer, vibration, and cavitation. - Material Constraints

The materials used in valve construction can limit their performance and durability, especially in harsh environments or with corrosive fluids. - Installation Challenges

Improper installation or misalignment of check valves can significantly impact their flow dynamics and overall efficiency. - Maintenance Requirements

Check valves often require frequent maintenance and inspection to ensure proper operation and prevent failures, which can be costly and time-consuming. - Sizing and Selection Issues

Selecting the appropriate valve size and type for specific applications can be challenging, as improper sizing can lead to flow disturbances and reduced efficiency.

Current Technical Solutions

01 Valve Structure and Design

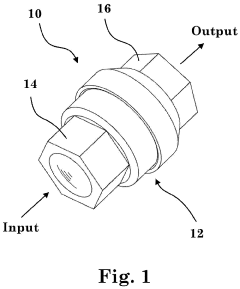

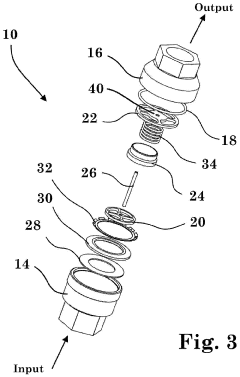

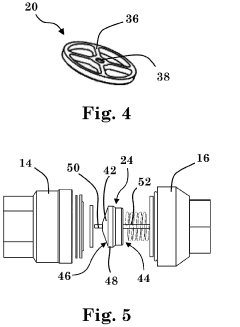

Covers different valve configurations like swing, lift, and tilting disc check valves, optimizing flow characteristics and preventing backflow.- Valve Structure and Design: Covers valve body configurations, valve seat arrangements, and valve disc/flapper mechanisms influencing flow dynamics and performance.

- Flow Characteristics Analysis: Focuses on analyzing fluid flow patterns, pressure drop, and flow coefficients to optimize valve design for improved flow dynamics.

- Applications and Installation: Addresses various applications and installation considerations for check valves in piping systems, fluid handling, and specific industries.

- Materials and Coatings: Discusses materials and coatings used in valve construction, affecting factors like flow resistance, wear resistance, and corrosion resistance.

- Control and Monitoring: Covers aspects related to controlling and monitoring valve operation, such as valve position sensing, flow monitoring, and control systems.

02 Flow Control and Regulation

Focuses on mechanisms for adjusting flow rates, pressure differentials, and flow directions, ensuring efficient and reliable operation.Expand Specific Solutions03 Materials and Coatings

Addresses the use of various materials and coatings to improve wear resistance and corrosion protection in valve construction.Expand Specific Solutions04 Sealing and Leak Prevention

Covers sealing mechanisms, gasket designs, and techniques to ensure proper sealing and minimize leakage, enhancing performance and reliability.Expand Specific Solutions05 Applications and Integration

Addresses the integration of check valves into specific systems and industries, addressing unique requirements and challenges.Expand Specific Solutions

Technology Main Player Analysis

Bendix Commercial Vehicle Systems LLC

ITT Manufacturing Enterprises LLC

Key Technology Interpretation

- Preventing undesired low flow rates: the fluid control valve is designed to prevent flow at initial travel points where the inertia of the fluid is insufficient to trigger a meters' measurement elements. this ensures that only the desired flow rate is allowed through the valve.

- Allowing flow to "jump" to a higher flow rate: once a specific flow rate is achieved downstream of the valve, the flow rate "jumps" to a higher range that can be more accurately measured by a metering element. this ensures that the flow rate is within the desired range and can be accurately measured by the metering element.

Check Valve Flow Dynamics Optimization Economic Analysis

The economic analysis of check valves with optimized flow dynamics involves evaluating the cost-benefit aspects relative to traditional designs. The primary consideration is the potential for enhanced efficiency leading to reduced energy consumption, which can provide significant long-term savings in industries such as oil and gas, water treatment, and chemical processing. Implementing these advanced check valves may require an initial investment in research, development, and retrofitting existing systems. However, this investment can be offset by the reduction in operational costs and the improvement in system reliability and lifespan.

Furthermore, the inclusion of advanced flow dynamics could result in lower maintenance needs due to reduced wear and tear, potentially decreasing downtime and associated costs. An economic analysis must also consider competitive market pricing strategies, ensuring that the development of these check valves remains financially viable for manufacturers while maintaining affordability for end-users. The potential to capitalize on sustainability trends by lowering environmental impact through improved energy efficiency could also enhance market attractiveness and create additional revenue streams through potential green certifications or incentives. Overall, the economic viability hinges on balancing initial costs with long-term savings and market positioning strategies.

Check Valve Flow Dynamics Optimization Policy And Regulatory Impact

Policy and regulatory frameworks play a crucial role in the development and implementation of check valves with optimized flow dynamics. Regulatory bodies set standards for safety, efficiency, and environmental compliance, which directly influence the design and operational criteria of these valves. For instance, stringent emissions regulations can drive the innovation of valves that minimize fluid resistance, thereby improving energy efficiency. Additionally, safety standards dictate the need for robustness and reliability, prompting manufacturers to enhance the materials and mechanisms used in valve construction.

Trade policies also impact market dynamics by influencing the availability and cost of raw materials necessary for manufacturing high-performance check valves. Regulations on import-export can further affect the distribution channels and market accessibility of these products.

The sustainability trend is another critical aspect where regulatory policies encourage the adoption of environmentally friendly technologies. This drives manufacturers to develop check valves with reduced carbon footprints and higher operational efficiencies. Compliance with such regulations is not only a legal obligation but taps into a growing consumer demand for sustainable solutions.

Aligning with these policy frameworks not only ensures legal compliance but also enhances market competitiveness by aligning products with global trends and demands. Integrating regulatory considerations into design and production phases is essential for leveraging market opportunities and fostering technological advancements in this field.