Reducing Sticking Issues In Check Valves

Technology Background And Goals

Furthermore, the report will delve into the core patents and technical literature focused on mitigating sticking issues, highlighting their innovative approaches and potential value. This will provide insights into the cutting-edge solutions being developed and pave the way for identifying promising future research directions and potential breakthroughs in addressing this challenge.

Check Valve Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, and water treatment. Factors such as infrastructure development, urbanization, and the need for efficient fluid control systems contribute to market expansion. - Industry Trends

Key trends shaping the check valve market include the adoption of advanced materials for improved durability and corrosion resistance, the demand for compact and lightweight designs, and the integration of smart technologies for remote monitoring and predictive maintenance. - Application Sectors

Check valves find widespread applications across various sectors, including:- Oil and gas: Upstream, midstream, and downstream operations

- Chemical processing: Handling corrosive and hazardous fluids

- Water and wastewater treatment: Preventing backflow and regulating flow direction

- Power generation: Steam and cooling systems in power plants

- Regional Dynamics

The Asia-Pacific region is expected to be a significant market for check valves, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe also represent mature markets with a focus on replacement and modernization of existing facilities.

Technology Status And Challenges

- Valve Sticking Issues

Sticking is a common issue in check valves, where the valve disc or flapper fails to open or close properly due to various factors. - Causes of Sticking

Potential causes include buildup of debris, corrosion, wear, and improper installation or maintenance. - Impact on Performance

Sticking can lead to reduced flow efficiency, increased pressure drop, and potential system failures or safety hazards. - Existing Solutions

Current solutions involve improved valve design, use of specialized materials, and regular maintenance and inspection protocols. - Technological Challenges

Challenges include developing more robust and reliable valve designs, improving material compatibility, and enhancing monitoring and diagnostic capabilities.

Current Technical Solutions

01 Debris or Contaminants

Check valves can become stuck or fail due to debris, contaminants, or foreign particles in the fluid flow path, preventing full closing or opening.- Debris or Contaminants: Check valves can stick or fail due to debris, contaminants, or foreign particles lodged between the valve seat and disc, preventing proper sealing.

- Wear or Erosion: Over time, wear or erosion of internal components like the valve seat, disc, or hinge pin can lead to improper sealing, increased friction, and valve sticking.

- Thermal Effects: Thermal expansion or contraction caused by temperature fluctuations or extreme temperatures can lead to interference between moving parts, causing valve sticking.

- Improper Installation or Assembly: Incorrect installation or assembly, such as misalignment, improper torque, or incorrect component placement, can result in binding or interference, leading to valve sticking.

- Material Incompatibility or Corrosion: Incompatibility between valve materials and the fluid, or exposure to corrosive environments, can cause degradation or buildup, leading to valve sticking or seizing.

02 Wear or Material Degradation

Over time, components can experience wear or material degradation due to friction, corrosion, or harsh operating conditions, causing valve sticking or malfunction.Expand Specific Solutions03 Improper Installation or Assembly

Improper installation or assembly can lead to misalignment or interference between valve components, causing the valve to stick or fail to operate correctly.Expand Specific Solutions04 Thermal Expansion or Contraction

Changes in temperature can cause thermal expansion or contraction of valve components, leading to interference or binding that prevents smooth operation.Expand Specific Solutions05 Design or Manufacturing Defects

Defects in design or manufacturing, such as improper tolerances, surface finishes, or material properties, can contribute to valve sticking or failure.Expand Specific Solutions

Technology Main Player Analysis

Honeywell International Technologies Ltd.

Azbil Corp.

Key Technology Interpretation

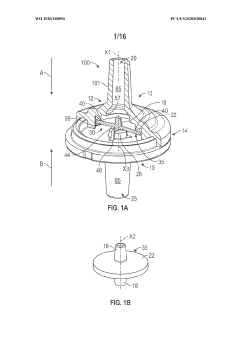

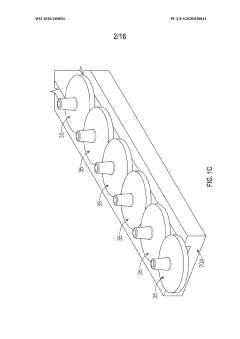

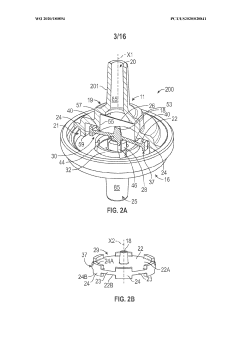

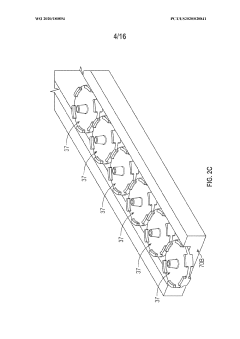

- The valve member has a plurality of feet that extend from the outer edge of the valve body, which helps prevent the valve members from sticking together during packing and assembly.

- The valve member has a stem that extends through the valve body, which may contribute to preventing sticking during packing and assembly.

- The design of the valve member aims to improve the functionality and reliability of check valves by preventing sticking during packing and assembly.

Technology Environmental Impact

Improving the design and operation of check valves to minimize sticking can lead to significant energy savings. When check valves stick, they can cause inefficiencies in fluid systems, leading to increased energy consumption as pumps and compressors work harder to maintain flow rates. By optimizing valve operation, we reduce the energy needed for system maintenance, thereby decreasing greenhouse gas emissions associated with electricity production.

Another important aspect is the reduction of waste and resource consumption. Check valves that experience less sticking have a longer lifespan and require less frequent replacement. This longevity reduces the need for manufacturing new valves, cutting down on material consumption and the environmental toll associated with extraction, processing, and transport of raw materials. Additionally, fewer replacements mean less waste is generated at the end of each valve's lifecycle, contributing to waste management and sustainability efforts.

Reducing sticking issues also has a positive impact on the overall efficiency and reliability of industrial systems. When systems operate more efficiently, they contribute less to pollution and resource overuse. Efficient systems are often better at avoiding leaks and unplanned emissions, which can have direct negative effects on air and water quality. Finally, efficient operation supports the responsible use of water and other fluids, ensuring these resources are not unnecessarily wasted or contaminated.

By addressing sticking issues in check valves through advanced materials, coatings, and improved designs, industries can not only achieve operational gains but also substantially mitigate the environmental impact of widespread fluid handling systems. These initiatives align with global efforts to enhance sustainability and reduce carbon footprints across various sectors.

Technology Policy And Regulatory Impact

Regulatory impacts on reducing sticking issues in check valves involve a complex interplay of safety standards, environmental regulations, and industry certifications that influence the design, materials, and operational protocols for these components. Regulations often mandate the use of materials and designs that minimize the risk of valve failure, which can lead to system inefficiencies or catastrophic failures, especially in industries like oil and gas, chemical processing, and water management.

In recent years, international standards such as those from the American Society of Mechanical Engineers (ASME), International Organization for Standardization (ISO), and various environmental protection agencies have imposed strict guidelines on the performance and reliability of check valves. These regulations generally require manufacturers to perform rigorous testing to ensure that their products can sustain operational integrity under varied pressure levels and environmental conditions.

The impact of these regulations is twofold: they drive innovation in new materials and coatings that are more resistant to conditions that cause sticking, such as corrosion and particulate buildup, and they encourage the development of advanced diagnostic technologies that can predict or detect potential sticking issues before they cause failure. Regulatory compliance thus acts as both a constraint and catalyst, compelling manufacturers to blend robust material science with precise engineering to maintain market competitiveness.

Furthermore, adherence to these regulatory frameworks ensures a level of safety and reliability that supports both public safety and environmental conservation goals. As a result, tackling the sticking issue is not merely a technical challenge but also a regulatory necessity that shapes product development cycles and investment in research and development.