Strategies for Implementing Regenerative Braking in Zero-Emission Vehicles

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Regenerative Braking Evolution and Objectives

Regenerative braking has emerged as a pivotal technology in the evolution of zero-emission vehicles, marking a significant shift in energy efficiency and sustainability within the automotive industry. The concept, which originated in the early 20th century with electric trains, has undergone substantial development to become a cornerstone of modern electric and hybrid vehicle design.

The primary objective of regenerative braking is to recapture kinetic energy that would otherwise be lost as heat during conventional braking processes. This recaptured energy is then converted into electrical energy and stored in the vehicle's battery system, effectively extending the driving range and improving overall energy efficiency. As environmental concerns and energy conservation have gained prominence, the automotive industry has increasingly focused on perfecting this technology.

The evolution of regenerative braking can be traced through several key stages. Initially, the technology was rudimentary, offering limited energy recovery. However, advancements in power electronics, battery technology, and electric motor design have dramatically enhanced its effectiveness. Modern systems can recover up to 70% of the kinetic energy during braking, significantly contributing to the vehicle's energy economy.

One of the critical objectives in the ongoing development of regenerative braking is to optimize the balance between energy recovery and traditional friction braking. This balance is essential for ensuring both maximum energy efficiency and maintaining the safety and reliability of the braking system under various driving conditions. Engineers are continually working to refine control algorithms that seamlessly integrate regenerative and friction braking.

Another key goal is to improve the user experience. Early regenerative braking systems were often criticized for their unnatural feel and inconsistent performance. Current research aims to develop systems that provide a more intuitive and comfortable driving experience while maximizing energy recovery. This includes fine-tuning the brake pedal feel and implementing adaptive systems that adjust regenerative braking intensity based on driving conditions and driver preferences.

As the automotive industry moves towards full electrification, the objectives for regenerative braking technology have expanded. There is a growing focus on developing more efficient and compact systems that can handle higher power levels. Additionally, researchers are exploring ways to integrate regenerative braking with other vehicle systems, such as active suspension and torque vectoring, to enhance overall vehicle dynamics and energy management.

The future trajectory of regenerative braking technology is closely tied to the broader goals of increasing vehicle range, reducing battery size and cost, and improving overall sustainability in the transportation sector. As such, ongoing research is aimed at pushing the boundaries of energy recovery efficiency, developing more advanced energy storage solutions, and creating intelligent, predictive braking systems that can anticipate and optimize energy recovery based on route information and traffic conditions.

The primary objective of regenerative braking is to recapture kinetic energy that would otherwise be lost as heat during conventional braking processes. This recaptured energy is then converted into electrical energy and stored in the vehicle's battery system, effectively extending the driving range and improving overall energy efficiency. As environmental concerns and energy conservation have gained prominence, the automotive industry has increasingly focused on perfecting this technology.

The evolution of regenerative braking can be traced through several key stages. Initially, the technology was rudimentary, offering limited energy recovery. However, advancements in power electronics, battery technology, and electric motor design have dramatically enhanced its effectiveness. Modern systems can recover up to 70% of the kinetic energy during braking, significantly contributing to the vehicle's energy economy.

One of the critical objectives in the ongoing development of regenerative braking is to optimize the balance between energy recovery and traditional friction braking. This balance is essential for ensuring both maximum energy efficiency and maintaining the safety and reliability of the braking system under various driving conditions. Engineers are continually working to refine control algorithms that seamlessly integrate regenerative and friction braking.

Another key goal is to improve the user experience. Early regenerative braking systems were often criticized for their unnatural feel and inconsistent performance. Current research aims to develop systems that provide a more intuitive and comfortable driving experience while maximizing energy recovery. This includes fine-tuning the brake pedal feel and implementing adaptive systems that adjust regenerative braking intensity based on driving conditions and driver preferences.

As the automotive industry moves towards full electrification, the objectives for regenerative braking technology have expanded. There is a growing focus on developing more efficient and compact systems that can handle higher power levels. Additionally, researchers are exploring ways to integrate regenerative braking with other vehicle systems, such as active suspension and torque vectoring, to enhance overall vehicle dynamics and energy management.

The future trajectory of regenerative braking technology is closely tied to the broader goals of increasing vehicle range, reducing battery size and cost, and improving overall sustainability in the transportation sector. As such, ongoing research is aimed at pushing the boundaries of energy recovery efficiency, developing more advanced energy storage solutions, and creating intelligent, predictive braking systems that can anticipate and optimize energy recovery based on route information and traffic conditions.

Market Demand for Energy-Efficient ZEVs

The market demand for energy-efficient Zero-Emission Vehicles (ZEVs) has been steadily increasing in recent years, driven by growing environmental concerns, stricter emissions regulations, and advancements in technology. Regenerative braking systems play a crucial role in enhancing the energy efficiency of ZEVs, making them more attractive to consumers and helping manufacturers meet stringent fuel economy standards.

Consumer awareness of climate change and the desire to reduce carbon footprints have significantly boosted the demand for ZEVs. As governments worldwide implement policies to phase out internal combustion engine vehicles, the market for energy-efficient ZEVs is expected to expand rapidly. This shift in consumer preferences is reflected in the rising sales figures of electric and hydrogen fuel cell vehicles across major automotive markets.

The automotive industry has recognized this trend and is investing heavily in the development and production of ZEVs. Major manufacturers are expanding their electric vehicle lineups and improving energy recovery systems, including regenerative braking, to meet consumer expectations for longer driving ranges and improved efficiency.

Regenerative braking technology is particularly appealing to consumers as it addresses one of the primary concerns associated with ZEVs – limited range. By recovering energy typically lost during braking and deceleration, these systems can extend the driving range of electric vehicles by up to 25%, depending on driving conditions and vehicle design. This improvement in efficiency not only enhances the practical usability of ZEVs but also contributes to lower operating costs for consumers.

Fleet operators and businesses are also driving demand for energy-efficient ZEVs with regenerative braking systems. The potential for reduced maintenance costs, lower fuel expenses, and improved sustainability metrics make these vehicles attractive for commercial applications. Delivery companies, ride-sharing services, and public transportation agencies are increasingly adopting ZEVs to reduce their environmental impact and operational costs.

Market research indicates that consumers are willing to pay a premium for vehicles with advanced energy recovery systems, including regenerative braking. This willingness is supported by the long-term cost savings associated with improved energy efficiency and the perceived environmental benefits. As a result, automotive manufacturers are prioritizing the development and marketing of ZEVs with sophisticated regenerative braking strategies.

The growing market demand for energy-efficient ZEVs is also stimulating innovation in regenerative braking technologies. Manufacturers are exploring advanced control algorithms, improved energy storage systems, and integration with other vehicle systems to maximize the benefits of regenerative braking. This ongoing development is expected to further enhance the appeal of ZEVs and accelerate market adoption.

Consumer awareness of climate change and the desire to reduce carbon footprints have significantly boosted the demand for ZEVs. As governments worldwide implement policies to phase out internal combustion engine vehicles, the market for energy-efficient ZEVs is expected to expand rapidly. This shift in consumer preferences is reflected in the rising sales figures of electric and hydrogen fuel cell vehicles across major automotive markets.

The automotive industry has recognized this trend and is investing heavily in the development and production of ZEVs. Major manufacturers are expanding their electric vehicle lineups and improving energy recovery systems, including regenerative braking, to meet consumer expectations for longer driving ranges and improved efficiency.

Regenerative braking technology is particularly appealing to consumers as it addresses one of the primary concerns associated with ZEVs – limited range. By recovering energy typically lost during braking and deceleration, these systems can extend the driving range of electric vehicles by up to 25%, depending on driving conditions and vehicle design. This improvement in efficiency not only enhances the practical usability of ZEVs but also contributes to lower operating costs for consumers.

Fleet operators and businesses are also driving demand for energy-efficient ZEVs with regenerative braking systems. The potential for reduced maintenance costs, lower fuel expenses, and improved sustainability metrics make these vehicles attractive for commercial applications. Delivery companies, ride-sharing services, and public transportation agencies are increasingly adopting ZEVs to reduce their environmental impact and operational costs.

Market research indicates that consumers are willing to pay a premium for vehicles with advanced energy recovery systems, including regenerative braking. This willingness is supported by the long-term cost savings associated with improved energy efficiency and the perceived environmental benefits. As a result, automotive manufacturers are prioritizing the development and marketing of ZEVs with sophisticated regenerative braking strategies.

The growing market demand for energy-efficient ZEVs is also stimulating innovation in regenerative braking technologies. Manufacturers are exploring advanced control algorithms, improved energy storage systems, and integration with other vehicle systems to maximize the benefits of regenerative braking. This ongoing development is expected to further enhance the appeal of ZEVs and accelerate market adoption.

Current Challenges in Regenerative Braking Systems

Despite the significant advancements in regenerative braking systems for zero-emission vehicles, several challenges persist in their implementation and optimization. One of the primary issues is the limited energy recovery efficiency, particularly at low speeds and during gentle braking. Current systems struggle to capture a substantial portion of the kinetic energy during these scenarios, resulting in missed opportunities for energy recuperation.

Another challenge lies in the integration of regenerative braking with conventional friction braking systems. Achieving a seamless transition between the two modes while maintaining optimal energy recovery and ensuring driver safety remains a complex task. The brake pedal feel and responsiveness must be consistent and predictable, regardless of the braking mode in operation.

The variability in energy recovery across different driving conditions poses another significant hurdle. Factors such as road gradient, vehicle speed, and battery state of charge can greatly influence the effectiveness of regenerative braking. Developing adaptive systems that can optimize energy recovery across this wide range of conditions without compromising vehicle performance or driver comfort is an ongoing challenge.

Thermal management of the regenerative braking system components, particularly the electric motor/generator and power electronics, presents another area of concern. High-power regenerative braking events can generate substantial heat, potentially leading to reduced efficiency or even system failure if not properly managed.

The cost and complexity of implementing advanced regenerative braking systems remain significant barriers, especially for mass-market adoption. Balancing the desire for maximum energy recovery with the need for cost-effective solutions that can be widely deployed across various vehicle segments is a persistent challenge for manufacturers.

Furthermore, the durability and longevity of regenerative braking components, such as the electric motor/generator and associated power electronics, need to be improved to match or exceed the lifespan of traditional braking systems. This is particularly crucial for ensuring the long-term reliability and cost-effectiveness of zero-emission vehicles.

Lastly, the optimization of regenerative braking strategies for different driving scenarios and driver preferences presents an ongoing challenge. Developing intelligent systems that can adapt to individual driving styles while maximizing energy recovery and maintaining safety requires sophisticated algorithms and extensive real-world testing.

Another challenge lies in the integration of regenerative braking with conventional friction braking systems. Achieving a seamless transition between the two modes while maintaining optimal energy recovery and ensuring driver safety remains a complex task. The brake pedal feel and responsiveness must be consistent and predictable, regardless of the braking mode in operation.

The variability in energy recovery across different driving conditions poses another significant hurdle. Factors such as road gradient, vehicle speed, and battery state of charge can greatly influence the effectiveness of regenerative braking. Developing adaptive systems that can optimize energy recovery across this wide range of conditions without compromising vehicle performance or driver comfort is an ongoing challenge.

Thermal management of the regenerative braking system components, particularly the electric motor/generator and power electronics, presents another area of concern. High-power regenerative braking events can generate substantial heat, potentially leading to reduced efficiency or even system failure if not properly managed.

The cost and complexity of implementing advanced regenerative braking systems remain significant barriers, especially for mass-market adoption. Balancing the desire for maximum energy recovery with the need for cost-effective solutions that can be widely deployed across various vehicle segments is a persistent challenge for manufacturers.

Furthermore, the durability and longevity of regenerative braking components, such as the electric motor/generator and associated power electronics, need to be improved to match or exceed the lifespan of traditional braking systems. This is particularly crucial for ensuring the long-term reliability and cost-effectiveness of zero-emission vehicles.

Lastly, the optimization of regenerative braking strategies for different driving scenarios and driver preferences presents an ongoing challenge. Developing intelligent systems that can adapt to individual driving styles while maximizing energy recovery and maintaining safety requires sophisticated algorithms and extensive real-world testing.

Existing Regenerative Braking Solutions

01 Regenerative braking systems for vehicles

Regenerative braking systems are used in vehicles to recover kinetic energy during deceleration. These systems convert the vehicle's kinetic energy into electrical energy, which can be stored in batteries or capacitors for later use. This technology improves overall energy efficiency and extends the driving range of electric and hybrid vehicles.- Regenerative braking systems for vehicles: Regenerative braking systems are used in vehicles to recover kinetic energy during deceleration. These systems convert the vehicle's kinetic energy into electrical energy, which can be stored in batteries or capacitors for later use. This technology improves overall energy efficiency and extends the driving range of electric and hybrid vehicles.

- Energy storage and management in regenerative braking: Efficient energy storage and management are crucial aspects of regenerative braking systems. Various technologies are employed to store the recovered energy, including advanced battery systems, ultracapacitors, and flywheels. Energy management systems optimize the distribution and utilization of recovered energy, enhancing the overall performance of the vehicle.

- Control strategies for regenerative braking: Advanced control strategies are implemented to maximize energy recovery during regenerative braking. These strategies involve sophisticated algorithms that balance between regenerative and friction braking, adapt to different driving conditions, and ensure smooth transitions between braking modes. The control systems also integrate with other vehicle systems to optimize overall performance and safety.

- Integration of regenerative braking with electric powertrains: Regenerative braking systems are closely integrated with electric powertrains in modern vehicles. This integration involves coordinating the operation of electric motors, power electronics, and energy storage systems to maximize energy recovery and improve overall drivetrain efficiency. Advanced designs allow for bidirectional power flow, enabling the electric motors to function as both propulsion units and generators.

- Regenerative braking in hybrid and multi-mode vehicles: Regenerative braking systems are adapted for use in hybrid and multi-mode vehicles, which combine internal combustion engines with electric powertrains. These systems are designed to work seamlessly across different operating modes, optimizing energy recovery and distribution between the various power sources. Advanced control strategies ensure efficient operation in diverse driving conditions and powertrain configurations.

02 Energy storage and management in regenerative braking

Efficient energy storage and management are crucial aspects of regenerative braking systems. Advanced battery technologies, supercapacitors, and intelligent control systems are employed to optimize energy recovery and storage. These systems ensure that the recovered energy is effectively utilized, improving the overall efficiency of the vehicle.Expand Specific Solutions03 Integration of regenerative braking with conventional braking systems

Regenerative braking systems are often integrated with conventional friction-based braking systems to provide optimal braking performance and energy recovery. This integration involves sophisticated control algorithms that balance the use of regenerative and friction braking based on various factors such as vehicle speed, battery state of charge, and driver input.Expand Specific Solutions04 Regenerative braking for electric and hybrid powertrains

Regenerative braking technology is particularly important for electric and hybrid vehicle powertrains. These systems are designed to maximize energy recovery during deceleration and braking, significantly improving the overall efficiency and range of these vehicles. Advanced motor-generator units and power electronics are used to facilitate efficient energy conversion and recovery.Expand Specific Solutions05 Control strategies for optimizing regenerative braking efficiency

Sophisticated control strategies are employed to optimize the efficiency of regenerative braking systems. These strategies take into account factors such as vehicle dynamics, road conditions, and driver behavior to maximize energy recovery while maintaining vehicle stability and safety. Machine learning and adaptive control techniques are often used to continuously improve system performance.Expand Specific Solutions

Key Players in ZEV Braking Systems

The competitive landscape for implementing regenerative braking in zero-emission vehicles is evolving rapidly, with the industry in a growth phase. The market size is expanding as more automakers invest in electric and hybrid vehicle technologies. Technological maturity varies among players, with established automotive giants like Ford, Hyundai, and Toyota leading the way. Companies such as Bosch and ZF are contributing significant innovations in component technologies. Emerging players like Gogoro and Faraday&Future are pushing boundaries with novel approaches. The competition is intensifying as traditional automakers, tech companies, and startups vie for market share in this crucial aspect of electric vehicle efficiency and performance.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has implemented an innovative regenerative braking strategy in their zero-emission vehicles, particularly in their all-electric and hybrid models. Their system utilizes a smart energy recovery approach that adapts to driving conditions and driver behavior. Ford's regenerative braking technology incorporates a dual-motor system in some models, allowing for more efficient energy recovery across a wider range of speeds and deceleration rates[10]. The company has also developed an intelligent brake coach feature that provides real-time feedback to drivers, helping them optimize their driving style for maximum energy recovery. Ford's system includes a seamless blending of regenerative and friction braking, ensuring consistent pedal feel and braking performance. Their latest regenerative braking technology can recover up to 94% of braking energy in city driving conditions[11], significantly extending the vehicle's electric range.

Strengths: High energy recovery efficiency, adaptive system based on driving conditions, and driver coaching for optimal usage. Weaknesses: Potential for increased system complexity in dual-motor configurations.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced regenerative braking system for zero-emission vehicles that integrates seamlessly with electric powertrains. Their system utilizes a sophisticated control algorithm that optimizes energy recovery based on vehicle speed, deceleration rate, and battery state of charge. The system employs a dual-mode operation, switching between regenerative and friction braking to maximize efficiency and maintain driver comfort. Bosch's solution incorporates a high-power inverter capable of handling up to 200 kW of regenerative braking power[1], allowing for rapid energy recovery during deceleration. The system also features adaptive blending of regenerative and hydraulic braking, ensuring smooth transitions and consistent pedal feel across various driving conditions[2].

Strengths: High energy recovery efficiency, seamless integration with existing vehicle systems, and advanced control algorithms for optimized performance. Weaknesses: Potentially higher initial cost and complexity compared to simpler regenerative braking systems.

Core Innovations in Energy Recovery

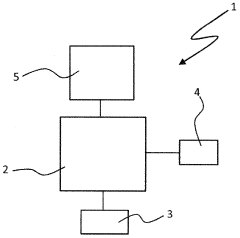

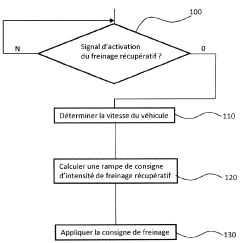

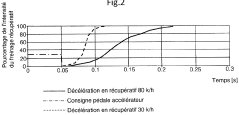

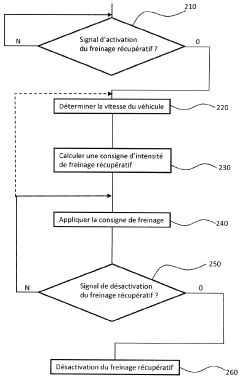

Motor vehicle regenerative braking method

PatentWO2010010283A2

Innovation

- A regenerative braking method that utilizes a computer-controlled system to adjust the intensity of the regenerative braking based on vehicle speed and driver input, using sensors to detect accelerator pedal actions and calculate a setpoint value for the braking action, allowing for adaptive and progressive control of the regenerative braking system.

Environmental Impact Assessment

The implementation of regenerative braking systems in zero-emission vehicles has significant environmental implications, both positive and negative. On the positive side, regenerative braking contributes to improved energy efficiency and reduced overall energy consumption. By capturing and storing energy that would otherwise be lost as heat during conventional braking, these systems extend the range of electric and hybrid vehicles, potentially reducing the frequency of charging or refueling. This, in turn, leads to a decrease in the overall energy demand and associated emissions from power generation.

Furthermore, the increased efficiency of regenerative braking systems can lead to a reduction in the size and weight of battery packs required in electric vehicles. Smaller batteries mean less raw material extraction and processing, which can have substantial environmental benefits in terms of reduced mining activities and associated habitat disruption. Additionally, the decreased vehicle weight resulting from smaller batteries can further enhance energy efficiency, creating a positive feedback loop for environmental conservation.

However, the environmental impact of regenerative braking systems is not entirely positive. The production of the specialized components required for these systems, such as high-capacity batteries and advanced power electronics, can have significant environmental costs. The mining and processing of rare earth elements and other materials used in these components often involve energy-intensive processes and can lead to localized environmental degradation.

Moreover, the increased complexity of vehicles equipped with regenerative braking systems may lead to more challenging end-of-life management. The presence of additional electronic components and specialized materials can complicate recycling processes, potentially leading to increased waste if proper recycling infrastructure is not in place.

The long-term durability and reliability of regenerative braking systems also play a role in their overall environmental impact. If these systems require frequent replacement or maintenance, the additional resource consumption and waste generation could offset some of the environmental benefits gained during operation.

It is crucial to consider the entire lifecycle of vehicles equipped with regenerative braking when assessing their environmental impact. This includes raw material extraction, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life disposal or recycling. A comprehensive analysis should also take into account the regional variations in energy sources used for charging electric vehicles, as the environmental benefits can vary significantly depending on the local energy mix.

In conclusion, while regenerative braking systems in zero-emission vehicles offer substantial environmental benefits through improved energy efficiency and reduced emissions, their overall impact is complex and multifaceted. Continued research and development in this field should focus not only on improving the efficiency of these systems but also on minimizing the environmental costs associated with their production and end-of-life management.

Furthermore, the increased efficiency of regenerative braking systems can lead to a reduction in the size and weight of battery packs required in electric vehicles. Smaller batteries mean less raw material extraction and processing, which can have substantial environmental benefits in terms of reduced mining activities and associated habitat disruption. Additionally, the decreased vehicle weight resulting from smaller batteries can further enhance energy efficiency, creating a positive feedback loop for environmental conservation.

However, the environmental impact of regenerative braking systems is not entirely positive. The production of the specialized components required for these systems, such as high-capacity batteries and advanced power electronics, can have significant environmental costs. The mining and processing of rare earth elements and other materials used in these components often involve energy-intensive processes and can lead to localized environmental degradation.

Moreover, the increased complexity of vehicles equipped with regenerative braking systems may lead to more challenging end-of-life management. The presence of additional electronic components and specialized materials can complicate recycling processes, potentially leading to increased waste if proper recycling infrastructure is not in place.

The long-term durability and reliability of regenerative braking systems also play a role in their overall environmental impact. If these systems require frequent replacement or maintenance, the additional resource consumption and waste generation could offset some of the environmental benefits gained during operation.

It is crucial to consider the entire lifecycle of vehicles equipped with regenerative braking when assessing their environmental impact. This includes raw material extraction, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life disposal or recycling. A comprehensive analysis should also take into account the regional variations in energy sources used for charging electric vehicles, as the environmental benefits can vary significantly depending on the local energy mix.

In conclusion, while regenerative braking systems in zero-emission vehicles offer substantial environmental benefits through improved energy efficiency and reduced emissions, their overall impact is complex and multifaceted. Continued research and development in this field should focus not only on improving the efficiency of these systems but also on minimizing the environmental costs associated with their production and end-of-life management.

Safety and Regulatory Compliance

The implementation of regenerative braking systems in zero-emission vehicles necessitates careful consideration of safety and regulatory compliance. These systems must adhere to stringent safety standards to ensure the protection of vehicle occupants and other road users. Regulatory bodies worldwide have established specific guidelines and requirements for regenerative braking systems, which manufacturers must comply with to obtain vehicle certification.

One of the primary safety concerns is the potential for sudden deceleration or loss of vehicle control due to regenerative braking. To address this, manufacturers are required to implement fail-safe mechanisms that can detect system malfunctions and revert to conventional friction braking when necessary. Additionally, the integration of anti-lock braking systems (ABS) with regenerative braking is crucial to maintain vehicle stability during emergency braking situations.

Regulatory compliance also extends to the electromagnetic compatibility (EMC) of regenerative braking systems. The high-power electrical components used in these systems must not interfere with other vehicle electronics or nearby electronic devices. Manufacturers are required to conduct extensive EMC testing to ensure compliance with international standards such as ISO 11451 and UNECE Regulation No. 10.

Another critical aspect of safety and regulatory compliance is the human-machine interface (HMI) design. The driver must be able to easily understand and control the regenerative braking system. Regulatory bodies often require clear indicators of system status and easily accessible controls for adjusting regenerative braking intensity. This ensures that drivers can adapt the system to their preferences and driving conditions while maintaining safe operation.

The thermal management of regenerative braking systems is also subject to regulatory scrutiny. The conversion of kinetic energy to electrical energy generates heat, which must be effectively dissipated to prevent system overheating and potential safety hazards. Manufacturers must demonstrate that their thermal management solutions can handle worst-case scenarios, such as repeated high-speed braking events.

Furthermore, the energy storage systems used in conjunction with regenerative braking, typically high-voltage batteries, must comply with specific safety standards. These include protection against electrical shock, fire resistance, and crash safety. Regulations such as UNECE Regulation No. 100 provide detailed requirements for the safety of rechargeable energy storage systems in electric vehicles.

As the technology evolves, regulatory bodies continue to update their requirements to address new safety concerns and technological advancements. Manufacturers must stay abreast of these changes and adapt their regenerative braking strategies accordingly. This ongoing process ensures that zero-emission vehicles equipped with regenerative braking systems remain safe and compliant throughout their lifecycle, fostering public trust and accelerating the adoption of sustainable transportation solutions.

One of the primary safety concerns is the potential for sudden deceleration or loss of vehicle control due to regenerative braking. To address this, manufacturers are required to implement fail-safe mechanisms that can detect system malfunctions and revert to conventional friction braking when necessary. Additionally, the integration of anti-lock braking systems (ABS) with regenerative braking is crucial to maintain vehicle stability during emergency braking situations.

Regulatory compliance also extends to the electromagnetic compatibility (EMC) of regenerative braking systems. The high-power electrical components used in these systems must not interfere with other vehicle electronics or nearby electronic devices. Manufacturers are required to conduct extensive EMC testing to ensure compliance with international standards such as ISO 11451 and UNECE Regulation No. 10.

Another critical aspect of safety and regulatory compliance is the human-machine interface (HMI) design. The driver must be able to easily understand and control the regenerative braking system. Regulatory bodies often require clear indicators of system status and easily accessible controls for adjusting regenerative braking intensity. This ensures that drivers can adapt the system to their preferences and driving conditions while maintaining safe operation.

The thermal management of regenerative braking systems is also subject to regulatory scrutiny. The conversion of kinetic energy to electrical energy generates heat, which must be effectively dissipated to prevent system overheating and potential safety hazards. Manufacturers must demonstrate that their thermal management solutions can handle worst-case scenarios, such as repeated high-speed braking events.

Furthermore, the energy storage systems used in conjunction with regenerative braking, typically high-voltage batteries, must comply with specific safety standards. These include protection against electrical shock, fire resistance, and crash safety. Regulations such as UNECE Regulation No. 100 provide detailed requirements for the safety of rechargeable energy storage systems in electric vehicles.

As the technology evolves, regulatory bodies continue to update their requirements to address new safety concerns and technological advancements. Manufacturers must stay abreast of these changes and adapt their regenerative braking strategies accordingly. This ongoing process ensures that zero-emission vehicles equipped with regenerative braking systems remain safe and compliant throughout their lifecycle, fostering public trust and accelerating the adoption of sustainable transportation solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!