Advanced Combustion Techniques For Turbine Engine Technology

SEP 23, 20255 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Advanced Combustion Techniques Technology Background and Goals

## Directory:

1. 技术背景与目标

## Run:

Advanced combustion techniques for turbine engine technology have evolved significantly over the years, driven by the need for higher efficiency, lower emissions, and improved performance. The primary goal of this research is to explore the historical development and future trends of these advanced combustion methods. This includes examining the progression from traditional combustion systems to more sophisticated approaches such as lean-burn, staged combustion, and low-emission technologies. Understanding these advancements is crucial for setting clear technical objectives aimed at enhancing fuel efficiency, reducing environmental impact, and meeting stringent regulatory standards. By analyzing the evolution of combustion techniques, we can identify key milestones and predict future breakthroughs that will shape the next generation of turbine engines.

Advanced Combustion Techniques Market Demand Analysis

The market demand for advanced combustion techniques in turbine engine technology is driven by several key factors.

- Environmental Regulations: Stricter global emissions standards necessitate cleaner and more efficient combustion methods to reduce pollutants.

- Fuel Efficiency: The need for higher fuel efficiency in both aviation and power generation sectors drives the demand for advanced combustion techniques that can maximize energy output while minimizing fuel consumption.

- Performance Requirements: Enhanced performance metrics, such as increased thrust and operational reliability, are critical for modern turbine engines, pushing the development of innovative combustion solutions.

- Market Growth: The expanding aviation industry and growing energy demands globally create a substantial market for advanced turbine engines, further boosting the need for cutting-edge combustion technologies.

- Technological Advancements: Continuous advancements in materials science, computational fluid dynamics, and sensor technologies support the development and implementation of sophisticated combustion techniques.

- Competitive Landscape: Major industry players are investing heavily in R&D to gain a competitive edge, fostering a dynamic market environment with rapid technological progress.

Advanced Combustion Techniques Technology Status and Challenges

### Advanced Combustion Techniques Technology Status and Challenges

- Current Status: Advanced combustion techniques for turbine engines are at the forefront of improving efficiency and reducing emissions. Technologies such as lean-burn, staged combustion, and catalytic combustion are being actively researched and developed.

- Efficiency Improvements: These techniques aim to enhance thermal efficiency by optimizing fuel-air mixtures and combustion processes, leading to better fuel economy and lower operational costs.

- Emission Reduction: A significant focus is on reducing NOx, CO2, and particulate emissions. Advanced combustion methods are designed to meet stringent environmental regulations.

- Technical Challenges: Key challenges include managing high-temperature materials, ensuring combustion stability, and achieving uniform fuel distribution. These factors are critical for maintaining engine performance and longevity.

- Geographical Distribution: Research and development are concentrated in regions with strong aerospace industries, such as North America, Europe, and Asia, where leading companies and research institutions are driving innovation.

Advanced Combustion Techniques Current Technical Solutions

01 Optimized Fuel Injection Systems

Advanced fuel injection systems enhance combustion efficiency with precise fuel delivery and optimal air-fuel mixture, using multiple injection stages and high-pressure injectors.- Use of advanced fuel injection systems: Advanced fuel injection systems improve combustion efficiency by precisely controlling the fuel-air mixture. Techniques include direct injection, multi-point injection, and variable injection timing.

- Implementation of exhaust gas recirculation (EGR): EGR reduces nitrogen oxide emissions and improves combustion efficiency by recirculating exhaust gases back into the combustion chamber, lowering peak combustion temperature.

- Utilization of turbocharging and supercharging: Turbocharging and supercharging increase air intake in the combustion chamber, allowing more fuel to burn, enhancing engine performance, and reducing fuel consumption.

- Adoption of lean burn combustion: Lean burn combustion uses a higher air-to-fuel ratio, leading to efficient fuel usage and lower emissions by ensuring more complete fuel combustion.

- Integration of advanced ignition systems: Advanced ignition systems like laser and plasma ignition provide precise and reliable ignition, leading to more complete combustion and improved engine performance.

02 Enhanced Combustion Chamber Design

Innovative combustion chamber designs improve efficiency by promoting better air-fuel mixing, reducing heat losses, and enhancing flame propagation.Expand Specific Solutions03 Advanced Ignition Systems

Advanced ignition systems like laser and plasma-assisted ignition provide reliable and faster ignition, improving overall engine performance.Expand Specific Solutions04 Exhaust Gas Recirculation (EGR) Techniques

EGR techniques improve combustion efficiency by reducing nitrogen oxide emissions and controlling combustion temperatures through exhaust gas recirculation.Expand Specific Solutions05 Use of Alternative Fuels

Alternative fuels like biofuels, hydrogen, or synthetic fuels enhance combustion efficiency and reduce emissions, offering better combustion characteristics and lower carbon footprints.Expand Specific Solutions

Advanced Combustion Techniques Main Player Analysis

The competitive landscape for advanced combustion techniques in turbine engine technology features established leaders and innovative newcomers. The industry is mature with significant technological advancements driven by the need for higher efficiency and lower emissions. Key players such as General Electric Technology GmbH, Pratt & Whitney Canada Corp., Rolls-Royce Plc, Siemens Energy Global GmbH & Co. KG, and Honeywell International Technologies Ltd. lead with high technical maturity, extensive R&D capabilities, and strong market presence.

General Electric Technology GmbH

Technical Solution: General Electric Technology GmbH focuses on advanced combustion techniques for turbine engines through its Dry Low NOx (DLN) combustion systems. These systems aim to reduce emissions while maintaining high efficiency and performance in turbine engines.

Strength: High efficiency and reduced emissions. Weakness: Complex design and higher initial costs.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada Corp. has developed the TALON X combustor technology, which aims to improve fuel efficiency and reduce emissions in turbine engines. This technology is designed to meet stringent environmental regulations while maintaining engine performance.

Strength: Meets environmental regulations. Weakness: Potentially higher maintenance costs.

Advanced Combustion Techniques Key Technology Interpretation

Expanding the operating envelope of advanced combustion engines using fuel-alcohol blends

PatentInactiveUS20100326387A1

Innovation

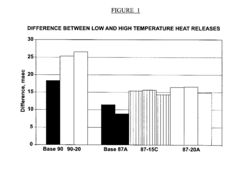

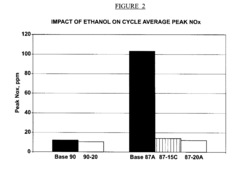

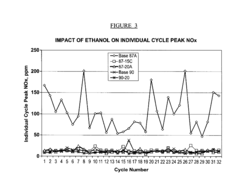

- Using fuel-alcohol blends to reduce peak NOx emissions and prolong ignition delay.

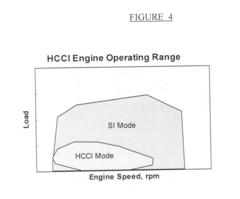

- Expanding the engine's operating envelope to allow operation over a wider range of speeds and loads without unacceptable engine noise or elevated NOx emissions.

- Improving combustion stability and reducing cycle-to-cycle variability by using a gasoline-alcohol blend with a specific value and a small amount of EGR.

Advanced Combustion Techniques Environmental Impact Analysis

The environmental impact of advanced combustion techniques for turbine engine technology is multifaceted, involving both positive and negative aspects. On the positive side, advanced combustion techniques, such as lean-burn and staged combustion, aim to improve fuel efficiency and reduce emissions of pollutants like nitrogen oxides (NOx) and particulate matter. These techniques can significantly lower the carbon footprint of turbine engines, contributing to global efforts to mitigate climate change. Additionally, the use of alternative fuels, such as biofuels and synthetic fuels, in conjunction with advanced combustion methods, can further reduce greenhouse gas emissions and reliance on fossil fuels.

However, the implementation of these advanced techniques also presents environmental challenges. The development and production of alternative fuels may involve land use changes, water consumption, and energy-intensive processes, potentially offsetting some of the environmental benefits. Moreover, the complexity of advanced combustion systems can lead to increased maintenance requirements and potential for operational issues, which might result in unintended emissions or resource use.

Overall, while advanced combustion techniques for turbine engines hold promise for reducing environmental impact, a comprehensive assessment of their lifecycle, including fuel production, engine operation, and end-of-life disposal, is essential to fully understand and mitigate any negative consequences. This holistic approach ensures that the adoption of these technologies aligns with broader environmental sustainability goals.

Advanced Combustion Techniques Regulatory and Policy Considerations

Regulatory and policy considerations play a pivotal role in the development and implementation of advanced combustion techniques for turbine engine technology. Governments and international bodies establish regulations to ensure environmental protection, safety, and efficiency. These regulations often focus on reducing emissions, such as NOx, CO2, and particulate matter, which are critical for meeting global climate goals and improving air quality. Compliance with these regulations requires continuous innovation and adaptation of combustion technologies.

Policy frameworks also influence the direction of research and development by providing funding, incentives, and guidelines. For instance, policies promoting renewable energy sources and cleaner technologies can drive the adoption of advanced combustion techniques. Additionally, international agreements and standards, such as those set by the International Civil Aviation Organization (ICAO) and the Environmental Protection Agency (EPA), create a unified approach to addressing environmental concerns, ensuring that advancements in turbine engine technology align with global sustainability objectives.

The regulatory landscape is dynamic, with evolving standards that necessitate ongoing monitoring and adaptation by industry players. Companies must stay abreast of policy changes to remain compliant and competitive. This involves not only technological advancements but also strategic planning to anticipate future regulatory trends and incorporate them into long-term development goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!