Advanced Cooling Techniques For Turbine Engine Technology

SEP 23, 20255 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background and Goals

The primary objective of this research is to explore advanced cooling techniques for turbine engine technology, focusing on the historical development and future goals of these technologies. Turbine engines, essential in aviation and power generation, face significant thermal challenges due to high operating temperatures. Over the years, various cooling methods have been developed to enhance engine efficiency and longevity. These include air cooling, liquid cooling, and advanced materials with superior thermal properties. The evolution of these techniques reflects a continuous effort to push the boundaries of engine performance while ensuring reliability and safety. Understanding the historical context and current trends in turbine engine cooling is crucial for identifying future advancements and setting realistic technical goals.

Turbine Engine Market Demand Analysis

- Market Demand: The demand for advanced cooling techniques in turbine engines is driven by the need for higher efficiency, reduced emissions, and improved performance. As industries seek to meet stringent environmental regulations, the adoption of these technologies is expected to grow.

- Industry Trends: The aerospace and power generation sectors are the primary markets for turbine engines. The increasing focus on sustainable energy and the development of next-generation aircraft are key trends influencing market demand.

- Market Size: The global turbine engine market is substantial, with significant investments in research and development. The market is projected to expand as new technologies emerge and existing systems are upgraded.

- Regional Analysis: North America and Europe are leading regions in turbine engine technology due to their advanced aerospace industries. Asia-Pacific is also a growing market, driven by rapid industrialization and increasing energy needs.

- Competitive Landscape: Major players in the turbine engine market are investing heavily in advanced cooling technologies. Companies such as General Electric, Rolls-Royce, and Pratt & Whitney are at the forefront, driving innovation and setting industry standards.

- Future Outlook: The market for advanced cooling techniques in turbine engines is expected to grow, with ongoing advancements in materials science and thermal management. The development of more efficient and environmentally friendly engines will continue to drive demand.

Turbine Engine Technology Status and Challenges

### Turbine Engine Technology Status and Challenges

**Current Status:**

- Turbine engine technology has advanced significantly, focusing on efficiency, power output, and environmental impact.

- Modern engines incorporate advanced materials, aerodynamics, and cooling techniques to enhance performance.

**Key Challenges:**

- **Thermal Management:** Managing high temperatures to prevent material degradation and ensure engine longevity.

- **Efficiency:** Balancing fuel efficiency with power output while minimizing emissions.

- **Material Limitations:** Developing materials that can withstand extreme conditions without compromising performance.

- **Environmental Regulations:** Adhering to stringent emission standards while maintaining engine performance.

**Geographical Distribution:**

- **North America and Europe:** Leading in research and development, with significant investments in advanced turbine technologies.

- **Asia:** Rapidly growing market with increasing focus on indigenous development and innovation.

**Conclusion:**

- Addressing these challenges requires continuous innovation in materials science, thermal management, and aerodynamic design.

Turbine Engine Current Technical Solutions

01 Film Cooling Techniques

Injects coolant fluid through small holes on turbine components, creating a protective layer that reduces thermal stress and increases lifespan.- Film Cooling Techniques: Injects coolant air through small holes on turbine blades, forming a protective film that insulates the blade from hot gases, reducing thermal load and increasing lifespan.

- Internal Cooling Channels: Designed within turbine blades to allow coolant air flow, dissipating heat and maintaining structural integrity under high temperatures.

- Thermal Barrier Coatings: Applied to turbine blade surfaces to provide thermal insulation, reducing heat transfer and allowing higher operating temperatures.

- Advanced Cooling Hole Designs: Enhance film cooling effectiveness by optimizing coolant air distribution and flow, improving cooling efficiency and reducing thermal stress.

- Convection Cooling: Utilizes coolant air flow over turbine surfaces to remove heat, often combined with other techniques for enhanced cooling performance.

02 Internal Cooling Channels

Designed within turbine blades and vanes to allow coolant flow, dissipating heat and maintaining structural integrity under high temperatures.Expand Specific Solutions03 Thermal Barrier Coatings

Applied to turbine surfaces to provide thermal insulation, reducing heat transfer and allowing higher operating temperatures.Expand Specific Solutions04 Advanced Cooling Materials

Uses materials with high thermal conductivity and low thermal expansion to enhance cooling efficiency, improving performance and durability.Expand Specific Solutions05 Convection Cooling

Uses air or other coolants to remove heat through convective transfer, often combined with other techniques for optimal thermal management.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competitive landscape for advanced cooling techniques in turbine engine technology features industry leaders and research institutions. Companies like United Technologies Corp., General Electric Company, Honeywell International Technologies Ltd., and Rolls-Royce Corp. lead with significant R&D investments and advanced products. Research institutions such as Beihang University and Northwestern Polytechnical University contribute to technological advancements, while Mitsubishi Hitachi Power Systems and Safran Aircraft Engines SAS push cooling technology boundaries.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced air cooling systems using innovative materials and cooling channel designs to enhance heat dissipation and engine performance.

Strength: High efficiency and reliability. Weakness: High development and implementation costs.

General Electric Company

Technical Solution: General Electric Company uses ceramic matrix composites (CMCs) for superior thermal resistance and reduced cooling needs, allowing higher operating temperatures and better fuel efficiency.

Strength: Enhanced thermal resistance and fuel efficiency. Weakness: High material costs and complex manufacturing processes.

Turbine Engine Key Technology Interpretation

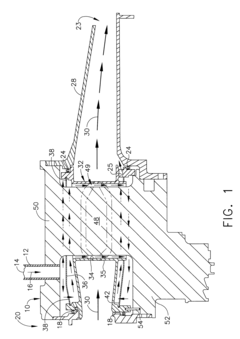

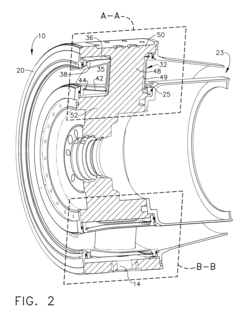

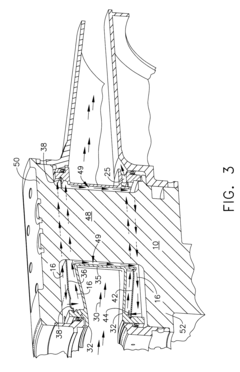

Method of forming a thermally isolated gas turbine engine housing

PatentInactiveUS6719524B2

Innovation

- The invention introduces a single cooling circuit for thermally isolating the turbine housing from high temperatures.

- The cooling circuit is designed to maintain the structural integrity of the housing while cooling bearings, seals, nozzles, and other engine components.

- The method allows for the operation of turbine engines at temperatures exceeding 2500°F without compromising system efficiency and power.

Advanced Cooling Techniques Economic Analysis

Economic analysis of advanced cooling techniques for turbine engine technology involves evaluating the cost-effectiveness and financial impact of implementing these innovations. The primary consideration is the initial investment required for research, development, and integration of advanced cooling systems into existing turbine engines. This includes costs associated with materials, labor, and potential modifications to current manufacturing processes. Additionally, ongoing maintenance and operational expenses must be factored in, as advanced cooling systems may require specialized components and regular upkeep to ensure optimal performance.

Another critical aspect is the potential for cost savings and efficiency gains. Advanced cooling techniques can significantly enhance turbine engine performance, leading to improved fuel efficiency and reduced operational costs over time. This can result in substantial long-term savings, particularly in industries where turbine engines are heavily utilized, such as aviation and power generation. Furthermore, the adoption of advanced cooling technologies can extend the lifespan of turbine engines, reducing the frequency and cost of replacements.

Market competitiveness and regulatory compliance also play a role in the economic analysis. Companies that invest in advanced cooling technologies may gain a competitive edge by offering more efficient and reliable products. Additionally, adherence to increasingly stringent environmental regulations can be achieved through improved cooling methods, potentially avoiding costly penalties and enhancing the company's market reputation. Overall, the economic analysis must balance the upfront costs with the long-term benefits and strategic advantages provided by advanced cooling techniques.

Advanced Cooling Techniques Policy and Regulatory Impact

The implementation of advanced cooling techniques for turbine engine technology is significantly influenced by policy and regulatory frameworks. These regulations ensure that new cooling technologies meet stringent safety, environmental, and performance standards. Policies often mandate reductions in emissions and improvements in fuel efficiency, driving innovation in cooling methods to enhance overall engine performance. Regulatory bodies such as the FAA and EASA set guidelines that manufacturers must adhere to, impacting the design and development of cooling systems.

Moreover, international agreements on climate change and emissions reduction, such as the Paris Agreement, exert additional pressure on the aerospace industry to adopt more efficient and environmentally friendly technologies. Compliance with these regulations not only ensures market access but also aligns with global sustainability goals. Companies investing in advanced cooling techniques must navigate these regulatory landscapes to achieve certification and market readiness.

In summary, the policy and regulatory impact on advanced cooling techniques for turbine engines is profound, shaping the direction of technological advancements and ensuring that innovations contribute to safer, more efficient, and environmentally sustainable aviation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!