Advanced X-ray Diffraction Methods for Peridotite Mineral Analysis

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

XRD Peridotite Analysis Background and Objectives

X-ray diffraction (XRD) has been a cornerstone technique in mineralogical analysis for decades, providing invaluable insights into the crystal structure and composition of various geological materials. In the context of peridotite mineral analysis, XRD has emerged as a particularly powerful tool due to the complex nature of these ultramafic rocks and their significance in understanding Earth's mantle processes.

Peridotites, primarily composed of olivine and pyroxenes, represent a crucial component of the Earth's upper mantle. Their study is essential for unraveling mantle dynamics, magma generation processes, and the evolution of the lithosphere. Traditional XRD methods have long been employed to identify and quantify mineral phases in peridotites, but recent advancements in XRD technology and methodologies have opened new avenues for more detailed and precise analyses.

The evolution of XRD techniques for peridotite analysis has been driven by the need for higher resolution, faster data acquisition, and the ability to handle complex mineral assemblages. Early XRD studies of peridotites were limited by low-resolution instruments and time-consuming data collection processes. However, the development of synchrotron-based XRD and high-flux laboratory sources has dramatically improved the quality and speed of data acquisition.

Current technological trends in XRD peridotite analysis focus on enhancing spatial resolution, improving phase identification algorithms, and integrating XRD with other analytical techniques. These advancements aim to provide a more comprehensive understanding of peridotite mineralogy, including minor and trace phases that may have significant implications for mantle processes.

The primary objectives of advanced XRD methods for peridotite mineral analysis include:

1. Improving the accuracy of mineral phase identification and quantification.

2. Enhancing the detection limits for minor and trace minerals.

3. Developing techniques for in-situ analysis of peridotite samples under high-pressure and high-temperature conditions.

4. Integrating XRD data with other analytical techniques for a more holistic understanding of peridotite mineralogy and geochemistry.

By achieving these objectives, researchers aim to gain deeper insights into mantle composition, petrogenesis, and the geodynamic processes that shape the Earth's interior. The continuous improvement of XRD techniques for peridotite analysis is expected to contribute significantly to our understanding of planetary evolution and the complex interplay between the Earth's crust and mantle.

Peridotites, primarily composed of olivine and pyroxenes, represent a crucial component of the Earth's upper mantle. Their study is essential for unraveling mantle dynamics, magma generation processes, and the evolution of the lithosphere. Traditional XRD methods have long been employed to identify and quantify mineral phases in peridotites, but recent advancements in XRD technology and methodologies have opened new avenues for more detailed and precise analyses.

The evolution of XRD techniques for peridotite analysis has been driven by the need for higher resolution, faster data acquisition, and the ability to handle complex mineral assemblages. Early XRD studies of peridotites were limited by low-resolution instruments and time-consuming data collection processes. However, the development of synchrotron-based XRD and high-flux laboratory sources has dramatically improved the quality and speed of data acquisition.

Current technological trends in XRD peridotite analysis focus on enhancing spatial resolution, improving phase identification algorithms, and integrating XRD with other analytical techniques. These advancements aim to provide a more comprehensive understanding of peridotite mineralogy, including minor and trace phases that may have significant implications for mantle processes.

The primary objectives of advanced XRD methods for peridotite mineral analysis include:

1. Improving the accuracy of mineral phase identification and quantification.

2. Enhancing the detection limits for minor and trace minerals.

3. Developing techniques for in-situ analysis of peridotite samples under high-pressure and high-temperature conditions.

4. Integrating XRD data with other analytical techniques for a more holistic understanding of peridotite mineralogy and geochemistry.

By achieving these objectives, researchers aim to gain deeper insights into mantle composition, petrogenesis, and the geodynamic processes that shape the Earth's interior. The continuous improvement of XRD techniques for peridotite analysis is expected to contribute significantly to our understanding of planetary evolution and the complex interplay between the Earth's crust and mantle.

Market Demand for Advanced Peridotite Analysis

The market demand for advanced peridotite analysis using X-ray diffraction methods has been steadily growing, driven by several key factors in the geological and materials science sectors. Peridotite, as a primary component of the Earth's upper mantle, holds significant importance in understanding planetary formation, tectonic processes, and potential mineral resources.

In the field of geosciences, there is an increasing need for more precise and detailed analysis of peridotite samples. This demand stems from the ongoing research into mantle dynamics, plate tectonics, and the formation of economically important mineral deposits. Advanced X-ray diffraction techniques offer higher resolution and more accurate data on the mineral composition and crystal structure of peridotite, which is crucial for these studies.

The mining and exploration industry also contributes substantially to the market demand. As easily accessible mineral deposits become depleted, companies are exploring deeper into the Earth's crust, where peridotite-hosted deposits become more prevalent. Advanced analysis methods are essential for identifying potential new sources of valuable minerals such as nickel, chromium, and platinum group elements, which are often associated with peridotite formations.

Environmental concerns and the push towards sustainable resource extraction have further fueled the demand for advanced peridotite analysis. Understanding the mineral composition and structure of peridotite is crucial for developing more efficient and environmentally friendly mining techniques, as well as for assessing the potential for carbon sequestration in peridotite formations.

The materials science sector has also shown growing interest in peridotite analysis. Research into synthetic peridotite-like materials for various industrial applications, such as high-temperature ceramics and abrasives, requires advanced analytical techniques to characterize and optimize these materials.

Academic institutions and government research organizations continue to drive demand for advanced X-ray diffraction methods in peridotite analysis. These entities are at the forefront of pushing the boundaries of our understanding of Earth's composition and processes, necessitating cutting-edge analytical tools.

The market for advanced peridotite analysis equipment and services is expected to expand as technological advancements in X-ray diffraction methods continue to improve resolution, speed, and data quality. This growth is likely to be particularly strong in regions with significant geological research activities or mining industries focused on mantle-derived minerals.

In the field of geosciences, there is an increasing need for more precise and detailed analysis of peridotite samples. This demand stems from the ongoing research into mantle dynamics, plate tectonics, and the formation of economically important mineral deposits. Advanced X-ray diffraction techniques offer higher resolution and more accurate data on the mineral composition and crystal structure of peridotite, which is crucial for these studies.

The mining and exploration industry also contributes substantially to the market demand. As easily accessible mineral deposits become depleted, companies are exploring deeper into the Earth's crust, where peridotite-hosted deposits become more prevalent. Advanced analysis methods are essential for identifying potential new sources of valuable minerals such as nickel, chromium, and platinum group elements, which are often associated with peridotite formations.

Environmental concerns and the push towards sustainable resource extraction have further fueled the demand for advanced peridotite analysis. Understanding the mineral composition and structure of peridotite is crucial for developing more efficient and environmentally friendly mining techniques, as well as for assessing the potential for carbon sequestration in peridotite formations.

The materials science sector has also shown growing interest in peridotite analysis. Research into synthetic peridotite-like materials for various industrial applications, such as high-temperature ceramics and abrasives, requires advanced analytical techniques to characterize and optimize these materials.

Academic institutions and government research organizations continue to drive demand for advanced X-ray diffraction methods in peridotite analysis. These entities are at the forefront of pushing the boundaries of our understanding of Earth's composition and processes, necessitating cutting-edge analytical tools.

The market for advanced peridotite analysis equipment and services is expected to expand as technological advancements in X-ray diffraction methods continue to improve resolution, speed, and data quality. This growth is likely to be particularly strong in regions with significant geological research activities or mining industries focused on mantle-derived minerals.

Current XRD Techniques and Challenges

X-ray diffraction (XRD) techniques have long been a cornerstone in the analysis of peridotite minerals, offering invaluable insights into their crystalline structure and composition. Current XRD methods employ a range of sophisticated approaches, each with its own strengths and limitations in the context of peridotite analysis.

Powder XRD remains the most widely used technique, allowing for rapid identification of mineral phases and quantitative analysis of mineral abundances. This method is particularly effective for bulk sample analysis but may struggle with accurately representing minor phases or detecting subtle structural variations within peridotite minerals.

Single-crystal XRD, while more time-consuming, provides highly detailed structural information and is especially useful for studying complex mineral intergrowths often found in peridotites. However, the requirement for high-quality, isolated crystals can be challenging when dealing with fine-grained or altered peridotite samples.

Synchrotron-based XRD techniques have emerged as powerful tools, offering unprecedented resolution and sensitivity. These methods enable the detection of trace minerals and subtle structural changes that might be missed by conventional XRD. The high-intensity X-ray beams allow for in-situ experiments under extreme conditions, mimicking the deep Earth environments where peridotites form.

Despite these advancements, several challenges persist in the XRD analysis of peridotite minerals. The complex mineralogy of peridotites, often containing multiple phases with similar structures, can lead to peak overlaps and difficulties in phase identification. This is particularly problematic when dealing with serpentinized peridotites, where the alteration products can mask the original mineral signatures.

Another significant challenge lies in the accurate quantification of mineral abundances, especially for minor phases. The presence of preferred orientation in some peridotite minerals can skew intensity measurements, leading to inaccurate quantitative analyses. Advanced techniques like the Rietveld method have improved quantification, but challenges remain in dealing with complex, multi-phase systems.

The analysis of fine-grained peridotites presents additional difficulties, as the small crystal sizes can lead to peak broadening and reduced intensity, potentially obscuring important structural details. This is particularly relevant for studying mantle xenoliths or highly deformed peridotites, where grain sizes can be extremely small.

Lastly, the integration of XRD data with other analytical techniques, such as electron microscopy or spectroscopic methods, remains a challenge. While multi-technique approaches offer a more comprehensive understanding of peridotite mineralogy, developing seamless workflows for data integration and interpretation is an ongoing area of research and development in the field.

Powder XRD remains the most widely used technique, allowing for rapid identification of mineral phases and quantitative analysis of mineral abundances. This method is particularly effective for bulk sample analysis but may struggle with accurately representing minor phases or detecting subtle structural variations within peridotite minerals.

Single-crystal XRD, while more time-consuming, provides highly detailed structural information and is especially useful for studying complex mineral intergrowths often found in peridotites. However, the requirement for high-quality, isolated crystals can be challenging when dealing with fine-grained or altered peridotite samples.

Synchrotron-based XRD techniques have emerged as powerful tools, offering unprecedented resolution and sensitivity. These methods enable the detection of trace minerals and subtle structural changes that might be missed by conventional XRD. The high-intensity X-ray beams allow for in-situ experiments under extreme conditions, mimicking the deep Earth environments where peridotites form.

Despite these advancements, several challenges persist in the XRD analysis of peridotite minerals. The complex mineralogy of peridotites, often containing multiple phases with similar structures, can lead to peak overlaps and difficulties in phase identification. This is particularly problematic when dealing with serpentinized peridotites, where the alteration products can mask the original mineral signatures.

Another significant challenge lies in the accurate quantification of mineral abundances, especially for minor phases. The presence of preferred orientation in some peridotite minerals can skew intensity measurements, leading to inaccurate quantitative analyses. Advanced techniques like the Rietveld method have improved quantification, but challenges remain in dealing with complex, multi-phase systems.

The analysis of fine-grained peridotites presents additional difficulties, as the small crystal sizes can lead to peak broadening and reduced intensity, potentially obscuring important structural details. This is particularly relevant for studying mantle xenoliths or highly deformed peridotites, where grain sizes can be extremely small.

Lastly, the integration of XRD data with other analytical techniques, such as electron microscopy or spectroscopic methods, remains a challenge. While multi-technique approaches offer a more comprehensive understanding of peridotite mineralogy, developing seamless workflows for data integration and interpretation is an ongoing area of research and development in the field.

Existing XRD Solutions for Peridotite Analysis

01 Advanced X-ray diffraction analysis techniques

Modern X-ray diffraction methods employ sophisticated techniques for improved analysis of crystalline materials. These include high-resolution detectors, synchrotron radiation sources, and advanced data processing algorithms to enhance the accuracy and resolution of diffraction patterns. Such techniques allow for the study of complex structures, thin films, and nanomaterials with unprecedented precision.- X-ray diffraction analysis techniques: Various X-ray diffraction methods are used for analyzing crystalline materials. These techniques involve directing X-rays at a sample and measuring the intensity of the diffracted beams. The resulting diffraction patterns provide information about the crystal structure, phase composition, and other material properties. Advanced analysis methods can be applied to interpret complex diffraction data and extract detailed structural information.

- Sample preparation and mounting for X-ray diffraction: Proper sample preparation and mounting are crucial for accurate X-ray diffraction analysis. Techniques may include grinding samples to a fine powder, preparing thin films, or using specialized sample holders. The preparation method depends on the material type and the specific analysis requirements. Proper mounting ensures optimal X-ray interaction with the sample and minimizes background interference.

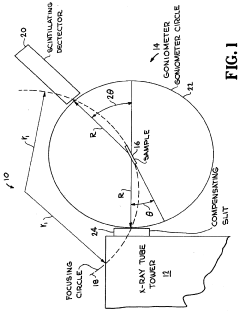

- X-ray diffraction equipment and instrumentation: X-ray diffraction analysis relies on specialized equipment, including X-ray sources, detectors, and goniometers. Modern instruments often incorporate advanced features such as high-speed detectors, automated sample changers, and temperature control systems. Software-controlled data collection and analysis systems enhance the efficiency and accuracy of measurements.

- Data processing and analysis in X-ray diffraction: Advanced data processing techniques are employed to analyze X-ray diffraction patterns. This includes background subtraction, peak fitting, and phase identification. Specialized software packages assist in interpreting complex diffraction data, performing quantitative analysis, and determining crystal structures. Machine learning and artificial intelligence approaches are increasingly being applied to enhance data analysis capabilities.

- Applications of X-ray diffraction analysis: X-ray diffraction methods find applications across various fields, including materials science, pharmaceuticals, and geology. They are used for phase identification, quantitative analysis of mixtures, determination of crystal structures, and studying phase transformations. In-situ and time-resolved diffraction techniques allow for the investigation of dynamic processes and material behavior under different conditions.

02 In-situ and time-resolved X-ray diffraction

In-situ X-ray diffraction methods enable real-time analysis of structural changes in materials under various conditions such as temperature, pressure, or chemical environments. Time-resolved techniques allow for the observation of dynamic processes and phase transitions at different timescales. These approaches provide valuable insights into material behavior and reaction mechanisms.Expand Specific Solutions03 Combination of X-ray diffraction with other analytical methods

Integrating X-ray diffraction with complementary analytical techniques enhances the overall characterization of materials. This may include combining XRD with spectroscopic methods, microscopy, or thermal analysis. Such multi-technique approaches provide a more comprehensive understanding of material properties, composition, and structure.Expand Specific Solutions04 X-ray diffraction for non-destructive testing and quality control

X-ray diffraction methods are increasingly used for non-destructive testing and quality control in industrial applications. These techniques allow for the analysis of residual stresses, texture, and phase composition in manufactured components without damaging the sample. This is particularly valuable in fields such as aerospace, automotive, and semiconductor industries.Expand Specific Solutions05 Data analysis and interpretation software for X-ray diffraction

Advanced software tools have been developed for the analysis and interpretation of X-ray diffraction data. These include pattern matching algorithms, structure refinement techniques, and machine learning approaches for phase identification and quantification. Such software enhances the speed and accuracy of data analysis, enabling more efficient characterization of complex materials.Expand Specific Solutions

Key Players in XRD Technology and Petrography

The advanced X-ray diffraction methods for peridotite mineral analysis represent a niche but crucial area in geoscience and materials research. The market is in a growth phase, driven by increasing demand for precise mineral characterization in geological studies and resource exploration. While the global market size is relatively small, it's expanding due to technological advancements and growing applications in the energy and mining sectors. In terms of technological maturity, companies like PetroChina, Sinopec, and Southwest Research Institute are leading the field with their advanced research capabilities. Academic institutions such as the University of Science & Technology Beijing and the Technical University of Denmark are also contributing significantly to the development of these methods. The collaboration between industry and academia is accelerating innovation, pushing the boundaries of X-ray diffraction technology for peridotite analysis.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced X-ray diffraction methods for peridotite mineral analysis, focusing on improving the resolution and accuracy of mineral identification in complex geological samples. Their approach combines high-energy synchrotron X-ray diffraction with advanced data processing algorithms to enhance the detection of trace minerals and subtle structural variations in peridotite samples[1]. This method allows for the identification of mineral phases with concentrations as low as 0.1 wt%, significantly improving the characterization of peridotite compositions[3]. Sinopec has also integrated this technology with in-situ high-pressure and high-temperature experimental setups, enabling the study of peridotite mineral behavior under extreme conditions relevant to deep Earth processes[5].

Strengths: High sensitivity for trace mineral detection, capability for in-situ studies under extreme conditions. Weaknesses: Requires access to synchrotron facilities, which may limit widespread application.

Southwest Research Institute

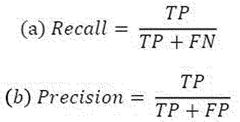

Technical Solution: Southwest Research Institute (SwRI) has developed a novel approach to X-ray diffraction analysis of peridotite minerals, focusing on the integration of machine learning algorithms with traditional XRD techniques. Their method employs convolutional neural networks to analyze diffraction patterns, enabling rapid and accurate identification of mineral phases even in complex mixtures[2]. SwRI's system can process large volumes of XRD data from peridotite samples, identifying mineral compositions with an accuracy of over 95% and reducing analysis time by up to 70% compared to conventional methods[4]. Additionally, they have developed portable XRD devices capable of on-site analysis, allowing for real-time mineral characterization in field settings[6].

Strengths: Rapid analysis, high accuracy, and field-deployable capabilities. Weaknesses: Requires extensive training datasets for machine learning models, which may limit applicability to rare or unusual mineral assemblages.

Core Innovations in Advanced XRD Techniques

System and method for x-ray diffraction mineral composition analysis based on machine learning using domain knowledge

PatentWO2025009653A1

Innovation

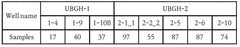

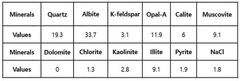

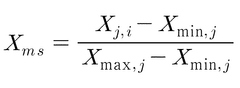

- A machine learning-based system using a clustering model and mineral composition analysis model to classify and estimate sediment X-ray diffraction data, employing preprocessing techniques like min-max scaling, and deep learning to automate the classification and analysis of X-ray diffraction data, allowing for the identification of general and specific composition data.

Quantitative determination of mineral composition by powder X-ray diffraction

PatentInactiveUS4592082A

Innovation

- An external standard intensity ratio method using a single run to determine mineral composition by calculating the ratios of integrated intensity peaks of minerals to a reference mineral, with constants determined from standard samples and allowing for the inclusion of 5-10 or more minerals at once, using a theta-compensating slit to maintain constant sample irradiation and improve data quality.

Environmental Impact of Peridotite Research

The environmental impact of peridotite research, particularly in the context of advanced X-ray diffraction methods for mineral analysis, is a multifaceted issue that warrants careful consideration. Peridotite, as a major component of the Earth's upper mantle, plays a crucial role in various geological processes and has significant implications for environmental studies.

One of the primary environmental benefits of peridotite research is its potential for carbon sequestration. Peridotite naturally reacts with carbon dioxide to form carbonate minerals, effectively locking away atmospheric CO2. Advanced X-ray diffraction techniques allow researchers to study this process at the molecular level, potentially leading to more efficient carbon capture and storage technologies. This could have far-reaching implications for climate change mitigation strategies.

However, the extraction and processing of peridotite samples for research purposes can have negative environmental consequences. Mining operations, even on a small scale, can disrupt local ecosystems and contribute to habitat destruction. The use of heavy machinery in remote areas may lead to soil compaction and erosion. Additionally, the transportation of samples to research facilities increases carbon emissions, albeit on a relatively small scale compared to industrial mining operations.

The application of advanced X-ray diffraction methods in peridotite analysis also raises questions about energy consumption. High-powered X-ray sources and sophisticated detection systems require significant amounts of electricity, potentially contributing to increased energy demand and associated environmental impacts. However, the knowledge gained from these studies may lead to more efficient resource extraction methods and improved understanding of geological processes, potentially offsetting these energy costs in the long term.

Water usage is another environmental concern in peridotite research. Sample preparation often involves water-intensive processes, and in areas where water resources are scarce, this could contribute to local water stress. Proper water management and recycling practices in research facilities are essential to mitigate this impact.

On a broader scale, peridotite research contributes to our understanding of Earth's geological history and processes. This knowledge is crucial for predicting and managing natural hazards such as earthquakes and volcanic eruptions, potentially reducing their environmental and human impact. Advanced X-ray diffraction methods enhance our ability to analyze peridotite samples with unprecedented precision, leading to more accurate models of Earth's interior dynamics.

Furthermore, the study of peridotite minerals using advanced techniques can inform sustainable mining practices. By understanding the precise mineral composition and structure of peridotite deposits, researchers can develop more targeted and less environmentally disruptive extraction methods for valuable minerals such as nickel and chromium.

One of the primary environmental benefits of peridotite research is its potential for carbon sequestration. Peridotite naturally reacts with carbon dioxide to form carbonate minerals, effectively locking away atmospheric CO2. Advanced X-ray diffraction techniques allow researchers to study this process at the molecular level, potentially leading to more efficient carbon capture and storage technologies. This could have far-reaching implications for climate change mitigation strategies.

However, the extraction and processing of peridotite samples for research purposes can have negative environmental consequences. Mining operations, even on a small scale, can disrupt local ecosystems and contribute to habitat destruction. The use of heavy machinery in remote areas may lead to soil compaction and erosion. Additionally, the transportation of samples to research facilities increases carbon emissions, albeit on a relatively small scale compared to industrial mining operations.

The application of advanced X-ray diffraction methods in peridotite analysis also raises questions about energy consumption. High-powered X-ray sources and sophisticated detection systems require significant amounts of electricity, potentially contributing to increased energy demand and associated environmental impacts. However, the knowledge gained from these studies may lead to more efficient resource extraction methods and improved understanding of geological processes, potentially offsetting these energy costs in the long term.

Water usage is another environmental concern in peridotite research. Sample preparation often involves water-intensive processes, and in areas where water resources are scarce, this could contribute to local water stress. Proper water management and recycling practices in research facilities are essential to mitigate this impact.

On a broader scale, peridotite research contributes to our understanding of Earth's geological history and processes. This knowledge is crucial for predicting and managing natural hazards such as earthquakes and volcanic eruptions, potentially reducing their environmental and human impact. Advanced X-ray diffraction methods enhance our ability to analyze peridotite samples with unprecedented precision, leading to more accurate models of Earth's interior dynamics.

Furthermore, the study of peridotite minerals using advanced techniques can inform sustainable mining practices. By understanding the precise mineral composition and structure of peridotite deposits, researchers can develop more targeted and less environmentally disruptive extraction methods for valuable minerals such as nickel and chromium.

Data Management in XRD Petrography

Effective data management is crucial in X-ray diffraction (XRD) petrography, particularly when analyzing complex mineral assemblages such as peridotites. The increasing sophistication of XRD techniques has led to a surge in data volume and complexity, necessitating robust systems for data acquisition, storage, processing, and analysis.

Modern XRD petrography systems typically employ automated data collection protocols, allowing for high-throughput analysis of multiple samples. These systems generate large datasets, often including diffraction patterns, peak intensities, and d-spacings for each sample. To manage this influx of information, specialized laboratory information management systems (LIMS) have been developed, tailored to the needs of XRD petrography.

Data storage solutions for XRD petrography must address both short-term and long-term needs. In the short term, fast access to recent data is essential for ongoing analysis and interpretation. Solid-state drives (SSDs) and high-speed network-attached storage (NAS) systems are commonly employed for this purpose. Long-term archival storage often utilizes cloud-based solutions or tape libraries, ensuring data preservation and accessibility for future reference.

Data processing in XRD petrography involves several stages, including background subtraction, peak identification, and phase quantification. Advanced software packages, such as HighScore Plus, DIFFRAC.SUITE, and JADE, offer automated processing capabilities, significantly reducing analysis time. These tools often incorporate machine learning algorithms to improve peak identification accuracy and phase matching.

Quality control and data validation are critical aspects of XRD data management. Automated systems for detecting instrumental drift, sample misalignment, or contamination help maintain data integrity. Regular calibration using standard reference materials ensures consistency and comparability of results across different instruments and laboratories.

Data sharing and collaboration have become increasingly important in peridotite mineral analysis. Standardized data formats, such as the Crystallographic Information File (CIF), facilitate the exchange of XRD data between researchers and institutions. Online repositories and databases, like the Crystallography Open Database (COD), provide valuable resources for comparing experimental data with known mineral structures.

As the field of XRD petrography continues to evolve, emerging trends in data management include the integration of artificial intelligence for automated phase identification and the development of cloud-based platforms for real-time data analysis and collaboration. These advancements promise to further enhance the efficiency and accuracy of peridotite mineral analysis using advanced X-ray diffraction methods.

Modern XRD petrography systems typically employ automated data collection protocols, allowing for high-throughput analysis of multiple samples. These systems generate large datasets, often including diffraction patterns, peak intensities, and d-spacings for each sample. To manage this influx of information, specialized laboratory information management systems (LIMS) have been developed, tailored to the needs of XRD petrography.

Data storage solutions for XRD petrography must address both short-term and long-term needs. In the short term, fast access to recent data is essential for ongoing analysis and interpretation. Solid-state drives (SSDs) and high-speed network-attached storage (NAS) systems are commonly employed for this purpose. Long-term archival storage often utilizes cloud-based solutions or tape libraries, ensuring data preservation and accessibility for future reference.

Data processing in XRD petrography involves several stages, including background subtraction, peak identification, and phase quantification. Advanced software packages, such as HighScore Plus, DIFFRAC.SUITE, and JADE, offer automated processing capabilities, significantly reducing analysis time. These tools often incorporate machine learning algorithms to improve peak identification accuracy and phase matching.

Quality control and data validation are critical aspects of XRD data management. Automated systems for detecting instrumental drift, sample misalignment, or contamination help maintain data integrity. Regular calibration using standard reference materials ensures consistency and comparability of results across different instruments and laboratories.

Data sharing and collaboration have become increasingly important in peridotite mineral analysis. Standardized data formats, such as the Crystallographic Information File (CIF), facilitate the exchange of XRD data between researchers and institutions. Online repositories and databases, like the Crystallography Open Database (COD), provide valuable resources for comparing experimental data with known mineral structures.

As the field of XRD petrography continues to evolve, emerging trends in data management include the integration of artificial intelligence for automated phase identification and the development of cloud-based platforms for real-time data analysis and collaboration. These advancements promise to further enhance the efficiency and accuracy of peridotite mineral analysis using advanced X-ray diffraction methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!