Comparative Study of Regenerative Braking Technologies in Hybrid and Electric Bicycles

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Regenerative Braking Evolution and Objectives

Regenerative braking technology in hybrid and electric bicycles has evolved significantly over the past few decades, driven by the growing demand for sustainable transportation solutions and energy efficiency. This technology, which converts kinetic energy into electrical energy during deceleration, has its roots in the automotive industry but has been adapted and refined for use in smaller, two-wheeled vehicles.

The evolution of regenerative braking in bicycles can be traced back to the early 2000s when the concept was first explored in prototype electric bikes. Initially, the systems were rudimentary, offering minimal energy recovery and often compromising ride quality. As battery technology improved and power electronics became more sophisticated, regenerative braking systems for bicycles began to show promise in terms of energy efficiency and performance.

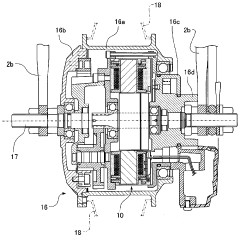

A significant milestone in this evolution was the development of hub motors with integrated regenerative braking capabilities. These compact units, typically housed in the rear wheel, allowed for seamless integration of the technology into bicycle designs without significantly altering the overall appearance or weight distribution of the vehicle. This breakthrough paved the way for wider adoption of regenerative braking in commercial electric bicycles.

The objectives of regenerative braking technology in hybrid and electric bicycles have remained consistent throughout its development. Primarily, the goal is to extend the range of the vehicle by recapturing energy that would otherwise be lost as heat during braking. This not only improves overall energy efficiency but also reduces the frequency of battery charging, enhancing the user experience and potentially lowering the total cost of ownership.

Another key objective is to provide supplementary braking power, reducing wear on traditional friction-based brake systems and potentially improving safety. In urban environments with frequent stops and starts, regenerative braking can significantly reduce the strain on conventional brakes, leading to lower maintenance costs and increased longevity of brake components.

As the technology continues to mature, additional objectives have emerged. These include improving the smoothness and controllability of regenerative braking to enhance rider comfort and safety. Engineers are also focusing on optimizing the balance between energy recovery and traditional braking to ensure reliable stopping power under all conditions.

Looking forward, the evolution of regenerative braking in hybrid and electric bicycles is likely to focus on increasing energy recovery efficiency, further miniaturization of components, and integration with smart cycling systems. The ultimate goal is to create a seamless, efficient, and user-friendly braking experience that maximizes energy recovery without compromising on safety or performance.

The evolution of regenerative braking in bicycles can be traced back to the early 2000s when the concept was first explored in prototype electric bikes. Initially, the systems were rudimentary, offering minimal energy recovery and often compromising ride quality. As battery technology improved and power electronics became more sophisticated, regenerative braking systems for bicycles began to show promise in terms of energy efficiency and performance.

A significant milestone in this evolution was the development of hub motors with integrated regenerative braking capabilities. These compact units, typically housed in the rear wheel, allowed for seamless integration of the technology into bicycle designs without significantly altering the overall appearance or weight distribution of the vehicle. This breakthrough paved the way for wider adoption of regenerative braking in commercial electric bicycles.

The objectives of regenerative braking technology in hybrid and electric bicycles have remained consistent throughout its development. Primarily, the goal is to extend the range of the vehicle by recapturing energy that would otherwise be lost as heat during braking. This not only improves overall energy efficiency but also reduces the frequency of battery charging, enhancing the user experience and potentially lowering the total cost of ownership.

Another key objective is to provide supplementary braking power, reducing wear on traditional friction-based brake systems and potentially improving safety. In urban environments with frequent stops and starts, regenerative braking can significantly reduce the strain on conventional brakes, leading to lower maintenance costs and increased longevity of brake components.

As the technology continues to mature, additional objectives have emerged. These include improving the smoothness and controllability of regenerative braking to enhance rider comfort and safety. Engineers are also focusing on optimizing the balance between energy recovery and traditional braking to ensure reliable stopping power under all conditions.

Looking forward, the evolution of regenerative braking in hybrid and electric bicycles is likely to focus on increasing energy recovery efficiency, further miniaturization of components, and integration with smart cycling systems. The ultimate goal is to create a seamless, efficient, and user-friendly braking experience that maximizes energy recovery without compromising on safety or performance.

Market Analysis for E-Bike Regenerative Systems

The market for regenerative braking systems in electric bicycles has shown significant growth potential in recent years. This trend is driven by the increasing adoption of e-bikes globally, coupled with a growing demand for more efficient and sustainable transportation solutions. The e-bike market itself has experienced robust expansion, with sales volumes rising steadily across major regions including Europe, North America, and Asia-Pacific.

Regenerative braking technology in e-bikes offers several advantages that appeal to both consumers and manufacturers. For consumers, it provides extended range capabilities, reducing the frequency of battery charging and potentially lowering overall operating costs. Manufacturers see it as a differentiating feature that can enhance their product offerings and improve overall e-bike performance.

The market demand for e-bike regenerative systems is closely tied to the broader e-bike market trends. As urban populations continue to grow and cities face increasing congestion and pollution challenges, e-bikes are becoming an attractive alternative for short to medium-distance commutes. This shift in urban mobility preferences is creating a fertile ground for advanced e-bike technologies, including regenerative braking systems.

Consumer awareness and interest in energy-efficient technologies are also driving market growth. As environmental concerns become more prominent, consumers are increasingly seeking products that offer improved sustainability features. Regenerative braking systems align well with this consumer sentiment, potentially boosting their market appeal.

From a regional perspective, Europe currently leads in the adoption of e-bikes with regenerative braking systems, followed by North America and Asia-Pacific. The European market benefits from supportive government policies promoting cycling infrastructure and e-bike usage. In North America, the market is gaining traction, particularly in urban areas with growing cycling cultures. The Asia-Pacific region, while having a large e-bike market, is still in the early stages of adopting advanced regenerative braking technologies.

The market for e-bike regenerative systems is expected to grow in tandem with technological advancements. As the technology becomes more efficient and cost-effective, its integration into a wider range of e-bike models is anticipated. This expansion is likely to drive down costs through economies of scale, making regenerative braking systems more accessible to a broader consumer base.

However, the market also faces certain challenges. The additional cost of incorporating regenerative braking systems into e-bikes can be a barrier for price-sensitive consumers. Additionally, the complexity of these systems may require specialized maintenance, potentially impacting long-term ownership costs and user experience. Overcoming these challenges will be crucial for widespread market adoption.

Regenerative braking technology in e-bikes offers several advantages that appeal to both consumers and manufacturers. For consumers, it provides extended range capabilities, reducing the frequency of battery charging and potentially lowering overall operating costs. Manufacturers see it as a differentiating feature that can enhance their product offerings and improve overall e-bike performance.

The market demand for e-bike regenerative systems is closely tied to the broader e-bike market trends. As urban populations continue to grow and cities face increasing congestion and pollution challenges, e-bikes are becoming an attractive alternative for short to medium-distance commutes. This shift in urban mobility preferences is creating a fertile ground for advanced e-bike technologies, including regenerative braking systems.

Consumer awareness and interest in energy-efficient technologies are also driving market growth. As environmental concerns become more prominent, consumers are increasingly seeking products that offer improved sustainability features. Regenerative braking systems align well with this consumer sentiment, potentially boosting their market appeal.

From a regional perspective, Europe currently leads in the adoption of e-bikes with regenerative braking systems, followed by North America and Asia-Pacific. The European market benefits from supportive government policies promoting cycling infrastructure and e-bike usage. In North America, the market is gaining traction, particularly in urban areas with growing cycling cultures. The Asia-Pacific region, while having a large e-bike market, is still in the early stages of adopting advanced regenerative braking technologies.

The market for e-bike regenerative systems is expected to grow in tandem with technological advancements. As the technology becomes more efficient and cost-effective, its integration into a wider range of e-bike models is anticipated. This expansion is likely to drive down costs through economies of scale, making regenerative braking systems more accessible to a broader consumer base.

However, the market also faces certain challenges. The additional cost of incorporating regenerative braking systems into e-bikes can be a barrier for price-sensitive consumers. Additionally, the complexity of these systems may require specialized maintenance, potentially impacting long-term ownership costs and user experience. Overcoming these challenges will be crucial for widespread market adoption.

Current Challenges in Bicycle Energy Recovery

Regenerative braking systems in hybrid and electric bicycles face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is the limited energy recovery potential due to the relatively low speeds and infrequent braking events typical in bicycle use. Unlike automobiles, bicycles operate at lower velocities and have less kinetic energy to recover during deceleration, reducing the overall efficiency of regenerative braking systems.

Another challenge lies in the integration of regenerative braking technology with existing bicycle components. The added complexity and weight of regenerative systems can compromise the lightweight and simple design that makes bicycles an attractive mode of transportation. Engineers must strike a delicate balance between energy recovery capabilities and maintaining the bicycle's core attributes of simplicity and ease of use.

The cost-effectiveness of implementing regenerative braking in bicycles remains a significant hurdle. The additional components required, such as generators, controllers, and energy storage systems, can substantially increase the overall cost of the bicycle. This price premium may deter potential consumers, especially in markets where affordability is a key factor in purchasing decisions.

Energy storage presents another set of challenges. The limited space available on bicycles restricts the size and capacity of batteries or other energy storage devices. This constraint affects the amount of energy that can be captured and stored during braking events, potentially limiting the overall impact of regenerative systems on extending the bicycle's range or power assistance capabilities.

The variability of riding conditions and user behavior also poses challenges for optimizing regenerative braking systems. Factors such as terrain, weather, and individual riding styles can significantly impact the effectiveness of energy recovery. Developing adaptive systems that can efficiently operate across a wide range of scenarios while providing a consistent user experience remains a complex engineering task.

Durability and maintenance requirements of regenerative braking systems in bicycles are additional concerns. The components must withstand diverse environmental conditions, frequent use, and potential impacts. Ensuring long-term reliability while minimizing maintenance needs is crucial for widespread acceptance of this technology in the bicycle market.

Lastly, the regulatory landscape surrounding electric and hybrid bicycles, including those with regenerative braking capabilities, is still evolving in many regions. Inconsistent or unclear regulations regarding power output, speed limits, and classification of these vehicles can create uncertainty for manufacturers and consumers alike, potentially slowing down innovation and adoption of advanced braking technologies in the bicycle industry.

Another challenge lies in the integration of regenerative braking technology with existing bicycle components. The added complexity and weight of regenerative systems can compromise the lightweight and simple design that makes bicycles an attractive mode of transportation. Engineers must strike a delicate balance between energy recovery capabilities and maintaining the bicycle's core attributes of simplicity and ease of use.

The cost-effectiveness of implementing regenerative braking in bicycles remains a significant hurdle. The additional components required, such as generators, controllers, and energy storage systems, can substantially increase the overall cost of the bicycle. This price premium may deter potential consumers, especially in markets where affordability is a key factor in purchasing decisions.

Energy storage presents another set of challenges. The limited space available on bicycles restricts the size and capacity of batteries or other energy storage devices. This constraint affects the amount of energy that can be captured and stored during braking events, potentially limiting the overall impact of regenerative systems on extending the bicycle's range or power assistance capabilities.

The variability of riding conditions and user behavior also poses challenges for optimizing regenerative braking systems. Factors such as terrain, weather, and individual riding styles can significantly impact the effectiveness of energy recovery. Developing adaptive systems that can efficiently operate across a wide range of scenarios while providing a consistent user experience remains a complex engineering task.

Durability and maintenance requirements of regenerative braking systems in bicycles are additional concerns. The components must withstand diverse environmental conditions, frequent use, and potential impacts. Ensuring long-term reliability while minimizing maintenance needs is crucial for widespread acceptance of this technology in the bicycle market.

Lastly, the regulatory landscape surrounding electric and hybrid bicycles, including those with regenerative braking capabilities, is still evolving in many regions. Inconsistent or unclear regulations regarding power output, speed limits, and classification of these vehicles can create uncertainty for manufacturers and consumers alike, potentially slowing down innovation and adoption of advanced braking technologies in the bicycle industry.

Existing Regenerative Solutions for Bicycles

01 Electric motor control for regenerative braking

Advanced control strategies for electric motors during regenerative braking can significantly improve braking efficiency. These methods involve optimizing the motor's operation to maximize energy recovery while maintaining vehicle stability and braking performance. Techniques may include adaptive control algorithms, torque distribution optimization, and integration with conventional friction brakes.- Electric motor control for regenerative braking: Advanced control strategies for electric motors during regenerative braking can significantly improve braking efficiency. These methods involve optimizing the motor's operation to maximize energy recovery while maintaining vehicle stability and braking performance. Techniques may include adaptive control algorithms, torque distribution optimization, and integration with conventional friction brakes.

- Energy storage systems for regenerative braking: Efficient energy storage systems are crucial for maximizing the benefits of regenerative braking. These systems may include advanced battery technologies, supercapacitors, or hybrid energy storage solutions. The design focuses on rapid charge acceptance, high power density, and minimal energy losses during the charging and discharging cycles.

- Integration of regenerative and friction braking systems: Seamless integration of regenerative and conventional friction braking systems can enhance overall braking efficiency. This involves developing sophisticated control algorithms that optimize the balance between regenerative and friction braking based on various factors such as vehicle speed, battery state of charge, and driver input. The goal is to maximize energy recovery while ensuring consistent and reliable braking performance.

- Predictive and adaptive regenerative braking strategies: Advanced regenerative braking systems utilize predictive and adaptive strategies to optimize braking efficiency. These may include machine learning algorithms, real-time road condition analysis, and integration with vehicle-to-infrastructure (V2I) communication systems. Such approaches allow the system to anticipate braking needs and adjust regenerative braking parameters for maximum efficiency and safety.

- Mechanical systems for enhancing regenerative braking: Innovative mechanical systems can complement electrical regenerative braking to improve overall efficiency. These may include advanced flywheel energy storage, hydraulic regenerative systems, or mechanical energy recovery devices. Such systems can capture and store energy that might otherwise be lost in scenarios where electrical regenerative braking is less effective, such as at very low speeds.

02 Energy storage systems for regenerative braking

Efficient energy storage systems are crucial for maximizing the benefits of regenerative braking. These systems may include advanced battery technologies, supercapacitors, or hybrid energy storage solutions. The design focuses on rapid charge acceptance, high power density, and minimal energy losses during the charging and discharging cycles.Expand Specific Solutions03 Integration of regenerative and friction braking systems

Seamless integration of regenerative and conventional friction braking systems can enhance overall braking efficiency. This involves developing sophisticated control algorithms that optimize the balance between regenerative and friction braking based on various factors such as vehicle speed, battery state of charge, and driver input. The goal is to maximize energy recovery while ensuring safe and consistent braking performance.Expand Specific Solutions04 Hydraulic regenerative braking systems

Hydraulic regenerative braking systems offer an alternative approach to electric systems, particularly for heavy-duty vehicles. These systems use hydraulic accumulators to store energy from braking, which can then be used to assist acceleration. The technology focuses on improving the efficiency of hydraulic components, reducing system weight, and optimizing control strategies for energy recovery and reuse.Expand Specific Solutions05 Predictive and adaptive regenerative braking strategies

Advanced regenerative braking systems incorporate predictive and adaptive strategies to optimize braking efficiency. These may include using GPS and topographical data to anticipate braking needs, adapting to driver behavior, or considering traffic conditions. Machine learning algorithms can be employed to continuously improve the system's performance and energy recovery efficiency over time.Expand Specific Solutions

Key E-Bike and Component Manufacturers

The regenerative braking technology market for hybrid and electric bicycles is in a growth phase, driven by increasing demand for sustainable transportation solutions. The market size is expanding rapidly, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing quickly, with major players like Hyundai, Ford, and Nissan investing heavily in research and development. Companies such as Shimano and Brembo are also contributing specialized expertise in bicycle components and braking systems. While the technology is maturing, there is still room for innovation, particularly in efficiency improvements and integration with electric drive systems. Universities like Tsinghua and Jiangsu are also actively involved in research, indicating the technology's potential for further advancement.

Ford Global Technologies LLC

Technical Solution: Ford has applied its automotive expertise to develop a regenerative braking system for electric bicycles that focuses on maximizing energy recovery in urban environments. The system utilizes a high-torque generator integrated into the rear hub, which engages during braking to capture kinetic energy. Ford's technology incorporates predictive algorithms that anticipate braking events based on GPS data and traffic patterns, allowing for optimal energy recovery. The system features a variable regenerative braking force that can be adjusted through a smartphone app, giving riders control over their energy recovery and riding experience. Ford claims their system can recover up to 60% of braking energy in stop-and-go urban traffic, potentially doubling the e-bike's range in city environments[5].

Strengths: Optimized for urban environments, user-customizable through smartphone integration, high energy recovery in stop-and-go traffic. Weaknesses: Reliance on GPS and smartphone connectivity may impact reliability, potentially less effective in rural or off-road settings.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has adapted its e-POWER technology from automotive applications to create a regenerative braking system for electric bicycles. The system uses a compact, high-efficiency electric motor-generator that can both propel the bicycle and recover energy during braking. Nissan's approach emphasizes seamless transitions between motor assist and regenerative braking, providing a natural riding experience. The system incorporates an intelligent energy management unit that optimizes power distribution between the battery, motor, and regenerative braking system based on riding conditions and user input. Nissan's technology can recover up to 75% of braking energy and features a unique "one-pedal" riding mode that allows riders to control both acceleration and deceleration through pedal pressure alone[6].

Strengths: Seamless integration of motor assist and regenerative braking, innovative "one-pedal" riding mode, high energy recovery efficiency. Weaknesses: Potentially higher cost due to advanced motor-generator technology, may require specialized maintenance.

Innovative Regenerative Braking Patents

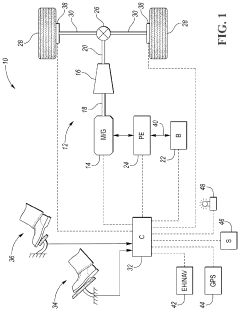

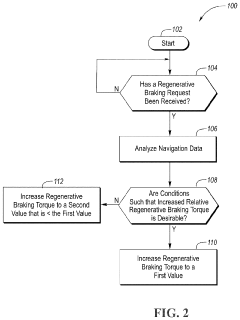

Regenerative braking control system for a hybrid or electric vehicle

PatentActiveUS11865947B2

Innovation

- A vehicle control system that includes an electric machine, sensors, a receiver, and an electronic horizon module, programmed to adjust regenerative braking torque dynamically based on route attribute data, external conditions, and navigation data, distinguishing between different driving scenarios to optimize torque levels.

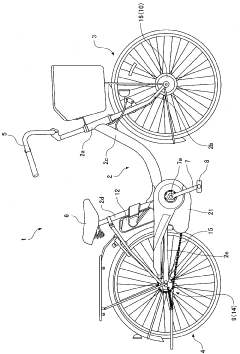

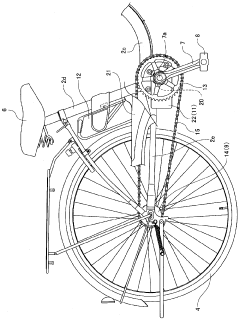

Electric bicycle

PatentWO2012035682A1

Innovation

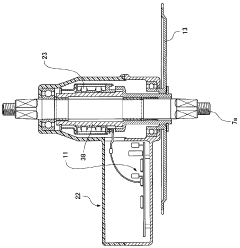

- An electric bicycle design featuring an electric motor in the rear wheel hub that activates a coaster brake when pedaled in reverse, combined with regenerative braking of the electric motor, allowing for braking without a brake lever and reducing manufacturing costs by eliminating the need for additional sensors.

Environmental Impact of Regenerative Systems

The environmental impact of regenerative braking systems in hybrid and electric bicycles is a crucial aspect to consider when evaluating their overall sustainability. These systems offer significant potential for reducing energy consumption and emissions, contributing to a greener transportation sector. By capturing and storing energy that would otherwise be lost during braking, regenerative systems can extend the range of electric bicycles and reduce the frequency of battery charging, thereby decreasing the overall energy demand from the grid.

One of the primary environmental benefits of regenerative braking in bicycles is the reduction of carbon emissions. As these systems improve the energy efficiency of the vehicle, they indirectly contribute to lower greenhouse gas emissions by reducing the need for frequent battery charging. This is particularly significant in regions where electricity generation relies heavily on fossil fuels. Studies have shown that the implementation of regenerative braking in electric bicycles can lead to a 5-15% increase in overall energy efficiency, translating to a proportional decrease in carbon footprint.

The manufacturing process of regenerative braking systems also plays a role in their environmental impact. While the production of these systems requires additional components and materials compared to traditional braking systems, the long-term benefits often outweigh the initial environmental costs. The use of rare earth metals in some regenerative braking designs has raised concerns about resource depletion and mining impacts. However, ongoing research is focused on developing alternative materials and more sustainable manufacturing processes to mitigate these issues.

Another important consideration is the end-of-life management of regenerative braking systems. As these systems become more prevalent in hybrid and electric bicycles, proper recycling and disposal methods must be developed to prevent environmental contamination. The complex nature of these systems, often integrating electronic components with mechanical parts, presents challenges for recycling. However, advancements in recycling technologies and the implementation of circular economy principles are beginning to address these concerns.

The impact on urban environments should also be noted. Regenerative braking systems contribute to reduced noise pollution in cities, as they allow for smoother deceleration and less reliance on friction-based braking. This not only improves the quality of life for urban residents but also reduces the environmental impact associated with brake pad wear and the release of particulate matter into the atmosphere.

In conclusion, while regenerative braking systems in hybrid and electric bicycles present some environmental challenges, particularly in manufacturing and end-of-life management, their overall impact is largely positive. The energy efficiency gains and subsequent reduction in emissions make them a valuable technology in the pursuit of sustainable urban transportation. As research continues and technology advances, it is likely that the environmental benefits of these systems will further increase, solidifying their role in eco-friendly mobility solutions.

One of the primary environmental benefits of regenerative braking in bicycles is the reduction of carbon emissions. As these systems improve the energy efficiency of the vehicle, they indirectly contribute to lower greenhouse gas emissions by reducing the need for frequent battery charging. This is particularly significant in regions where electricity generation relies heavily on fossil fuels. Studies have shown that the implementation of regenerative braking in electric bicycles can lead to a 5-15% increase in overall energy efficiency, translating to a proportional decrease in carbon footprint.

The manufacturing process of regenerative braking systems also plays a role in their environmental impact. While the production of these systems requires additional components and materials compared to traditional braking systems, the long-term benefits often outweigh the initial environmental costs. The use of rare earth metals in some regenerative braking designs has raised concerns about resource depletion and mining impacts. However, ongoing research is focused on developing alternative materials and more sustainable manufacturing processes to mitigate these issues.

Another important consideration is the end-of-life management of regenerative braking systems. As these systems become more prevalent in hybrid and electric bicycles, proper recycling and disposal methods must be developed to prevent environmental contamination. The complex nature of these systems, often integrating electronic components with mechanical parts, presents challenges for recycling. However, advancements in recycling technologies and the implementation of circular economy principles are beginning to address these concerns.

The impact on urban environments should also be noted. Regenerative braking systems contribute to reduced noise pollution in cities, as they allow for smoother deceleration and less reliance on friction-based braking. This not only improves the quality of life for urban residents but also reduces the environmental impact associated with brake pad wear and the release of particulate matter into the atmosphere.

In conclusion, while regenerative braking systems in hybrid and electric bicycles present some environmental challenges, particularly in manufacturing and end-of-life management, their overall impact is largely positive. The energy efficiency gains and subsequent reduction in emissions make them a valuable technology in the pursuit of sustainable urban transportation. As research continues and technology advances, it is likely that the environmental benefits of these systems will further increase, solidifying their role in eco-friendly mobility solutions.

Safety Regulations for E-Bike Braking Systems

Safety regulations for e-bike braking systems are crucial for ensuring the well-being of riders and pedestrians alike. These regulations typically encompass a range of requirements, including minimum braking performance standards, durability testing, and fail-safe mechanisms. In many jurisdictions, e-bikes are required to have at least two independent braking systems, usually one for each wheel, to provide redundancy in case of failure.

The European Union, through its EN 15194 standard, mandates specific braking performance criteria for e-bikes. This includes requirements for braking distance and deceleration rates under various conditions, such as dry and wet surfaces. The standard also specifies testing procedures to ensure consistent and reliable braking performance over time.

In the United States, the Consumer Product Safety Commission (CPSC) sets safety standards for bicycles, including e-bikes. These regulations cover aspects such as brake control location, actuation force, and stopping distances. Additionally, many states have adopted their own e-bike regulations, which may include specific braking system requirements.

Regenerative braking systems in e-bikes present unique challenges for safety regulators. While these systems can enhance overall braking performance and energy efficiency, they must be carefully integrated with traditional friction brakes to ensure consistent and predictable braking behavior. Regulations may require that regenerative braking systems do not interfere with the operation of conventional brakes and that they provide a smooth transition between regenerative and friction braking.

Safety regulations also address the potential risks associated with battery-powered braking systems. This includes requirements for electrical isolation, protection against short circuits, and safeguards to prevent unintended brake activation or release due to electrical system failures.

Manufacturers must conduct extensive testing to demonstrate compliance with these safety regulations. This often involves simulated long-term use, extreme weather conditions, and various failure scenarios to ensure the braking system remains effective and reliable throughout the e-bike's lifecycle.

As e-bike technology continues to evolve, safety regulations are likely to adapt to address new challenges and opportunities. This may include specific provisions for advanced braking technologies, such as anti-lock braking systems (ABS) for e-bikes, which are beginning to enter the market. Future regulations may also need to consider the implications of connected and autonomous features in e-bikes, which could impact braking system design and operation.

The European Union, through its EN 15194 standard, mandates specific braking performance criteria for e-bikes. This includes requirements for braking distance and deceleration rates under various conditions, such as dry and wet surfaces. The standard also specifies testing procedures to ensure consistent and reliable braking performance over time.

In the United States, the Consumer Product Safety Commission (CPSC) sets safety standards for bicycles, including e-bikes. These regulations cover aspects such as brake control location, actuation force, and stopping distances. Additionally, many states have adopted their own e-bike regulations, which may include specific braking system requirements.

Regenerative braking systems in e-bikes present unique challenges for safety regulators. While these systems can enhance overall braking performance and energy efficiency, they must be carefully integrated with traditional friction brakes to ensure consistent and predictable braking behavior. Regulations may require that regenerative braking systems do not interfere with the operation of conventional brakes and that they provide a smooth transition between regenerative and friction braking.

Safety regulations also address the potential risks associated with battery-powered braking systems. This includes requirements for electrical isolation, protection against short circuits, and safeguards to prevent unintended brake activation or release due to electrical system failures.

Manufacturers must conduct extensive testing to demonstrate compliance with these safety regulations. This often involves simulated long-term use, extreme weather conditions, and various failure scenarios to ensure the braking system remains effective and reliable throughout the e-bike's lifecycle.

As e-bike technology continues to evolve, safety regulations are likely to adapt to address new challenges and opportunities. This may include specific provisions for advanced braking technologies, such as anti-lock braking systems (ABS) for e-bikes, which are beginning to enter the market. Future regulations may also need to consider the implications of connected and autonomous features in e-bikes, which could impact braking system design and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!