Comparison of Shape-memory Polymer Actuators and Piezoelectric Devices

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Materials Background and Objectives

Smart materials represent a revolutionary class of engineered materials that respond to external stimuli by changing their properties or behaviors in a controlled manner. The evolution of these materials has been marked by significant advancements over the past few decades, transitioning from laboratory curiosities to commercially viable technologies with diverse applications. Shape-memory polymer actuators and piezoelectric devices stand as two prominent categories within this domain, each offering unique capabilities for converting various forms of energy into mechanical work.

Shape-memory polymers (SMPs) emerged in the 1960s but gained substantial research momentum in the 1990s with the development of more sophisticated polymer chemistries. These materials possess the remarkable ability to "remember" and return to their original shape when subjected to specific stimuli such as heat, light, or electrical current. The technology has evolved from simple thermal-responsive systems to multi-responsive smart materials capable of complex shape transformations.

Piezoelectric materials, discovered by Jacques and Pierre Curie in 1880, have undergone significant refinement since their initial discovery. These materials generate an electrical charge in response to mechanical stress and, conversely, deform when exposed to an electric field. The development trajectory has moved from natural crystals like quartz to engineered ceramics such as lead zirconate titanate (PZT) and, more recently, to lead-free alternatives and polymer-based piezoelectrics.

The technological objectives in comparing these two smart material systems encompass several dimensions. First, there is a pressing need to understand their relative performance metrics including response time, actuation force, displacement range, energy efficiency, and operational lifespan. Second, researchers aim to identify the optimal application domains for each technology based on their inherent strengths and limitations.

Current research trends focus on enhancing the responsiveness of SMPs while improving the energy density of piezoelectric materials. There is also significant interest in developing hybrid systems that leverage the complementary advantages of both technologies. The ultimate goal is to create more efficient, versatile, and sustainable actuator technologies that can meet the demands of emerging applications in robotics, biomedical devices, aerospace systems, and consumer electronics.

The evolution of these smart materials is increasingly driven by sustainability considerations, with efforts directed toward reducing reliance on rare or toxic elements, minimizing energy consumption during operation, and ensuring recyclability at end-of-life. This aligns with broader technological trends toward environmentally responsible innovation and circular economy principles in advanced materials development.

Shape-memory polymers (SMPs) emerged in the 1960s but gained substantial research momentum in the 1990s with the development of more sophisticated polymer chemistries. These materials possess the remarkable ability to "remember" and return to their original shape when subjected to specific stimuli such as heat, light, or electrical current. The technology has evolved from simple thermal-responsive systems to multi-responsive smart materials capable of complex shape transformations.

Piezoelectric materials, discovered by Jacques and Pierre Curie in 1880, have undergone significant refinement since their initial discovery. These materials generate an electrical charge in response to mechanical stress and, conversely, deform when exposed to an electric field. The development trajectory has moved from natural crystals like quartz to engineered ceramics such as lead zirconate titanate (PZT) and, more recently, to lead-free alternatives and polymer-based piezoelectrics.

The technological objectives in comparing these two smart material systems encompass several dimensions. First, there is a pressing need to understand their relative performance metrics including response time, actuation force, displacement range, energy efficiency, and operational lifespan. Second, researchers aim to identify the optimal application domains for each technology based on their inherent strengths and limitations.

Current research trends focus on enhancing the responsiveness of SMPs while improving the energy density of piezoelectric materials. There is also significant interest in developing hybrid systems that leverage the complementary advantages of both technologies. The ultimate goal is to create more efficient, versatile, and sustainable actuator technologies that can meet the demands of emerging applications in robotics, biomedical devices, aerospace systems, and consumer electronics.

The evolution of these smart materials is increasingly driven by sustainability considerations, with efforts directed toward reducing reliance on rare or toxic elements, minimizing energy consumption during operation, and ensuring recyclability at end-of-life. This aligns with broader technological trends toward environmentally responsible innovation and circular economy principles in advanced materials development.

Market Applications Analysis for Smart Actuators

The smart actuator market is experiencing significant growth across multiple industries, driven by the increasing demand for precision control systems and automation. Shape-memory polymer (SMP) actuators and piezoelectric devices represent two of the most promising technologies in this space, each offering unique advantages for specific applications.

In the healthcare sector, smart actuators are revolutionizing medical devices and surgical tools. SMP actuators are particularly valuable in minimally invasive surgery, where their ability to change shape in response to body temperature enables the development of self-deploying stents and catheters. Piezoelectric devices, with their precise micro-positioning capabilities, are finding applications in drug delivery systems and micro-surgical tools where nanometer-level precision is required.

The aerospace industry represents another major market for smart actuators. Shape-memory polymer actuators offer significant weight reduction compared to traditional mechanical systems, making them ideal for morphing aircraft structures and deployable space components. Piezoelectric actuators are widely used in vibration control systems and precision positioning mechanisms in satellites and aircraft, where their fast response times and high force generation are critical advantages.

Consumer electronics constitutes a rapidly expanding market for these technologies. Piezoelectric devices dominate in haptic feedback systems for smartphones, gaming controllers, and wearable devices, providing tactile sensations with minimal power consumption. SMP actuators are emerging in applications such as self-adjusting earbuds and adaptive wearable devices that conform to user anatomy.

The automotive sector is increasingly adopting smart actuators for various applications. Piezoelectric devices are used in fuel injection systems, active suspension components, and advanced driver assistance systems. Shape-memory polymers show promise for deployable aerodynamic components and self-healing surfaces that can repair minor damage.

In robotics and automation, both technologies offer complementary benefits. Piezoelectric actuators excel in applications requiring high precision and frequency response, such as micro-robotics and high-speed automation. SMP actuators are advantageous in soft robotics, where their compliant nature and programmable stiffness enable safe human-robot interaction and adaptable gripping mechanisms.

The environmental sensing and monitoring market is also adopting these technologies, with piezoelectric devices widely used in pressure sensors and energy harvesting systems. SMP actuators are being developed for adaptive environmental monitoring systems that can deploy and retract sensing elements based on environmental conditions.

In the healthcare sector, smart actuators are revolutionizing medical devices and surgical tools. SMP actuators are particularly valuable in minimally invasive surgery, where their ability to change shape in response to body temperature enables the development of self-deploying stents and catheters. Piezoelectric devices, with their precise micro-positioning capabilities, are finding applications in drug delivery systems and micro-surgical tools where nanometer-level precision is required.

The aerospace industry represents another major market for smart actuators. Shape-memory polymer actuators offer significant weight reduction compared to traditional mechanical systems, making them ideal for morphing aircraft structures and deployable space components. Piezoelectric actuators are widely used in vibration control systems and precision positioning mechanisms in satellites and aircraft, where their fast response times and high force generation are critical advantages.

Consumer electronics constitutes a rapidly expanding market for these technologies. Piezoelectric devices dominate in haptic feedback systems for smartphones, gaming controllers, and wearable devices, providing tactile sensations with minimal power consumption. SMP actuators are emerging in applications such as self-adjusting earbuds and adaptive wearable devices that conform to user anatomy.

The automotive sector is increasingly adopting smart actuators for various applications. Piezoelectric devices are used in fuel injection systems, active suspension components, and advanced driver assistance systems. Shape-memory polymers show promise for deployable aerodynamic components and self-healing surfaces that can repair minor damage.

In robotics and automation, both technologies offer complementary benefits. Piezoelectric actuators excel in applications requiring high precision and frequency response, such as micro-robotics and high-speed automation. SMP actuators are advantageous in soft robotics, where their compliant nature and programmable stiffness enable safe human-robot interaction and adaptable gripping mechanisms.

The environmental sensing and monitoring market is also adopting these technologies, with piezoelectric devices widely used in pressure sensors and energy harvesting systems. SMP actuators are being developed for adaptive environmental monitoring systems that can deploy and retract sensing elements based on environmental conditions.

Technical Challenges in SMP and Piezoelectric Technologies

Shape-memory polymer (SMP) actuators and piezoelectric devices represent two distinct approaches to creating responsive materials, each facing unique technical challenges. SMPs encounter significant hurdles in achieving precise control over actuation parameters. The response time of SMPs is inherently slow compared to electronic alternatives, with typical activation periods ranging from seconds to minutes, limiting their application in scenarios requiring rapid response. Additionally, SMPs often demonstrate limited cycle life, with performance degradation occurring after repeated shape-memory cycles due to material fatigue and microstructural changes.

Temperature control presents another critical challenge for SMPs, as they require precise thermal management to achieve reliable actuation. The narrow temperature window between activation and potential material degradation creates engineering constraints that complicate implementation in variable environments. Force generation capabilities of SMPs also remain relatively modest compared to conventional actuators, typically producing stresses in the range of 1-3 MPa, which restricts their application in high-load scenarios.

Piezoelectric devices face a different set of technical obstacles. Their inherent brittleness makes them susceptible to mechanical failure, particularly in applications involving significant deformation or impact. This fragility necessitates careful design considerations and often requires protective encapsulation, adding complexity to device architecture. The hysteresis effect in piezoelectric materials creates non-linear relationships between applied voltage and resulting displacement, complicating precise control systems and requiring sophisticated compensation algorithms.

Voltage requirements represent another significant challenge for piezoelectric technologies. Many piezoelectric actuators require high driving voltages (often hundreds of volts), necessitating specialized power electronics that increase system complexity, cost, and safety considerations. Temperature sensitivity also affects piezoelectric performance, with many materials exhibiting significant property changes across operational temperature ranges, potentially leading to unpredictable behavior in variable environments.

Manufacturing scalability presents challenges for both technologies. SMPs often require complex processing techniques to achieve desired properties, while piezoelectric devices face difficulties in consistent large-scale production of defect-free materials. The integration of either technology into existing systems demands specialized interfaces and control mechanisms that add engineering complexity.

Environmental considerations further complicate implementation. Many high-performance SMPs utilize potentially toxic components, while piezoelectric materials often contain lead or other environmentally problematic elements. As regulatory frameworks increasingly emphasize sustainability, developing eco-friendly alternatives without compromising performance represents a significant research challenge for both technologies.

Cross-cutting challenges include achieving multifunctionality, miniaturization, and energy efficiency. Both technologies must overcome significant hurdles to meet the demanding requirements of emerging applications in soft robotics, biomedical devices, and smart structures.

Temperature control presents another critical challenge for SMPs, as they require precise thermal management to achieve reliable actuation. The narrow temperature window between activation and potential material degradation creates engineering constraints that complicate implementation in variable environments. Force generation capabilities of SMPs also remain relatively modest compared to conventional actuators, typically producing stresses in the range of 1-3 MPa, which restricts their application in high-load scenarios.

Piezoelectric devices face a different set of technical obstacles. Their inherent brittleness makes them susceptible to mechanical failure, particularly in applications involving significant deformation or impact. This fragility necessitates careful design considerations and often requires protective encapsulation, adding complexity to device architecture. The hysteresis effect in piezoelectric materials creates non-linear relationships between applied voltage and resulting displacement, complicating precise control systems and requiring sophisticated compensation algorithms.

Voltage requirements represent another significant challenge for piezoelectric technologies. Many piezoelectric actuators require high driving voltages (often hundreds of volts), necessitating specialized power electronics that increase system complexity, cost, and safety considerations. Temperature sensitivity also affects piezoelectric performance, with many materials exhibiting significant property changes across operational temperature ranges, potentially leading to unpredictable behavior in variable environments.

Manufacturing scalability presents challenges for both technologies. SMPs often require complex processing techniques to achieve desired properties, while piezoelectric devices face difficulties in consistent large-scale production of defect-free materials. The integration of either technology into existing systems demands specialized interfaces and control mechanisms that add engineering complexity.

Environmental considerations further complicate implementation. Many high-performance SMPs utilize potentially toxic components, while piezoelectric materials often contain lead or other environmentally problematic elements. As regulatory frameworks increasingly emphasize sustainability, developing eco-friendly alternatives without compromising performance represents a significant research challenge for both technologies.

Cross-cutting challenges include achieving multifunctionality, miniaturization, and energy efficiency. Both technologies must overcome significant hurdles to meet the demanding requirements of emerging applications in soft robotics, biomedical devices, and smart structures.

Current Implementation Solutions and Architectures

01 Shape-memory polymer actuators for mechanical systems

Shape-memory polymers can be used as actuators in mechanical systems, where they respond to external stimuli such as temperature changes to generate motion or force. These materials can remember their original shape and return to it after deformation when triggered. This property makes them valuable for applications requiring controlled movement or force generation in compact designs. The shape recovery process can be harnessed to create mechanical work in various engineering applications.- Shape-memory polymer actuators for mechanical applications: Shape-memory polymers can be used as actuators in various mechanical applications. These polymers can change their shape in response to external stimuli such as temperature, light, or electrical signals. When integrated into mechanical systems, they can generate motion or force, making them suitable for applications in robotics, aerospace, and automotive industries. The shape-memory effect allows these actuators to return to their original shape after deformation, enabling repeatable actuation cycles.

- Piezoelectric devices for energy harvesting and sensing: Piezoelectric devices convert mechanical energy into electrical energy and vice versa. These devices can be used for energy harvesting from ambient vibrations, pressure, or motion, as well as for sensing applications. The piezoelectric materials generate an electric charge when subjected to mechanical stress, making them suitable for applications in sensors, transducers, and energy harvesting systems. These devices can be integrated into various systems to provide power for low-energy electronics or to detect mechanical changes in the environment.

- Medical applications of shape-memory polymers and piezoelectric devices: Shape-memory polymers and piezoelectric devices have significant applications in medical fields. These materials can be used in minimally invasive surgical tools, implantable devices, and drug delivery systems. The shape-memory effect allows for the deployment of devices in compact forms that later expand to their functional shape within the body. Piezoelectric materials can be used for ultrasound imaging, tissue stimulation, and monitoring of physiological parameters. These technologies enable advanced medical procedures and treatments with reduced patient trauma.

- Composite materials combining shape-memory and piezoelectric properties: Innovative composite materials that combine shape-memory polymers with piezoelectric elements create multifunctional systems with enhanced capabilities. These composites can simultaneously respond to multiple stimuli and perform various functions, such as sensing, actuation, and energy harvesting. The integration of these properties allows for smart materials that can adapt to changing environments, self-monitor their condition, and respond accordingly. Applications include smart textiles, adaptive structures, and self-healing materials that can detect damage and initiate repair processes.

- Control systems for shape-memory polymer actuators: Advanced control systems are essential for optimizing the performance of shape-memory polymer actuators. These systems include sensors, feedback mechanisms, and algorithms that regulate the actuation process based on environmental conditions and desired outcomes. The control systems can manage the timing, magnitude, and direction of the shape change, enabling precise and repeatable actuation. Integration with electronic components allows for programmable responses and remote operation, expanding the potential applications of shape-memory polymer actuators in autonomous systems and smart devices.

02 Piezoelectric devices for energy harvesting and sensing

Piezoelectric devices convert mechanical energy into electrical energy and vice versa. These devices can be used for energy harvesting from ambient vibrations or for sensing applications. The piezoelectric effect allows these materials to generate an electric charge in response to applied mechanical stress, making them useful for creating self-powered sensors and energy harvesting systems. They can be integrated into various structures to monitor conditions or provide power for low-energy electronics.Expand Specific Solutions03 Medical applications of shape-memory polymers and piezoelectric devices

Shape-memory polymers and piezoelectric devices have significant applications in medical fields. These materials can be used to create minimally invasive surgical tools, implantable devices, and drug delivery systems. Their ability to change shape in response to body temperature or other stimuli makes them ideal for applications where devices need to navigate through small spaces before deploying. Piezoelectric elements can be used for precise movement control in medical instruments or for monitoring physiological parameters.Expand Specific Solutions04 Composite materials combining shape-memory polymers with piezoelectric elements

Innovative composite materials that combine shape-memory polymers with piezoelectric elements create multifunctional systems with enhanced capabilities. These composites can both sense their environment and respond with physical changes. The integration allows for smart materials that can self-regulate, adapt to changing conditions, or perform complex functions. Such composites enable the development of autonomous systems that can both detect stimuli and respond accordingly without external control systems.Expand Specific Solutions05 Control systems for shape-memory polymer actuators

Advanced control systems are essential for optimizing the performance of shape-memory polymer actuators. These systems can precisely manage the stimuli that trigger shape changes, allowing for controlled actuation rates and positions. Control algorithms can compensate for environmental variations and material aging effects, ensuring consistent performance over time. Integration with sensors creates closed-loop systems that can adapt to changing conditions and provide precise movement control for complex applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The shape-memory polymer actuators and piezoelectric devices market is in a growth phase, characterized by increasing applications across automotive, aerospace, and consumer electronics sectors. The global market size is expanding rapidly, projected to reach significant value as smart materials gain traction in various industries. Technologically, piezoelectric devices represent a more mature technology with established players like Seiko Epson, Mitsubishi Electric, and Alps Alpine leading commercial applications. Shape-memory polymers are emerging with companies like SABIC, Covestro, and Sumitomo Heavy Industries advancing material innovations. Research institutions including NASA, Harbin Institute of Technology, and CNRS are driving fundamental breakthroughs, while IBM and Huawei are exploring integration with smart systems. The competitive landscape shows traditional electronics manufacturers expanding into new applications while materials companies develop next-generation polymer solutions.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed significant research contributions in both shape-memory polymer actuators and piezoelectric devices, with particular emphasis on their comparative performance in extreme environments. Their SMP research focuses on novel composite materials incorporating carbon nanotubes and graphene to enhance electrical conductivity, enabling electrically-triggered actuation rather than purely thermal activation. This approach has yielded SMPs with response times approximately 60% faster than conventional thermally-activated polymers. Their work includes detailed characterization of actuation forces, with their latest SMP composites achieving stress generation of up to 4 MPa. In parallel, their piezoelectric research has centered on lead-free piezoelectric materials with enhanced temperature stability, addressing environmental concerns while maintaining performance. Their comparative studies have quantified the energy efficiency of both technologies across temperature ranges from -40°C to 150°C, demonstrating that their modified SMPs maintain functionality at lower temperatures where standard SMPs become ineffective, while their piezoelectric devices offer superior performance in high-frequency applications requiring precise positioning with nanometer accuracy. The institute has also pioneered hybrid systems that integrate both technologies to overcome individual limitations.

Strengths: HIT's electrically-conductive SMP composites significantly reduce response time limitations while maintaining the large displacement advantages of shape-memory materials. Their lead-free piezoelectric materials address environmental concerns without sacrificing performance. Weaknesses: The enhanced SMP composites still require more energy for activation than piezoelectric alternatives, and manufacturing consistency at scale remains challenging. Their piezoelectric materials continue to face displacement limitations compared to SMP options.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has developed comprehensive research programs comparing shape-memory polymer (SMP) actuators and piezoelectric devices across multiple performance parameters. Their SMP research focuses on multi-responsive polymers that can be activated through various stimuli including heat, light, and electrical fields, significantly expanding application versatility. Their proprietary SMP formulations achieve strain recovery rates exceeding 95% even after 1000+ actuation cycles, representing a substantial improvement over conventional SMPs that typically show performance degradation after fewer cycles. For piezoelectric technology, the university has pioneered novel ceramic compositions with enhanced electromechanical coupling coefficients approaching 0.75, substantially higher than industry standards. Their comparative analysis framework evaluates both technologies across metrics including energy density (where their SMPs achieve up to 0.3 J/cm³), response time (with their piezoelectric devices operating in the sub-millisecond range), operational frequency range, and environmental adaptability. The university has also developed innovative manufacturing techniques for both technologies, including 4D printing methods for complex SMP geometries and advanced sintering processes for high-performance piezoelectric ceramics with improved grain structure control.

Strengths: HUST's multi-responsive SMPs offer unprecedented versatility in activation methods, while their advanced piezoelectric compositions achieve superior electromechanical coupling. Their manufacturing innovations enable complex geometries for both technologies. Weaknesses: The multi-responsive SMPs still face challenges with simultaneous optimization for different stimuli types, creating performance trade-offs. Their high-performance piezoelectric materials involve more complex manufacturing processes, increasing production costs.

Key Patents and Technical Innovations Analysis

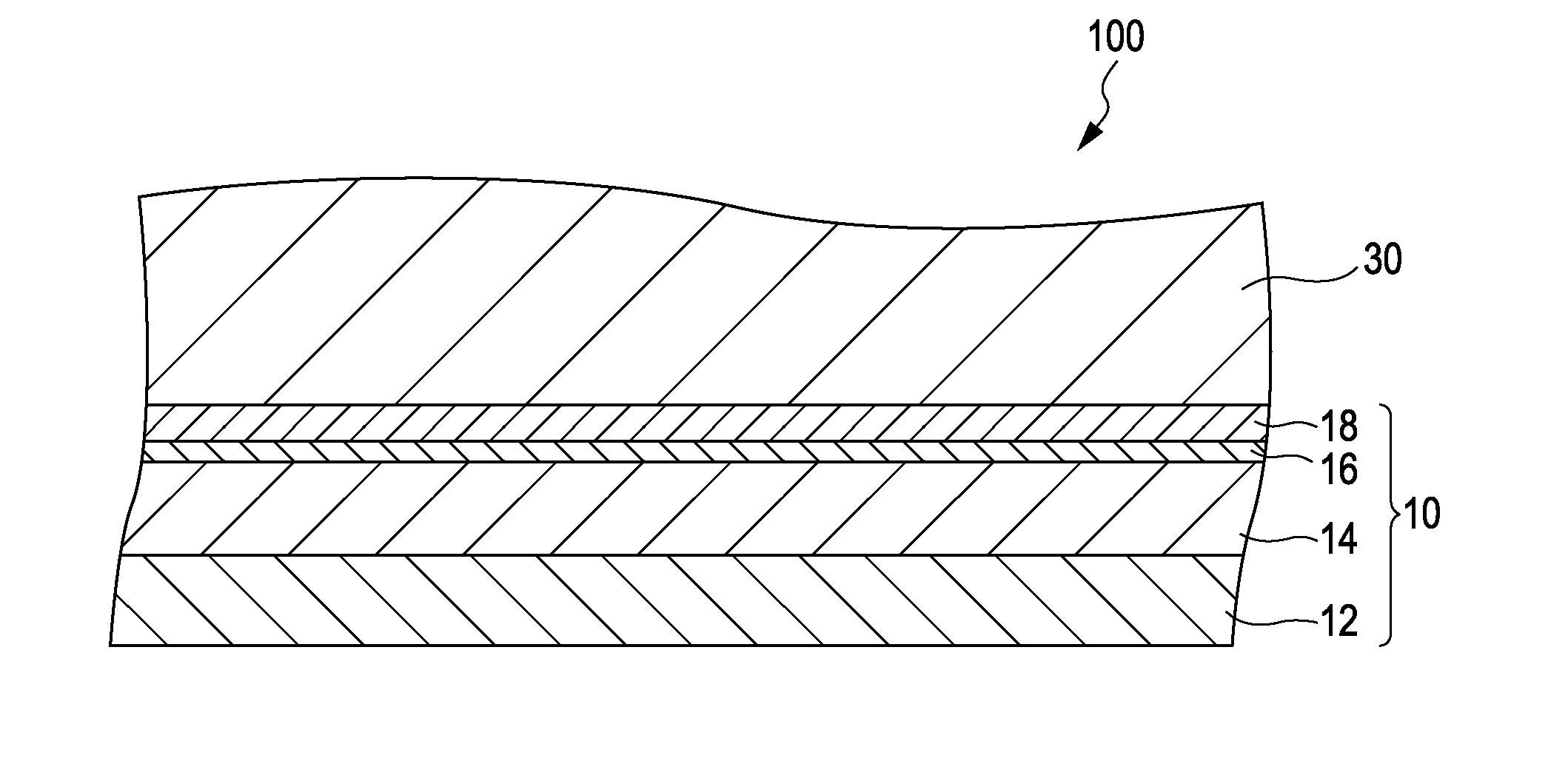

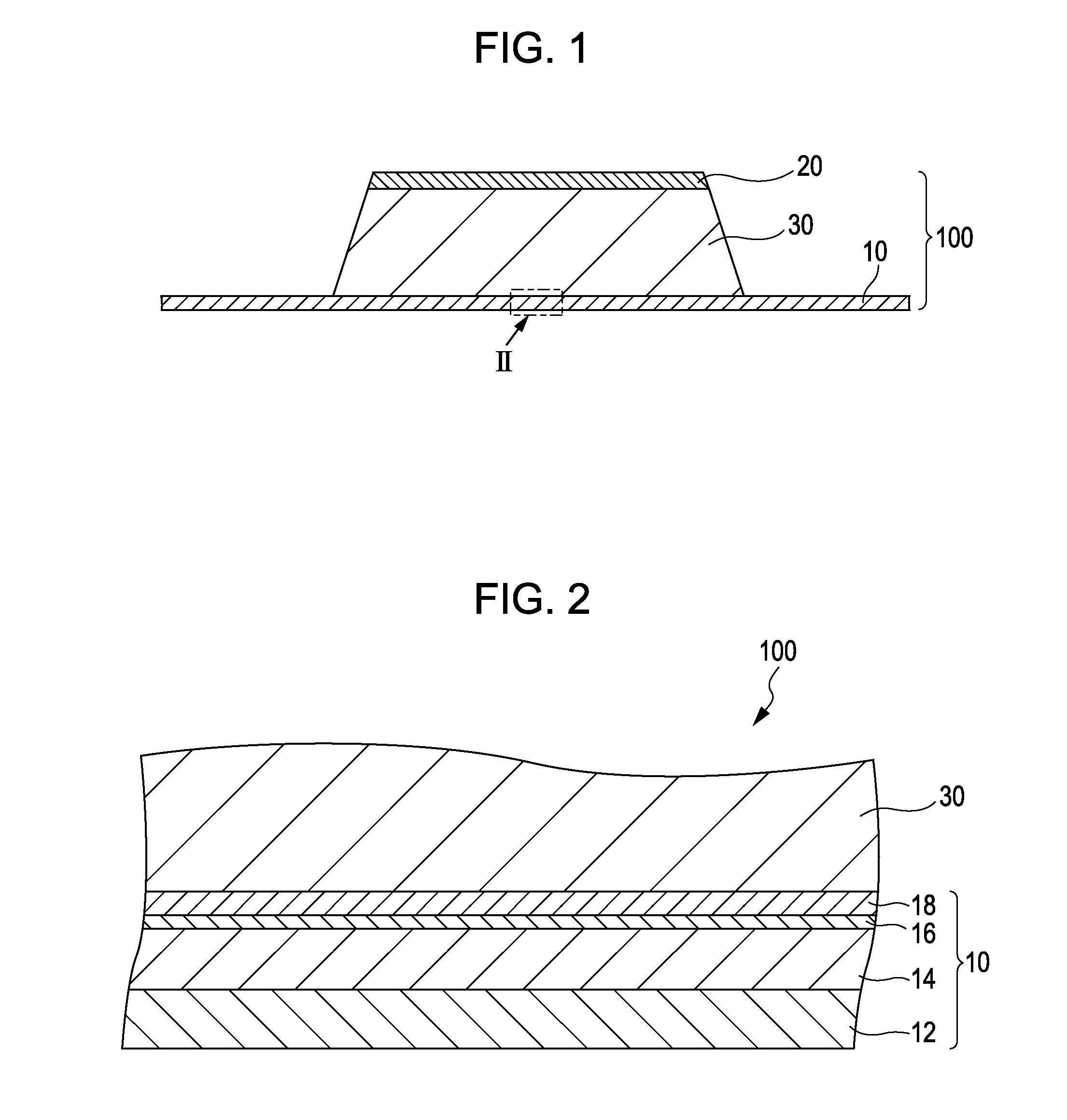

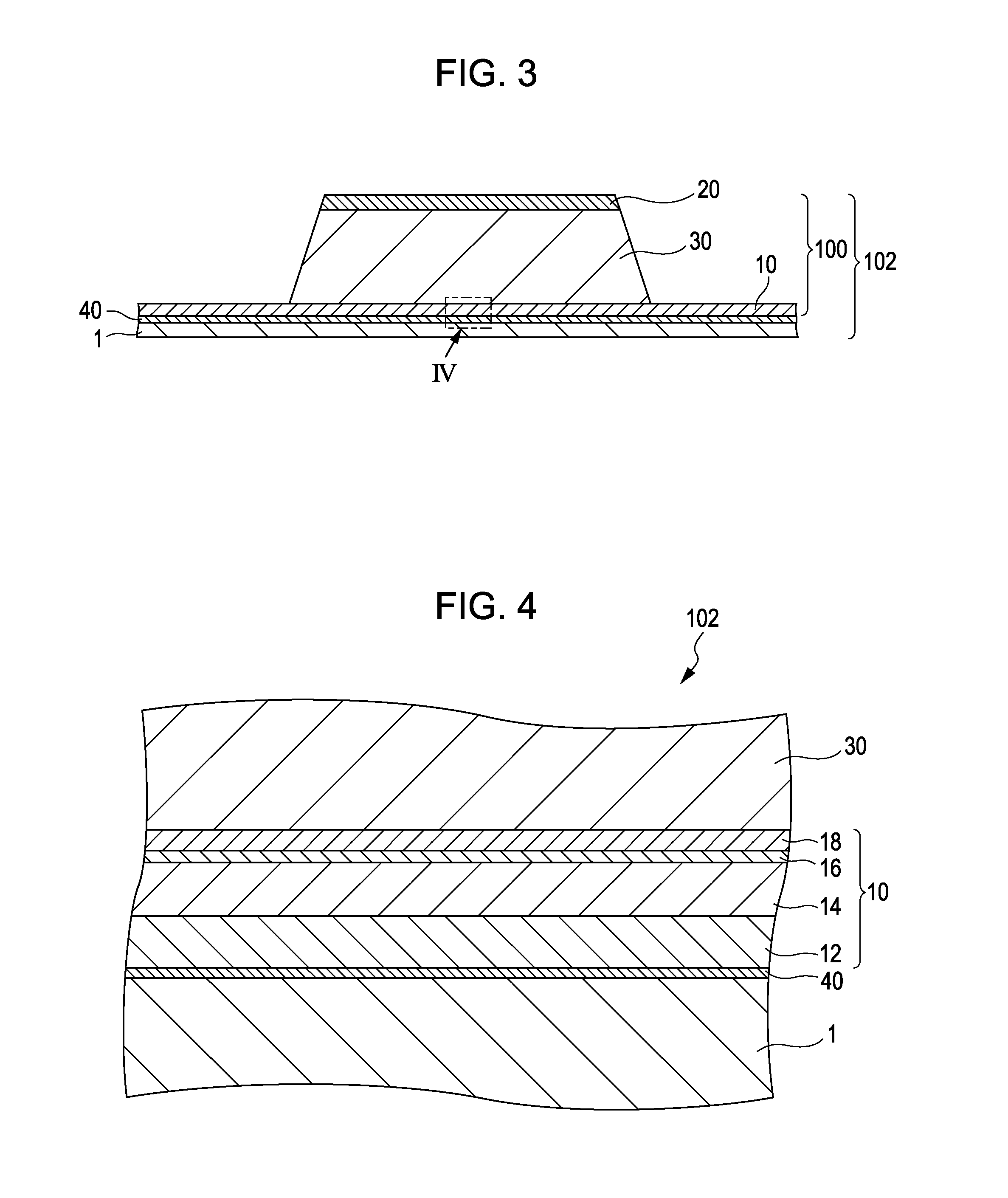

Piezoelectric device, piezoelectric actuator, liquid ejecting head, and liquid ejecting apparatus

PatentActiveUS20110109701A1

Innovation

- A piezoelectric device configuration featuring a first electrode with a conductive layer made from metals like Ti, Zr, or alloys, an intermediate nitrogen compound layer, and a conductive oxide second electrode, which enhances electrical conductivity, flexibility, and adherence, reducing the need for noble metals and lowering production costs.

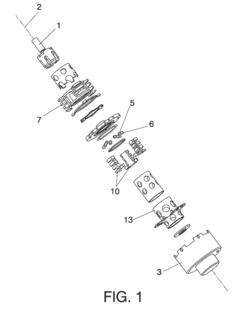

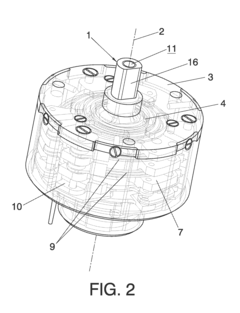

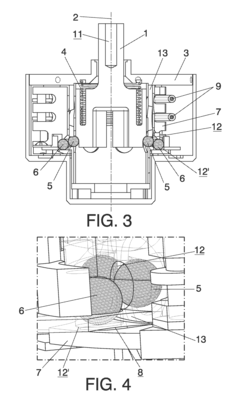

Linear actuator device

PatentActiveUS20130104680A1

Innovation

- A compact linear actuator device utilizing a shaft aligned axially within a casing, actuated by elastic means and supported by intermediate elements, which allows for remote retention and deployment of elements, featuring a shape memory alloy (SMA) actuator for high-temperature operation and low-shock performance, reducing the necessary force for actuation and minimizing electromagnetic noise.

Performance Metrics and Benchmarking Methodology

To effectively compare Shape-memory Polymer Actuators (SMPs) and Piezoelectric Devices, standardized performance metrics and benchmarking methodologies are essential. These frameworks enable objective evaluation across diverse applications and operating conditions, facilitating informed technology selection decisions.

The primary performance metrics for both technologies include actuation strain, which measures dimensional change during activation. SMPs typically exhibit 10-400% strain capability, significantly exceeding piezoelectric materials' 0.1-0.3% range. Force generation capacity represents another critical parameter, with piezoelectric devices generally producing higher force densities (up to 40 MPa) compared to SMPs (0.1-3 MPa).

Response time constitutes a fundamental differentiator, with piezoelectric devices operating in the microsecond to millisecond range, while SMPs require seconds to minutes for complete actuation cycles. Energy efficiency metrics, including energy density and conversion efficiency, reveal piezoelectric devices' superior performance in rapid-cycling applications, whereas SMPs demonstrate advantages in sustained positioning tasks.

Durability testing protocols examine cycle life, environmental stability, and degradation mechanisms. Standard methodologies include accelerated aging tests under varied temperature, humidity, and mechanical loading conditions. Piezoelectric devices typically achieve 10^8-10^9 cycles before significant performance degradation, while SMPs generally sustain 10^2-10^4 complete actuation cycles.

Standardized benchmarking methodologies incorporate application-specific testing environments that simulate real-world conditions. These include temperature variation tests (particularly relevant for SMPs), frequency response analysis (critical for piezoelectric devices), and load-displacement characterization under controlled conditions.

Multi-parameter performance mapping techniques enable visualization of operational envelopes, illustrating performance trade-offs across different operating regimes. These maps typically plot actuation strain versus response time, force generation versus energy consumption, or durability versus operating conditions.

Emerging benchmarking approaches increasingly incorporate sustainability metrics, including embodied energy, material recyclability, and life-cycle environmental impact. These considerations have gained prominence as applications expand into consumer electronics, medical devices, and automotive systems where end-of-life management presents significant challenges.

The development of standardized testing protocols remains an active research area, with organizations like ASTM International and IEEE working to establish industry-wide standards that facilitate direct technology comparisons and accelerate adoption across emerging application domains.

The primary performance metrics for both technologies include actuation strain, which measures dimensional change during activation. SMPs typically exhibit 10-400% strain capability, significantly exceeding piezoelectric materials' 0.1-0.3% range. Force generation capacity represents another critical parameter, with piezoelectric devices generally producing higher force densities (up to 40 MPa) compared to SMPs (0.1-3 MPa).

Response time constitutes a fundamental differentiator, with piezoelectric devices operating in the microsecond to millisecond range, while SMPs require seconds to minutes for complete actuation cycles. Energy efficiency metrics, including energy density and conversion efficiency, reveal piezoelectric devices' superior performance in rapid-cycling applications, whereas SMPs demonstrate advantages in sustained positioning tasks.

Durability testing protocols examine cycle life, environmental stability, and degradation mechanisms. Standard methodologies include accelerated aging tests under varied temperature, humidity, and mechanical loading conditions. Piezoelectric devices typically achieve 10^8-10^9 cycles before significant performance degradation, while SMPs generally sustain 10^2-10^4 complete actuation cycles.

Standardized benchmarking methodologies incorporate application-specific testing environments that simulate real-world conditions. These include temperature variation tests (particularly relevant for SMPs), frequency response analysis (critical for piezoelectric devices), and load-displacement characterization under controlled conditions.

Multi-parameter performance mapping techniques enable visualization of operational envelopes, illustrating performance trade-offs across different operating regimes. These maps typically plot actuation strain versus response time, force generation versus energy consumption, or durability versus operating conditions.

Emerging benchmarking approaches increasingly incorporate sustainability metrics, including embodied energy, material recyclability, and life-cycle environmental impact. These considerations have gained prominence as applications expand into consumer electronics, medical devices, and automotive systems where end-of-life management presents significant challenges.

The development of standardized testing protocols remains an active research area, with organizations like ASTM International and IEEE working to establish industry-wide standards that facilitate direct technology comparisons and accelerate adoption across emerging application domains.

Environmental Impact and Sustainability Considerations

The environmental impact of actuator technologies has become increasingly important as industries strive for sustainable development. Shape-memory polymer (SMP) actuators and piezoelectric devices present distinct environmental profiles throughout their lifecycle, from raw material extraction to end-of-life disposal.

Shape-memory polymer actuators generally offer favorable environmental characteristics compared to many traditional actuator technologies. These polymers typically require less energy-intensive manufacturing processes than their metallic counterparts. Many SMPs are derived from thermoplastics that can be recycled through conventional methods, potentially reducing waste. Additionally, some research groups have successfully developed bio-based SMPs from renewable resources such as cellulose derivatives and plant oils, further enhancing their sustainability credentials.

In contrast, piezoelectric devices present more complex environmental considerations. Traditional piezoelectric materials like lead zirconate titanate (PZT) contain significant amounts of lead, a toxic heavy metal with well-documented environmental and health hazards. The extraction and processing of these materials involve energy-intensive processes and generate hazardous waste. However, recent advances in lead-free piezoelectric materials, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), represent promising alternatives with reduced environmental impact.

Energy efficiency during operation represents another critical environmental factor. Piezoelectric devices generally exhibit excellent energy conversion efficiency, often exceeding 90% in optimal conditions. This high efficiency can translate to lower lifetime energy consumption compared to other actuator technologies. SMP actuators typically demonstrate lower energy efficiency during operation but may require less frequent actuation in certain applications, potentially offsetting this disadvantage.

Durability and service life also influence environmental sustainability. Piezoelectric devices can withstand millions of actuation cycles with minimal degradation, potentially reducing replacement frequency and associated resource consumption. SMPs typically exhibit more limited cycle life, though recent advances in material science have significantly improved their durability.

End-of-life considerations reveal further distinctions. While many SMPs can be recycled through conventional methods, piezoelectric devices often require specialized recycling processes to recover valuable materials and prevent toxic substances from entering the environment. The complex composition of piezoelectric devices can make disassembly and material separation challenging, potentially limiting recycling rates.

Carbon footprint assessments indicate that both technologies can offer advantages over conventional electromagnetic or hydraulic actuators in specific applications. However, comprehensive lifecycle analyses comparing these technologies across diverse application scenarios remain limited, highlighting a need for further research to guide environmentally conscious design decisions.

Shape-memory polymer actuators generally offer favorable environmental characteristics compared to many traditional actuator technologies. These polymers typically require less energy-intensive manufacturing processes than their metallic counterparts. Many SMPs are derived from thermoplastics that can be recycled through conventional methods, potentially reducing waste. Additionally, some research groups have successfully developed bio-based SMPs from renewable resources such as cellulose derivatives and plant oils, further enhancing their sustainability credentials.

In contrast, piezoelectric devices present more complex environmental considerations. Traditional piezoelectric materials like lead zirconate titanate (PZT) contain significant amounts of lead, a toxic heavy metal with well-documented environmental and health hazards. The extraction and processing of these materials involve energy-intensive processes and generate hazardous waste. However, recent advances in lead-free piezoelectric materials, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), represent promising alternatives with reduced environmental impact.

Energy efficiency during operation represents another critical environmental factor. Piezoelectric devices generally exhibit excellent energy conversion efficiency, often exceeding 90% in optimal conditions. This high efficiency can translate to lower lifetime energy consumption compared to other actuator technologies. SMP actuators typically demonstrate lower energy efficiency during operation but may require less frequent actuation in certain applications, potentially offsetting this disadvantage.

Durability and service life also influence environmental sustainability. Piezoelectric devices can withstand millions of actuation cycles with minimal degradation, potentially reducing replacement frequency and associated resource consumption. SMPs typically exhibit more limited cycle life, though recent advances in material science have significantly improved their durability.

End-of-life considerations reveal further distinctions. While many SMPs can be recycled through conventional methods, piezoelectric devices often require specialized recycling processes to recover valuable materials and prevent toxic substances from entering the environment. The complex composition of piezoelectric devices can make disassembly and material separation challenging, potentially limiting recycling rates.

Carbon footprint assessments indicate that both technologies can offer advantages over conventional electromagnetic or hydraulic actuators in specific applications. However, comprehensive lifecycle analyses comparing these technologies across diverse application scenarios remain limited, highlighting a need for further research to guide environmentally conscious design decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!