Enhancing Electrical Insulation: PTFE’s Role in Advancements

PTFE Insulation Evolution

The evolution of PTFE insulation represents a significant milestone in the field of electrical engineering. Polytetrafluoroethylene (PTFE), discovered serendipitously by Roy Plunkett in 1938, has since become a cornerstone material in electrical insulation due to its exceptional properties.

In its early stages, PTFE's potential as an insulator was quickly recognized. Its high dielectric strength, low dielectric constant, and excellent resistance to heat and chemicals made it an ideal candidate for electrical applications. The 1950s saw the first commercial applications of PTFE in electrical insulation, primarily in high-frequency communication equipment.

The 1960s and 1970s marked a period of rapid advancement in PTFE insulation technology. Researchers developed methods to modify PTFE's structure, creating expanded PTFE (ePTFE) with even better insulating properties. This innovation allowed for thinner insulation layers without compromising performance, leading to more compact and efficient electrical components.

The 1980s brought about a focus on PTFE composites. By incorporating other materials like glass fibers or ceramic particles, engineers created PTFE-based insulators with enhanced mechanical strength and thermal conductivity. These composites found applications in demanding environments such as aerospace and high-power electronics.

In the 1990s and early 2000s, the emphasis shifted towards nanoscale modifications of PTFE. Nanotechnology allowed for precise control over the material's structure, resulting in PTFE insulators with improved breakdown strength and reduced electrical losses. This era also saw the development of PTFE-based thin films, enabling new possibilities in flexible electronics and miniaturized devices.

Recent years have witnessed a growing interest in environmentally friendly alternatives to traditional PTFE production methods. Researchers are exploring sustainable synthesis routes and investigating bio-based fluoropolymers that could potentially replace PTFE in some applications while maintaining similar insulating properties.

The ongoing evolution of PTFE insulation continues to push the boundaries of electrical engineering. Current research focuses on smart PTFE composites that can self-heal or adapt to changing electrical conditions. Additionally, the integration of PTFE with emerging technologies like 5G communications and electric vehicles presents new challenges and opportunities for innovation in electrical insulation.

Market Demand Analysis

The market demand for enhanced electrical insulation, particularly focusing on PTFE's role, has been steadily increasing across various industries. This growth is primarily driven by the rising need for high-performance insulation materials in sectors such as electronics, aerospace, automotive, and energy.

In the electronics industry, the miniaturization trend and the push for higher efficiency in devices have created a significant demand for advanced insulation materials. PTFE, with its excellent dielectric properties and thermal stability, has become a crucial component in printed circuit boards, connectors, and high-frequency applications. The global printed circuit board market, a key consumer of PTFE-based insulation, is projected to grow substantially in the coming years.

The aerospace sector presents another major market for PTFE-based electrical insulation. With the increasing electrification of aircraft systems and the development of more electric aircraft (MEA), the demand for reliable, lightweight, and high-performance insulation materials has surged. PTFE's resistance to extreme temperatures and chemicals makes it an ideal choice for wiring and cable insulation in aircraft, contributing to improved safety and performance.

In the automotive industry, the shift towards electric and hybrid vehicles has created new opportunities for PTFE-based insulation. The high-voltage systems in these vehicles require superior insulation to ensure safety and efficiency. PTFE's ability to withstand high temperatures and maintain its electrical properties under stress makes it a preferred material for insulating battery components, motor windings, and power electronics.

The energy sector, particularly in renewable energy applications, has also shown increased demand for advanced insulation materials. Wind turbines and solar panels require insulation that can withstand harsh environmental conditions while maintaining electrical integrity. PTFE's weather resistance and long-term stability make it an attractive option for these applications.

Furthermore, the industrial sector's growing automation and the increasing adoption of smart manufacturing technologies have led to a higher demand for reliable insulation in industrial equipment and machinery. PTFE's chemical inertness and ability to perform in challenging environments have made it a go-to material for insulation in industrial sensors, control systems, and power distribution equipment.

The market for PTFE-based electrical insulation is also being driven by stringent safety regulations and performance standards across industries. As manufacturers seek to comply with these standards while improving product performance, the demand for high-quality insulation materials like PTFE continues to rise.

In conclusion, the market demand for enhanced electrical insulation, particularly PTFE-based solutions, shows a strong growth trajectory across multiple sectors. This demand is fueled by technological advancements, industry trends towards electrification and miniaturization, and the need for materials that can perform reliably in challenging environments.

Technical Challenges

Despite PTFE's remarkable properties as an electrical insulator, several technical challenges persist in its application for enhancing electrical insulation. One of the primary obstacles is the difficulty in achieving uniform and consistent PTFE coatings on complex surfaces. The non-stick nature of PTFE, while beneficial in many applications, complicates the adhesion process to various substrates, particularly metals and ceramics commonly used in electrical components.

Another significant challenge lies in maintaining PTFE's insulating properties under extreme conditions. While PTFE exhibits excellent thermal stability, prolonged exposure to high temperatures can lead to degradation of its molecular structure, potentially compromising its insulating capabilities. This is particularly problematic in high-voltage applications where heat generation is inevitable.

The porosity of PTFE films presents another hurdle. Although PTFE is inherently hydrophobic, microscopic pores in the material can allow moisture ingress over time, especially under high-humidity conditions. This moisture absorption can significantly reduce the material's dielectric strength and overall insulation performance.

PTFE's relatively low mechanical strength compared to other insulating materials poses challenges in applications where the insulation layer is subject to physical stress or abrasion. This limitation necessitates careful design considerations and often requires the use of composite materials or protective layers, adding complexity to the manufacturing process.

The processing of PTFE for electrical insulation applications also presents technical difficulties. Its high melting point and melt viscosity make traditional thermoplastic processing methods ineffective. Specialized techniques such as sintering and ram extrusion are required, which can be energy-intensive and limit the range of possible product geometries.

Environmental concerns associated with PTFE production and disposal represent another significant challenge. The use of perfluorooctanoic acid (PFOA) in PTFE manufacturing has raised environmental and health concerns, leading to a push for alternative production methods. Additionally, the non-biodegradable nature of PTFE complicates end-of-life management for electrical components using this material.

Lastly, the cost factor remains a persistent challenge in widespread adoption of PTFE for electrical insulation. The raw material and processing costs of PTFE are significantly higher than those of many conventional insulating materials, making it economically viable only for high-performance or specialized applications. This cost barrier limits the material's use in mass-market electrical products where cost-effectiveness is a primary consideration.

Current PTFE Solutions

01 PTFE coating for electrical insulation

PTFE is applied as a coating on electrical components to provide excellent insulation properties. This coating method enhances the dielectric strength and thermal resistance of various electrical parts, making them suitable for high-performance applications.- PTFE coating for electrical insulation: PTFE is applied as a coating on electrical components to provide excellent insulation properties. This coating method enhances the dielectric strength and thermal resistance of various electrical parts, making them suitable for high-performance applications.

- PTFE-based composite materials for insulation: Composite materials incorporating PTFE and other substances are developed to improve electrical insulation properties. These composites often combine the benefits of PTFE with other materials to enhance overall performance, such as increased mechanical strength or improved heat dissipation.

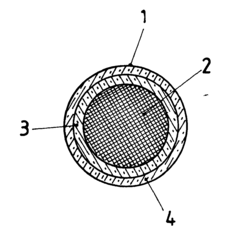

- PTFE film and tape for wire and cable insulation: PTFE films and tapes are used to insulate wires and cables in various electrical applications. These thin PTFE layers provide excellent dielectric properties, chemical resistance, and high-temperature stability, making them ideal for demanding environments.

- PTFE-insulated connectors and terminals: Electrical connectors and terminals are designed with PTFE insulation to ensure reliable performance in challenging conditions. The PTFE insulation helps prevent short circuits, reduces signal loss, and maintains integrity in high-frequency applications.

- Manufacturing processes for PTFE insulation: Various manufacturing techniques are developed to produce PTFE-based insulation materials efficiently. These processes may include extrusion, molding, or sintering methods to create PTFE components with specific shapes and properties for electrical insulation applications.

02 PTFE-based composite materials for insulation

Composite materials incorporating PTFE are developed to improve electrical insulation characteristics. These composites combine the excellent dielectric properties of PTFE with other materials to enhance overall performance, such as mechanical strength or thermal conductivity.Expand Specific Solutions03 PTFE film and tape for wire insulation

PTFE films and tapes are used to insulate wires and cables. These thin PTFE layers provide superior electrical insulation, heat resistance, and chemical inertness, making them ideal for demanding environments and applications.Expand Specific Solutions04 Porous PTFE structures for electrical insulation

Porous PTFE structures are developed to enhance insulation properties. These structures combine the excellent dielectric characteristics of PTFE with improved mechanical properties and potential for impregnation with other materials to further enhance performance.Expand Specific Solutions05 PTFE-based insulation for high-frequency applications

PTFE-based insulation materials are specifically designed for high-frequency applications. These materials maintain their excellent dielectric properties at high frequencies, making them suitable for use in telecommunications, radar systems, and other high-frequency electronic devices.Expand Specific Solutions

Key Industry Players

The electrical insulation market, driven by PTFE advancements, is in a growth phase with increasing demand across various industries. The global market size for PTFE in electrical insulation is expanding, fueled by technological innovations and applications in high-performance sectors. Companies like DAIKIN INDUSTRIES Ltd., W. L. Gore & Associates, Inc., and DuPont de Nemours, Inc. are at the forefront of PTFE technology development, demonstrating high technical maturity. Emerging players such as Zhejiang University and Jiangsu Hengxin Technology Co., Ltd. are contributing to the competitive landscape, focusing on research and development to enhance PTFE's electrical insulation properties. The industry is characterized by ongoing innovation and a push towards more efficient and sustainable insulation solutions.

DAIKIN INDUSTRIES Ltd.

W. L. Gore & Associates, Inc.

PTFE Innovations

- A two-layer PTFE insulation structure is implemented, with the first layer directly on the conductor modified with a thermoplastic polymer to enhance adhesion, and a second layer added through paste extrusion and sintering, forming a compact and mechanically strong connection, using a polymer mixture that includes 5-30% thermoplastic components like polyvinylidene fluoride and polyetheretherketone for improved heat resistance and mechanical strength.

- A PTFE material formulation with controlled metal oxide content, lubricant, and wetting agent, combined with a controlled granulometry and specific surface area, is extruded and calendered to achieve a high-density, anti-corona effect, using a two-stage mixing process to minimize aggregates.

Environmental Impact

The environmental impact of PTFE (Polytetrafluoroethylene) in electrical insulation applications is a complex and multifaceted issue that requires careful consideration. While PTFE offers significant advantages in terms of electrical insulation properties, its production and disposal processes raise important environmental concerns.

PTFE manufacturing involves the use of fluoropolymers, which are known to have a high global warming potential. The production process releases perfluorooctanoic acid (PFOA) and other perfluorinated compounds, which are persistent environmental pollutants. These substances can accumulate in the environment and have been linked to various ecological and health issues. However, it is worth noting that many manufacturers have made efforts to phase out PFOA and develop alternative production methods with reduced environmental impact.

In terms of energy consumption, the production of PTFE is relatively energy-intensive compared to some other insulation materials. This higher energy requirement contributes to increased carbon emissions during the manufacturing phase. Nevertheless, the long lifespan and durability of PTFE in electrical applications can offset some of these initial environmental costs over time.

PTFE's resistance to degradation, while beneficial for its performance as an electrical insulator, poses challenges for end-of-life management. The material is not biodegradable and can persist in the environment for extended periods. Recycling PTFE is technically possible but often economically challenging due to the specialized processes required. As a result, a significant portion of PTFE waste may end up in landfills or incineration facilities.

On the positive side, PTFE's excellent electrical insulation properties contribute to improved energy efficiency in various applications. By reducing electrical losses and enhancing the performance of electrical systems, PTFE indirectly helps to reduce overall energy consumption and associated environmental impacts. Additionally, its chemical inertness means that it does not leach harmful substances into the environment during its use phase.

The development of more environmentally friendly alternatives to traditional PTFE is an active area of research. Bio-based fluoropolymers and fluorine-free materials with similar insulation properties are being explored as potential substitutes. These innovations aim to address the environmental concerns associated with PTFE while maintaining its beneficial electrical insulation characteristics.

In conclusion, while PTFE offers significant advantages in electrical insulation, its environmental impact remains a concern. Balancing its performance benefits against environmental considerations is crucial for sustainable development in the electrical industry. Ongoing research and development efforts are focused on mitigating these environmental challenges, paving the way for more sustainable insulation solutions in the future.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of PTFE-based electrical insulation solutions. As the demand for enhanced electrical insulation continues to grow, manufacturers and end-users must navigate a complex landscape of regulations and standards to ensure the safety, reliability, and environmental sustainability of their products.

In the United States, the primary regulatory body overseeing electrical insulation materials is the Occupational Safety and Health Administration (OSHA). OSHA sets forth guidelines for the safe use of electrical insulation materials in various industrial applications. Additionally, the National Electrical Code (NEC), published by the National Fire Protection Association (NFPA), provides comprehensive standards for electrical wiring and equipment, including insulation requirements.

The European Union has established the RoHS (Restriction of Hazardous Substances) Directive, which restricts the use of certain hazardous substances in electrical and electronic equipment. While PTFE itself is not directly regulated under RoHS, manufacturers must ensure that any additives or processing aids used in PTFE production comply with these restrictions.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have developed specific standards for electrical insulation materials. These standards, including IEC 60243 and IEEE 43, provide guidelines for testing and evaluating the performance of insulation materials, including PTFE.

Environmental regulations also impact the use of PTFE in electrical insulation applications. The Stockholm Convention on Persistent Organic Pollutants has led to increased scrutiny of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE production. As a result, manufacturers have been developing PFOA-free PTFE formulations to comply with global environmental regulations.

Compliance with these regulations and standards requires ongoing efforts from manufacturers and users of PTFE-based electrical insulation. This includes regular testing and certification of materials, implementation of quality control measures, and documentation of compliance. Many companies are investing in research and development to create PTFE formulations that not only meet current regulatory requirements but also anticipate future regulatory changes.

As the regulatory landscape continues to evolve, industry stakeholders must stay informed about emerging regulations and standards. This may involve participating in industry associations, engaging with regulatory bodies, and collaborating with research institutions to develop innovative solutions that meet both technical and regulatory requirements.

In conclusion, regulatory compliance is a critical aspect of advancing PTFE-based electrical insulation technologies. By adhering to established regulations and standards, manufacturers can ensure the safety and reliability of their products while also contributing to the overall advancement of electrical insulation technology.