PTFE: Breakthroughs in Non‑Stick Coating Technology

PTFE Evolution and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has revolutionized the field of non-stick coatings since its accidental discovery by Roy Plunkett in 1938. This synthetic fluoropolymer has undergone significant evolution over the past eight decades, transforming various industries and consumer products.

The development of PTFE can be traced through several key milestones. Initially used in military applications during World War II, PTFE's potential for commercial use became apparent in the 1950s. The first non-stick cookware coated with PTFE was introduced in 1956, marking the beginning of its widespread adoption in household products.

Throughout the 1960s and 1970s, researchers focused on improving PTFE's durability and adhesion properties. This led to the development of reinforced PTFE composites and better application techniques, expanding its use in industrial settings. The 1980s and 1990s saw further advancements in PTFE formulations, resulting in enhanced scratch resistance and longer-lasting coatings.

In recent years, the focus has shifted towards developing more environmentally friendly PTFE alternatives and production methods. This includes the elimination of perfluorooctanoic acid (PFOA) from the manufacturing process, addressing concerns about its potential health and environmental impacts.

The current objectives in PTFE technology are multifaceted. Researchers are striving to enhance the material's performance characteristics, such as improved heat resistance, better chemical inertness, and increased durability. There is also a strong emphasis on developing PTFE coatings that can be applied at lower temperatures, reducing energy consumption during the manufacturing process.

Another key goal is to expand PTFE's applications beyond traditional uses. This includes exploring its potential in emerging fields such as nanotechnology, where PTFE nanoparticles could revolutionize surface treatments and lubricants. Additionally, there is ongoing research into incorporating PTFE into advanced composite materials for aerospace and automotive industries.

Sustainability remains a critical objective in PTFE development. Scientists are working on creating bio-based alternatives that maintain PTFE's desirable properties while reducing its environmental footprint. This includes research into fluorine-free alternatives that mimic PTFE's non-stick and low-friction characteristics.

As we look to the future, the evolution of PTFE technology aims to balance performance improvements with environmental responsibility. The ultimate goal is to develop next-generation non-stick coatings that offer superior functionality, durability, and sustainability, ensuring PTFE's continued relevance in an increasingly eco-conscious world.

Non-Stick Coating Market Analysis

The non-stick coating market has experienced significant growth in recent years, driven by increasing demand across various industries. The global market for non-stick coatings, particularly those based on PTFE (polytetrafluoroethylene), is projected to continue its upward trajectory due to several key factors.

One of the primary drivers of market growth is the expanding cookware and bakeware industry. As consumers become more health-conscious and seek convenient cooking solutions, the demand for non-stick cookware has surged. This trend is particularly evident in developing economies where rising disposable incomes and changing lifestyles are fueling the adoption of modern kitchen appliances.

The automotive sector represents another substantial market for non-stick coatings. PTFE-based coatings are increasingly used in automotive components to reduce friction, improve fuel efficiency, and enhance overall performance. As the automotive industry continues to evolve, with a focus on lightweight materials and improved efficiency, the demand for advanced non-stick coatings is expected to grow.

In the industrial sector, non-stick coatings find applications in various manufacturing processes, particularly in the production of molds and tools. The ability of PTFE coatings to withstand high temperatures and provide excellent release properties makes them invaluable in industries such as plastics, rubber, and composites manufacturing.

The food processing industry is another significant consumer of non-stick coatings. PTFE-coated equipment is widely used in food production lines to prevent sticking and facilitate easy cleaning, thereby improving operational efficiency and maintaining hygiene standards.

Geographically, North America and Europe currently dominate the non-stick coating market, owing to their well-established manufacturing sectors and high consumer awareness. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, urbanization, and changing consumer preferences in countries like China and India.

Despite the positive outlook, the non-stick coating market faces challenges related to environmental concerns and regulatory pressures. The use of certain chemicals in traditional PTFE coatings has raised health and environmental issues, prompting research into more sustainable alternatives. This has led to the development of eco-friendly non-stick coatings, which are expected to gain traction in the coming years.

PTFE Technology Challenges

PTFE (Polytetrafluoroethylene) has revolutionized non-stick coating technology, but it still faces several significant challenges. One of the primary issues is the durability of PTFE coatings. While PTFE exhibits excellent non-stick properties, it is prone to scratching and wear, especially when exposed to metal utensils or abrasive cleaning methods. This limitation reduces the lifespan of PTFE-coated products and necessitates frequent replacement.

Another challenge lies in the high-temperature performance of PTFE. Although it can withstand temperatures up to 260°C (500°F), prolonged exposure to high heat can cause degradation of the coating. This thermal limitation restricts its use in certain high-temperature applications and can lead to the release of potentially harmful fumes if overheated.

The environmental impact of PTFE production and disposal presents a significant concern. The manufacturing process involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health risks. While efforts have been made to phase out PFOA, finding equally effective and environmentally friendly alternatives remains a challenge.

Adhesion to substrate materials is another technical hurdle for PTFE coatings. The inherent non-stick properties that make PTFE desirable also make it difficult to bond effectively to surfaces. This can result in peeling or flaking of the coating, particularly under stress or with repeated use.

The cost of PTFE production and application is a factor that limits its widespread use in certain industries. The complex manufacturing process and the need for specialized application techniques contribute to higher production costs compared to some alternative coating materials.

Achieving uniform coating thickness and consistency across various substrate geometries poses a technical challenge. Uneven application can lead to performance inconsistencies and reduced effectiveness of the non-stick properties.

Lastly, there is an ongoing challenge to improve the chemical resistance of PTFE coatings. While PTFE is generally chemically inert, certain aggressive chemicals can still degrade the coating over time, limiting its applications in some industrial and laboratory settings.

Addressing these challenges requires continued research and development in materials science, application techniques, and manufacturing processes. Innovations in nanocomposite materials, surface modification technologies, and alternative fluoropolymers are some of the areas being explored to overcome these limitations and expand the capabilities of non-stick coating technology.

Current PTFE Coating Solutions

01 Surface modification for enhanced non-stick properties

Various surface modification techniques are employed to enhance the non-stick properties of PTFE. These methods include plasma treatment, chemical etching, and the application of nanoparticles or other coatings to create a more hydrophobic surface. These modifications can improve the durability and performance of PTFE-coated products.- Surface modification for enhanced non-stick properties: PTFE surfaces can be modified through various techniques to enhance their non-stick properties. These modifications can include plasma treatment, chemical etching, or the application of additional coatings. Such treatments can alter the surface energy and roughness, leading to improved hydrophobicity and oleophobicity, thus enhancing the non-stick performance of PTFE.

- Incorporation of nanoparticles or fillers: The addition of nanoparticles or fillers to PTFE can significantly improve its non-stick properties. Materials such as silica, carbon nanotubes, or metal oxides can be incorporated into the PTFE matrix. These additives can enhance the material's durability, scratch resistance, and overall non-stick performance while maintaining the inherent properties of PTFE.

- Multi-layer PTFE coatings: Developing multi-layer PTFE coatings can optimize non-stick properties. These coatings typically consist of a primer layer for adhesion, one or more intermediate layers for durability, and a top layer with enhanced non-stick properties. The combination of different layers allows for tailored performance characteristics, improving both the non-stick properties and the longevity of the coating.

- PTFE composite materials: Creating composite materials by blending PTFE with other polymers or materials can enhance its non-stick properties. These composites can combine the excellent non-stick characteristics of PTFE with additional benefits such as improved mechanical strength, thermal stability, or chemical resistance. The resulting materials often exhibit superior performance in various applications requiring non-stick surfaces.

- Surface texturing and patterning: Implementing specific surface textures or patterns on PTFE surfaces can enhance their non-stick properties. Techniques such as laser etching, embossing, or micro-molding can create controlled surface structures. These textures can increase the contact angle, reduce adhesion, and improve the overall non-stick performance of PTFE surfaces in various applications.

02 PTFE composite materials for improved non-stick performance

PTFE is often combined with other materials to create composites with enhanced non-stick properties. These composites may include ceramic particles, metal oxides, or other polymers. The resulting materials can offer improved wear resistance, thermal stability, and non-stick performance compared to pure PTFE.Expand Specific Solutions03 Specialized PTFE formulations for specific applications

Researchers have developed specialized PTFE formulations tailored for specific non-stick applications. These formulations may include additives or modified molecular structures to enhance properties such as chemical resistance, temperature tolerance, or ease of cleaning. Such formulations are particularly useful in industries like food processing, automotive, and electronics.Expand Specific Solutions04 Nanotechnology in PTFE non-stick coatings

Nanotechnology is being applied to PTFE coatings to further improve their non-stick properties. This includes the incorporation of nanoparticles, creation of nanostructured surfaces, or the development of nano-thin PTFE films. These innovations can lead to more durable, efficient, and effective non-stick surfaces.Expand Specific Solutions05 Environmental and health considerations in PTFE non-stick coatings

With increasing focus on environmental and health concerns, research is being conducted on developing more eco-friendly and safe PTFE-based non-stick coatings. This includes the exploration of PFOA-free formulations, biodegradable alternatives, and methods to reduce the release of potentially harmful particles during use or manufacturing.Expand Specific Solutions

PTFE Industry Leaders

The PTFE non-stick coating technology market is in a mature stage, with a global market size estimated to reach $2.5 billion by 2027. The industry is characterized by intense competition among established players like 3M, AGC, and DAIKIN INDUSTRIES, who are focusing on product innovation and performance improvements. Emerging companies such as Zhejiang Pfluon Technology and Hangzhou Jihua Polymer Material are challenging incumbents with cost-effective solutions. The technology's maturity is evident in its widespread application across various industries, from cookware to industrial coatings. However, ongoing research by companies like W. L. Gore & Associates and PPG Industries Ohio indicates potential for further advancements in durability and environmental sustainability.

3M Innovative Properties Co.

W. L. Gore & Associates, Inc.

Key PTFE Innovations

- A non-stick coating composition comprising a first primer layer with 9-15% fluorocarbon resin, 4-5% polyamide imide resin, 0.12-1.1% polyetheretherketone (PEEK) resin, and technological additives, applied directly to a metal support without an undercoat, providing excellent scratch resistance while reducing material costs and simplifying the manufacturing process.

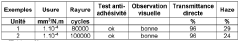

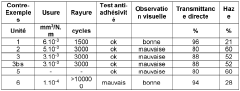

- A non-stick coating with a transparent finishing layer comprising thermostable resin and fillers where the d50 of the fillers is greater than the average thickness of the layer, ensuring durability without degrading non-stick properties and maintaining transparency, with a direct transmittance greater than 90% and a total Haze value less than 40%, allowing for the presence of visual attributes.

Environmental Impact of PTFE

The environmental impact of PTFE (Polytetrafluoroethylene) has been a subject of increasing concern as the use of non-stick coatings continues to grow across various industries. While PTFE offers numerous benefits in terms of performance and durability, its production and disposal processes have raised significant environmental questions.

One of the primary environmental concerns associated with PTFE is the use of perfluorooctanoic acid (PFOA) in its manufacturing process. PFOA is a persistent organic pollutant that has been linked to various health and environmental issues. It can contaminate water sources and accumulate in living organisms, potentially causing long-term ecological damage. In response to these concerns, many manufacturers have committed to phasing out PFOA and developing alternative production methods.

The durability of PTFE coatings, while advantageous for product longevity, presents challenges in terms of waste management and recycling. PTFE-coated products are often difficult to recycle due to the strong chemical bonds that make the material so resistant to degradation. This has led to increased amounts of PTFE-containing waste in landfills, where it can persist for extended periods without breaking down.

Efforts to mitigate the environmental impact of PTFE have focused on several key areas. Research into biodegradable alternatives and eco-friendly production methods has gained momentum in recent years. Some manufacturers have explored the use of water-based PTFE dispersions, which reduce the need for harmful solvents and minimize air pollution during the application process.

Additionally, advancements in recycling technologies have shown promise in addressing the end-of-life issues associated with PTFE products. Innovative techniques for separating PTFE from other materials and reprocessing it for new applications are being developed, potentially reducing the amount of PTFE waste that ends up in landfills.

The release of fluoropolymer particles into the environment during the use and disposal of PTFE-coated products is another area of concern. These microscopic particles can enter ecosystems and potentially impact wildlife and human health. Research is ongoing to better understand the long-term effects of these particles and to develop strategies for minimizing their release.

As environmental regulations become more stringent, the PTFE industry is adapting by investing in cleaner production technologies and more sustainable product designs. This includes the development of PTFE coatings that require less material while maintaining performance, as well as exploring bio-based alternatives that could offer similar non-stick properties with a reduced environmental footprint.

PTFE Safety Regulations

The safety regulations surrounding PTFE (Polytetrafluoroethylene) have evolved significantly since its initial development and widespread use in non-stick coating applications. These regulations primarily focus on addressing potential health and environmental concerns associated with the production, use, and disposal of PTFE-based products.

One of the key areas of regulatory focus has been the use of perfluorooctanoic acid (PFOA) in the manufacturing process of PTFE. PFOA, a synthetic chemical used to produce fluoropolymers, has been linked to various health issues and environmental persistence. In response, regulatory bodies worldwide have implemented stringent measures to phase out PFOA and related long-chain perfluorinated compounds.

The United States Environmental Protection Agency (EPA) initiated the PFOA Stewardship Program in 2006, encouraging major fluoropolymer manufacturers to eliminate PFOA from their production processes by 2015. This voluntary program has since been reinforced by mandatory regulations, including the Significant New Use Rule (SNUR) under the Toxic Substances Control Act (TSCA), which restricts the manufacture and import of certain long-chain perfluoroalkyl carboxylate substances.

In the European Union, the use of PFOA and its salts in the production of fluoropolymers has been restricted under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation. The restriction, which came into effect in 2020, limits the presence of PFOA to no more than 25 ppb in products or mixtures placed on the market.

Beyond PFOA, regulatory bodies have also focused on the potential release of harmful substances during the high-temperature use of PTFE coatings. Guidelines have been established for the proper use and maintenance of PTFE-coated cookware to prevent the release of toxic fumes at elevated temperatures. Manufacturers are required to provide clear instructions and warnings to consumers regarding the safe use of these products.

Occupational safety regulations have been implemented to protect workers involved in the production and processing of PTFE. These include guidelines for proper ventilation, personal protective equipment, and handling procedures to minimize exposure to potentially harmful substances during manufacturing processes.

As research continues to uncover potential long-term effects of PTFE and related compounds, regulatory frameworks are expected to evolve further. There is an increasing focus on developing alternative, more environmentally friendly non-stick coating technologies that can meet or exceed the performance of PTFE while addressing safety concerns. This ongoing regulatory landscape continues to shape the development and application of non-stick coating technologies, driving innovation towards safer and more sustainable solutions.