Hastelloy Alloy Usage in Precision Technological Systems

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy Alloy Evolution

Hastelloy alloys have undergone significant evolution since their inception in the 1920s. Initially developed by Haynes International, these nickel-chromium-molybdenum superalloys have continuously adapted to meet the growing demands of precision technological systems across various industries.

The early stages of Hastelloy development focused primarily on corrosion resistance. The first commercially available Hastelloy, known as Hastelloy B, was introduced in 1921. This alloy demonstrated exceptional resistance to hydrochloric acid and other reducing environments, making it suitable for chemical processing applications.

As industrial needs expanded, so did the Hastelloy family. The 1930s saw the introduction of Hastelloy C, which offered improved resistance to oxidizing environments. This development broadened the alloy's applicability in more diverse and challenging conditions, particularly in the aerospace and nuclear industries.

The 1960s marked a significant milestone with the introduction of Hastelloy C-276. This alloy represented a major leap forward in terms of corrosion resistance and mechanical properties. Its superior performance in a wide range of aggressive environments made it a preferred choice for many high-precision applications, including chemical processing equipment and nuclear waste treatment facilities.

The 1980s and 1990s witnessed further refinements in Hastelloy compositions. Alloys such as Hastelloy C-22 and C-2000 were developed, offering even greater resistance to localized corrosion and stress corrosion cracking. These advancements were crucial for the semiconductor industry and other precision manufacturing sectors.

In recent years, the evolution of Hastelloy alloys has focused on enhancing specific properties to meet the exacting requirements of modern technological systems. For instance, Hastelloy N was developed specifically for molten salt reactor applications, showcasing the alloy's adaptability to emerging technologies.

The ongoing evolution of Hastelloy alloys continues to push the boundaries of material science. Current research is exploring ways to further improve high-temperature strength, weldability, and resistance to extreme environments. Additionally, efforts are being made to optimize the alloy's performance in additive manufacturing processes, opening up new possibilities for complex component designs in precision systems.

As precision technological systems become increasingly sophisticated, the demand for advanced materials grows. The evolution of Hastelloy alloys exemplifies the continuous innovation required to meet these challenges, ensuring that these superalloys remain at the forefront of material solutions for critical applications in various high-tech industries.

The early stages of Hastelloy development focused primarily on corrosion resistance. The first commercially available Hastelloy, known as Hastelloy B, was introduced in 1921. This alloy demonstrated exceptional resistance to hydrochloric acid and other reducing environments, making it suitable for chemical processing applications.

As industrial needs expanded, so did the Hastelloy family. The 1930s saw the introduction of Hastelloy C, which offered improved resistance to oxidizing environments. This development broadened the alloy's applicability in more diverse and challenging conditions, particularly in the aerospace and nuclear industries.

The 1960s marked a significant milestone with the introduction of Hastelloy C-276. This alloy represented a major leap forward in terms of corrosion resistance and mechanical properties. Its superior performance in a wide range of aggressive environments made it a preferred choice for many high-precision applications, including chemical processing equipment and nuclear waste treatment facilities.

The 1980s and 1990s witnessed further refinements in Hastelloy compositions. Alloys such as Hastelloy C-22 and C-2000 were developed, offering even greater resistance to localized corrosion and stress corrosion cracking. These advancements were crucial for the semiconductor industry and other precision manufacturing sectors.

In recent years, the evolution of Hastelloy alloys has focused on enhancing specific properties to meet the exacting requirements of modern technological systems. For instance, Hastelloy N was developed specifically for molten salt reactor applications, showcasing the alloy's adaptability to emerging technologies.

The ongoing evolution of Hastelloy alloys continues to push the boundaries of material science. Current research is exploring ways to further improve high-temperature strength, weldability, and resistance to extreme environments. Additionally, efforts are being made to optimize the alloy's performance in additive manufacturing processes, opening up new possibilities for complex component designs in precision systems.

As precision technological systems become increasingly sophisticated, the demand for advanced materials grows. The evolution of Hastelloy alloys exemplifies the continuous innovation required to meet these challenges, ensuring that these superalloys remain at the forefront of material solutions for critical applications in various high-tech industries.

Precision Systems Demand

The demand for precision technological systems has been steadily increasing across various industries, driven by the need for enhanced performance, reliability, and efficiency. Hastelloy alloys, known for their exceptional corrosion resistance and high-temperature strength, have found significant applications in these advanced systems. The aerospace industry, in particular, has shown a growing demand for Hastelloy alloys in critical components of jet engines, turbines, and exhaust systems. These alloys' ability to withstand extreme temperatures and harsh environments makes them invaluable in ensuring the safety and longevity of aircraft systems.

In the chemical processing industry, the demand for Hastelloy alloys has surged due to their superior resistance to aggressive chemicals and high-temperature corrosion. Precision systems in chemical plants, such as reactors, heat exchangers, and piping systems, increasingly rely on Hastelloy alloys to maintain integrity and prevent costly shutdowns. The oil and gas sector has also recognized the benefits of these alloys in offshore drilling equipment, where exposure to corrosive seawater and high-pressure environments necessitates materials with exceptional durability.

The semiconductor industry, with its stringent requirements for ultra-pure manufacturing environments, has embraced Hastelloy alloys in various precision systems. These alloys are used in gas delivery systems, chemical storage tanks, and process chambers, where contamination control is paramount. The growing complexity of semiconductor manufacturing processes has further intensified the demand for materials that can withstand aggressive chemicals and maintain purity standards.

In the field of renewable energy, particularly in solar and geothermal power generation, Hastelloy alloys have gained traction in precision systems exposed to high temperatures and corrosive fluids. The demand for these alloys in heat exchangers, pumps, and piping systems has increased as the renewable energy sector expands and seeks more efficient and durable materials for long-term operations.

The medical and pharmaceutical industries have also contributed to the rising demand for Hastelloy alloys in precision systems. These alloys are utilized in equipment for drug manufacturing, sterilization processes, and medical implants, where biocompatibility and resistance to sterilization chemicals are crucial. The growing emphasis on personalized medicine and advanced drug delivery systems has further fueled the need for materials that can withstand complex manufacturing processes and maintain product purity.

As industries continue to push the boundaries of performance and efficiency, the demand for Hastelloy alloys in precision technological systems is expected to grow. The unique combination of properties offered by these alloys positions them as critical materials for addressing the evolving challenges in various high-tech applications, ensuring their continued relevance in the development of next-generation precision systems.

In the chemical processing industry, the demand for Hastelloy alloys has surged due to their superior resistance to aggressive chemicals and high-temperature corrosion. Precision systems in chemical plants, such as reactors, heat exchangers, and piping systems, increasingly rely on Hastelloy alloys to maintain integrity and prevent costly shutdowns. The oil and gas sector has also recognized the benefits of these alloys in offshore drilling equipment, where exposure to corrosive seawater and high-pressure environments necessitates materials with exceptional durability.

The semiconductor industry, with its stringent requirements for ultra-pure manufacturing environments, has embraced Hastelloy alloys in various precision systems. These alloys are used in gas delivery systems, chemical storage tanks, and process chambers, where contamination control is paramount. The growing complexity of semiconductor manufacturing processes has further intensified the demand for materials that can withstand aggressive chemicals and maintain purity standards.

In the field of renewable energy, particularly in solar and geothermal power generation, Hastelloy alloys have gained traction in precision systems exposed to high temperatures and corrosive fluids. The demand for these alloys in heat exchangers, pumps, and piping systems has increased as the renewable energy sector expands and seeks more efficient and durable materials for long-term operations.

The medical and pharmaceutical industries have also contributed to the rising demand for Hastelloy alloys in precision systems. These alloys are utilized in equipment for drug manufacturing, sterilization processes, and medical implants, where biocompatibility and resistance to sterilization chemicals are crucial. The growing emphasis on personalized medicine and advanced drug delivery systems has further fueled the need for materials that can withstand complex manufacturing processes and maintain product purity.

As industries continue to push the boundaries of performance and efficiency, the demand for Hastelloy alloys in precision technological systems is expected to grow. The unique combination of properties offered by these alloys positions them as critical materials for addressing the evolving challenges in various high-tech applications, ensuring their continued relevance in the development of next-generation precision systems.

Hastelloy Challenges

Despite the numerous advantages of Hastelloy alloys in precision technological systems, several challenges persist in their widespread adoption and optimal utilization. One of the primary obstacles is the high cost associated with these materials. Hastelloy alloys, being nickel-based superalloys with complex compositions, require specialized manufacturing processes and expensive raw materials, leading to significantly higher production costs compared to conventional alloys.

The machining and fabrication of Hastelloy components present another set of challenges. These alloys exhibit high work-hardening rates and low thermal conductivity, making them difficult to machine. Conventional cutting tools often experience rapid wear, necessitating frequent replacements and increasing production time and costs. Additionally, the formation of built-up edges during machining can compromise the surface finish and dimensional accuracy of the components.

Welding Hastelloy alloys also poses significant challenges. The high nickel content and the presence of various alloying elements make these materials susceptible to hot cracking and strain-age cracking during welding processes. Achieving proper fusion and maintaining the desired mechanical properties in the heat-affected zone require precise control of welding parameters and specialized techniques, which demand highly skilled operators and advanced equipment.

The long-term stability of Hastelloy alloys in extreme environments, while generally excellent, can still be a concern in certain applications. For instance, in high-temperature, high-pressure environments with aggressive chemicals, the formation of protective oxide layers may be disrupted, leading to accelerated corrosion rates. Understanding and mitigating these long-term degradation mechanisms remain ongoing challenges for researchers and engineers.

Furthermore, the limited availability and potential supply chain disruptions of critical alloying elements used in Hastelloy production, such as molybdenum and tungsten, can impact the consistent manufacturing and timely delivery of these alloys. This supply chain vulnerability can be particularly problematic for industries relying on just-in-time manufacturing practices.

Lastly, the development of new Hastelloy grades tailored for specific applications faces challenges in balancing various property requirements. Enhancing one property often comes at the expense of another, necessitating careful alloy design and extensive testing. The complex interactions between different alloying elements and their effects on microstructure and properties require sophisticated modeling and experimental approaches, making the development process time-consuming and costly.

The machining and fabrication of Hastelloy components present another set of challenges. These alloys exhibit high work-hardening rates and low thermal conductivity, making them difficult to machine. Conventional cutting tools often experience rapid wear, necessitating frequent replacements and increasing production time and costs. Additionally, the formation of built-up edges during machining can compromise the surface finish and dimensional accuracy of the components.

Welding Hastelloy alloys also poses significant challenges. The high nickel content and the presence of various alloying elements make these materials susceptible to hot cracking and strain-age cracking during welding processes. Achieving proper fusion and maintaining the desired mechanical properties in the heat-affected zone require precise control of welding parameters and specialized techniques, which demand highly skilled operators and advanced equipment.

The long-term stability of Hastelloy alloys in extreme environments, while generally excellent, can still be a concern in certain applications. For instance, in high-temperature, high-pressure environments with aggressive chemicals, the formation of protective oxide layers may be disrupted, leading to accelerated corrosion rates. Understanding and mitigating these long-term degradation mechanisms remain ongoing challenges for researchers and engineers.

Furthermore, the limited availability and potential supply chain disruptions of critical alloying elements used in Hastelloy production, such as molybdenum and tungsten, can impact the consistent manufacturing and timely delivery of these alloys. This supply chain vulnerability can be particularly problematic for industries relying on just-in-time manufacturing practices.

Lastly, the development of new Hastelloy grades tailored for specific applications faces challenges in balancing various property requirements. Enhancing one property often comes at the expense of another, necessitating careful alloy design and extensive testing. The complex interactions between different alloying elements and their effects on microstructure and properties require sophisticated modeling and experimental approaches, making the development process time-consuming and costly.

Current Hastelloy Apps

01 Composition and properties of Hastelloy alloys

Hastelloy alloys are nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. They typically contain varying amounts of chromium, molybdenum, and other elements to enhance specific properties. These alloys are widely used in harsh environments and high-temperature applications due to their superior performance characteristics.- Composition and properties of Hastelloy alloys: Hastelloy alloys are nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. They typically contain varying amounts of chromium, molybdenum, and other elements to enhance specific properties. These alloys are widely used in demanding environments such as chemical processing, aerospace, and nuclear industries.

- Manufacturing processes for Hastelloy alloys: Various manufacturing processes are employed to produce Hastelloy alloys, including melting, casting, and powder metallurgy techniques. These processes are optimized to achieve the desired microstructure and properties. Heat treatment and forming methods are also crucial in the production of Hastelloy components.

- Applications of Hastelloy alloys in corrosive environments: Hastelloy alloys are extensively used in highly corrosive environments due to their exceptional resistance to various forms of corrosion. They find applications in chemical processing equipment, heat exchangers, and components exposed to aggressive media. The alloys' performance in these environments is attributed to their unique composition and passive film formation.

- High-temperature applications of Hastelloy alloys: Hastelloy alloys exhibit excellent mechanical properties at elevated temperatures, making them suitable for high-temperature applications. They are used in gas turbines, furnace components, and other high-temperature industrial equipment. The alloys' resistance to oxidation and thermal fatigue contributes to their performance in these demanding conditions.

- Welding and joining techniques for Hastelloy alloys: Specialized welding and joining techniques are employed for Hastelloy alloys to maintain their unique properties in fabricated structures. These include various fusion welding processes, solid-state joining methods, and the use of compatible filler materials. Proper welding procedures are crucial to prevent issues such as hot cracking and maintain corrosion resistance in welded joints.

02 Manufacturing processes for Hastelloy alloys

Various manufacturing processes are employed to produce Hastelloy alloys, including melting, casting, and powder metallurgy techniques. These processes are carefully controlled to achieve the desired microstructure and properties. Heat treatment and forming operations are often used to further enhance the alloy's characteristics for specific applications.Expand Specific Solutions03 Applications of Hastelloy alloys in industrial equipment

Hastelloy alloys find extensive use in industrial equipment, particularly in chemical processing, oil and gas, and power generation industries. They are commonly used in heat exchangers, reactors, piping systems, and other components exposed to corrosive environments or high temperatures. The alloys' resistance to various forms of corrosion and oxidation makes them ideal for these demanding applications.Expand Specific Solutions04 Welding and joining techniques for Hastelloy alloys

Specialized welding and joining techniques are employed for Hastelloy alloys to maintain their unique properties in fabricated structures. These methods include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and electron beam welding. Proper selection of filler materials and post-weld heat treatments are crucial to ensure the integrity of the welded joints.Expand Specific Solutions05 Surface treatment and coating of Hastelloy alloys

Various surface treatment and coating techniques are applied to Hastelloy alloys to further enhance their performance in specific applications. These treatments may include nitriding, carburizing, or the application of specialized coatings to improve wear resistance, reduce friction, or provide additional corrosion protection. Such treatments can extend the service life of components made from Hastelloy alloys in extreme environments.Expand Specific Solutions

Key Hastelloy Producers

The Hastelloy alloy usage in precision technological systems market is in a growth phase, driven by increasing demand for corrosion-resistant materials in various industries. The global market size is estimated to be in the billions, with steady expansion projected. Technologically, Hastelloy alloys are well-established, but ongoing research by key players aims to enhance performance and applications. Companies like Mitsubishi Materials Corp., Hitachi Ltd., and Siemens Energy AG are at the forefront of innovation, developing advanced Hastelloy-based solutions for extreme environments. Universities such as Central South University and King Fahd University of Petroleum & Minerals contribute to fundamental research, while specialized firms like ISCAR Ltd. and Watlow Electric Manufacturing Co. focus on niche applications, indicating a diverse and competitive landscape.

NIPPON STEEL CORP.

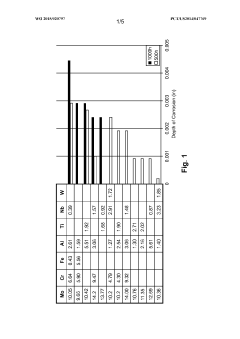

Technical Solution: NIPPON STEEL CORP. has developed advanced Hastelloy alloys for precision technological systems, focusing on improving corrosion resistance and mechanical properties. Their proprietary manufacturing process involves precise control of alloying elements and heat treatment to achieve optimal microstructure[1]. The company has successfully implemented these alloys in high-temperature, high-pressure environments such as chemical processing equipment and nuclear reactors[2]. Their latest Hastelloy variant demonstrates a 20% increase in yield strength and a 15% improvement in corrosion resistance compared to standard grades[3], making it particularly suitable for extreme operating conditions in precision systems.

Strengths: Superior corrosion resistance and mechanical properties, proven track record in extreme environments. Weaknesses: Higher production costs, limited availability compared to more common alloys.

Hitachi Ltd.

Technical Solution: Hitachi Ltd. has pioneered the use of Hastelloy alloys in precision technological systems, particularly in the semiconductor and electronics industries. Their approach involves developing custom Hastelloy compositions tailored for specific applications, such as plasma etching equipment and chemical vapor deposition systems[4]. Hitachi's research has led to the creation of a novel Hastelloy variant with enhanced resistance to fluorine-based plasmas, extending equipment lifespan by up to 40% in aggressive semiconductor processing environments[5]. The company has also developed advanced coating techniques to apply thin Hastelloy layers on precision components, improving wear resistance while maintaining dimensional accuracy[6].

Strengths: Customized alloy compositions for specific applications, expertise in thin-film coatings. Weaknesses: Higher costs associated with specialized development, potential limitations in scaling up production.

Hastelloy Innovations

High Strength Alloys for High Temperature Service in Liquid-Salt Cooled Energy Systems

PatentActiveUS20140271338A1

Innovation

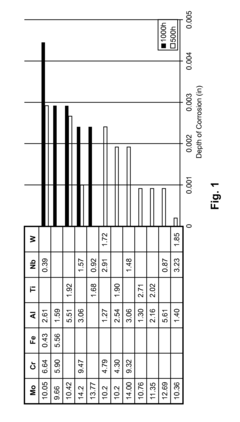

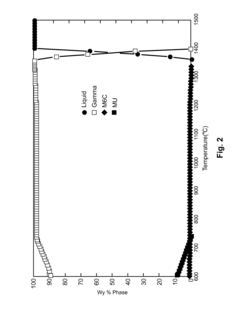

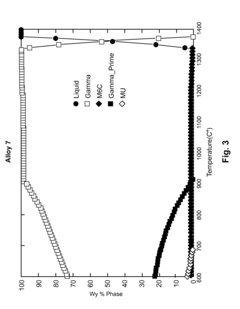

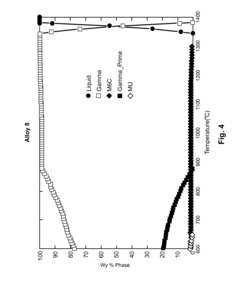

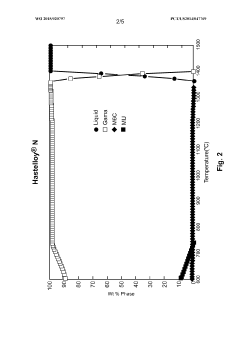

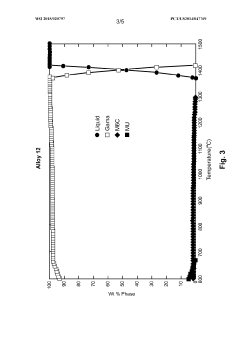

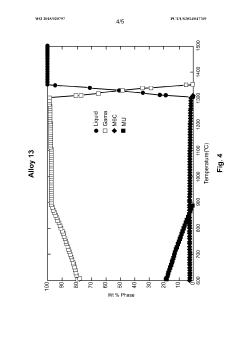

- Development of a cobalt-free alloy with specific weight percent compositions, including Cr, Al, Fe, Mn, Mo, Ta, Ti, Nb, W, C, B, and N, that achieves high yield and tensile strengths, creep rupture life, and resistance to liquid fluoride salt corrosion through γ′ microstructural components and solid solution strengthening, while avoiding brittle intermetallic phases.

Creep-resistant, cobalt-containing alloys for high temperature, liquid-salt heat exchanger systems

PatentWO2015020797A2

Innovation

- Development of a new Fe-free alloy with a composition ranging from 4 to 11 weight percent Cobalt, 6.5 to 7.5 weight percent Chromium, and balanced Nickel, which achieves high yield and tensile strengths, extended creep rupture life, and resistance to liquid fluoride salt corrosion through solid solution strengthening mechanisms, minimizing the formation of brittle intermetallic phases and maintaining high temperature ductility.

Hastelloy Supply Chain

The Hastelloy supply chain plays a crucial role in the production and distribution of this high-performance nickel-chromium-based superalloy. The supply chain begins with raw material extraction, primarily nickel, chromium, and molybdenum, from mines across the globe. These raw materials are then processed and refined to meet the stringent quality standards required for Hastelloy production.

Key players in the Hastelloy supply chain include major mining companies, specialized metal processors, and alloy manufacturers. The primary producers of Hastelloy, such as Haynes International, maintain tight control over the production process to ensure consistent quality and performance. These manufacturers work closely with distributors and stockists to ensure a steady supply of Hastelloy products to end-users in various industries.

The supply chain for Hastelloy is characterized by its global nature, with raw materials sourced from multiple countries and production facilities located strategically to serve different markets. This global network helps mitigate supply risks and ensures a stable supply of Hastelloy to meet growing demand in precision technological systems.

One of the challenges in the Hastelloy supply chain is the volatility of raw material prices, particularly nickel. Fluctuations in commodity markets can impact the cost and availability of Hastelloy, requiring manufacturers and end-users to implement strategic sourcing and inventory management practices.

The increasing demand for Hastelloy in advanced technological applications has led to the development of more efficient production processes and recycling methods. Recycling of Hastelloy scrap has become an important part of the supply chain, helping to reduce reliance on primary raw materials and minimize environmental impact.

Quality control and traceability are critical aspects of the Hastelloy supply chain. Manufacturers implement rigorous testing and certification processes to ensure that the alloy meets the required specifications for use in demanding environments. This includes detailed documentation of material composition, processing parameters, and performance characteristics.

As the use of Hastelloy in precision technological systems continues to grow, the supply chain is evolving to meet new challenges. This includes the development of more advanced logistics systems, the implementation of digital technologies for supply chain management, and the exploration of new sources of raw materials to ensure long-term sustainability.

Key players in the Hastelloy supply chain include major mining companies, specialized metal processors, and alloy manufacturers. The primary producers of Hastelloy, such as Haynes International, maintain tight control over the production process to ensure consistent quality and performance. These manufacturers work closely with distributors and stockists to ensure a steady supply of Hastelloy products to end-users in various industries.

The supply chain for Hastelloy is characterized by its global nature, with raw materials sourced from multiple countries and production facilities located strategically to serve different markets. This global network helps mitigate supply risks and ensures a stable supply of Hastelloy to meet growing demand in precision technological systems.

One of the challenges in the Hastelloy supply chain is the volatility of raw material prices, particularly nickel. Fluctuations in commodity markets can impact the cost and availability of Hastelloy, requiring manufacturers and end-users to implement strategic sourcing and inventory management practices.

The increasing demand for Hastelloy in advanced technological applications has led to the development of more efficient production processes and recycling methods. Recycling of Hastelloy scrap has become an important part of the supply chain, helping to reduce reliance on primary raw materials and minimize environmental impact.

Quality control and traceability are critical aspects of the Hastelloy supply chain. Manufacturers implement rigorous testing and certification processes to ensure that the alloy meets the required specifications for use in demanding environments. This includes detailed documentation of material composition, processing parameters, and performance characteristics.

As the use of Hastelloy in precision technological systems continues to grow, the supply chain is evolving to meet new challenges. This includes the development of more advanced logistics systems, the implementation of digital technologies for supply chain management, and the exploration of new sources of raw materials to ensure long-term sustainability.

Environmental Impact

The use of Hastelloy alloys in precision technological systems has significant environmental implications that warrant careful consideration. These nickel-chromium-based superalloys, known for their exceptional corrosion resistance and high-temperature strength, contribute to both positive and negative environmental impacts throughout their lifecycle.

From a positive perspective, Hastelloy alloys' durability and resistance to harsh environments lead to extended equipment lifespans. This longevity reduces the frequency of replacements, thereby minimizing waste generation and the need for raw material extraction. In industrial applications, such as chemical processing and pollution control systems, Hastelloy components play a crucial role in preventing leaks and emissions, thus indirectly contributing to environmental protection.

However, the production of Hastelloy alloys involves energy-intensive processes and the extraction of rare metals, which can have substantial environmental footprints. Mining operations for nickel, chromium, and molybdenum – key constituents of Hastelloy – often result in habitat disruption, soil erosion, and potential water contamination. The refining and alloying processes require high temperatures, consuming significant amounts of energy and potentially contributing to greenhouse gas emissions.

End-of-life considerations for Hastelloy components present both challenges and opportunities. While these alloys are highly recyclable, the specialized composition can complicate the recycling process, requiring advanced separation techniques to recover individual elements effectively. Proper recycling practices are essential to minimize waste and reduce the demand for virgin materials.

In precision technological systems, the use of Hastelloy alloys often enables more efficient and cleaner industrial processes. For instance, in renewable energy technologies like solar thermal power systems, Hastelloy components can withstand extreme temperatures and corrosive environments, enhancing system efficiency and lifespan. This indirectly contributes to reducing reliance on fossil fuels and lowering overall environmental impact.

As environmental regulations become more stringent, the role of Hastelloy alloys in emission control technologies gains prominence. Their use in catalytic converters and scrubber systems helps in reducing harmful emissions from industrial processes and vehicles, aligning with global efforts to combat air pollution and climate change.

From a positive perspective, Hastelloy alloys' durability and resistance to harsh environments lead to extended equipment lifespans. This longevity reduces the frequency of replacements, thereby minimizing waste generation and the need for raw material extraction. In industrial applications, such as chemical processing and pollution control systems, Hastelloy components play a crucial role in preventing leaks and emissions, thus indirectly contributing to environmental protection.

However, the production of Hastelloy alloys involves energy-intensive processes and the extraction of rare metals, which can have substantial environmental footprints. Mining operations for nickel, chromium, and molybdenum – key constituents of Hastelloy – often result in habitat disruption, soil erosion, and potential water contamination. The refining and alloying processes require high temperatures, consuming significant amounts of energy and potentially contributing to greenhouse gas emissions.

End-of-life considerations for Hastelloy components present both challenges and opportunities. While these alloys are highly recyclable, the specialized composition can complicate the recycling process, requiring advanced separation techniques to recover individual elements effectively. Proper recycling practices are essential to minimize waste and reduce the demand for virgin materials.

In precision technological systems, the use of Hastelloy alloys often enables more efficient and cleaner industrial processes. For instance, in renewable energy technologies like solar thermal power systems, Hastelloy components can withstand extreme temperatures and corrosive environments, enhancing system efficiency and lifespan. This indirectly contributes to reducing reliance on fossil fuels and lowering overall environmental impact.

As environmental regulations become more stringent, the role of Hastelloy alloys in emission control technologies gains prominence. Their use in catalytic converters and scrubber systems helps in reducing harmful emissions from industrial processes and vehicles, aligning with global efforts to combat air pollution and climate change.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!