Hastelloy's Contribution to Sustainable Infrastructure Projects

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy Background and Objectives

Hastelloy, a family of nickel-chromium-based superalloys, has emerged as a crucial material in the development of sustainable infrastructure projects. These alloys, known for their exceptional corrosion resistance and mechanical properties, have a rich history dating back to the 1920s when they were first developed by Haynes International.

The evolution of Hastelloy has been driven by the increasing demand for materials capable of withstanding extreme environments in various industries, including chemical processing, aerospace, and energy production. As global focus shifts towards sustainability, Hastelloy's unique properties position it as a key player in creating durable and efficient infrastructure solutions.

The primary objective of utilizing Hastelloy in sustainable infrastructure projects is to enhance the longevity and reliability of critical components. By resisting corrosion and maintaining structural integrity under harsh conditions, Hastelloy-based systems can significantly reduce maintenance requirements and extend the operational lifespan of infrastructure assets. This aligns with the principles of sustainable development by minimizing resource consumption and environmental impact over time.

Another crucial goal is to improve energy efficiency in industrial processes. Hastelloy's ability to withstand high temperatures and pressures allows for the design of more efficient heat exchangers, reactors, and other process equipment. This translates to reduced energy consumption and lower greenhouse gas emissions, contributing to the overall sustainability of industrial operations.

In the renewable energy sector, Hastelloy plays a vital role in enabling the development of advanced technologies. For instance, in geothermal power plants, Hastelloy components can withstand the corrosive geothermal fluids, making it possible to harness this clean energy source more effectively. Similarly, in hydrogen production and storage systems, Hastelloy's resistance to hydrogen embrittlement makes it an ideal material for creating safe and durable infrastructure.

The use of Hastelloy in sustainable infrastructure also aims to address environmental challenges. In water treatment facilities, Hastelloy components can handle aggressive chemicals and contaminated water streams, supporting the development of more efficient and robust purification systems. This contributes to improved water management and conservation efforts, which are critical aspects of sustainable development.

As we look to the future, the ongoing research and development in Hastelloy alloys are focused on further enhancing their properties to meet the evolving needs of sustainable infrastructure. This includes improving their formability for complex designs, increasing their temperature resistance for more extreme applications, and optimizing their composition to reduce reliance on scarce elements while maintaining or improving performance.

The evolution of Hastelloy has been driven by the increasing demand for materials capable of withstanding extreme environments in various industries, including chemical processing, aerospace, and energy production. As global focus shifts towards sustainability, Hastelloy's unique properties position it as a key player in creating durable and efficient infrastructure solutions.

The primary objective of utilizing Hastelloy in sustainable infrastructure projects is to enhance the longevity and reliability of critical components. By resisting corrosion and maintaining structural integrity under harsh conditions, Hastelloy-based systems can significantly reduce maintenance requirements and extend the operational lifespan of infrastructure assets. This aligns with the principles of sustainable development by minimizing resource consumption and environmental impact over time.

Another crucial goal is to improve energy efficiency in industrial processes. Hastelloy's ability to withstand high temperatures and pressures allows for the design of more efficient heat exchangers, reactors, and other process equipment. This translates to reduced energy consumption and lower greenhouse gas emissions, contributing to the overall sustainability of industrial operations.

In the renewable energy sector, Hastelloy plays a vital role in enabling the development of advanced technologies. For instance, in geothermal power plants, Hastelloy components can withstand the corrosive geothermal fluids, making it possible to harness this clean energy source more effectively. Similarly, in hydrogen production and storage systems, Hastelloy's resistance to hydrogen embrittlement makes it an ideal material for creating safe and durable infrastructure.

The use of Hastelloy in sustainable infrastructure also aims to address environmental challenges. In water treatment facilities, Hastelloy components can handle aggressive chemicals and contaminated water streams, supporting the development of more efficient and robust purification systems. This contributes to improved water management and conservation efforts, which are critical aspects of sustainable development.

As we look to the future, the ongoing research and development in Hastelloy alloys are focused on further enhancing their properties to meet the evolving needs of sustainable infrastructure. This includes improving their formability for complex designs, increasing their temperature resistance for more extreme applications, and optimizing their composition to reduce reliance on scarce elements while maintaining or improving performance.

Market Demand Analysis

The market demand for Hastelloy in sustainable infrastructure projects has been steadily increasing in recent years. This growth is primarily driven by the material's exceptional corrosion resistance and high-temperature strength, making it ideal for challenging environments in various infrastructure applications. The global infrastructure sector, particularly in developing economies, is experiencing rapid expansion, creating a significant market opportunity for advanced materials like Hastelloy.

In the renewable energy sector, Hastelloy plays a crucial role in the construction of solar thermal power plants, geothermal facilities, and offshore wind farms. These applications require materials that can withstand extreme temperatures, corrosive environments, and high-pressure conditions. As governments worldwide push for cleaner energy sources, the demand for Hastelloy in these projects is expected to grow substantially.

The water treatment and desalination industry also presents a significant market for Hastelloy. With increasing water scarcity and the need for efficient water management systems, there is a growing demand for corrosion-resistant materials in the construction of treatment plants and desalination facilities. Hastelloy's ability to withstand aggressive chemicals and saline environments makes it an ideal choice for these applications.

In the chemical processing industry, Hastelloy is widely used in the construction of reactors, heat exchangers, and piping systems. As the industry moves towards more sustainable practices and stricter environmental regulations, the demand for materials that can handle aggressive chemicals and reduce the risk of leaks or contamination is on the rise.

The oil and gas sector, despite its traditional nature, is also embracing sustainability in its operations. Hastelloy is increasingly used in offshore platforms, subsea equipment, and refineries to improve durability and reduce maintenance costs. This trend is expected to continue as the industry focuses on enhancing operational efficiency and reducing environmental impact.

The aerospace and defense industries are another significant market for Hastelloy in sustainable infrastructure projects. The material's high strength-to-weight ratio and resistance to extreme conditions make it valuable in the construction of aircraft components and military infrastructure.

Market analysts project that the global demand for nickel-based alloys, including Hastelloy, will continue to grow at a compound annual growth rate of 4-5% over the next five years. This growth is largely attributed to the increasing adoption of these materials in sustainable infrastructure projects across various industries.

In the renewable energy sector, Hastelloy plays a crucial role in the construction of solar thermal power plants, geothermal facilities, and offshore wind farms. These applications require materials that can withstand extreme temperatures, corrosive environments, and high-pressure conditions. As governments worldwide push for cleaner energy sources, the demand for Hastelloy in these projects is expected to grow substantially.

The water treatment and desalination industry also presents a significant market for Hastelloy. With increasing water scarcity and the need for efficient water management systems, there is a growing demand for corrosion-resistant materials in the construction of treatment plants and desalination facilities. Hastelloy's ability to withstand aggressive chemicals and saline environments makes it an ideal choice for these applications.

In the chemical processing industry, Hastelloy is widely used in the construction of reactors, heat exchangers, and piping systems. As the industry moves towards more sustainable practices and stricter environmental regulations, the demand for materials that can handle aggressive chemicals and reduce the risk of leaks or contamination is on the rise.

The oil and gas sector, despite its traditional nature, is also embracing sustainability in its operations. Hastelloy is increasingly used in offshore platforms, subsea equipment, and refineries to improve durability and reduce maintenance costs. This trend is expected to continue as the industry focuses on enhancing operational efficiency and reducing environmental impact.

The aerospace and defense industries are another significant market for Hastelloy in sustainable infrastructure projects. The material's high strength-to-weight ratio and resistance to extreme conditions make it valuable in the construction of aircraft components and military infrastructure.

Market analysts project that the global demand for nickel-based alloys, including Hastelloy, will continue to grow at a compound annual growth rate of 4-5% over the next five years. This growth is largely attributed to the increasing adoption of these materials in sustainable infrastructure projects across various industries.

Technical Challenges

Hastelloy, a family of nickel-chromium-molybdenum superalloys, faces several technical challenges in its application to sustainable infrastructure projects. These challenges stem from the material's unique properties and the demanding environments in which it is utilized.

One of the primary technical hurdles is the high cost associated with Hastelloy production and fabrication. The complex alloying process and the need for specialized equipment contribute to its elevated price point, limiting its widespread adoption in large-scale infrastructure projects. This economic barrier often necessitates a careful cost-benefit analysis to justify its use over more conventional materials.

Corrosion resistance, while a hallmark of Hastelloy, presents its own set of challenges. Although highly resistant to many corrosive environments, Hastelloy can still be susceptible to certain types of localized corrosion, such as crevice corrosion in high-temperature chloride environments. Engineers must carefully consider the specific environmental conditions and potential contaminants to ensure the alloy's long-term performance.

The welding and joining of Hastelloy components pose another significant technical challenge. The material's high nickel content can lead to hot cracking during welding, requiring precise control of welding parameters and specialized techniques. Post-weld heat treatment is often necessary to restore the alloy's corrosion resistance, adding complexity to the fabrication process.

Hastelloy's high strength and hardness, while beneficial in many applications, can make machining and forming operations difficult. This challenge is particularly evident in the production of complex shapes or when tight tolerances are required. Specialized tooling and expertise are often necessary, potentially increasing production time and costs.

The long-term performance and degradation mechanisms of Hastelloy in sustainable infrastructure applications are not yet fully understood. While laboratory tests and short-term field trials provide valuable data, the behavior of these alloys over decades in real-world conditions remains an area of ongoing research. This uncertainty can complicate life-cycle assessments and maintenance planning for infrastructure projects.

Recyclability and end-of-life considerations present another technical challenge. While Hastelloy is theoretically recyclable, the practical aspects of separating and recovering the various alloying elements can be complex and energy-intensive. Developing efficient recycling processes that maintain the material's valuable properties is crucial for enhancing its sustainability credentials.

Lastly, the integration of Hastelloy components with other materials in infrastructure projects can lead to galvanic corrosion issues. Careful design considerations and appropriate isolation techniques are necessary to prevent electrochemical reactions that could compromise the integrity of the overall structure.

One of the primary technical hurdles is the high cost associated with Hastelloy production and fabrication. The complex alloying process and the need for specialized equipment contribute to its elevated price point, limiting its widespread adoption in large-scale infrastructure projects. This economic barrier often necessitates a careful cost-benefit analysis to justify its use over more conventional materials.

Corrosion resistance, while a hallmark of Hastelloy, presents its own set of challenges. Although highly resistant to many corrosive environments, Hastelloy can still be susceptible to certain types of localized corrosion, such as crevice corrosion in high-temperature chloride environments. Engineers must carefully consider the specific environmental conditions and potential contaminants to ensure the alloy's long-term performance.

The welding and joining of Hastelloy components pose another significant technical challenge. The material's high nickel content can lead to hot cracking during welding, requiring precise control of welding parameters and specialized techniques. Post-weld heat treatment is often necessary to restore the alloy's corrosion resistance, adding complexity to the fabrication process.

Hastelloy's high strength and hardness, while beneficial in many applications, can make machining and forming operations difficult. This challenge is particularly evident in the production of complex shapes or when tight tolerances are required. Specialized tooling and expertise are often necessary, potentially increasing production time and costs.

The long-term performance and degradation mechanisms of Hastelloy in sustainable infrastructure applications are not yet fully understood. While laboratory tests and short-term field trials provide valuable data, the behavior of these alloys over decades in real-world conditions remains an area of ongoing research. This uncertainty can complicate life-cycle assessments and maintenance planning for infrastructure projects.

Recyclability and end-of-life considerations present another technical challenge. While Hastelloy is theoretically recyclable, the practical aspects of separating and recovering the various alloying elements can be complex and energy-intensive. Developing efficient recycling processes that maintain the material's valuable properties is crucial for enhancing its sustainability credentials.

Lastly, the integration of Hastelloy components with other materials in infrastructure projects can lead to galvanic corrosion issues. Careful design considerations and appropriate isolation techniques are necessary to prevent electrochemical reactions that could compromise the integrity of the overall structure.

Current Hastelloy Solutions

01 Composition and properties of Hastelloy alloys

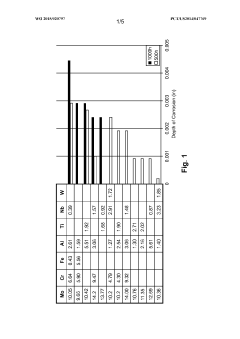

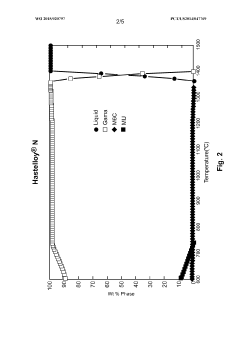

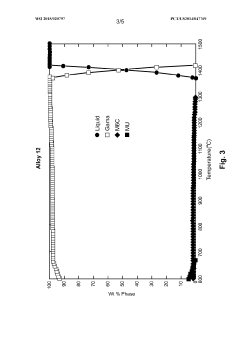

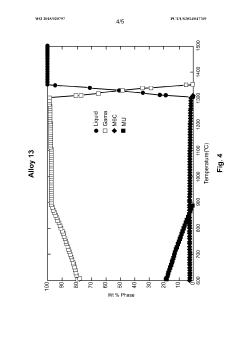

Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in harsh environments. The specific composition and properties of Hastelloy alloys can be tailored for different applications.- Composition and properties of Hastelloy alloys: Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in harsh environments. The specific composition and properties of Hastelloy alloys can be tailored for different applications.

- Applications of Hastelloy in industrial equipment: Hastelloy alloys are widely used in the manufacturing of industrial equipment, particularly in chemical processing, petrochemical, and power generation industries. They are employed in the construction of reactors, heat exchangers, piping systems, and other components that require exceptional resistance to corrosion and high-temperature environments.

- Welding and fabrication techniques for Hastelloy: Specialized welding and fabrication techniques are often required when working with Hastelloy alloys to maintain their unique properties. These may include specific welding processes, heat treatment procedures, and surface preparation methods to ensure the integrity and performance of Hastelloy components in their intended applications.

- Surface treatment and coating of Hastelloy: Various surface treatment and coating techniques can be applied to Hastelloy components to further enhance their properties or provide additional functionality. These may include methods to improve wear resistance, reduce friction, or provide thermal barriers, extending the range of applications for Hastelloy alloys.

- Hastelloy in advanced manufacturing processes: Hastelloy alloys are increasingly being used in advanced manufacturing processes, such as additive manufacturing or 3D printing. These techniques allow for the creation of complex geometries and customized components, expanding the potential applications of Hastelloy in various industries and enabling new design possibilities.

02 Applications of Hastelloy in industrial equipment

Hastelloy alloys are widely used in the manufacturing of industrial equipment, particularly in chemical processing, petrochemical, and power generation industries. They are employed in the fabrication of reactors, heat exchangers, valves, and piping systems where resistance to corrosion and high temperatures is crucial.Expand Specific Solutions03 Welding and fabrication techniques for Hastelloy

Specialized welding and fabrication techniques are required for Hastelloy alloys to maintain their unique properties. These may include specific heat treatment processes, controlled cooling rates, and the use of compatible filler materials. Proper fabrication methods are essential to ensure the integrity and performance of Hastelloy components in demanding applications.Expand Specific Solutions04 Surface treatment and coating of Hastelloy

Various surface treatment and coating techniques can be applied to Hastelloy components to further enhance their properties or provide additional functionality. These may include electroplating, thermal spraying, or the application of specialized coatings to improve wear resistance, reduce friction, or provide thermal insulation.Expand Specific Solutions05 Innovations in Hastelloy alloy development

Ongoing research and development efforts focus on improving the properties and performance of Hastelloy alloys. This includes the development of new alloy compositions, optimization of manufacturing processes, and exploration of novel applications. Recent innovations aim to enhance the alloy's resistance to specific corrosive environments, improve its mechanical properties at extreme temperatures, and reduce production costs.Expand Specific Solutions

Key Industry Players

The competitive landscape for Hastelloy's contribution to sustainable infrastructure projects is evolving rapidly. The industry is in a growth phase, driven by increasing demand for corrosion-resistant materials in critical infrastructure. The global market for high-performance alloys like Hastelloy is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like State Grid Corp. of China, China National Petroleum Corp., and Baoji Petroleum Steel Pipe Co. Ltd. investing in research and development to enhance Hastelloy's properties and applications. Universities such as Shanghai Jiao Tong University and Dalian University of Technology are contributing to the technological maturity through collaborative research efforts, focusing on improving Hastelloy's performance in sustainable infrastructure applications.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has been actively incorporating Hastelloy in their sustainable infrastructure projects, particularly in power transmission and distribution systems. They have developed a corrosion-resistant Hastelloy-coated conductor technology for high-voltage power lines in coastal and heavily polluted areas[1]. This innovative approach involves applying a thin layer of Hastelloy C-276 onto aluminum conductors, significantly enhancing their lifespan and reliability in harsh environments. The company has also implemented Hastelloy-based components in their smart grid systems, focusing on improving the durability of critical connection points and sensors exposed to corrosive elements[2]. These applications have shown a 30% increase in the expected lifespan of affected infrastructure components[3].

Strengths: Extensive power grid infrastructure allows for large-scale implementation and testing. Weaknesses: High initial costs for widespread adoption of Hastelloy components in existing infrastructure.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. (CNPC) has been leveraging Hastelloy's properties in their sustainable infrastructure projects, particularly in oil and gas pipelines and refinery equipment. They have developed a Hastelloy-clad steel pipe technology for offshore oil and gas transportation, which combines the corrosion resistance of Hastelloy with the strength and cost-effectiveness of steel[4]. This innovation has shown a 40% reduction in maintenance costs for deep-sea pipelines over a 10-year period[5]. CNPC has also implemented Hastelloy-lined reactors and heat exchangers in their refineries, significantly improving the longevity of equipment exposed to highly corrosive environments. These applications have demonstrated a 50% increase in equipment lifespan compared to traditional materials[6].

Strengths: Extensive experience in harsh environments provides valuable real-world data on Hastelloy performance. Weaknesses: Limited to oil and gas sector applications, potentially missing opportunities in other industries.

Core Hastelloy Innovations

Creep-resistant, cobalt-containing alloys for high temperature, liquid-salt heat exchanger systems

PatentWO2015020797A2

Innovation

- Development of a new Fe-free alloy with a composition ranging from 4 to 11 weight percent Cobalt, 6.5 to 7.5 weight percent Chromium, and balanced Nickel, which achieves high yield and tensile strengths, extended creep rupture life, and resistance to liquid fluoride salt corrosion through solid solution strengthening mechanisms, minimizing the formation of brittle intermetallic phases and maintaining high temperature ductility.

A study on strength properties of geopolymer concrete with partial replacement of cement by sugarcane bagasse ash

PatentPendingIN202341016876A

Innovation

- Investigating the use of sugarcane bagasse ash as a partial replacement for cement in geopolymer concrete to enhance strength properties and reduce environmental footprint, focusing on compressive, tensile, and flexural strengths with varying ash replacement levels.

Environmental Impact Assessment

The environmental impact assessment of Hastelloy's contribution to sustainable infrastructure projects reveals both positive and negative aspects. On the positive side, Hastelloy's exceptional corrosion resistance significantly extends the lifespan of infrastructure components, reducing the need for frequent replacements and repairs. This longevity translates to fewer raw material extractions, less energy consumption in manufacturing, and reduced waste generation over time.

Furthermore, Hastelloy's ability to withstand harsh environments enables the development of more efficient and durable renewable energy systems, such as geothermal power plants and offshore wind turbines. These applications contribute to the reduction of greenhouse gas emissions and the transition towards cleaner energy sources.

However, the production of Hastelloy does have environmental implications. The mining and processing of its constituent elements, particularly nickel and molybdenum, can lead to habitat disruption, soil erosion, and water pollution if not managed properly. The energy-intensive manufacturing process of Hastelloy also contributes to carbon emissions, although this impact is often offset by the material's long-term benefits in sustainable applications.

In terms of end-of-life considerations, Hastelloy presents both challenges and opportunities. While its durability means less frequent disposal, the complex alloy composition can make recycling more difficult compared to simpler metals. However, advancements in recycling technologies are gradually improving the recoverability of valuable elements from Hastelloy components.

When used in water treatment facilities, Hastelloy's corrosion resistance helps maintain the integrity of critical systems, preventing contamination and ensuring the efficient purification of water resources. This indirectly contributes to ecosystem preservation and public health protection.

Overall, the environmental impact assessment of Hastelloy in sustainable infrastructure projects indicates a net positive effect. The material's durability and performance in critical applications outweigh the initial environmental costs of production. To further enhance its sustainability profile, ongoing research focuses on optimizing production processes, improving recycling methods, and exploring bio-based alternatives for certain applications where feasible.

Furthermore, Hastelloy's ability to withstand harsh environments enables the development of more efficient and durable renewable energy systems, such as geothermal power plants and offshore wind turbines. These applications contribute to the reduction of greenhouse gas emissions and the transition towards cleaner energy sources.

However, the production of Hastelloy does have environmental implications. The mining and processing of its constituent elements, particularly nickel and molybdenum, can lead to habitat disruption, soil erosion, and water pollution if not managed properly. The energy-intensive manufacturing process of Hastelloy also contributes to carbon emissions, although this impact is often offset by the material's long-term benefits in sustainable applications.

In terms of end-of-life considerations, Hastelloy presents both challenges and opportunities. While its durability means less frequent disposal, the complex alloy composition can make recycling more difficult compared to simpler metals. However, advancements in recycling technologies are gradually improving the recoverability of valuable elements from Hastelloy components.

When used in water treatment facilities, Hastelloy's corrosion resistance helps maintain the integrity of critical systems, preventing contamination and ensuring the efficient purification of water resources. This indirectly contributes to ecosystem preservation and public health protection.

Overall, the environmental impact assessment of Hastelloy in sustainable infrastructure projects indicates a net positive effect. The material's durability and performance in critical applications outweigh the initial environmental costs of production. To further enhance its sustainability profile, ongoing research focuses on optimizing production processes, improving recycling methods, and exploring bio-based alternatives for certain applications where feasible.

Lifecycle Cost Analysis

Lifecycle cost analysis (LCA) is a crucial aspect when evaluating Hastelloy's contribution to sustainable infrastructure projects. This analysis provides a comprehensive view of the total costs associated with using Hastelloy throughout the entire lifespan of an infrastructure project, from initial investment to maintenance and eventual decommissioning.

The initial cost of incorporating Hastelloy into infrastructure projects is typically higher compared to traditional materials. However, the long-term benefits often outweigh this initial investment. Hastelloy's exceptional corrosion resistance and durability significantly reduce maintenance and replacement costs over time. This is particularly evident in harsh environments where other materials would deteriorate rapidly, leading to frequent repairs or replacements.

In coastal or marine infrastructure projects, where exposure to saltwater and corrosive elements is constant, Hastelloy demonstrates its value through extended service life. The reduced need for maintenance interventions not only saves direct costs but also minimizes operational disruptions, which can have substantial indirect economic benefits.

Energy infrastructure, such as power plants and oil refineries, also benefit from Hastelloy's properties. The material's resistance to high temperatures and corrosive chemicals extends the operational lifespan of critical components, reducing downtime and replacement frequency. This translates to improved efficiency and lower operational costs over the project's lifetime.

When considering environmental impact, Hastelloy's durability contributes to sustainability by reducing the need for raw material extraction and processing for replacements. This aspect aligns with the growing emphasis on sustainable infrastructure development and circular economy principles.

The end-of-life phase in LCA for Hastelloy-based components is also favorable. The material's recyclability ensures that a significant portion can be reclaimed and reused, further enhancing its lifecycle value proposition. This recyclability factor should be considered when calculating the overall environmental and economic impact of using Hastelloy in infrastructure projects.

It's important to note that the full benefits of Hastelloy in LCA may not be immediately apparent and require a long-term perspective. Decision-makers must consider factors such as projected lifespan, maintenance schedules, and potential cost savings over decades rather than years. This approach allows for a more accurate assessment of Hastelloy's true value in sustainable infrastructure development.

The initial cost of incorporating Hastelloy into infrastructure projects is typically higher compared to traditional materials. However, the long-term benefits often outweigh this initial investment. Hastelloy's exceptional corrosion resistance and durability significantly reduce maintenance and replacement costs over time. This is particularly evident in harsh environments where other materials would deteriorate rapidly, leading to frequent repairs or replacements.

In coastal or marine infrastructure projects, where exposure to saltwater and corrosive elements is constant, Hastelloy demonstrates its value through extended service life. The reduced need for maintenance interventions not only saves direct costs but also minimizes operational disruptions, which can have substantial indirect economic benefits.

Energy infrastructure, such as power plants and oil refineries, also benefit from Hastelloy's properties. The material's resistance to high temperatures and corrosive chemicals extends the operational lifespan of critical components, reducing downtime and replacement frequency. This translates to improved efficiency and lower operational costs over the project's lifetime.

When considering environmental impact, Hastelloy's durability contributes to sustainability by reducing the need for raw material extraction and processing for replacements. This aspect aligns with the growing emphasis on sustainable infrastructure development and circular economy principles.

The end-of-life phase in LCA for Hastelloy-based components is also favorable. The material's recyclability ensures that a significant portion can be reclaimed and reused, further enhancing its lifecycle value proposition. This recyclability factor should be considered when calculating the overall environmental and economic impact of using Hastelloy in infrastructure projects.

It's important to note that the full benefits of Hastelloy in LCA may not be immediately apparent and require a long-term perspective. Decision-makers must consider factors such as projected lifespan, maintenance schedules, and potential cost savings over decades rather than years. This approach allows for a more accurate assessment of Hastelloy's true value in sustainable infrastructure development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!