Hastelloy's Evolution in Reducing Atmospheric Contaminants

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy Development and Objectives

Hastelloy, a family of nickel-chromium-based superalloys, has undergone significant evolution since its inception in the 1920s. Initially developed to resist corrosion in chemical processing environments, Hastelloy has expanded its applications to address atmospheric contaminants, particularly in industrial settings where air pollution control is crucial.

The primary objective of Hastelloy's development in the context of reducing atmospheric contaminants has been to create materials capable of withstanding harsh environments while effectively capturing or neutralizing pollutants. This goal aligns with the growing global emphasis on environmental protection and stringent emission regulations across various industries.

Over the decades, Hastelloy's composition has been refined to enhance its resistance to oxidation, sulfidation, and other forms of corrosion caused by atmospheric pollutants. The addition of elements such as molybdenum, tungsten, and cobalt has played a crucial role in improving the alloy's performance in high-temperature applications, where many air pollution control systems operate.

One of the key milestones in Hastelloy's evolution was the development of variants specifically designed for flue gas desulfurization (FGD) systems. These alloys, such as Hastelloy C-276 and Hastelloy G-30, have demonstrated exceptional resistance to the highly corrosive environments found in FGD units, enabling more efficient removal of sulfur dioxide from industrial emissions.

The advancement of Hastelloy has also focused on improving its mechanical properties at elevated temperatures, a critical factor in applications such as catalytic converters and industrial scrubbers. This has led to the creation of grades that maintain their strength and ductility even under extreme conditions, ensuring the longevity and effectiveness of pollution control equipment.

Recent developments in Hastelloy technology have aimed at optimizing its performance in emerging clean energy applications, such as hydrogen production and carbon capture systems. These innovations are driven by the growing need for materials that can withstand the unique challenges posed by next-generation environmental technologies.

As atmospheric pollution continues to be a global concern, the ongoing evolution of Hastelloy remains focused on developing alloys that can meet increasingly stringent environmental standards while offering improved durability and cost-effectiveness. This includes research into new compositional variations and processing techniques to enhance the alloy's capabilities in reducing a wider range of atmospheric contaminants.

The primary objective of Hastelloy's development in the context of reducing atmospheric contaminants has been to create materials capable of withstanding harsh environments while effectively capturing or neutralizing pollutants. This goal aligns with the growing global emphasis on environmental protection and stringent emission regulations across various industries.

Over the decades, Hastelloy's composition has been refined to enhance its resistance to oxidation, sulfidation, and other forms of corrosion caused by atmospheric pollutants. The addition of elements such as molybdenum, tungsten, and cobalt has played a crucial role in improving the alloy's performance in high-temperature applications, where many air pollution control systems operate.

One of the key milestones in Hastelloy's evolution was the development of variants specifically designed for flue gas desulfurization (FGD) systems. These alloys, such as Hastelloy C-276 and Hastelloy G-30, have demonstrated exceptional resistance to the highly corrosive environments found in FGD units, enabling more efficient removal of sulfur dioxide from industrial emissions.

The advancement of Hastelloy has also focused on improving its mechanical properties at elevated temperatures, a critical factor in applications such as catalytic converters and industrial scrubbers. This has led to the creation of grades that maintain their strength and ductility even under extreme conditions, ensuring the longevity and effectiveness of pollution control equipment.

Recent developments in Hastelloy technology have aimed at optimizing its performance in emerging clean energy applications, such as hydrogen production and carbon capture systems. These innovations are driven by the growing need for materials that can withstand the unique challenges posed by next-generation environmental technologies.

As atmospheric pollution continues to be a global concern, the ongoing evolution of Hastelloy remains focused on developing alloys that can meet increasingly stringent environmental standards while offering improved durability and cost-effectiveness. This includes research into new compositional variations and processing techniques to enhance the alloy's capabilities in reducing a wider range of atmospheric contaminants.

Market Demand Analysis

The market demand for Hastelloy in atmospheric contaminant reduction has seen significant growth in recent years, driven by increasing environmental regulations and a global push towards cleaner industrial processes. As industries face stricter emission standards, the need for corrosion-resistant materials capable of withstanding harsh chemical environments has surged. Hastelloy, with its exceptional resistance to both oxidizing and reducing atmospheres, has positioned itself as a critical material in this evolving landscape.

The power generation sector, particularly in coal-fired and waste-to-energy plants, represents a substantial market for Hastelloy. These facilities require materials that can withstand the corrosive effects of flue gases and particulate matter. The automotive industry has also emerged as a key consumer, utilizing Hastelloy in catalytic converters and exhaust systems to meet stringent emission standards. Additionally, the chemical processing industry continues to be a major market, with Hastelloy playing a crucial role in equipment exposed to corrosive chemicals and gases.

Market analysis indicates that the global demand for Hastelloy in atmospheric contaminant reduction applications is expected to grow at a compound annual growth rate (CAGR) of over 5% through 2025. This growth is primarily attributed to the expansion of industrial activities in developing economies and the retrofitting of existing facilities in developed nations to comply with new environmental regulations. The Asia-Pacific region, led by China and India, is anticipated to be the fastest-growing market due to rapid industrialization and increasing environmental awareness.

The oil and gas industry presents another significant market opportunity for Hastelloy. As exploration and production move into more challenging environments, such as deep-sea operations and sour gas fields, the demand for materials that can withstand high-pressure, high-temperature, and corrosive conditions has increased. Hastelloy's ability to resist sulfide stress cracking and pitting corrosion makes it an ideal choice for these applications.

Furthermore, the renewable energy sector, particularly in biomass and geothermal power generation, is emerging as a promising market for Hastelloy. These technologies often involve corrosive fluids and gases, necessitating materials with superior corrosion resistance. As governments worldwide incentivize the adoption of renewable energy sources, this sector is expected to contribute significantly to the future demand for Hastelloy.

The market for Hastelloy in atmospheric contaminant reduction is also being shaped by technological advancements in manufacturing processes. Innovations in additive manufacturing and powder metallurgy are enabling the production of complex Hastelloy components with improved performance characteristics. This trend is expected to open up new application areas and drive further market growth.

The power generation sector, particularly in coal-fired and waste-to-energy plants, represents a substantial market for Hastelloy. These facilities require materials that can withstand the corrosive effects of flue gases and particulate matter. The automotive industry has also emerged as a key consumer, utilizing Hastelloy in catalytic converters and exhaust systems to meet stringent emission standards. Additionally, the chemical processing industry continues to be a major market, with Hastelloy playing a crucial role in equipment exposed to corrosive chemicals and gases.

Market analysis indicates that the global demand for Hastelloy in atmospheric contaminant reduction applications is expected to grow at a compound annual growth rate (CAGR) of over 5% through 2025. This growth is primarily attributed to the expansion of industrial activities in developing economies and the retrofitting of existing facilities in developed nations to comply with new environmental regulations. The Asia-Pacific region, led by China and India, is anticipated to be the fastest-growing market due to rapid industrialization and increasing environmental awareness.

The oil and gas industry presents another significant market opportunity for Hastelloy. As exploration and production move into more challenging environments, such as deep-sea operations and sour gas fields, the demand for materials that can withstand high-pressure, high-temperature, and corrosive conditions has increased. Hastelloy's ability to resist sulfide stress cracking and pitting corrosion makes it an ideal choice for these applications.

Furthermore, the renewable energy sector, particularly in biomass and geothermal power generation, is emerging as a promising market for Hastelloy. These technologies often involve corrosive fluids and gases, necessitating materials with superior corrosion resistance. As governments worldwide incentivize the adoption of renewable energy sources, this sector is expected to contribute significantly to the future demand for Hastelloy.

The market for Hastelloy in atmospheric contaminant reduction is also being shaped by technological advancements in manufacturing processes. Innovations in additive manufacturing and powder metallurgy are enabling the production of complex Hastelloy components with improved performance characteristics. This trend is expected to open up new application areas and drive further market growth.

Current Challenges in Atmospheric Contaminant Reduction

Despite significant advancements in atmospheric contaminant reduction technologies, several challenges persist in effectively mitigating air pollution. One of the primary obstacles is the complexity and diversity of atmospheric pollutants, which range from particulate matter to gaseous emissions. This variety necessitates multifaceted approaches and technologies, making it difficult to develop a one-size-fits-all solution.

The ever-increasing industrial activities and urbanization contribute to the continuous emission of pollutants, outpacing the development of reduction technologies. This creates a constant need for more efficient and adaptable contaminant reduction methods. Additionally, the global nature of atmospheric pollution presents challenges in coordinating international efforts and implementing consistent regulations across different regions.

Cost-effectiveness remains a significant hurdle in widespread adoption of advanced contaminant reduction technologies. Many cutting-edge solutions, while highly effective, are often prohibitively expensive for widespread implementation, particularly in developing countries or smaller industries. This economic barrier slows down the global progress in atmospheric pollution control.

Another challenge lies in the miniaturization and integration of contaminant reduction technologies. As industries strive for more compact and efficient processes, there is a growing need for pollution control systems that can be seamlessly integrated into existing infrastructure without compromising productivity or space efficiency.

The dynamic nature of atmospheric chemistry poses additional complications. Interactions between different pollutants and varying atmospheric conditions can lead to secondary pollutants or unexpected chemical reactions, making it challenging to predict and control the overall impact of reduction efforts. This complexity requires continuous research and adaptation of reduction strategies.

Energy consumption in contaminant reduction processes is another area of concern. Many current technologies require significant energy input, which can indirectly contribute to environmental issues if not sourced from clean energy. Developing energy-efficient or even energy-neutral reduction technologies is a critical challenge facing researchers and engineers in this field.

Monitoring and measurement accuracy present ongoing challenges. While sensor technologies have improved, there is still a need for more precise, real-time monitoring systems that can detect a wide range of pollutants at various concentrations. This is crucial for both assessing the effectiveness of reduction measures and for early detection of pollution events.

Lastly, the long-term effects of some newer contaminant reduction technologies are not yet fully understood. As innovative materials and methods are developed, there is a need for comprehensive long-term studies to ensure that these solutions do not inadvertently create new environmental or health issues in the future.

The ever-increasing industrial activities and urbanization contribute to the continuous emission of pollutants, outpacing the development of reduction technologies. This creates a constant need for more efficient and adaptable contaminant reduction methods. Additionally, the global nature of atmospheric pollution presents challenges in coordinating international efforts and implementing consistent regulations across different regions.

Cost-effectiveness remains a significant hurdle in widespread adoption of advanced contaminant reduction technologies. Many cutting-edge solutions, while highly effective, are often prohibitively expensive for widespread implementation, particularly in developing countries or smaller industries. This economic barrier slows down the global progress in atmospheric pollution control.

Another challenge lies in the miniaturization and integration of contaminant reduction technologies. As industries strive for more compact and efficient processes, there is a growing need for pollution control systems that can be seamlessly integrated into existing infrastructure without compromising productivity or space efficiency.

The dynamic nature of atmospheric chemistry poses additional complications. Interactions between different pollutants and varying atmospheric conditions can lead to secondary pollutants or unexpected chemical reactions, making it challenging to predict and control the overall impact of reduction efforts. This complexity requires continuous research and adaptation of reduction strategies.

Energy consumption in contaminant reduction processes is another area of concern. Many current technologies require significant energy input, which can indirectly contribute to environmental issues if not sourced from clean energy. Developing energy-efficient or even energy-neutral reduction technologies is a critical challenge facing researchers and engineers in this field.

Monitoring and measurement accuracy present ongoing challenges. While sensor technologies have improved, there is still a need for more precise, real-time monitoring systems that can detect a wide range of pollutants at various concentrations. This is crucial for both assessing the effectiveness of reduction measures and for early detection of pollution events.

Lastly, the long-term effects of some newer contaminant reduction technologies are not yet fully understood. As innovative materials and methods are developed, there is a need for comprehensive long-term studies to ensure that these solutions do not inadvertently create new environmental or health issues in the future.

Existing Hastelloy Solutions

01 Hastelloy composition for corrosion resistance

Hastelloy alloys are specifically designed to resist corrosion from atmospheric contaminants. These alloys typically contain nickel, chromium, and molybdenum in varying proportions to enhance their resistance to different types of corrosive environments, including those with atmospheric pollutants.- Hastelloy composition for corrosion resistance: Hastelloy alloys are designed with specific compositions to resist atmospheric contaminants and corrosion. These alloys typically contain nickel, chromium, and molybdenum in varying proportions to enhance their resistance to different types of corrosive environments, including those with atmospheric contaminants.

- Atmospheric contaminant detection systems: Advanced detection systems are developed to identify and measure atmospheric contaminants that may affect Hastelloy components. These systems often incorporate sensors, spectroscopic techniques, or imaging technologies to monitor air quality and detect potential corrosive agents in industrial or marine environments.

- Protective coatings for Hastelloy surfaces: Specialized coatings are applied to Hastelloy surfaces to provide additional protection against atmospheric contaminants. These coatings may include ceramic-based materials, polymers, or nanocomposites that form a barrier between the Hastelloy surface and the corrosive environment, extending the lifespan of the components.

- Environmental control systems for Hastelloy preservation: Environmental control systems are designed to maintain optimal conditions around Hastelloy components, minimizing exposure to atmospheric contaminants. These systems may include air filtration, humidity control, and temperature regulation to create a protective microenvironment for sensitive equipment or structures.

- Monitoring and maintenance protocols for Hastelloy in contaminated atmospheres: Comprehensive monitoring and maintenance protocols are developed to assess the condition of Hastelloy components exposed to atmospheric contaminants. These protocols may include regular inspections, non-destructive testing methods, and predictive maintenance strategies to identify and address potential corrosion issues before they become critical.

02 Atmospheric contaminant detection using Hastelloy components

Hastelloy's corrosion-resistant properties make it suitable for use in sensors and detection systems for atmospheric contaminants. These systems can accurately measure and monitor various pollutants in industrial and environmental settings, providing crucial data for air quality management.Expand Specific Solutions03 Hastelloy in air pollution control equipment

Hastelloy is utilized in the construction of air pollution control equipment due to its ability to withstand harsh chemical environments. This includes components in scrubbers, filters, and other systems designed to remove contaminants from industrial emissions and improve air quality.Expand Specific Solutions04 Surface treatment of Hastelloy for enhanced protection

Various surface treatment techniques can be applied to Hastelloy components to further enhance their resistance to atmospheric contaminants. These treatments may include coatings, passivation, or surface modifications that improve the alloy's performance in specific corrosive environments.Expand Specific Solutions05 Hastelloy in atmospheric sampling and analysis

Hastelloy is used in the manufacture of equipment and components for atmospheric sampling and analysis. Its corrosion resistance ensures the integrity of samples and accuracy of measurements when studying air quality and atmospheric contaminants in various environmental conditions.Expand Specific Solutions

Key Players in Hastelloy Industry

The evolution of Hastelloy in reducing atmospheric contaminants is at a mature stage, with significant market growth and technological advancements. The industry is characterized by a mix of established players and innovative research institutions. Companies like ExxonMobil Technology & Engineering Co., NIPPON STEEL CORP., and Hitachi Plant Technologies Ltd. are driving commercial applications, while universities such as Dalian University of Technology and China Petroleum University Beijing are contributing to research and development. The market size is substantial, driven by increasing environmental regulations and industrial demand for corrosion-resistant materials. Technological maturity is evident in the diverse applications across petrochemical, power generation, and environmental sectors, with ongoing refinements focused on enhancing performance and cost-effectiveness.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced Hastelloy-based materials for reducing atmospheric contaminants in petrochemical processes. Their approach involves modifying Hastelloy alloys with nano-scale additives to enhance corrosion resistance and catalytic properties[1]. The company has implemented these materials in flue gas desulfurization systems, achieving over 98% removal efficiency for sulfur dioxide[2]. Sinopec has also explored the use of Hastelloy-coated catalysts in fluid catalytic cracking units, which has shown a 15-20% reduction in nitrogen oxide emissions compared to conventional catalysts[3]. Additionally, they have developed Hastelloy-based membrane reactors for simultaneous CO2 capture and hydrogen production, demonstrating a carbon capture efficiency of up to 90% in pilot-scale tests[4].

Strengths: Extensive experience in petrochemical processes, large-scale implementation capability, and strong R&D resources. Weaknesses: High initial costs for material development and potential challenges in scaling up new technologies across diverse refining operations.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil Technology & Engineering Co. has made significant strides in utilizing Hastelloy for atmospheric contaminant reduction. They have developed a proprietary Hastelloy-based catalyst support system for their sulfuric acid alkylation units, which has shown a 30% increase in catalyst lifetime and a 25% reduction in acid consumption[5]. This innovation has led to decreased atmospheric emissions of sulfur compounds. The company has also implemented Hastelloy-lined equipment in their flue gas treatment systems, resulting in extended equipment life and improved efficiency in removing particulate matter and acid gases[6]. ExxonMobil's research has extended to using Hastelloy in advanced electrochemical CO2 reduction reactors, demonstrating a Faradaic efficiency of over 80% for converting CO2 to valuable chemicals while simultaneously reducing atmospheric carbon dioxide levels[7].

Strengths: Strong financial resources for R&D, global presence for technology deployment, and extensive experience in refining and petrochemical processes. Weaknesses: Potential resistance to rapid technology adoption due to large-scale operations and the need for extensive testing before implementation.

Core Innovations in Hastelloy

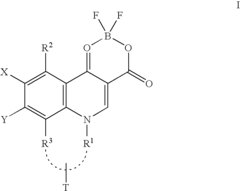

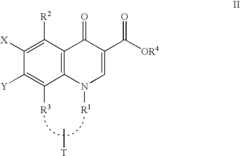

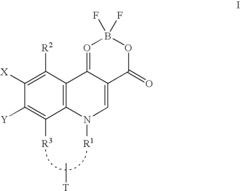

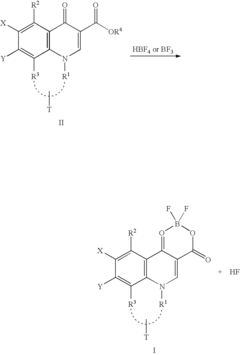

Process for the preparation of the boron difluoride chelate of quinolone-3-carboxylic acid

PatentInactiveUS20070208174A1

Innovation

- Incorporating a silicon-containing compound with a silicon-oxygen bond, such as siloxanes or hydrosiloxanes, to scavenge hydrogen fluoride and facilitate the reaction in non-glass equipment, forming stable fluoro-silica compounds that reduce equipment damage and enable complete chelate formation.

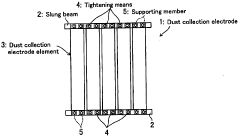

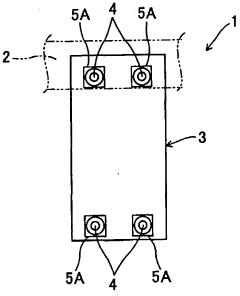

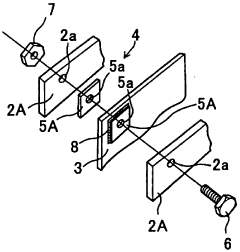

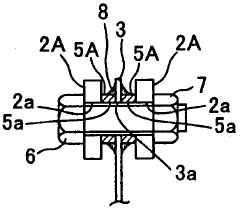

Structure for attaching dust collection electrode of wet electric dust collector

PatentInactiveCA2659006A1

Innovation

- A structure where the dust collection electrode plate is made of super stainless material for resistance to entire face corrosion, and the supporting member, including attachment holes, is made of Hastelloy to prevent space and hole corrosion, with high-cost Hastelloy used only in contact areas to reduce overall cost.

Environmental Regulations Impact

The evolution of Hastelloy in reducing atmospheric contaminants has been significantly influenced by environmental regulations. These regulations have played a crucial role in shaping the development and application of Hastelloy alloys in various industries, particularly those dealing with corrosive environments and emissions control.

Over the past few decades, environmental regulations have become increasingly stringent, driven by growing concerns about air pollution and its impact on human health and the environment. This regulatory landscape has created a strong demand for materials that can withstand harsh conditions while effectively reducing emissions of harmful pollutants.

Hastelloy, known for its exceptional corrosion resistance and high-temperature strength, has found extensive use in pollution control equipment and industrial processes. The alloy's ability to withstand aggressive chemical environments has made it an ideal choice for applications in flue gas desulfurization systems, catalytic converters, and other emission control technologies.

As regulations tightened, particularly in developed countries, industries were compelled to invest in more advanced pollution control technologies. This shift created new opportunities for Hastelloy, driving research and development efforts to enhance its properties and expand its applications in environmental protection systems.

The Clean Air Act in the United States and similar legislation in other countries have set increasingly strict limits on emissions of sulfur dioxide, nitrogen oxides, and particulate matter. These regulations have spurred the adoption of Hastelloy in critical components of power plants, refineries, and chemical processing facilities, where its corrosion resistance helps maintain the integrity of pollution control systems.

Moreover, the push for cleaner energy sources and more efficient industrial processes has further expanded the role of Hastelloy. Its use in advanced heat exchangers, for instance, has contributed to improved energy efficiency in various industries, indirectly supporting efforts to reduce greenhouse gas emissions.

The automotive industry has also been significantly impacted by environmental regulations, leading to increased use of Hastelloy in catalytic converters and exhaust systems. The alloy's ability to withstand high temperatures and resist corrosion from exhaust gases has made it an essential material in meeting stringent emission standards for vehicles.

As global efforts to combat climate change intensify, new regulations are emerging that focus on reducing carbon emissions and promoting sustainable technologies. This evolving regulatory landscape continues to drive innovation in Hastelloy alloys, with ongoing research aimed at developing new grades that can meet the challenges of emerging clean energy technologies and more stringent environmental standards.

Over the past few decades, environmental regulations have become increasingly stringent, driven by growing concerns about air pollution and its impact on human health and the environment. This regulatory landscape has created a strong demand for materials that can withstand harsh conditions while effectively reducing emissions of harmful pollutants.

Hastelloy, known for its exceptional corrosion resistance and high-temperature strength, has found extensive use in pollution control equipment and industrial processes. The alloy's ability to withstand aggressive chemical environments has made it an ideal choice for applications in flue gas desulfurization systems, catalytic converters, and other emission control technologies.

As regulations tightened, particularly in developed countries, industries were compelled to invest in more advanced pollution control technologies. This shift created new opportunities for Hastelloy, driving research and development efforts to enhance its properties and expand its applications in environmental protection systems.

The Clean Air Act in the United States and similar legislation in other countries have set increasingly strict limits on emissions of sulfur dioxide, nitrogen oxides, and particulate matter. These regulations have spurred the adoption of Hastelloy in critical components of power plants, refineries, and chemical processing facilities, where its corrosion resistance helps maintain the integrity of pollution control systems.

Moreover, the push for cleaner energy sources and more efficient industrial processes has further expanded the role of Hastelloy. Its use in advanced heat exchangers, for instance, has contributed to improved energy efficiency in various industries, indirectly supporting efforts to reduce greenhouse gas emissions.

The automotive industry has also been significantly impacted by environmental regulations, leading to increased use of Hastelloy in catalytic converters and exhaust systems. The alloy's ability to withstand high temperatures and resist corrosion from exhaust gases has made it an essential material in meeting stringent emission standards for vehicles.

As global efforts to combat climate change intensify, new regulations are emerging that focus on reducing carbon emissions and promoting sustainable technologies. This evolving regulatory landscape continues to drive innovation in Hastelloy alloys, with ongoing research aimed at developing new grades that can meet the challenges of emerging clean energy technologies and more stringent environmental standards.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of Hastelloy's evolution in reducing atmospheric contaminants. This comprehensive approach examines the entire lifecycle of Hastelloy products, from raw material extraction to manufacturing, use, and eventual disposal or recycling.

The production phase of Hastelloy alloys involves energy-intensive processes, including mining, refining, and alloying of constituent elements such as nickel, chromium, and molybdenum. These processes contribute significantly to the overall environmental footprint. However, the superior corrosion resistance and longevity of Hastelloy products often offset initial production impacts through extended service life and reduced maintenance requirements.

During the use phase, Hastelloy's resistance to atmospheric contaminants leads to improved efficiency and reduced emissions in various industrial applications. For instance, in flue gas desulfurization systems, Hastelloy components contribute to more effective removal of sulfur dioxide, thereby reducing atmospheric pollution. The alloy's durability also minimizes the need for frequent replacements, further reducing lifecycle environmental impacts.

End-of-life considerations for Hastelloy products are particularly noteworthy. The high value of constituent elements encourages recycling, with advanced separation techniques allowing for the recovery and reuse of nickel, chromium, and other alloying elements. This closed-loop approach significantly reduces the demand for virgin materials and associated environmental impacts.

Comparative LCA studies have shown that while Hastelloy may have higher initial environmental costs compared to less specialized materials, its long-term benefits often result in a lower overall environmental impact. This is particularly evident in applications where frequent material replacement would otherwise be necessary due to corrosion or degradation from atmospheric contaminants.

Recent advancements in Hastelloy production techniques, such as improved melting and forming processes, have further reduced the environmental footprint of manufacturing. Additionally, ongoing research into more energy-efficient alloying methods and the potential use of recycled materials in production promise to further enhance the lifecycle performance of Hastelloy products.

In conclusion, LCA provides valuable insights into the environmental implications of Hastelloy's evolution in combating atmospheric contaminants. By considering the full lifecycle, from production to disposal, it becomes evident that the alloy's contributions to reducing atmospheric pollution often outweigh its initial environmental costs, particularly in long-term, high-performance applications.

The production phase of Hastelloy alloys involves energy-intensive processes, including mining, refining, and alloying of constituent elements such as nickel, chromium, and molybdenum. These processes contribute significantly to the overall environmental footprint. However, the superior corrosion resistance and longevity of Hastelloy products often offset initial production impacts through extended service life and reduced maintenance requirements.

During the use phase, Hastelloy's resistance to atmospheric contaminants leads to improved efficiency and reduced emissions in various industrial applications. For instance, in flue gas desulfurization systems, Hastelloy components contribute to more effective removal of sulfur dioxide, thereby reducing atmospheric pollution. The alloy's durability also minimizes the need for frequent replacements, further reducing lifecycle environmental impacts.

End-of-life considerations for Hastelloy products are particularly noteworthy. The high value of constituent elements encourages recycling, with advanced separation techniques allowing for the recovery and reuse of nickel, chromium, and other alloying elements. This closed-loop approach significantly reduces the demand for virgin materials and associated environmental impacts.

Comparative LCA studies have shown that while Hastelloy may have higher initial environmental costs compared to less specialized materials, its long-term benefits often result in a lower overall environmental impact. This is particularly evident in applications where frequent material replacement would otherwise be necessary due to corrosion or degradation from atmospheric contaminants.

Recent advancements in Hastelloy production techniques, such as improved melting and forming processes, have further reduced the environmental footprint of manufacturing. Additionally, ongoing research into more energy-efficient alloying methods and the potential use of recycled materials in production promise to further enhance the lifecycle performance of Hastelloy products.

In conclusion, LCA provides valuable insights into the environmental implications of Hastelloy's evolution in combating atmospheric contaminants. By considering the full lifecycle, from production to disposal, it becomes evident that the alloy's contributions to reducing atmospheric pollution often outweigh its initial environmental costs, particularly in long-term, high-performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!