Hastelloy's Role in Environmental Monitoring Systems

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hastelloy in Environmental Monitoring: Background and Objectives

Hastelloy, a family of nickel-chromium-based superalloys, has emerged as a crucial material in the field of environmental monitoring systems. The evolution of this technology can be traced back to the mid-20th century when the need for corrosion-resistant materials in harsh environments became increasingly apparent. As industrial processes and environmental concerns grew more complex, the demand for reliable monitoring systems capable of withstanding extreme conditions intensified.

The primary objective of incorporating Hastelloy into environmental monitoring systems is to enhance the durability, accuracy, and longevity of sensing equipment exposed to corrosive environments. This alloy's exceptional resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking, makes it an ideal candidate for applications in wastewater treatment plants, chemical processing facilities, and marine environments.

The technological trajectory of Hastelloy in environmental monitoring has been marked by continuous improvements in alloy composition and manufacturing processes. Early iterations focused on enhancing corrosion resistance, while recent developments have aimed at optimizing mechanical properties and expanding the range of operating temperatures. This evolution has enabled the creation of more sophisticated and reliable monitoring systems capable of providing accurate data in increasingly challenging environments.

As environmental regulations have become more stringent globally, the role of Hastelloy in monitoring systems has gained prominence. The alloy's ability to maintain its integrity in the presence of aggressive chemicals and extreme pH levels has made it indispensable in ensuring compliance with environmental standards. This has led to its widespread adoption in air quality monitoring stations, water quality sensors, and soil contamination detection systems.

The integration of Hastelloy into environmental monitoring technologies aligns with the broader trend of developing smart and sustainable environmental management solutions. As the Internet of Things (IoT) and big data analytics continue to revolutionize environmental monitoring, the demand for robust, long-lasting sensor components has intensified. Hastelloy's unique properties position it as a key enabler in the development of next-generation monitoring systems that can provide real-time, continuous data collection in even the most challenging environmental conditions.

Looking ahead, the objectives for Hastelloy in environmental monitoring systems include further enhancing its performance in extreme temperatures, improving its resistance to specific corrosive agents, and reducing manufacturing costs to enable wider adoption. Additionally, research is ongoing to explore the potential of Hastelloy in emerging environmental monitoring applications, such as deep-sea exploration and atmospheric pollution detection in highly industrialized areas.

The primary objective of incorporating Hastelloy into environmental monitoring systems is to enhance the durability, accuracy, and longevity of sensing equipment exposed to corrosive environments. This alloy's exceptional resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking, makes it an ideal candidate for applications in wastewater treatment plants, chemical processing facilities, and marine environments.

The technological trajectory of Hastelloy in environmental monitoring has been marked by continuous improvements in alloy composition and manufacturing processes. Early iterations focused on enhancing corrosion resistance, while recent developments have aimed at optimizing mechanical properties and expanding the range of operating temperatures. This evolution has enabled the creation of more sophisticated and reliable monitoring systems capable of providing accurate data in increasingly challenging environments.

As environmental regulations have become more stringent globally, the role of Hastelloy in monitoring systems has gained prominence. The alloy's ability to maintain its integrity in the presence of aggressive chemicals and extreme pH levels has made it indispensable in ensuring compliance with environmental standards. This has led to its widespread adoption in air quality monitoring stations, water quality sensors, and soil contamination detection systems.

The integration of Hastelloy into environmental monitoring technologies aligns with the broader trend of developing smart and sustainable environmental management solutions. As the Internet of Things (IoT) and big data analytics continue to revolutionize environmental monitoring, the demand for robust, long-lasting sensor components has intensified. Hastelloy's unique properties position it as a key enabler in the development of next-generation monitoring systems that can provide real-time, continuous data collection in even the most challenging environmental conditions.

Looking ahead, the objectives for Hastelloy in environmental monitoring systems include further enhancing its performance in extreme temperatures, improving its resistance to specific corrosive agents, and reducing manufacturing costs to enable wider adoption. Additionally, research is ongoing to explore the potential of Hastelloy in emerging environmental monitoring applications, such as deep-sea exploration and atmospheric pollution detection in highly industrialized areas.

Market Analysis for Hastelloy-based Monitoring Systems

The market for Hastelloy-based environmental monitoring systems has shown significant growth potential in recent years, driven by increasing environmental regulations and the need for reliable, corrosion-resistant materials in harsh monitoring conditions. Hastelloy, a nickel-chromium-molybdenum alloy known for its exceptional resistance to corrosion and high-temperature environments, has found a crucial niche in this sector.

The global environmental monitoring market, which encompasses Hastelloy-based systems, was valued at $19.6 billion in 2021 and is projected to reach $28.9 billion by 2026, growing at a CAGR of 8.1%. Within this broader market, Hastelloy-based systems are carving out an increasingly important role, particularly in applications involving aggressive chemicals, high temperatures, and corrosive environments.

Key industries driving the demand for Hastelloy-based monitoring systems include chemical processing, oil and gas, power generation, and wastewater treatment. These sectors require monitoring equipment that can withstand extreme conditions while maintaining accuracy and reliability. Hastelloy's unique properties make it ideal for sensors, probes, and other components used in monitoring systems for air quality, water quality, and emissions control.

The market for Hastelloy-based systems is particularly strong in regions with stringent environmental regulations, such as North America, Europe, and parts of Asia-Pacific. These regions are investing heavily in advanced monitoring technologies to ensure compliance with environmental standards and to improve overall environmental management practices.

One of the key drivers of market growth is the increasing focus on real-time, continuous monitoring of environmental parameters. Hastelloy-based systems offer the durability and reliability needed for long-term deployment in challenging environments, making them ideal for continuous monitoring applications. This trend is further supported by the growing adoption of IoT and cloud-based monitoring solutions, which require robust sensor technologies capable of withstanding harsh conditions.

Despite its advantages, the high cost of Hastelloy compared to other materials presents a challenge for market expansion, particularly in price-sensitive markets. However, the long-term cost benefits due to reduced maintenance and replacement needs are increasingly recognized by end-users, helping to justify the initial investment.

Looking ahead, the market for Hastelloy-based environmental monitoring systems is expected to continue its growth trajectory. Emerging applications in areas such as offshore wind farms, geothermal energy production, and advanced waste treatment facilities are likely to create new opportunities for Hastelloy-based monitoring solutions. Additionally, ongoing research and development efforts aimed at improving the performance and reducing the cost of Hastelloy alloys could further expand their applicability in environmental monitoring systems.

The global environmental monitoring market, which encompasses Hastelloy-based systems, was valued at $19.6 billion in 2021 and is projected to reach $28.9 billion by 2026, growing at a CAGR of 8.1%. Within this broader market, Hastelloy-based systems are carving out an increasingly important role, particularly in applications involving aggressive chemicals, high temperatures, and corrosive environments.

Key industries driving the demand for Hastelloy-based monitoring systems include chemical processing, oil and gas, power generation, and wastewater treatment. These sectors require monitoring equipment that can withstand extreme conditions while maintaining accuracy and reliability. Hastelloy's unique properties make it ideal for sensors, probes, and other components used in monitoring systems for air quality, water quality, and emissions control.

The market for Hastelloy-based systems is particularly strong in regions with stringent environmental regulations, such as North America, Europe, and parts of Asia-Pacific. These regions are investing heavily in advanced monitoring technologies to ensure compliance with environmental standards and to improve overall environmental management practices.

One of the key drivers of market growth is the increasing focus on real-time, continuous monitoring of environmental parameters. Hastelloy-based systems offer the durability and reliability needed for long-term deployment in challenging environments, making them ideal for continuous monitoring applications. This trend is further supported by the growing adoption of IoT and cloud-based monitoring solutions, which require robust sensor technologies capable of withstanding harsh conditions.

Despite its advantages, the high cost of Hastelloy compared to other materials presents a challenge for market expansion, particularly in price-sensitive markets. However, the long-term cost benefits due to reduced maintenance and replacement needs are increasingly recognized by end-users, helping to justify the initial investment.

Looking ahead, the market for Hastelloy-based environmental monitoring systems is expected to continue its growth trajectory. Emerging applications in areas such as offshore wind farms, geothermal energy production, and advanced waste treatment facilities are likely to create new opportunities for Hastelloy-based monitoring solutions. Additionally, ongoing research and development efforts aimed at improving the performance and reducing the cost of Hastelloy alloys could further expand their applicability in environmental monitoring systems.

Current Challenges in Hastelloy Environmental Applications

Despite Hastelloy's exceptional corrosion resistance and durability, its application in environmental monitoring systems faces several significant challenges. One of the primary issues is the high cost associated with Hastelloy components, which can significantly impact the overall expense of monitoring systems. This cost factor often limits the widespread adoption of Hastelloy in environmental applications, particularly in large-scale or distributed monitoring networks.

Another challenge lies in the complexity of manufacturing and fabricating Hastelloy parts. The material's unique properties that make it ideal for harsh environments also make it difficult to machine and form. This complexity can lead to longer production times and increased manufacturing costs, potentially causing delays in the deployment of environmental monitoring systems.

The weight of Hastelloy components presents an additional hurdle, especially in portable or remote sensing applications. While its density contributes to its strength, it can make monitoring devices heavier and less manageable in field operations. This weight issue becomes particularly problematic in applications requiring frequent transportation or installation in hard-to-reach locations.

Hastelloy's thermal properties, while beneficial in many industrial applications, can pose challenges in certain environmental monitoring scenarios. Its relatively low thermal conductivity compared to some other metals may affect the response time and accuracy of sensors in applications where rapid temperature changes need to be detected or where heat dissipation is crucial.

The limited availability of specialized Hastelloy grades tailored for specific environmental monitoring needs is another obstacle. While Hastelloy offers excellent general corrosion resistance, certain extreme or unique environmental conditions may require specially formulated alloys that are not readily available or are still in development stages.

Lastly, the long-term performance and reliability of Hastelloy in diverse environmental conditions remain areas of ongoing research. While laboratory tests and controlled environment studies show promising results, real-world, long-term exposure data in varied environmental monitoring applications are still being gathered. This lack of comprehensive long-term data can create uncertainty in predicting the lifespan and maintenance requirements of Hastelloy components in environmental monitoring systems, potentially affecting the planning and budgeting of long-term monitoring projects.

Another challenge lies in the complexity of manufacturing and fabricating Hastelloy parts. The material's unique properties that make it ideal for harsh environments also make it difficult to machine and form. This complexity can lead to longer production times and increased manufacturing costs, potentially causing delays in the deployment of environmental monitoring systems.

The weight of Hastelloy components presents an additional hurdle, especially in portable or remote sensing applications. While its density contributes to its strength, it can make monitoring devices heavier and less manageable in field operations. This weight issue becomes particularly problematic in applications requiring frequent transportation or installation in hard-to-reach locations.

Hastelloy's thermal properties, while beneficial in many industrial applications, can pose challenges in certain environmental monitoring scenarios. Its relatively low thermal conductivity compared to some other metals may affect the response time and accuracy of sensors in applications where rapid temperature changes need to be detected or where heat dissipation is crucial.

The limited availability of specialized Hastelloy grades tailored for specific environmental monitoring needs is another obstacle. While Hastelloy offers excellent general corrosion resistance, certain extreme or unique environmental conditions may require specially formulated alloys that are not readily available or are still in development stages.

Lastly, the long-term performance and reliability of Hastelloy in diverse environmental conditions remain areas of ongoing research. While laboratory tests and controlled environment studies show promising results, real-world, long-term exposure data in varied environmental monitoring applications are still being gathered. This lack of comprehensive long-term data can create uncertainty in predicting the lifespan and maintenance requirements of Hastelloy components in environmental monitoring systems, potentially affecting the planning and budgeting of long-term monitoring projects.

Existing Hastelloy Solutions for Harsh Environments

01 Composition and properties of Hastelloy alloys

Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in harsh environments. The specific composition and properties can be tailored for different applications, such as chemical processing, aerospace, and nuclear industries.- Composition and properties of Hastelloy alloys: Hastelloy is a family of nickel-based superalloys known for their excellent corrosion resistance and high-temperature strength. These alloys typically contain varying amounts of chromium, molybdenum, and other elements to enhance their performance in extreme environments. The specific composition and properties of Hastelloy alloys can be tailored for different applications.

- Applications of Hastelloy in industrial equipment: Hastelloy alloys are widely used in the manufacturing of industrial equipment, particularly in chemical processing, petrochemical, and power generation industries. They are employed in the construction of reactors, heat exchangers, valves, and piping systems where resistance to corrosive environments and high temperatures is crucial.

- Welding and fabrication techniques for Hastelloy: Specialized welding and fabrication techniques are required for Hastelloy alloys to maintain their unique properties. These may include specific heat treatment processes, controlled cooling rates, and the use of compatible filler materials. Proper fabrication methods are essential to ensure the integrity and performance of Hastelloy components in demanding applications.

- Surface treatment and coating of Hastelloy: Various surface treatment and coating techniques can be applied to Hastelloy components to further enhance their properties or provide additional functionality. These may include electroplating, thermal spraying, or the application of specialized coatings to improve wear resistance, reduce friction, or provide thermal insulation.

- Innovations in Hastelloy alloy development: Ongoing research and development efforts focus on improving the properties of Hastelloy alloys and developing new variants for specific applications. This includes optimizing alloy compositions, exploring novel processing techniques, and investigating the use of advanced manufacturing methods such as additive manufacturing for producing Hastelloy components with complex geometries.

02 Manufacturing processes for Hastelloy components

Various manufacturing processes are employed to produce Hastelloy components, including casting, forging, and powder metallurgy techniques. Advanced manufacturing methods, such as additive manufacturing or 3D printing, are also being explored to create complex Hastelloy parts with improved performance characteristics. Heat treatment and surface finishing processes are often applied to optimize the material's properties for specific applications.Expand Specific Solutions03 Applications of Hastelloy in corrosive environments

Hastelloy alloys are widely used in industries where corrosion resistance is critical. They are particularly suitable for applications involving aggressive chemicals, high temperatures, and pressure. Common applications include heat exchangers, chemical reactors, piping systems, and components in offshore oil and gas production. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking makes it valuable in these challenging environments.Expand Specific Solutions04 Welding and joining techniques for Hastelloy

Specialized welding and joining techniques are required for Hastelloy components due to their unique properties. These may include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and electron beam welding. Proper selection of filler materials, pre-heating, and post-weld heat treatment are crucial to maintain the alloy's corrosion resistance and mechanical properties in the welded areas. Advanced joining methods, such as diffusion bonding, may also be employed for certain applications.Expand Specific Solutions05 Surface treatment and coating of Hastelloy

Various surface treatment and coating techniques are applied to Hastelloy components to further enhance their performance or provide additional functionality. These may include electroplating, thermal spraying, or the application of specialized coatings to improve wear resistance, reduce friction, or provide thermal insulation. Surface treatments can also be used to modify the surface chemistry or microstructure of the alloy for specific applications, such as improving catalytic properties or enhancing biocompatibility.Expand Specific Solutions

Key Players in Hastelloy and Environmental Monitoring

The environmental monitoring systems market, including Hastelloy's role, is in a growth phase characterized by increasing demand for advanced materials in sensor technologies. The market size is expanding due to stricter environmental regulations and growing awareness of pollution impacts. Technologically, the field is evolving rapidly, with companies like Battelle Memorial Institute, NASA, and Helmholtz Zentrum München leading research efforts. Firms such as Network Integrity Systems and Air Liquide Advanced Technologies are developing innovative monitoring solutions, while academic institutions like California Institute of Technology contribute to fundamental research, indicating a maturing but still dynamic technological landscape.

China Institute of Water Resources & Hydropower Research

Technical Solution: The China Institute of Water Resources & Hydropower Research has incorporated Hastelloy into environmental monitoring systems for water quality assessment and hydropower plant operations. Their technology utilizes Hastelloy C-4 in sensors for monitoring dissolved oxygen and heavy metal concentrations in river systems and reservoirs[13]. The institute has developed Hastelloy-based monitoring equipment for use in hydroelectric turbines, capable of withstanding high-pressure and cavitation effects while providing real-time data on water quality and turbine efficiency[15]. Their systems also feature Hastelloy C-276 components in sediment monitoring devices, ensuring long-term reliability in abrasive environments[17].

Strengths: Excellent performance in aquatic environments, resistance to erosion and cavitation, and integration with hydropower infrastructure. Weaknesses: Limited applicability outside of water-related monitoring and potential for biofouling in certain applications.

Battelle Memorial Institute

Technical Solution: Battelle has developed innovative environmental monitoring systems incorporating Hastelloy for use in challenging industrial and natural environments. Their technology includes Hastelloy C-22 probes for long-term monitoring of groundwater contaminants in highly acidic or saline conditions[8]. Battelle's systems feature Hastelloy B-3 components in sensors designed for continuous monitoring of corrosive chemical processes in the petrochemical industry[10]. The institute has also pioneered the use of Hastelloy N alloy in nuclear waste monitoring applications, providing exceptional resistance to molten salt environments[12].

Strengths: Versatility across various challenging environments, long-term durability, and expertise in specialized applications. Weaknesses: High development costs and potential overengineering for less demanding applications.

Innovations in Hastelloy for Environmental Sensors

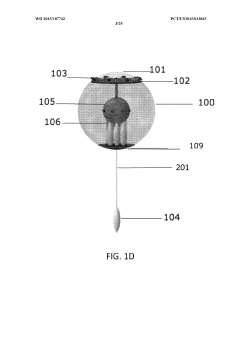

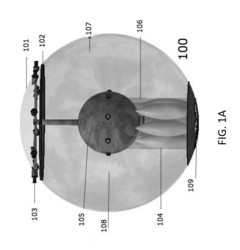

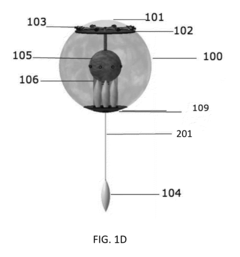

Controllable buoys and networked BUOY systems

PatentWO2015187742A2

Innovation

- The development of controllable and reconfigurable networked buoy systems equipped with communication devices, energy-providing units, propulsion units, and tethered underwater vehicles, which can move autonomously, share tasks, and adapt to environmental conditions, using peer-to-peer communication and decentralized control to optimize resource usage and coverage.

Controllable buoys and networked BUOY systems

PatentActiveUS20150344109A1

Innovation

- The development of controllable and reconfigurable networked buoy systems equipped with communication devices, energy-providing units, propulsion units, and tethered underwater vehicles, allowing for peer-to-peer communication and autonomous decision-making to optimize task distribution and resource usage, with buoys capable of moving between the surface and submerged positions based on sensor data and external instructions.

Environmental Regulations and Compliance Standards

Environmental regulations and compliance standards play a crucial role in shaping the use of Hastelloy in environmental monitoring systems. These regulations are designed to protect human health and the environment by setting limits on pollutant emissions and establishing guidelines for monitoring and reporting.

The Clean Air Act (CAA) and Clean Water Act (CWA) in the United States are two primary pieces of legislation that drive the need for robust environmental monitoring systems. These acts require industries to monitor and report emissions of various pollutants, necessitating the use of corrosion-resistant materials like Hastelloy in monitoring equipment.

The European Union's Industrial Emissions Directive (IED) sets similar standards for industrial activities, mandating continuous monitoring of emissions and the use of Best Available Techniques (BAT) in pollution control. This directive has led to increased adoption of advanced monitoring systems incorporating Hastelloy components.

International standards such as ISO 14001 for Environmental Management Systems also influence the design and implementation of monitoring systems. These standards emphasize the importance of accurate and reliable environmental data collection, further driving the demand for high-performance materials like Hastelloy.

Specific regulations for different industries also impact the use of Hastelloy in monitoring systems. For example, the petroleum industry must comply with EPA regulations on refinery emissions, which require continuous monitoring of sulfur dioxide and other pollutants. The chemical industry faces similar requirements under the EPA's Hazardous Air Pollutants (HAPs) regulations.

Compliance with these regulations often requires monitoring equipment to operate in harsh environments, exposed to corrosive chemicals and extreme temperatures. Hastelloy's exceptional corrosion resistance and high-temperature stability make it an ideal material for these applications, ensuring long-term reliability and accuracy of monitoring systems.

As environmental regulations become increasingly stringent, the demand for more sophisticated monitoring systems is growing. This trend is driving innovation in sensor technologies and materials science, with Hastelloy playing a key role in enabling more precise and durable monitoring solutions.

The global nature of environmental concerns has led to international agreements such as the Paris Agreement on climate change. These agreements are likely to result in more harmonized global standards for environmental monitoring, potentially expanding the use of advanced materials like Hastelloy in monitoring systems worldwide.

The Clean Air Act (CAA) and Clean Water Act (CWA) in the United States are two primary pieces of legislation that drive the need for robust environmental monitoring systems. These acts require industries to monitor and report emissions of various pollutants, necessitating the use of corrosion-resistant materials like Hastelloy in monitoring equipment.

The European Union's Industrial Emissions Directive (IED) sets similar standards for industrial activities, mandating continuous monitoring of emissions and the use of Best Available Techniques (BAT) in pollution control. This directive has led to increased adoption of advanced monitoring systems incorporating Hastelloy components.

International standards such as ISO 14001 for Environmental Management Systems also influence the design and implementation of monitoring systems. These standards emphasize the importance of accurate and reliable environmental data collection, further driving the demand for high-performance materials like Hastelloy.

Specific regulations for different industries also impact the use of Hastelloy in monitoring systems. For example, the petroleum industry must comply with EPA regulations on refinery emissions, which require continuous monitoring of sulfur dioxide and other pollutants. The chemical industry faces similar requirements under the EPA's Hazardous Air Pollutants (HAPs) regulations.

Compliance with these regulations often requires monitoring equipment to operate in harsh environments, exposed to corrosive chemicals and extreme temperatures. Hastelloy's exceptional corrosion resistance and high-temperature stability make it an ideal material for these applications, ensuring long-term reliability and accuracy of monitoring systems.

As environmental regulations become increasingly stringent, the demand for more sophisticated monitoring systems is growing. This trend is driving innovation in sensor technologies and materials science, with Hastelloy playing a key role in enabling more precise and durable monitoring solutions.

The global nature of environmental concerns has led to international agreements such as the Paris Agreement on climate change. These agreements are likely to result in more harmonized global standards for environmental monitoring, potentially expanding the use of advanced materials like Hastelloy in monitoring systems worldwide.

Lifecycle Assessment of Hastelloy in Monitoring Systems

The lifecycle assessment of Hastelloy in monitoring systems provides crucial insights into the environmental impact and sustainability of this high-performance alloy throughout its use in environmental monitoring applications. Hastelloy, known for its exceptional corrosion resistance and durability, plays a significant role in the longevity and reliability of monitoring equipment exposed to harsh environmental conditions.

The assessment begins with the raw material extraction phase, where the primary components of Hastelloy, including nickel, chromium, and molybdenum, are mined and processed. This stage typically involves energy-intensive operations and potential environmental impacts associated with mining activities. However, the long lifespan of Hastelloy components in monitoring systems often offsets these initial environmental costs over time.

During the manufacturing phase, the production of Hastelloy involves high-temperature melting and forming processes, which require substantial energy inputs. Advanced manufacturing techniques, such as precision casting and machining, are employed to create specialized components for monitoring systems. While energy-intensive, these processes contribute to the creation of highly durable and precise parts that are essential for accurate environmental monitoring.

The use phase of Hastelloy in monitoring systems is characterized by its exceptional performance in challenging environments. Its resistance to corrosion, high temperatures, and chemical degradation ensures extended operational lifetimes for monitoring equipment. This longevity reduces the frequency of replacements and maintenance, thereby minimizing the overall environmental impact associated with manufacturing and transportation of replacement parts.

End-of-life considerations for Hastelloy components in monitoring systems are particularly favorable. The alloy's high value and recyclability make it an excellent candidate for recovery and reuse. Advanced recycling technologies can effectively separate and reclaim the constituent elements of Hastelloy, allowing them to be reintegrated into new production cycles with minimal loss of quality.

When comparing the lifecycle impact of Hastelloy to alternative materials in monitoring systems, its superior durability often results in a lower overall environmental footprint. While initial production may have higher energy requirements, the extended service life and reduced need for replacements typically lead to net positive environmental outcomes over the long term.

The assessment begins with the raw material extraction phase, where the primary components of Hastelloy, including nickel, chromium, and molybdenum, are mined and processed. This stage typically involves energy-intensive operations and potential environmental impacts associated with mining activities. However, the long lifespan of Hastelloy components in monitoring systems often offsets these initial environmental costs over time.

During the manufacturing phase, the production of Hastelloy involves high-temperature melting and forming processes, which require substantial energy inputs. Advanced manufacturing techniques, such as precision casting and machining, are employed to create specialized components for monitoring systems. While energy-intensive, these processes contribute to the creation of highly durable and precise parts that are essential for accurate environmental monitoring.

The use phase of Hastelloy in monitoring systems is characterized by its exceptional performance in challenging environments. Its resistance to corrosion, high temperatures, and chemical degradation ensures extended operational lifetimes for monitoring equipment. This longevity reduces the frequency of replacements and maintenance, thereby minimizing the overall environmental impact associated with manufacturing and transportation of replacement parts.

End-of-life considerations for Hastelloy components in monitoring systems are particularly favorable. The alloy's high value and recyclability make it an excellent candidate for recovery and reuse. Advanced recycling technologies can effectively separate and reclaim the constituent elements of Hastelloy, allowing them to be reintegrated into new production cycles with minimal loss of quality.

When comparing the lifecycle impact of Hastelloy to alternative materials in monitoring systems, its superior durability often results in a lower overall environmental footprint. While initial production may have higher energy requirements, the extended service life and reduced need for replacements typically lead to net positive environmental outcomes over the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!