How Kevlar-Aided Technologies Foster Sustainable Development?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Evolution and Sustainability Goals

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has undergone significant evolution since its inception. Initially designed for use in tires, Kevlar's exceptional strength-to-weight ratio and heat-resistant properties quickly led to its adoption in various industries. The fiber's journey from a specialized material to a versatile component in sustainable technologies reflects the broader trend of innovative materials driving environmental progress.

The evolution of Kevlar has been marked by continuous improvements in its manufacturing process and the expansion of its applications. Early developments focused on enhancing its strength and durability, making it ideal for protective gear and aerospace components. As sustainability became a global priority, researchers began exploring Kevlar's potential in eco-friendly technologies.

One of the key sustainability goals associated with Kevlar-aided technologies is the reduction of energy consumption and carbon emissions. Kevlar's lightweight nature allows for the creation of more fuel-efficient vehicles and aircraft, directly contributing to decreased greenhouse gas emissions. In the automotive industry, Kevlar-reinforced components have enabled the production of lighter, more fuel-efficient cars without compromising safety standards.

Another significant sustainability objective is the extension of product lifecycles. Kevlar's durability and resistance to wear and tear mean that products incorporating this material last longer, reducing the need for frequent replacements and, consequently, minimizing waste. This aspect is particularly evident in industries such as construction and infrastructure, where Kevlar-reinforced materials can significantly extend the lifespan of buildings and bridges.

Water conservation represents another area where Kevlar-aided technologies are making strides towards sustainability. Advanced filtration systems utilizing Kevlar membranes have shown promise in improving water purification processes, potentially increasing access to clean water in water-scarce regions. These systems demonstrate higher efficiency and longevity compared to traditional filtration methods, aligning with global water sustainability goals.

The renewable energy sector has also benefited from Kevlar's unique properties. Wind turbine blades reinforced with Kevlar are lighter, stronger, and more resistant to fatigue, enhancing the overall efficiency and lifespan of wind energy systems. This application directly supports the transition to cleaner energy sources and the reduction of reliance on fossil fuels.

As research continues, new applications of Kevlar in sustainable technologies are emerging. From advanced recycling processes that utilize Kevlar to strengthen recycled plastics, to its use in developing more efficient and durable energy storage solutions, the material continues to play a crucial role in fostering sustainable development across multiple sectors.

The evolution of Kevlar has been marked by continuous improvements in its manufacturing process and the expansion of its applications. Early developments focused on enhancing its strength and durability, making it ideal for protective gear and aerospace components. As sustainability became a global priority, researchers began exploring Kevlar's potential in eco-friendly technologies.

One of the key sustainability goals associated with Kevlar-aided technologies is the reduction of energy consumption and carbon emissions. Kevlar's lightweight nature allows for the creation of more fuel-efficient vehicles and aircraft, directly contributing to decreased greenhouse gas emissions. In the automotive industry, Kevlar-reinforced components have enabled the production of lighter, more fuel-efficient cars without compromising safety standards.

Another significant sustainability objective is the extension of product lifecycles. Kevlar's durability and resistance to wear and tear mean that products incorporating this material last longer, reducing the need for frequent replacements and, consequently, minimizing waste. This aspect is particularly evident in industries such as construction and infrastructure, where Kevlar-reinforced materials can significantly extend the lifespan of buildings and bridges.

Water conservation represents another area where Kevlar-aided technologies are making strides towards sustainability. Advanced filtration systems utilizing Kevlar membranes have shown promise in improving water purification processes, potentially increasing access to clean water in water-scarce regions. These systems demonstrate higher efficiency and longevity compared to traditional filtration methods, aligning with global water sustainability goals.

The renewable energy sector has also benefited from Kevlar's unique properties. Wind turbine blades reinforced with Kevlar are lighter, stronger, and more resistant to fatigue, enhancing the overall efficiency and lifespan of wind energy systems. This application directly supports the transition to cleaner energy sources and the reduction of reliance on fossil fuels.

As research continues, new applications of Kevlar in sustainable technologies are emerging. From advanced recycling processes that utilize Kevlar to strengthen recycled plastics, to its use in developing more efficient and durable energy storage solutions, the material continues to play a crucial role in fostering sustainable development across multiple sectors.

Market Demand for Sustainable Kevlar Applications

The market demand for sustainable Kevlar applications has been steadily growing in recent years, driven by increasing environmental awareness and the need for more eco-friendly materials across various industries. Kevlar, known for its exceptional strength-to-weight ratio and durability, is finding new applications in sustainable product development and green technologies.

In the automotive sector, there is a rising demand for lightweight materials to improve fuel efficiency and reduce emissions. Kevlar-reinforced composites are being increasingly used in vehicle body parts, reducing overall weight while maintaining structural integrity. This trend is expected to continue as automakers strive to meet stringent environmental regulations and consumer preferences for greener vehicles.

The renewable energy industry is another key driver of sustainable Kevlar applications. Wind turbine blades reinforced with Kevlar fibers offer improved strength and longevity, enhancing the efficiency and lifespan of wind energy systems. As the global push for clean energy intensifies, the demand for Kevlar in this sector is projected to grow significantly.

In the construction industry, there is a growing interest in sustainable building materials. Kevlar-reinforced concrete and other construction materials offer enhanced durability and reduced maintenance requirements, leading to more sustainable infrastructure. This application is particularly relevant in regions prone to natural disasters, where resilient building materials are crucial.

The aerospace industry is also exploring sustainable Kevlar applications to reduce aircraft weight and improve fuel efficiency. Kevlar composites are being used in interior components and non-structural parts, contributing to overall sustainability efforts in aviation.

Consumer goods manufacturers are increasingly incorporating Kevlar into products designed for longevity and recyclability. From durable outdoor gear to long-lasting consumer electronics, Kevlar's properties align well with the growing consumer demand for sustainable, high-quality products that reduce waste and environmental impact.

The textile industry is witnessing a surge in demand for sustainable fabrics. Kevlar blends are being developed to create durable, long-lasting textiles that reduce the need for frequent replacements, addressing the issue of fast fashion and its environmental consequences.

As circular economy principles gain traction, there is growing interest in developing recycling technologies for Kevlar-based products. This trend is likely to further boost the material's appeal in sustainable applications, as it addresses end-of-life concerns and promotes a closed-loop system.

The market for sustainable Kevlar applications is expected to expand across various geographical regions. Developed economies in North America and Europe are currently leading in adoption, driven by stringent environmental regulations and consumer awareness. However, emerging economies in Asia and Latin America are showing increasing interest as they balance rapid industrialization with sustainability goals.

In the automotive sector, there is a rising demand for lightweight materials to improve fuel efficiency and reduce emissions. Kevlar-reinforced composites are being increasingly used in vehicle body parts, reducing overall weight while maintaining structural integrity. This trend is expected to continue as automakers strive to meet stringent environmental regulations and consumer preferences for greener vehicles.

The renewable energy industry is another key driver of sustainable Kevlar applications. Wind turbine blades reinforced with Kevlar fibers offer improved strength and longevity, enhancing the efficiency and lifespan of wind energy systems. As the global push for clean energy intensifies, the demand for Kevlar in this sector is projected to grow significantly.

In the construction industry, there is a growing interest in sustainable building materials. Kevlar-reinforced concrete and other construction materials offer enhanced durability and reduced maintenance requirements, leading to more sustainable infrastructure. This application is particularly relevant in regions prone to natural disasters, where resilient building materials are crucial.

The aerospace industry is also exploring sustainable Kevlar applications to reduce aircraft weight and improve fuel efficiency. Kevlar composites are being used in interior components and non-structural parts, contributing to overall sustainability efforts in aviation.

Consumer goods manufacturers are increasingly incorporating Kevlar into products designed for longevity and recyclability. From durable outdoor gear to long-lasting consumer electronics, Kevlar's properties align well with the growing consumer demand for sustainable, high-quality products that reduce waste and environmental impact.

The textile industry is witnessing a surge in demand for sustainable fabrics. Kevlar blends are being developed to create durable, long-lasting textiles that reduce the need for frequent replacements, addressing the issue of fast fashion and its environmental consequences.

As circular economy principles gain traction, there is growing interest in developing recycling technologies for Kevlar-based products. This trend is likely to further boost the material's appeal in sustainable applications, as it addresses end-of-life concerns and promotes a closed-loop system.

The market for sustainable Kevlar applications is expected to expand across various geographical regions. Developed economies in North America and Europe are currently leading in adoption, driven by stringent environmental regulations and consumer awareness. However, emerging economies in Asia and Latin America are showing increasing interest as they balance rapid industrialization with sustainability goals.

Current State of Kevlar-Aided Sustainable Technologies

Kevlar-aided technologies have made significant strides in fostering sustainable development across various sectors. The current state of these technologies showcases a blend of innovative applications and ongoing research efforts aimed at enhancing sustainability.

In the construction industry, Kevlar-reinforced concrete has emerged as a promising solution for creating more durable and energy-efficient structures. This composite material exhibits superior strength-to-weight ratio, reducing the overall mass of buildings while maintaining structural integrity. Consequently, it leads to decreased energy consumption in both construction and long-term building maintenance.

The renewable energy sector has also benefited from Kevlar-based innovations. Wind turbine blades incorporating Kevlar fibers demonstrate enhanced durability and performance, extending the lifespan of wind energy systems. This advancement contributes to the increased efficiency and cost-effectiveness of renewable energy production, supporting the global transition towards cleaner power sources.

In the automotive industry, Kevlar-aided technologies are playing a crucial role in developing lightweight vehicles. By incorporating Kevlar composites into car bodies and components, manufacturers can significantly reduce vehicle weight without compromising safety. This weight reduction translates to improved fuel efficiency and reduced carbon emissions, aligning with sustainable transportation goals.

The water management sector has seen the implementation of Kevlar-reinforced pipes and filtration systems. These applications offer enhanced durability and resistance to corrosion, leading to more efficient water distribution networks and treatment facilities. The extended lifespan of these infrastructures contributes to resource conservation and reduced maintenance requirements.

Kevlar-based materials are also making inroads in sustainable agriculture. Protective coverings and netting made from Kevlar fibers provide durable and lightweight solutions for crop protection against pests and adverse weather conditions. This application helps in reducing the use of pesticides and improving crop yields, supporting sustainable farming practices.

In the realm of waste management, Kevlar-enhanced recycling equipment has shown promise in improving the efficiency and durability of recycling processes. The wear-resistant properties of Kevlar contribute to longer-lasting machinery, reducing downtime and increasing the overall effectiveness of recycling operations.

Research and development efforts continue to explore new avenues for Kevlar-aided sustainable technologies. Current focus areas include biodegradable Kevlar composites, which aim to address end-of-life disposal concerns, and the integration of Kevlar with other advanced materials to create hybrid solutions with enhanced sustainability profiles.

While these advancements are promising, challenges remain in scaling up production, reducing costs, and further improving the environmental footprint of Kevlar manufacturing processes. Ongoing collaborations between industry, academia, and research institutions are crucial in addressing these challenges and unlocking the full potential of Kevlar-aided technologies in fostering sustainable development.

In the construction industry, Kevlar-reinforced concrete has emerged as a promising solution for creating more durable and energy-efficient structures. This composite material exhibits superior strength-to-weight ratio, reducing the overall mass of buildings while maintaining structural integrity. Consequently, it leads to decreased energy consumption in both construction and long-term building maintenance.

The renewable energy sector has also benefited from Kevlar-based innovations. Wind turbine blades incorporating Kevlar fibers demonstrate enhanced durability and performance, extending the lifespan of wind energy systems. This advancement contributes to the increased efficiency and cost-effectiveness of renewable energy production, supporting the global transition towards cleaner power sources.

In the automotive industry, Kevlar-aided technologies are playing a crucial role in developing lightweight vehicles. By incorporating Kevlar composites into car bodies and components, manufacturers can significantly reduce vehicle weight without compromising safety. This weight reduction translates to improved fuel efficiency and reduced carbon emissions, aligning with sustainable transportation goals.

The water management sector has seen the implementation of Kevlar-reinforced pipes and filtration systems. These applications offer enhanced durability and resistance to corrosion, leading to more efficient water distribution networks and treatment facilities. The extended lifespan of these infrastructures contributes to resource conservation and reduced maintenance requirements.

Kevlar-based materials are also making inroads in sustainable agriculture. Protective coverings and netting made from Kevlar fibers provide durable and lightweight solutions for crop protection against pests and adverse weather conditions. This application helps in reducing the use of pesticides and improving crop yields, supporting sustainable farming practices.

In the realm of waste management, Kevlar-enhanced recycling equipment has shown promise in improving the efficiency and durability of recycling processes. The wear-resistant properties of Kevlar contribute to longer-lasting machinery, reducing downtime and increasing the overall effectiveness of recycling operations.

Research and development efforts continue to explore new avenues for Kevlar-aided sustainable technologies. Current focus areas include biodegradable Kevlar composites, which aim to address end-of-life disposal concerns, and the integration of Kevlar with other advanced materials to create hybrid solutions with enhanced sustainability profiles.

While these advancements are promising, challenges remain in scaling up production, reducing costs, and further improving the environmental footprint of Kevlar manufacturing processes. Ongoing collaborations between industry, academia, and research institutions are crucial in addressing these challenges and unlocking the full potential of Kevlar-aided technologies in fostering sustainable development.

Existing Sustainable Kevlar Applications

01 Kevlar-reinforced composite materials

Kevlar fibers are incorporated into various composite materials to enhance their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The integration of Kevlar improves the overall performance and lightweight properties of the resulting materials.- Kevlar-reinforced composite materials: Kevlar fibers are incorporated into various composite materials to enhance their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The addition of Kevlar significantly improves the mechanical properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is extensively used in the development of personal protective equipment, including bulletproof vests, helmets, and other body armor. The high tensile strength and lightweight nature of Kevlar make it ideal for creating protective gear that offers superior ballistic protection while maintaining user comfort and mobility.

- Kevlar-enhanced textiles and fabrics: Kevlar fibers are integrated into various textiles and fabrics to create high-performance materials with improved tear resistance, abrasion resistance, and heat resistance. These enhanced textiles find applications in protective clothing, outdoor gear, and industrial workwear.

- Kevlar in aerospace and automotive applications: Kevlar is utilized in aerospace and automotive industries for its lightweight and high-strength properties. It is used in the construction of aircraft components, spacecraft heat shields, and automotive parts to reduce weight while maintaining structural integrity and improving fuel efficiency.

- Kevlar-based nanotechnology: Research is being conducted on the use of Kevlar at the nanoscale level to develop advanced materials with unique properties. Kevlar nanofibers and nanocomposites are being explored for applications in electronics, energy storage, and biomedical fields, offering potential for innovative technological advancements.

02 Kevlar-based protective gear and clothing

Kevlar is utilized in the development of advanced protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. The high tensile strength and heat-resistant properties of Kevlar make it ideal for personal protection equipment in military, law enforcement, and industrial applications.Expand Specific Solutions03 Kevlar-enhanced electronic devices

Kevlar is incorporated into electronic devices to improve their durability and resistance to physical damage. This technology is applied in smartphone cases, laptop shells, and other portable electronic equipment to enhance their protection against impacts, scratches, and everyday wear and tear.Expand Specific Solutions04 Kevlar-based filtration and separation technologies

Kevlar fibers are used in advanced filtration and separation technologies for industrial and environmental applications. The chemical resistance and strength of Kevlar make it suitable for creating high-performance filters and membranes used in water treatment, air purification, and chemical processing industries.Expand Specific Solutions05 Kevlar-reinforced construction materials

Kevlar is incorporated into construction materials to enhance their strength, durability, and fire resistance. This technology is applied in the development of reinforced concrete, structural panels, and fire-resistant building components. The use of Kevlar in construction materials improves the overall safety and longevity of buildings and infrastructure.Expand Specific Solutions

Key Players in Kevlar-Based Sustainable Solutions

The development of Kevlar-aided technologies for sustainable development is in a growth phase, with increasing market size and technological advancements. The global market for these technologies is expanding, driven by the demand for lightweight, high-strength materials in various industries. Technologically, the field is progressing rapidly, with research institutions like Massachusetts Institute of Technology, Sichuan University, and Indian Institutes of Technology leading academic efforts. Companies such as Teijin Ltd. and Bridgestone EMEA are actively developing commercial applications, while government agencies like the Council of Scientific & Industrial Research are supporting research initiatives. The collaboration between academia, industry, and government is accelerating the maturation of Kevlar-based sustainable technologies.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has leveraged Kevlar-aided technologies to promote sustainable development in aerospace and defense sectors. They've developed lightweight Kevlar composites for aircraft structures, significantly reducing fuel consumption and emissions[1]. The company has also created Kevlar-based protective gear that is not only more effective but also recyclable, reducing waste in military operations[2]. In the field of space exploration, Northrop Grumman has utilized Kevlar in satellite components and space habitats, enhancing durability while minimizing material usage[3]. Additionally, they've implemented Kevlar in advanced sensor technologies for environmental monitoring, aiding in climate change research and natural resource management[4].

Strengths: Extensive experience in high-tech applications, strong R&D capabilities, integration of sustainability in defense technologies. Weaknesses: Primary focus on defense sector may limit broader applications, potential high costs of technologies.

Council of Scientific & Industrial Research

Technical Solution: CSIR has been actively developing Kevlar-aided technologies for sustainable development, with a focus on applications relevant to developing countries. They've created Kevlar-reinforced materials for affordable, disaster-resistant housing, improving resilience in vulnerable communities[1]. CSIR has also developed Kevlar-based water filtration systems tailored for rural areas, providing clean water access with minimal energy requirements[2]. In the agricultural sector, they've utilized Kevlar in the design of lightweight, durable farming equipment, enhancing productivity while reducing resource consumption[3]. Additionally, CSIR has explored Kevlar applications in renewable energy, developing reinforced components for solar panels and wind turbines to increase their lifespan and efficiency in harsh environments[4].

Strengths: Focus on practical, cost-effective solutions for developing regions, strong emphasis on social impact. Weaknesses: May face challenges in scaling up technologies, potential limitations in accessing cutting-edge research facilities.

Innovative Kevlar Sustainability Patents

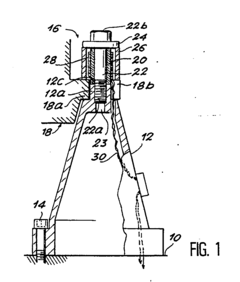

Development of fuel tank composite using kevlar fiber

PatentPendingIN202141050987A

Innovation

- The use of Kevlar fiber, which provides thermal protection up to 800 degrees Fahrenheit, is proposed to prevent fuel evaporation in fuel tanks.

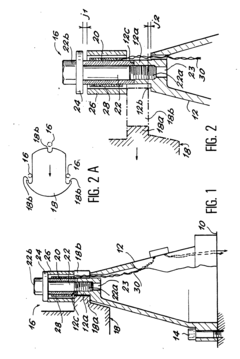

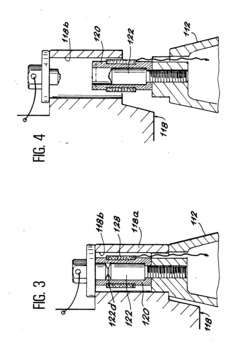

Device for a temporary connection, especially for the appendix of an artificial satellite and process of opening this connection

PatentInactiveEP0402263A1

Innovation

- A temporary connection device utilizing a holding mechanism with a release member made of shape-memory material that changes shape or dimensions when heated above its structural transformation temperature, allowing for controlled elongation or breakage of tie rods or tilting brackets, eliminating mechanical tension and enabling relative movement between elements.

Environmental Impact Assessment of Kevlar Technologies

The environmental impact assessment of Kevlar technologies reveals a complex interplay between sustainability benefits and potential drawbacks. Kevlar, a high-strength synthetic fiber, contributes significantly to sustainable development through its durability and lightweight properties. These characteristics enable the production of long-lasting, energy-efficient products across various industries.

In the automotive sector, Kevlar-reinforced components reduce vehicle weight, leading to improved fuel efficiency and decreased carbon emissions. This aligns with global efforts to combat climate change and reduce dependency on fossil fuels. Similarly, in aerospace applications, Kevlar's use in aircraft construction results in lighter planes, reducing fuel consumption and environmental impact during flight operations.

Kevlar's durability extends the lifespan of products, reducing the need for frequent replacements and thereby minimizing waste generation. This is particularly evident in industries such as protective gear, where Kevlar-based equipment offers superior longevity compared to traditional materials. The reduced frequency of replacement translates to lower resource consumption and decreased environmental burden associated with manufacturing and disposal processes.

However, the production of Kevlar involves energy-intensive processes and the use of chemical solvents, which can have negative environmental implications. The manufacturing process requires careful management to mitigate potential air and water pollution. Additionally, the non-biodegradable nature of Kevlar poses challenges for end-of-life disposal, necessitating the development of effective recycling and upcycling strategies.

Efforts are underway to address these environmental concerns. Research into more sustainable production methods, including the use of bio-based precursors and green solvents, shows promise in reducing the environmental footprint of Kevlar manufacturing. Furthermore, advancements in recycling technologies are enabling the recovery and reuse of Kevlar fibers from end-of-life products, contributing to a more circular economy.

The application of Kevlar in renewable energy technologies, such as wind turbine blades, further underscores its role in fostering sustainable development. The material's high strength-to-weight ratio enables the construction of larger, more efficient wind turbines, enhancing clean energy production capabilities.

In conclusion, while Kevlar technologies present certain environmental challenges, their overall contribution to sustainable development is significant. The material's ability to enhance energy efficiency, extend product lifespans, and support renewable energy infrastructure outweighs its production-related environmental impacts. Continued research and innovation in sustainable manufacturing and recycling processes will be crucial in maximizing the positive environmental impact of Kevlar-aided technologies in the future.

In the automotive sector, Kevlar-reinforced components reduce vehicle weight, leading to improved fuel efficiency and decreased carbon emissions. This aligns with global efforts to combat climate change and reduce dependency on fossil fuels. Similarly, in aerospace applications, Kevlar's use in aircraft construction results in lighter planes, reducing fuel consumption and environmental impact during flight operations.

Kevlar's durability extends the lifespan of products, reducing the need for frequent replacements and thereby minimizing waste generation. This is particularly evident in industries such as protective gear, where Kevlar-based equipment offers superior longevity compared to traditional materials. The reduced frequency of replacement translates to lower resource consumption and decreased environmental burden associated with manufacturing and disposal processes.

However, the production of Kevlar involves energy-intensive processes and the use of chemical solvents, which can have negative environmental implications. The manufacturing process requires careful management to mitigate potential air and water pollution. Additionally, the non-biodegradable nature of Kevlar poses challenges for end-of-life disposal, necessitating the development of effective recycling and upcycling strategies.

Efforts are underway to address these environmental concerns. Research into more sustainable production methods, including the use of bio-based precursors and green solvents, shows promise in reducing the environmental footprint of Kevlar manufacturing. Furthermore, advancements in recycling technologies are enabling the recovery and reuse of Kevlar fibers from end-of-life products, contributing to a more circular economy.

The application of Kevlar in renewable energy technologies, such as wind turbine blades, further underscores its role in fostering sustainable development. The material's high strength-to-weight ratio enables the construction of larger, more efficient wind turbines, enhancing clean energy production capabilities.

In conclusion, while Kevlar technologies present certain environmental challenges, their overall contribution to sustainable development is significant. The material's ability to enhance energy efficiency, extend product lifespans, and support renewable energy infrastructure outweighs its production-related environmental impacts. Continued research and innovation in sustainable manufacturing and recycling processes will be crucial in maximizing the positive environmental impact of Kevlar-aided technologies in the future.

Circular Economy Strategies for Kevlar Products

Circular economy strategies for Kevlar products are pivotal in fostering sustainable development through Kevlar-aided technologies. These strategies focus on maximizing resource efficiency, minimizing waste, and extending the lifecycle of Kevlar-based materials and products.

One key approach is the implementation of take-back programs for end-of-life Kevlar products. Manufacturers can establish collection systems to recover used Kevlar items, such as bulletproof vests, automotive parts, and industrial equipment. This initiative not only reduces landfill waste but also provides a steady stream of recyclable materials for reprocessing.

Advanced recycling technologies play a crucial role in the circular economy of Kevlar. Chemical recycling methods, such as depolymerization, can break down Kevlar fibers into their constituent monomers. These recovered monomers can then be used to produce new Kevlar fibers, maintaining the material's high-performance characteristics. Mechanical recycling techniques, involving shredding and repurposing, offer another avenue for transforming Kevlar waste into valuable secondary products.

Design for disassembly is another essential strategy in the circular economy of Kevlar products. By incorporating modular designs and easily separable components, manufacturers can facilitate the recovery and recycling of Kevlar materials at the end of a product's life. This approach not only simplifies the recycling process but also enables the replacement of worn parts, extending the overall lifespan of Kevlar-based products.

Upcycling initiatives present innovative opportunities for repurposing Kevlar materials. For instance, reclaimed Kevlar fibers can be incorporated into composite materials for construction, automotive, or aerospace applications. This not only diverts waste from landfills but also creates new value streams for recycled Kevlar.

Collaboration across the value chain is crucial for implementing effective circular economy strategies. Partnerships between Kevlar manufacturers, product designers, recycling facilities, and end-users can foster innovation in recycling technologies and create closed-loop systems for Kevlar materials.

By adopting these circular economy strategies, the Kevlar industry can significantly reduce its environmental footprint while maintaining the material's high-performance capabilities. This approach not only aligns with sustainable development goals but also presents opportunities for innovation and new business models in the Kevlar sector.

One key approach is the implementation of take-back programs for end-of-life Kevlar products. Manufacturers can establish collection systems to recover used Kevlar items, such as bulletproof vests, automotive parts, and industrial equipment. This initiative not only reduces landfill waste but also provides a steady stream of recyclable materials for reprocessing.

Advanced recycling technologies play a crucial role in the circular economy of Kevlar. Chemical recycling methods, such as depolymerization, can break down Kevlar fibers into their constituent monomers. These recovered monomers can then be used to produce new Kevlar fibers, maintaining the material's high-performance characteristics. Mechanical recycling techniques, involving shredding and repurposing, offer another avenue for transforming Kevlar waste into valuable secondary products.

Design for disassembly is another essential strategy in the circular economy of Kevlar products. By incorporating modular designs and easily separable components, manufacturers can facilitate the recovery and recycling of Kevlar materials at the end of a product's life. This approach not only simplifies the recycling process but also enables the replacement of worn parts, extending the overall lifespan of Kevlar-based products.

Upcycling initiatives present innovative opportunities for repurposing Kevlar materials. For instance, reclaimed Kevlar fibers can be incorporated into composite materials for construction, automotive, or aerospace applications. This not only diverts waste from landfills but also creates new value streams for recycled Kevlar.

Collaboration across the value chain is crucial for implementing effective circular economy strategies. Partnerships between Kevlar manufacturers, product designers, recycling facilities, and end-users can foster innovation in recycling technologies and create closed-loop systems for Kevlar materials.

By adopting these circular economy strategies, the Kevlar industry can significantly reduce its environmental footprint while maintaining the material's high-performance capabilities. This approach not only aligns with sustainable development goals but also presents opportunities for innovation and new business models in the Kevlar sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!