How Kevlar Transforms Protective Technologies in Healthcare?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Healthcare: Evolution and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized protective technologies across various industries, including healthcare. Initially designed for use in tires, Kevlar's exceptional strength-to-weight ratio and heat-resistant properties quickly found applications in body armor and other protective equipment. The evolution of Kevlar in healthcare has been driven by the increasing need for advanced protective solutions in medical settings.

The journey of Kevlar in healthcare began with its use in personal protective equipment (PPE) for medical professionals. As healthcare workers faced growing risks from sharp objects and infectious materials, Kevlar-reinforced gloves and protective clothing emerged as crucial safeguards. These innovations significantly reduced the incidence of needlestick injuries and exposure to hazardous substances, marking a pivotal moment in healthcare safety.

Over time, the applications of Kevlar in healthcare expanded beyond PPE. Researchers and engineers recognized its potential in medical devices and equipment. Kevlar's durability and flexibility made it an ideal material for reinforcing catheters, guidewires, and other invasive medical tools. This enhancement improved the performance and safety of these devices, enabling more precise and less traumatic medical procedures.

The objectives of incorporating Kevlar into healthcare technologies have evolved alongside advancements in medical science. One primary goal has been to develop lighter, more comfortable protective gear that does not compromise on safety. This has led to the creation of hybrid materials that combine Kevlar with other advanced fibers, resulting in PPE that offers superior protection while reducing user fatigue during long procedures or in high-stress environments.

Another significant objective has been to leverage Kevlar's unique properties to create innovative medical solutions. For instance, researchers have explored using Kevlar-based materials in tissue engineering and regenerative medicine. The fiber's biocompatibility and strength make it a promising candidate for scaffolds in tissue repair and artificial organ development, potentially revolutionizing transplant medicine and wound healing.

As healthcare faces new challenges, such as emerging infectious diseases and the need for more sustainable practices, the objectives for Kevlar in medical applications continue to evolve. Current research focuses on developing Kevlar-based materials with antimicrobial properties, enhancing the fiber's ability to protect against a wider range of pathogens. Additionally, efforts are underway to improve the recyclability and environmental impact of Kevlar-containing medical products, aligning with the growing emphasis on sustainability in healthcare.

The ongoing evolution of Kevlar in healthcare underscores its transformative potential. From its initial use in basic protective gear to its current role in cutting-edge medical technologies, Kevlar continues to push the boundaries of what's possible in healthcare protection and innovation. As research progresses, the objectives for Kevlar in healthcare are likely to expand further, promising even more advanced and effective protective technologies for the medical field.

The journey of Kevlar in healthcare began with its use in personal protective equipment (PPE) for medical professionals. As healthcare workers faced growing risks from sharp objects and infectious materials, Kevlar-reinforced gloves and protective clothing emerged as crucial safeguards. These innovations significantly reduced the incidence of needlestick injuries and exposure to hazardous substances, marking a pivotal moment in healthcare safety.

Over time, the applications of Kevlar in healthcare expanded beyond PPE. Researchers and engineers recognized its potential in medical devices and equipment. Kevlar's durability and flexibility made it an ideal material for reinforcing catheters, guidewires, and other invasive medical tools. This enhancement improved the performance and safety of these devices, enabling more precise and less traumatic medical procedures.

The objectives of incorporating Kevlar into healthcare technologies have evolved alongside advancements in medical science. One primary goal has been to develop lighter, more comfortable protective gear that does not compromise on safety. This has led to the creation of hybrid materials that combine Kevlar with other advanced fibers, resulting in PPE that offers superior protection while reducing user fatigue during long procedures or in high-stress environments.

Another significant objective has been to leverage Kevlar's unique properties to create innovative medical solutions. For instance, researchers have explored using Kevlar-based materials in tissue engineering and regenerative medicine. The fiber's biocompatibility and strength make it a promising candidate for scaffolds in tissue repair and artificial organ development, potentially revolutionizing transplant medicine and wound healing.

As healthcare faces new challenges, such as emerging infectious diseases and the need for more sustainable practices, the objectives for Kevlar in medical applications continue to evolve. Current research focuses on developing Kevlar-based materials with antimicrobial properties, enhancing the fiber's ability to protect against a wider range of pathogens. Additionally, efforts are underway to improve the recyclability and environmental impact of Kevlar-containing medical products, aligning with the growing emphasis on sustainability in healthcare.

The ongoing evolution of Kevlar in healthcare underscores its transformative potential. From its initial use in basic protective gear to its current role in cutting-edge medical technologies, Kevlar continues to push the boundaries of what's possible in healthcare protection and innovation. As research progresses, the objectives for Kevlar in healthcare are likely to expand further, promising even more advanced and effective protective technologies for the medical field.

Market Demand Analysis for Kevlar-Based Medical Protection

The market demand for Kevlar-based medical protection has been steadily increasing, driven by the growing awareness of healthcare worker safety and the need for advanced protective equipment in medical settings. Kevlar, known for its exceptional strength-to-weight ratio and heat-resistant properties, has found significant applications in healthcare protective technologies.

In recent years, the global healthcare personal protective equipment (PPE) market has experienced substantial growth, with a particular emphasis on high-performance materials like Kevlar. The COVID-19 pandemic has further accelerated this trend, highlighting the critical importance of effective protective gear for healthcare professionals.

Kevlar-based medical protection products are primarily sought after in high-risk medical environments, such as emergency rooms, intensive care units, and infectious disease wards. These areas require protective gear that can withstand punctures, cuts, and extreme conditions while maintaining flexibility and comfort for extended wear.

The market demand for Kevlar-enhanced medical gloves has seen a significant uptick. These gloves offer superior protection against needlestick injuries and sharp objects, addressing a major concern in healthcare settings. Hospitals and medical facilities are increasingly investing in these advanced gloves to reduce the risk of injury and infection among their staff.

Kevlar-reinforced surgical gowns and aprons have also gained traction in the market. These garments provide enhanced protection against fluid penetration and potential contamination, making them ideal for use in surgical procedures and when handling hazardous materials.

The demand for Kevlar-based face shields and masks has surged, particularly in response to airborne infectious diseases. These products offer improved durability and impact resistance compared to traditional alternatives, ensuring better protection for healthcare workers in high-risk environments.

In the field of emergency medical services, there is a growing interest in Kevlar-enhanced protective gear for paramedics and first responders. This includes reinforced uniforms, helmets, and body armor designed to protect against both physical hazards and potential chemical or biological threats encountered in the field.

The market for Kevlar-based medical protection extends beyond direct healthcare applications. Research laboratories, pharmaceutical manufacturing facilities, and biotechnology companies are also driving demand for high-performance protective equipment to ensure the safety of their personnel.

As healthcare institutions worldwide continue to prioritize worker safety and invest in advanced protective technologies, the market for Kevlar-based medical protection is expected to expand further. This growth is likely to be accompanied by ongoing research and development efforts to optimize Kevlar's properties for specific medical applications, potentially leading to new and innovative protective products in the coming years.

In recent years, the global healthcare personal protective equipment (PPE) market has experienced substantial growth, with a particular emphasis on high-performance materials like Kevlar. The COVID-19 pandemic has further accelerated this trend, highlighting the critical importance of effective protective gear for healthcare professionals.

Kevlar-based medical protection products are primarily sought after in high-risk medical environments, such as emergency rooms, intensive care units, and infectious disease wards. These areas require protective gear that can withstand punctures, cuts, and extreme conditions while maintaining flexibility and comfort for extended wear.

The market demand for Kevlar-enhanced medical gloves has seen a significant uptick. These gloves offer superior protection against needlestick injuries and sharp objects, addressing a major concern in healthcare settings. Hospitals and medical facilities are increasingly investing in these advanced gloves to reduce the risk of injury and infection among their staff.

Kevlar-reinforced surgical gowns and aprons have also gained traction in the market. These garments provide enhanced protection against fluid penetration and potential contamination, making them ideal for use in surgical procedures and when handling hazardous materials.

The demand for Kevlar-based face shields and masks has surged, particularly in response to airborne infectious diseases. These products offer improved durability and impact resistance compared to traditional alternatives, ensuring better protection for healthcare workers in high-risk environments.

In the field of emergency medical services, there is a growing interest in Kevlar-enhanced protective gear for paramedics and first responders. This includes reinforced uniforms, helmets, and body armor designed to protect against both physical hazards and potential chemical or biological threats encountered in the field.

The market for Kevlar-based medical protection extends beyond direct healthcare applications. Research laboratories, pharmaceutical manufacturing facilities, and biotechnology companies are also driving demand for high-performance protective equipment to ensure the safety of their personnel.

As healthcare institutions worldwide continue to prioritize worker safety and invest in advanced protective technologies, the market for Kevlar-based medical protection is expected to expand further. This growth is likely to be accompanied by ongoing research and development efforts to optimize Kevlar's properties for specific medical applications, potentially leading to new and innovative protective products in the coming years.

Current State and Challenges of Kevlar in Healthcare

Kevlar, a high-strength synthetic fiber, has made significant inroads into healthcare protective technologies. Its current state in the healthcare sector is characterized by a growing adoption in various applications, ranging from personal protective equipment (PPE) to medical devices. The material's exceptional strength-to-weight ratio and heat-resistant properties have positioned it as a valuable asset in enhancing safety measures for healthcare professionals and patients alike.

In the realm of PPE, Kevlar is increasingly being incorporated into protective garments, gloves, and face shields. These Kevlar-enhanced products offer improved puncture and cut resistance, crucial for healthcare workers handling sharp instruments or working in high-risk environments. The material's durability also contributes to the longevity of protective gear, potentially reducing replacement costs and waste in healthcare settings.

Medical device manufacturers have begun exploring Kevlar's potential in developing more robust and reliable equipment. Its application in surgical instruments, for instance, has shown promise in creating lighter yet stronger tools that can withstand repeated sterilization processes without compromising structural integrity. Additionally, Kevlar's use in prosthetics and orthotics has opened new avenues for creating more durable and comfortable assistive devices for patients.

Despite these advancements, the integration of Kevlar in healthcare faces several challenges. One significant hurdle is the cost factor. Kevlar remains a relatively expensive material compared to traditional alternatives, which can limit its widespread adoption, particularly in resource-constrained healthcare systems. This cost barrier necessitates a careful balance between the material's benefits and economic feasibility.

Another challenge lies in the regulatory landscape. As a relatively new material in healthcare applications, Kevlar-based products often require extensive testing and certification to meet stringent medical standards. This process can be time-consuming and costly, potentially slowing down innovation and market entry for new Kevlar-enhanced healthcare solutions.

The biocompatibility of Kevlar in certain medical applications also presents a challenge. While the material is generally considered safe for external use, its long-term effects in internal medical applications are still under investigation. This uncertainty can limit Kevlar's use in certain invasive medical devices or implants, requiring further research and development to address potential biocompatibility concerns.

Lastly, the manufacturing and processing of Kevlar for healthcare applications pose technical challenges. Adapting Kevlar's properties to meet specific medical requirements often involves complex manufacturing processes. Ensuring consistent quality, especially in applications where precision is critical, remains a significant challenge for manufacturers in the healthcare sector.

In the realm of PPE, Kevlar is increasingly being incorporated into protective garments, gloves, and face shields. These Kevlar-enhanced products offer improved puncture and cut resistance, crucial for healthcare workers handling sharp instruments or working in high-risk environments. The material's durability also contributes to the longevity of protective gear, potentially reducing replacement costs and waste in healthcare settings.

Medical device manufacturers have begun exploring Kevlar's potential in developing more robust and reliable equipment. Its application in surgical instruments, for instance, has shown promise in creating lighter yet stronger tools that can withstand repeated sterilization processes without compromising structural integrity. Additionally, Kevlar's use in prosthetics and orthotics has opened new avenues for creating more durable and comfortable assistive devices for patients.

Despite these advancements, the integration of Kevlar in healthcare faces several challenges. One significant hurdle is the cost factor. Kevlar remains a relatively expensive material compared to traditional alternatives, which can limit its widespread adoption, particularly in resource-constrained healthcare systems. This cost barrier necessitates a careful balance between the material's benefits and economic feasibility.

Another challenge lies in the regulatory landscape. As a relatively new material in healthcare applications, Kevlar-based products often require extensive testing and certification to meet stringent medical standards. This process can be time-consuming and costly, potentially slowing down innovation and market entry for new Kevlar-enhanced healthcare solutions.

The biocompatibility of Kevlar in certain medical applications also presents a challenge. While the material is generally considered safe for external use, its long-term effects in internal medical applications are still under investigation. This uncertainty can limit Kevlar's use in certain invasive medical devices or implants, requiring further research and development to address potential biocompatibility concerns.

Lastly, the manufacturing and processing of Kevlar for healthcare applications pose technical challenges. Adapting Kevlar's properties to meet specific medical requirements often involves complex manufacturing processes. Ensuring consistent quality, especially in applications where precision is critical, remains a significant challenge for manufacturers in the healthcare sector.

Existing Kevlar Solutions in Healthcare Protection

01 Kevlar-based protective clothing

Kevlar is widely used in protective clothing due to its high strength and heat resistance. It is incorporated into various garments such as bulletproof vests, firefighter suits, and military uniforms to provide enhanced protection against ballistic threats, heat, and abrasion.- Ballistic protection in body armor: Kevlar is widely used in body armor due to its exceptional ballistic protection capabilities. It can be incorporated into various types of protective gear, including vests, helmets, and shields. The high tensile strength and energy-absorbing properties of Kevlar fibers make it effective in stopping or slowing down projectiles, enhancing personal safety in high-risk environments.

- Composite materials for enhanced protection: Kevlar can be combined with other materials to create advanced composite structures, improving overall protective capabilities. These composites may include layers of different materials or be infused with other substances to enhance specific properties such as heat resistance, impact absorption, or flexibility. Such combinations can result in lighter yet more effective protective solutions for various applications.

- Cut and abrasion resistance: Kevlar exhibits excellent cut and abrasion resistance, making it suitable for protective gear in industrial and outdoor settings. This property is particularly useful in gloves, sleeves, and other garments designed to protect against sharp objects, rough surfaces, or high-friction environments. The material's durability contributes to longer-lasting protective equipment and increased safety in various occupational scenarios.

- Flame and heat resistance: Kevlar demonstrates notable flame and heat resistance properties, enhancing its protective capabilities in fire-related hazards. This characteristic makes it valuable in firefighting gear, racing suits, and other applications where exposure to high temperatures is a concern. The material's ability to maintain its integrity under extreme heat conditions contributes to improved safety in potentially dangerous situations.

- Lightweight and flexible protection: One of Kevlar's key advantages is its ability to provide high-level protection while remaining lightweight and flexible. This characteristic allows for the creation of protective gear that doesn't significantly impede movement or cause excessive fatigue during prolonged use. The material's versatility enables its application in various forms, from thin, flexible fabrics to rigid, molded components, catering to diverse protective needs across different industries.

02 Kevlar composites for improved protection

Kevlar is often combined with other materials to create composite structures that offer enhanced protective capabilities. These composites can provide improved resistance to impact, puncture, and cutting, making them suitable for use in personal protective equipment and vehicle armor.Expand Specific Solutions03 Kevlar in protective helmets

Kevlar is utilized in the construction of protective helmets for various applications, including military, law enforcement, and sports. The material's high strength-to-weight ratio allows for the creation of lightweight yet highly protective headgear that can resist impacts and penetration.Expand Specific Solutions04 Kevlar-reinforced protective gloves

Kevlar fibers are incorporated into protective gloves to enhance cut resistance and durability. These gloves are used in industries such as manufacturing, construction, and law enforcement, where hand protection against sharp objects and abrasive materials is crucial.Expand Specific Solutions05 Kevlar in blast-resistant structures

Kevlar is employed in the construction of blast-resistant structures and panels. Its high tensile strength and energy-absorbing properties make it effective in mitigating the effects of explosions, protecting buildings, vehicles, and personnel in high-risk environments.Expand Specific Solutions

Key Players in Kevlar-Enhanced Medical Products

The development of Kevlar-enhanced protective technologies in healthcare is in a growth phase, with increasing market size and technological advancements. The global market for medical protective equipment is expanding, driven by heightened safety concerns and the need for advanced materials in healthcare settings. Companies like Poly Medicure Ltd., Retractable Technologies, Inc., and Becton, Dickinson & Co. are at the forefront of integrating Kevlar into medical devices, leveraging its exceptional strength-to-weight ratio and cut-resistant properties. The technology's maturity is progressing, with ongoing research and development efforts by industry leaders and academic institutions such as the Indian Institutes of Technology and Massachusetts Institute of Technology, focusing on enhancing Kevlar's biocompatibility and application in diverse medical products.

Becton, Dickinson & Co.

Technical Solution: Becton, Dickinson & Co. (BD) has developed innovative Kevlar-reinforced medical devices, particularly in the field of vascular access. Their advanced catheter technology incorporates Kevlar fibers to enhance structural integrity and reduce the risk of kinking or collapse during insertion and use. This approach has led to the creation of ultra-thin-walled catheters that maintain excellent tensile strength and flexibility[1]. BD's Kevlar-enhanced catheters demonstrate improved pushability and torque transmission, allowing for more precise navigation through complex vascular structures[2]. The company has also applied Kevlar technology to their needleless connectors and IV set components, significantly increasing their durability and resistance to disconnection under high-pressure conditions[3].

Strengths: Enhanced durability and kink resistance in catheters, improved navigation in complex vascular structures, increased safety in high-pressure applications. Weaknesses: Potentially higher production costs, limited application to specific product lines.

Massachusetts Institute of Technology

Technical Solution: Researchers at the Massachusetts Institute of Technology (MIT) have been at the forefront of developing novel applications for Kevlar in healthcare technologies. One significant innovation is the creation of Kevlar-based nanofibers for advanced wound dressings. These nanofibers exhibit exceptional strength and flexibility while providing an ideal scaffold for cell growth and tissue regeneration[10]. MIT scientists have also explored the use of Kevlar in biosensors, developing ultra-thin, flexible sensors capable of detecting minute changes in biological markers with high sensitivity[11]. In the field of prosthetics, MIT has pioneered the use of Kevlar composites to create lightweight, high-strength artificial limbs that offer improved mobility and comfort for patients[12]. Additionally, MIT researchers have investigated the potential of Kevlar-based materials in drug delivery systems, utilizing the material's unique properties to create controlled-release mechanisms for targeted therapies[13].

Strengths: Cutting-edge research in nanofiber technology, innovative applications in biosensors and prosthetics, potential for revolutionary drug delivery systems. Weaknesses: Many applications still in experimental stages, potential challenges in scaling up for commercial production.

Core Innovations in Kevlar for Medical Safety

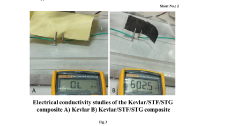

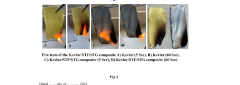

An improved process for fabricating kevlar fabric composite for multifunctional soft body armor

PatentPendingIN202321039845A

Innovation

- A composite material process involving Kevlar fabric impregnated with shear thickening fluid (STF) and shear-stiffening gel (STG), utilizing metal phosphate and carbon nanotubes, to enhance impact resistance, electrical conductivity, and flame retardancy, while allowing for temperature regulation.

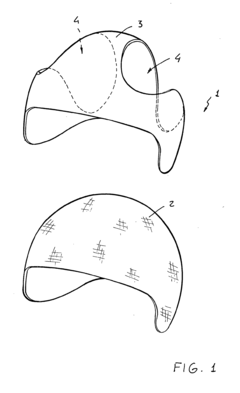

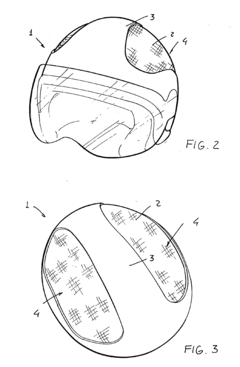

Method for decorating and reinforcing a high strength safety helmet and helmet made thereby

PatentInactiveEP1300089A1

Innovation

- A method involving layering high-strength fibers like carbon and Kevlar in a mold, followed by applying a thermoplastic overcap that provides reinforcement and aesthetic enhancement by exposing selected regions while integrating conventional safety features.

Regulatory Framework for Advanced Medical Materials

The regulatory framework for advanced medical materials, such as Kevlar in healthcare applications, is a complex and evolving landscape. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the safety and efficacy of medical devices and materials. Kevlar-based protective technologies in healthcare fall under the purview of the FDA's Center for Devices and Radiological Health (CDRH).

The FDA classifies medical devices into three categories based on their risk level and intended use. Kevlar-enhanced protective equipment typically falls into Class I or Class II, depending on its specific application. Class I devices are subject to general controls, while Class II devices require special controls and often premarket notification (510(k)) submission.

For Kevlar-based healthcare products to gain regulatory approval, manufacturers must demonstrate compliance with Good Manufacturing Practices (GMP) and provide substantial evidence of safety and effectiveness. This often involves conducting clinical trials and submitting comprehensive data on material properties, biocompatibility, and performance under various conditions.

Internationally, regulatory bodies such as the European Medicines Agency (EMA) and Japan's Pharmaceuticals and Medical Devices Agency (PMDA) have their own frameworks for advanced medical materials. The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) set stringent requirements for medical devices, including those incorporating Kevlar technology.

Harmonization efforts, such as the International Medical Device Regulators Forum (IMDRF), aim to streamline regulatory processes across different countries. This facilitates the global adoption of innovative protective technologies while maintaining high safety standards.

As Kevlar applications in healthcare continue to evolve, regulatory frameworks must adapt to address new challenges. This includes developing specific guidelines for nanotechnology-enhanced materials and considering the long-term effects of advanced composites in medical settings. Regulatory bodies are increasingly focusing on post-market surveillance to monitor the performance and safety of Kevlar-based medical products throughout their lifecycle.

Manufacturers and researchers working with Kevlar in healthcare must navigate these regulatory requirements carefully. Collaboration with regulatory experts and early engagement with authorities can help streamline the approval process and ensure compliance with evolving standards. As the field advances, it is likely that regulatory frameworks will continue to evolve, balancing the need for innovation with the paramount importance of patient safety.

The FDA classifies medical devices into three categories based on their risk level and intended use. Kevlar-enhanced protective equipment typically falls into Class I or Class II, depending on its specific application. Class I devices are subject to general controls, while Class II devices require special controls and often premarket notification (510(k)) submission.

For Kevlar-based healthcare products to gain regulatory approval, manufacturers must demonstrate compliance with Good Manufacturing Practices (GMP) and provide substantial evidence of safety and effectiveness. This often involves conducting clinical trials and submitting comprehensive data on material properties, biocompatibility, and performance under various conditions.

Internationally, regulatory bodies such as the European Medicines Agency (EMA) and Japan's Pharmaceuticals and Medical Devices Agency (PMDA) have their own frameworks for advanced medical materials. The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) set stringent requirements for medical devices, including those incorporating Kevlar technology.

Harmonization efforts, such as the International Medical Device Regulators Forum (IMDRF), aim to streamline regulatory processes across different countries. This facilitates the global adoption of innovative protective technologies while maintaining high safety standards.

As Kevlar applications in healthcare continue to evolve, regulatory frameworks must adapt to address new challenges. This includes developing specific guidelines for nanotechnology-enhanced materials and considering the long-term effects of advanced composites in medical settings. Regulatory bodies are increasingly focusing on post-market surveillance to monitor the performance and safety of Kevlar-based medical products throughout their lifecycle.

Manufacturers and researchers working with Kevlar in healthcare must navigate these regulatory requirements carefully. Collaboration with regulatory experts and early engagement with authorities can help streamline the approval process and ensure compliance with evolving standards. As the field advances, it is likely that regulatory frameworks will continue to evolve, balancing the need for innovation with the paramount importance of patient safety.

Environmental Impact of Kevlar in Healthcare Products

The environmental impact of Kevlar in healthcare products is a complex issue that requires careful consideration. Kevlar, a high-strength synthetic fiber, has found widespread use in various protective technologies within the healthcare sector. While its durability and protective properties offer significant benefits, the environmental implications of its production and disposal warrant examination.

The manufacturing process of Kevlar involves energy-intensive procedures and the use of chemical solvents, which can contribute to greenhouse gas emissions and potential environmental contamination if not properly managed. However, advancements in production techniques have led to more efficient and environmentally friendly manufacturing processes, reducing the overall carbon footprint associated with Kevlar production.

One of the primary environmental advantages of Kevlar in healthcare products is its exceptional durability. This longevity translates to reduced waste generation, as Kevlar-based protective equipment often outlasts conventional alternatives. Consequently, fewer replacements are needed over time, leading to a decrease in the overall volume of medical waste produced by healthcare facilities.

The disposal of Kevlar-containing healthcare products presents both challenges and opportunities. While Kevlar itself is not biodegradable, it can be recycled through specialized processes. Some manufacturers have implemented take-back programs to collect and recycle used Kevlar products, promoting a circular economy approach within the healthcare industry.

In terms of end-of-life management, incineration is often employed for disposing of medical waste containing Kevlar. This method, when conducted under controlled conditions, can effectively neutralize potential biohazards while recovering energy. However, it is crucial to ensure proper filtration systems are in place to mitigate any harmful emissions resulting from the incineration process.

The use of Kevlar in healthcare products also indirectly contributes to environmental sustainability by enhancing the safety and efficiency of medical procedures. By reducing the risk of injuries and contamination, Kevlar-based protective equipment minimizes the need for additional medical interventions and resource consumption, thereby lowering the overall environmental impact of healthcare delivery.

As the healthcare industry continues to prioritize sustainability, ongoing research is focused on developing bio-based alternatives to synthetic fibers like Kevlar. These efforts aim to create materials with similar protective properties but with reduced environmental impact throughout their lifecycle. While such alternatives are still in development, they represent a promising direction for future innovations in healthcare protective technologies.

The manufacturing process of Kevlar involves energy-intensive procedures and the use of chemical solvents, which can contribute to greenhouse gas emissions and potential environmental contamination if not properly managed. However, advancements in production techniques have led to more efficient and environmentally friendly manufacturing processes, reducing the overall carbon footprint associated with Kevlar production.

One of the primary environmental advantages of Kevlar in healthcare products is its exceptional durability. This longevity translates to reduced waste generation, as Kevlar-based protective equipment often outlasts conventional alternatives. Consequently, fewer replacements are needed over time, leading to a decrease in the overall volume of medical waste produced by healthcare facilities.

The disposal of Kevlar-containing healthcare products presents both challenges and opportunities. While Kevlar itself is not biodegradable, it can be recycled through specialized processes. Some manufacturers have implemented take-back programs to collect and recycle used Kevlar products, promoting a circular economy approach within the healthcare industry.

In terms of end-of-life management, incineration is often employed for disposing of medical waste containing Kevlar. This method, when conducted under controlled conditions, can effectively neutralize potential biohazards while recovering energy. However, it is crucial to ensure proper filtration systems are in place to mitigate any harmful emissions resulting from the incineration process.

The use of Kevlar in healthcare products also indirectly contributes to environmental sustainability by enhancing the safety and efficiency of medical procedures. By reducing the risk of injuries and contamination, Kevlar-based protective equipment minimizes the need for additional medical interventions and resource consumption, thereby lowering the overall environmental impact of healthcare delivery.

As the healthcare industry continues to prioritize sustainability, ongoing research is focused on developing bio-based alternatives to synthetic fibers like Kevlar. These efforts aim to create materials with similar protective properties but with reduced environmental impact throughout their lifecycle. While such alternatives are still in development, they represent a promising direction for future innovations in healthcare protective technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!