How Regenerative Braking Supports Electric Vehicle Manufacturing Trends

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Regen Braking Evolution and Objectives

Regenerative braking has emerged as a pivotal technology in the evolution of electric vehicles (EVs), playing a crucial role in enhancing energy efficiency and extending driving range. This innovative braking system has undergone significant development since its inception, with its objectives closely aligned with the broader trends in EV manufacturing.

The concept of regenerative braking dates back to the early 20th century, but its practical implementation in EVs gained momentum in the 1990s. Initially, the primary goal was to recover energy that would otherwise be lost as heat during conventional braking. As EV technology progressed, the objectives of regenerative braking systems expanded to address key challenges in electric vehicle performance and adoption.

One of the primary evolutionary objectives has been to maximize energy recovery efficiency. Early systems could only recapture a small percentage of braking energy, but modern regenerative braking technologies can recover up to 70% of the kinetic energy during deceleration. This dramatic improvement has been driven by advancements in power electronics, motor design, and energy storage technologies.

Another critical objective in the evolution of regenerative braking has been seamless integration with traditional friction braking systems. This integration aims to provide a smooth and intuitive driving experience while maximizing energy recovery. The development of sophisticated brake blending algorithms and improved control systems has been instrumental in achieving this goal.

The trend towards increased electrification in vehicles has further shaped the objectives of regenerative braking systems. As automakers strive to extend the range of EVs, regenerative braking has become a key component in energy management strategies. The focus has shifted towards developing more intelligent and adaptive regenerative braking systems that can optimize energy recovery based on driving conditions, route information, and driver behavior.

In recent years, the objectives of regenerative braking development have expanded to include support for advanced driver assistance systems (ADAS) and autonomous driving features. This has led to the integration of regenerative braking with other vehicle systems, such as adaptive cruise control and predictive energy management, to enhance overall vehicle efficiency and safety.

Looking ahead, the evolution of regenerative braking is likely to continue in parallel with advancements in EV manufacturing. Objectives for future development include further improvements in energy recovery efficiency, enhanced integration with other vehicle systems, and the exploration of novel braking technologies that could complement or even replace current regenerative braking methods. As EVs become more prevalent, the role of regenerative braking in supporting sustainable transportation and reducing environmental impact will remain a key focus for manufacturers and researchers alike.

The concept of regenerative braking dates back to the early 20th century, but its practical implementation in EVs gained momentum in the 1990s. Initially, the primary goal was to recover energy that would otherwise be lost as heat during conventional braking. As EV technology progressed, the objectives of regenerative braking systems expanded to address key challenges in electric vehicle performance and adoption.

One of the primary evolutionary objectives has been to maximize energy recovery efficiency. Early systems could only recapture a small percentage of braking energy, but modern regenerative braking technologies can recover up to 70% of the kinetic energy during deceleration. This dramatic improvement has been driven by advancements in power electronics, motor design, and energy storage technologies.

Another critical objective in the evolution of regenerative braking has been seamless integration with traditional friction braking systems. This integration aims to provide a smooth and intuitive driving experience while maximizing energy recovery. The development of sophisticated brake blending algorithms and improved control systems has been instrumental in achieving this goal.

The trend towards increased electrification in vehicles has further shaped the objectives of regenerative braking systems. As automakers strive to extend the range of EVs, regenerative braking has become a key component in energy management strategies. The focus has shifted towards developing more intelligent and adaptive regenerative braking systems that can optimize energy recovery based on driving conditions, route information, and driver behavior.

In recent years, the objectives of regenerative braking development have expanded to include support for advanced driver assistance systems (ADAS) and autonomous driving features. This has led to the integration of regenerative braking with other vehicle systems, such as adaptive cruise control and predictive energy management, to enhance overall vehicle efficiency and safety.

Looking ahead, the evolution of regenerative braking is likely to continue in parallel with advancements in EV manufacturing. Objectives for future development include further improvements in energy recovery efficiency, enhanced integration with other vehicle systems, and the exploration of novel braking technologies that could complement or even replace current regenerative braking methods. As EVs become more prevalent, the role of regenerative braking in supporting sustainable transportation and reducing environmental impact will remain a key focus for manufacturers and researchers alike.

EV Market Demand Analysis

The electric vehicle (EV) market has experienced significant growth in recent years, driven by increasing environmental awareness, government incentives, and technological advancements. This surge in demand for EVs has created a ripple effect throughout the automotive industry, influencing manufacturing trends and technological innovations.

Regenerative braking systems have emerged as a crucial component in supporting the growing EV market. As consumers seek more efficient and environmentally friendly transportation options, the demand for EVs with advanced energy recovery systems has increased substantially. This technology not only improves the overall efficiency of electric vehicles but also addresses consumer concerns about range anxiety, making EVs more attractive to a broader market segment.

The global EV market is projected to continue its rapid expansion, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is particularly pronounced in regions with strong government support for EV adoption, such as China, Europe, and parts of North America. As the market expands, there is an increasing demand for EVs that offer superior performance, longer range, and enhanced energy efficiency.

Regenerative braking systems play a vital role in meeting these market demands. By capturing and converting kinetic energy into electrical energy during deceleration, these systems extend the driving range of EVs, a key factor in consumer purchasing decisions. This technology directly addresses one of the primary concerns potential EV buyers have – the fear of running out of battery power during long trips.

Furthermore, the integration of regenerative braking systems aligns with the broader trend of sustainable manufacturing in the automotive industry. As automakers strive to reduce the overall environmental impact of their vehicles, technologies that improve energy efficiency and reduce waste are becoming increasingly important. Regenerative braking not only enhances the eco-friendliness of EVs during operation but also contributes to a more sustainable product lifecycle.

The market demand for EVs with advanced regenerative braking capabilities is also driven by the growing interest in smart and connected vehicles. Consumers are increasingly seeking vehicles that offer sophisticated energy management systems, and regenerative braking is often viewed as a key component of these intelligent vehicle ecosystems. This trend is pushing manufacturers to develop more advanced and efficient regenerative braking technologies, further supporting the growth of the EV market.

In conclusion, the analysis of EV market demand clearly indicates a strong correlation between the adoption of regenerative braking systems and the overall growth of the electric vehicle sector. As consumers continue to prioritize efficiency, range, and sustainability in their vehicle choices, regenerative braking technology is poised to play an increasingly important role in shaping EV manufacturing trends and meeting market demands.

Regenerative braking systems have emerged as a crucial component in supporting the growing EV market. As consumers seek more efficient and environmentally friendly transportation options, the demand for EVs with advanced energy recovery systems has increased substantially. This technology not only improves the overall efficiency of electric vehicles but also addresses consumer concerns about range anxiety, making EVs more attractive to a broader market segment.

The global EV market is projected to continue its rapid expansion, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is particularly pronounced in regions with strong government support for EV adoption, such as China, Europe, and parts of North America. As the market expands, there is an increasing demand for EVs that offer superior performance, longer range, and enhanced energy efficiency.

Regenerative braking systems play a vital role in meeting these market demands. By capturing and converting kinetic energy into electrical energy during deceleration, these systems extend the driving range of EVs, a key factor in consumer purchasing decisions. This technology directly addresses one of the primary concerns potential EV buyers have – the fear of running out of battery power during long trips.

Furthermore, the integration of regenerative braking systems aligns with the broader trend of sustainable manufacturing in the automotive industry. As automakers strive to reduce the overall environmental impact of their vehicles, technologies that improve energy efficiency and reduce waste are becoming increasingly important. Regenerative braking not only enhances the eco-friendliness of EVs during operation but also contributes to a more sustainable product lifecycle.

The market demand for EVs with advanced regenerative braking capabilities is also driven by the growing interest in smart and connected vehicles. Consumers are increasingly seeking vehicles that offer sophisticated energy management systems, and regenerative braking is often viewed as a key component of these intelligent vehicle ecosystems. This trend is pushing manufacturers to develop more advanced and efficient regenerative braking technologies, further supporting the growth of the EV market.

In conclusion, the analysis of EV market demand clearly indicates a strong correlation between the adoption of regenerative braking systems and the overall growth of the electric vehicle sector. As consumers continue to prioritize efficiency, range, and sustainability in their vehicle choices, regenerative braking technology is poised to play an increasingly important role in shaping EV manufacturing trends and meeting market demands.

Regen Braking Tech Challenges

Regenerative braking technology, while promising significant benefits for electric vehicle (EV) efficiency, faces several technical challenges that need to be addressed for widespread adoption and optimal performance. One of the primary hurdles is the integration of regenerative braking systems with traditional friction brakes. Achieving a seamless transition between these two braking methods requires sophisticated control algorithms and hardware that can respond quickly to changing driving conditions.

The efficiency of energy recovery in regenerative braking systems presents another significant challenge. Current systems are limited in their ability to capture and convert kinetic energy into electrical energy, especially during high-speed or sudden braking scenarios. This limitation reduces the overall energy savings potential of regenerative braking, particularly in urban driving environments where frequent stops are common.

Thermal management is a critical issue in regenerative braking systems. The process of converting kinetic energy to electrical energy generates heat, which must be effectively dissipated to prevent damage to the battery and other electrical components. Developing efficient cooling systems that can handle the heat load without adding significant weight or complexity to the vehicle remains a technical challenge.

The variability of regenerative braking performance under different driving conditions poses another challenge. Factors such as road gradient, vehicle speed, and battery state of charge can significantly affect the system's efficiency. Creating adaptive systems that can optimize performance across a wide range of conditions requires advanced sensors and control systems, adding to the complexity and cost of EV manufacturing.

Battery technology limitations also impact the effectiveness of regenerative braking. The ability of batteries to accept high rates of charge during braking events is crucial for maximizing energy recovery. However, current battery technologies have limitations in charge acceptance rates, particularly as the battery nears full capacity. Developing battery systems that can handle rapid charging without degradation or safety issues is an ongoing challenge.

The durability and longevity of regenerative braking components are also areas of concern. The frequent cycling between braking and acceleration puts significant stress on electrical motors and power electronics. Ensuring these components can withstand the rigors of long-term use without frequent replacement or maintenance is essential for the cost-effectiveness and reliability of EVs.

Lastly, the integration of regenerative braking with advanced driver assistance systems (ADAS) and autonomous driving technologies presents new challenges. Coordinating regenerative braking with features like adaptive cruise control and automatic emergency braking requires complex system integration and fail-safe mechanisms to ensure safety and optimal performance in all driving scenarios.

The efficiency of energy recovery in regenerative braking systems presents another significant challenge. Current systems are limited in their ability to capture and convert kinetic energy into electrical energy, especially during high-speed or sudden braking scenarios. This limitation reduces the overall energy savings potential of regenerative braking, particularly in urban driving environments where frequent stops are common.

Thermal management is a critical issue in regenerative braking systems. The process of converting kinetic energy to electrical energy generates heat, which must be effectively dissipated to prevent damage to the battery and other electrical components. Developing efficient cooling systems that can handle the heat load without adding significant weight or complexity to the vehicle remains a technical challenge.

The variability of regenerative braking performance under different driving conditions poses another challenge. Factors such as road gradient, vehicle speed, and battery state of charge can significantly affect the system's efficiency. Creating adaptive systems that can optimize performance across a wide range of conditions requires advanced sensors and control systems, adding to the complexity and cost of EV manufacturing.

Battery technology limitations also impact the effectiveness of regenerative braking. The ability of batteries to accept high rates of charge during braking events is crucial for maximizing energy recovery. However, current battery technologies have limitations in charge acceptance rates, particularly as the battery nears full capacity. Developing battery systems that can handle rapid charging without degradation or safety issues is an ongoing challenge.

The durability and longevity of regenerative braking components are also areas of concern. The frequent cycling between braking and acceleration puts significant stress on electrical motors and power electronics. Ensuring these components can withstand the rigors of long-term use without frequent replacement or maintenance is essential for the cost-effectiveness and reliability of EVs.

Lastly, the integration of regenerative braking with advanced driver assistance systems (ADAS) and autonomous driving technologies presents new challenges. Coordinating regenerative braking with features like adaptive cruise control and automatic emergency braking requires complex system integration and fail-safe mechanisms to ensure safety and optimal performance in all driving scenarios.

Current Regen Braking Solutions

01 Energy recovery systems in regenerative braking

Regenerative braking systems are designed to recover and store energy during deceleration. These systems convert kinetic energy into electrical energy, which can be stored in batteries or capacitors for later use. This process significantly improves the overall energy efficiency of vehicles, particularly in electric and hybrid vehicles.- Energy recovery systems for regenerative braking: Advanced energy recovery systems are implemented to maximize the efficiency of regenerative braking. These systems capture and store kinetic energy during deceleration, which can then be used to power the vehicle or auxiliary systems. The recovered energy can be stored in various forms, such as electrical energy in batteries or mechanical energy in flywheels, improving overall vehicle efficiency.

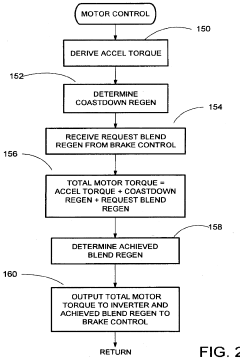

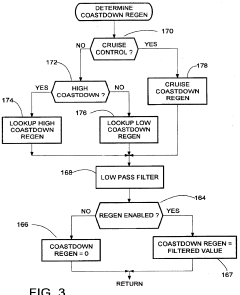

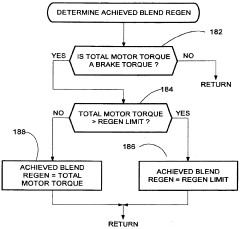

- Control strategies for optimizing regenerative braking: Sophisticated control algorithms are developed to optimize the balance between regenerative and friction braking. These strategies consider factors such as vehicle speed, battery state of charge, and road conditions to maximize energy recovery while maintaining vehicle stability and braking performance. Advanced control systems can also predict upcoming braking events to further enhance efficiency.

- Integration of regenerative braking with hybrid powertrains: Regenerative braking systems are integrated with hybrid powertrains to maximize energy efficiency. This integration allows for seamless coordination between the electric motor, internal combustion engine, and braking system. The recovered energy can be used to charge the battery or directly power the electric motor, reducing fuel consumption and emissions in hybrid vehicles.

- Improved energy storage technologies for regenerative braking: Advanced energy storage technologies are developed to enhance the efficiency of regenerative braking systems. These include high-capacity batteries, supercapacitors, and mechanical energy storage devices like flywheels. These technologies allow for rapid energy capture during braking events and efficient storage for later use, improving overall system performance.

- Regenerative braking efficiency in electric and fuel cell vehicles: Specialized regenerative braking systems are designed for electric and fuel cell vehicles to maximize energy recovery. These systems take advantage of the high-efficiency electric drivetrains to capture a larger percentage of braking energy. Advanced power electronics and motor designs allow for more efficient energy conversion during both acceleration and deceleration phases.

02 Control strategies for optimizing regenerative braking

Advanced control algorithms are employed to maximize energy recovery during braking. These strategies involve precise control of the electric motor's operation as a generator, balancing between regenerative and friction braking, and adapting to various driving conditions. Such control methods enhance the efficiency of energy recuperation while maintaining vehicle stability and driver comfort.Expand Specific Solutions03 Integration with hydraulic and pneumatic systems

Some regenerative braking systems incorporate hydraulic or pneumatic components to enhance energy recovery and storage. These hybrid systems can capture and store energy in the form of compressed air or hydraulic pressure, which can be later used for vehicle propulsion or auxiliary systems, further improving overall energy efficiency.Expand Specific Solutions04 Thermal management in regenerative braking

Efficient thermal management is crucial in regenerative braking systems to maintain optimal performance. This involves managing heat generated during the energy conversion process, cooling of electrical components, and ensuring the longevity of the system. Proper thermal management contributes to increased energy efficiency and system reliability.Expand Specific Solutions05 Energy storage technologies for regenerative braking

The choice of energy storage technology plays a vital role in the efficiency of regenerative braking systems. Advanced battery technologies, supercapacitors, and flywheel systems are used to store recovered energy effectively. These storage solutions are designed to handle rapid charge and discharge cycles, maximizing the amount of energy that can be captured and reused.Expand Specific Solutions

Key EV Regen Braking Players

The regenerative braking technology in electric vehicles is at a mature stage, with widespread adoption across the industry. The market for this technology is substantial and growing, driven by the increasing demand for electric vehicles globally. Major players like Hyundai Motor Co., GM Global Technology Operations, BYD Co., and Ford Motor Co. have integrated regenerative braking systems into their electric vehicle lineups. These companies, along with others such as Kia Corp. and NXP Semiconductors, are continuously improving the efficiency and performance of regenerative braking systems. The technology's development is closely tied to advancements in electric powertrain systems and energy storage solutions, indicating a highly competitive and innovative landscape in the electric vehicle manufacturing sector.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an advanced regenerative braking system for their electric vehicles, utilizing a combination of hydraulic and electric braking. Their system employs a smart energy recovery strategy that adapts to driving conditions and driver behavior. The system can recover up to 90% of kinetic energy during deceleration[1], significantly extending the vehicle's range. Hyundai's regenerative braking technology integrates seamlessly with their electric powertrain, using a sophisticated control algorithm to optimize energy recuperation and brake feel. The system also incorporates predictive technology, using GPS and traffic data to anticipate upcoming braking events and maximize energy recovery[3].

Strengths: High energy recovery rate, adaptive system, seamless integration with powertrain. Weaknesses: Complexity may lead to higher maintenance costs, potential for reduced brake feel in some situations.

GM Global Technology Operations LLC

Technical Solution: GM has implemented a regenerative braking system in their electric vehicles that utilizes a blended approach, combining traditional friction brakes with electric motor braking. Their system features a variable regenerative braking mode, allowing drivers to adjust the level of regeneration using paddle shifters[2]. GM's technology also incorporates a "one-pedal driving" mode, which maximizes energy recovery by engaging strong regenerative braking when the accelerator pedal is released. The system is capable of capturing up to 70% of braking energy in typical driving conditions[4]. GM has also developed an advanced brake-by-wire system that seamlessly transitions between regenerative and friction braking, enhancing both efficiency and safety.

Strengths: User-customizable regeneration levels, one-pedal driving capability, seamless blending of regenerative and friction braking. Weaknesses: Slightly lower energy recovery rate compared to some competitors, potential for driver confusion with multiple regeneration modes.

Core Regen Braking Innovations

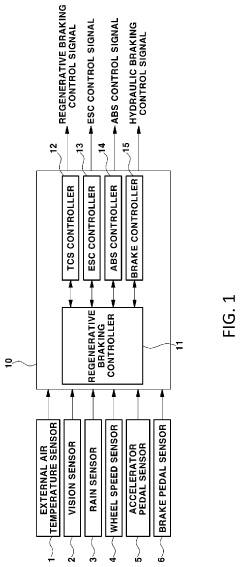

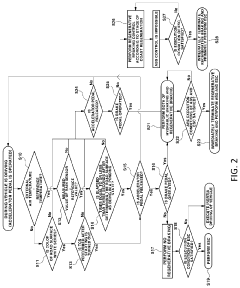

Regenerative braking control method of vehicle

PatentActiveUS11845434B2

Innovation

- A regenerative braking control method that assesses the driving risk of a road surface using sensors like vision and rain sensors, external air temperature, and traction control system data to determine whether to perform regenerative braking, hydraulic braking, or a combination of both, ensuring driving stability by adjusting braking modes based on the detected risk and driver intent.

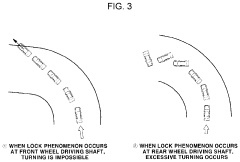

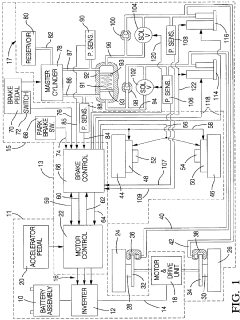

Electric vehicle with regenerative and anti-lock braking

PatentInactiveUS5615933A

Innovation

- A control system that blends regenerative and friction braking, with regenerative braking removed during anti-lock braking activation to prevent wheel lockup on low friction surfaces, and ramps down regenerative braking smoothly to maintain braking consistency, using a microprocessor-based control unit to coordinate motor and brake systems.

EV Energy Recovery Efficiency

Regenerative braking systems have become a cornerstone technology in improving the energy efficiency of electric vehicles (EVs). This innovative approach to energy recovery has significantly enhanced the overall performance and range of EVs, making them more competitive in the automotive market. The efficiency of energy recovery in EVs through regenerative braking varies depending on several factors, including vehicle design, driving conditions, and the specific regenerative braking system employed.

Modern regenerative braking systems in EVs can recover up to 70% of the kinetic energy that would otherwise be lost as heat during conventional braking. This recovered energy is then converted back into electrical energy and stored in the vehicle's battery, effectively extending the driving range. The efficiency of this process is influenced by the power of the electric motor, the capacity of the battery to accept charge, and the sophistication of the energy management system.

Urban driving scenarios, characterized by frequent stops and starts, provide optimal conditions for regenerative braking. In these environments, EVs can recover a substantial amount of energy, with some studies reporting energy recovery rates of up to 30% of the total energy consumed during a typical urban drive cycle. This efficiency drops in highway driving scenarios where braking is less frequent, but still contributes to overall energy savings.

The integration of advanced power electronics and intelligent control systems has further improved the efficiency of regenerative braking. These systems can dynamically adjust the level of regenerative braking based on driving conditions, battery state of charge, and driver input, maximizing energy recovery while maintaining vehicle stability and driver comfort. Some high-end EV models now feature predictive regenerative braking systems that use GPS and topographical data to anticipate upcoming braking needs and optimize energy recovery.

Continuous advancements in motor technology, particularly the development of more efficient and powerful electric motors, have also contributed to improved regenerative braking efficiency. Permanent magnet synchronous motors (PMSMs) and switched reluctance motors (SRMs) have shown promising results in enhancing the energy recovery capabilities of EVs, with some experimental systems achieving energy recovery rates of up to 80% under ideal conditions.

As EV manufacturers strive to extend vehicle range and reduce battery costs, the focus on improving regenerative braking efficiency remains a key area of research and development. Emerging technologies, such as supercapacitors and advanced battery management systems, hold the potential to further enhance energy recovery and storage capabilities, pushing the boundaries of EV efficiency and performance.

Modern regenerative braking systems in EVs can recover up to 70% of the kinetic energy that would otherwise be lost as heat during conventional braking. This recovered energy is then converted back into electrical energy and stored in the vehicle's battery, effectively extending the driving range. The efficiency of this process is influenced by the power of the electric motor, the capacity of the battery to accept charge, and the sophistication of the energy management system.

Urban driving scenarios, characterized by frequent stops and starts, provide optimal conditions for regenerative braking. In these environments, EVs can recover a substantial amount of energy, with some studies reporting energy recovery rates of up to 30% of the total energy consumed during a typical urban drive cycle. This efficiency drops in highway driving scenarios where braking is less frequent, but still contributes to overall energy savings.

The integration of advanced power electronics and intelligent control systems has further improved the efficiency of regenerative braking. These systems can dynamically adjust the level of regenerative braking based on driving conditions, battery state of charge, and driver input, maximizing energy recovery while maintaining vehicle stability and driver comfort. Some high-end EV models now feature predictive regenerative braking systems that use GPS and topographical data to anticipate upcoming braking needs and optimize energy recovery.

Continuous advancements in motor technology, particularly the development of more efficient and powerful electric motors, have also contributed to improved regenerative braking efficiency. Permanent magnet synchronous motors (PMSMs) and switched reluctance motors (SRMs) have shown promising results in enhancing the energy recovery capabilities of EVs, with some experimental systems achieving energy recovery rates of up to 80% under ideal conditions.

As EV manufacturers strive to extend vehicle range and reduce battery costs, the focus on improving regenerative braking efficiency remains a key area of research and development. Emerging technologies, such as supercapacitors and advanced battery management systems, hold the potential to further enhance energy recovery and storage capabilities, pushing the boundaries of EV efficiency and performance.

Regen Braking Safety Standards

Regenerative braking systems in electric vehicles (EVs) have become a critical component in enhancing energy efficiency and extending driving range. As such, the development and implementation of safety standards for these systems have become paramount in the EV manufacturing industry. These standards aim to ensure the reliability, performance, and safety of regenerative braking systems across various operating conditions.

One of the primary safety considerations for regenerative braking is the system's integration with traditional friction brakes. Standards have been established to govern the seamless transition between regenerative and friction braking, ensuring consistent deceleration and preventing unexpected vehicle behavior. These standards typically require manufacturers to implement fail-safe mechanisms that automatically engage friction brakes in case of regenerative braking system failure.

Another crucial aspect of regenerative braking safety standards is the management of energy recuperation during adverse weather conditions. Regulations mandate that EVs must be equipped with systems that can detect low-traction situations, such as icy or wet roads, and adjust the regenerative braking force accordingly to prevent wheel lock-up or loss of vehicle control.

Battery safety is also a key focus of regenerative braking standards. Guidelines have been established to prevent overcharging and manage thermal loads during aggressive regenerative braking events. These standards often require sophisticated battery management systems that can monitor and control the rate of energy recuperation to protect the battery from damage and ensure long-term performance.

Electromagnetic compatibility (EMC) is another critical area addressed by safety standards for regenerative braking systems. As these systems involve high-power electrical components, regulations have been put in place to limit electromagnetic emissions and ensure that regenerative braking does not interfere with other vehicle systems or nearby electronic devices.

Human-machine interface (HMI) standards have also been developed to ensure that drivers can easily understand and interact with regenerative braking systems. These standards typically require clear indicators of system status and intuitive controls for adjusting regenerative braking intensity, enhancing driver confidence and promoting safe operation.

Lastly, safety standards for regenerative braking systems include rigorous testing protocols. These protocols often involve simulated emergency situations, long-term durability tests, and performance evaluations under various environmental conditions. Compliance with these testing standards is essential for EV manufacturers to obtain necessary certifications and approvals for their vehicles.

As EV technology continues to evolve, safety standards for regenerative braking systems are expected to become increasingly sophisticated, adapting to new challenges and opportunities in electric vehicle manufacturing. This ongoing development of standards plays a crucial role in supporting the growth and acceptance of EVs in the global automotive market.

One of the primary safety considerations for regenerative braking is the system's integration with traditional friction brakes. Standards have been established to govern the seamless transition between regenerative and friction braking, ensuring consistent deceleration and preventing unexpected vehicle behavior. These standards typically require manufacturers to implement fail-safe mechanisms that automatically engage friction brakes in case of regenerative braking system failure.

Another crucial aspect of regenerative braking safety standards is the management of energy recuperation during adverse weather conditions. Regulations mandate that EVs must be equipped with systems that can detect low-traction situations, such as icy or wet roads, and adjust the regenerative braking force accordingly to prevent wheel lock-up or loss of vehicle control.

Battery safety is also a key focus of regenerative braking standards. Guidelines have been established to prevent overcharging and manage thermal loads during aggressive regenerative braking events. These standards often require sophisticated battery management systems that can monitor and control the rate of energy recuperation to protect the battery from damage and ensure long-term performance.

Electromagnetic compatibility (EMC) is another critical area addressed by safety standards for regenerative braking systems. As these systems involve high-power electrical components, regulations have been put in place to limit electromagnetic emissions and ensure that regenerative braking does not interfere with other vehicle systems or nearby electronic devices.

Human-machine interface (HMI) standards have also been developed to ensure that drivers can easily understand and interact with regenerative braking systems. These standards typically require clear indicators of system status and intuitive controls for adjusting regenerative braking intensity, enhancing driver confidence and promoting safe operation.

Lastly, safety standards for regenerative braking systems include rigorous testing protocols. These protocols often involve simulated emergency situations, long-term durability tests, and performance evaluations under various environmental conditions. Compliance with these testing standards is essential for EV manufacturers to obtain necessary certifications and approvals for their vehicles.

As EV technology continues to evolve, safety standards for regenerative braking systems are expected to become increasingly sophisticated, adapting to new challenges and opportunities in electric vehicle manufacturing. This ongoing development of standards plays a crucial role in supporting the growth and acceptance of EVs in the global automotive market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!