How to Achieve Optimal Performance in Polycarbonate Applications?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Evolution and Performance Goals

Polycarbonate has undergone significant evolution since its discovery in 1953, with continuous advancements in its properties and applications. Initially developed as a durable, transparent plastic, polycarbonate has become a versatile material used across various industries. The evolution of polycarbonate has been driven by the need for improved performance characteristics, including enhanced impact resistance, thermal stability, and optical clarity.

In the early stages, polycarbonate was primarily utilized in safety equipment and automotive applications due to its high impact strength. As manufacturing processes improved, the material found its way into consumer electronics, medical devices, and construction materials. The development of UV-resistant grades in the 1970s expanded its outdoor applications, while advancements in flame-retardant additives in the 1980s opened up new possibilities in electrical and electronic components.

Recent years have seen a focus on developing polycarbonate grades with improved chemical resistance, weatherability, and sustainability. The introduction of bio-based polycarbonates and recycling technologies has addressed growing environmental concerns. Simultaneously, research into nanocomposites and blends has led to polycarbonate materials with enhanced mechanical and thermal properties.

The current performance goals for polycarbonate applications are multifaceted, addressing both industry-specific requirements and broader sustainability objectives. Key areas of focus include increasing the glass transition temperature to improve heat resistance, enhancing impact strength without compromising optical clarity, and developing grades with improved chemical resistance for demanding environments.

Another critical goal is to reduce the environmental footprint of polycarbonate production and use. This involves developing more energy-efficient manufacturing processes, increasing the use of recycled content, and improving end-of-life recyclability. Additionally, there is a push to create polycarbonate grades that maintain their high-performance characteristics while being derived from renewable resources.

In the realm of optical applications, researchers are striving to enhance light transmission and reduce haze, particularly for use in automotive lighting and consumer electronics displays. For structural applications, the focus is on improving the strength-to-weight ratio and long-term durability under various environmental conditions.

As polycarbonate continues to evolve, the overarching goal is to achieve optimal performance across a wide range of applications while addressing sustainability concerns. This involves balancing mechanical, thermal, and optical properties with processability, cost-effectiveness, and environmental impact. The future of polycarbonate lies in smart, multifunctional materials that can adapt to changing conditions and meet the complex demands of emerging technologies.

In the early stages, polycarbonate was primarily utilized in safety equipment and automotive applications due to its high impact strength. As manufacturing processes improved, the material found its way into consumer electronics, medical devices, and construction materials. The development of UV-resistant grades in the 1970s expanded its outdoor applications, while advancements in flame-retardant additives in the 1980s opened up new possibilities in electrical and electronic components.

Recent years have seen a focus on developing polycarbonate grades with improved chemical resistance, weatherability, and sustainability. The introduction of bio-based polycarbonates and recycling technologies has addressed growing environmental concerns. Simultaneously, research into nanocomposites and blends has led to polycarbonate materials with enhanced mechanical and thermal properties.

The current performance goals for polycarbonate applications are multifaceted, addressing both industry-specific requirements and broader sustainability objectives. Key areas of focus include increasing the glass transition temperature to improve heat resistance, enhancing impact strength without compromising optical clarity, and developing grades with improved chemical resistance for demanding environments.

Another critical goal is to reduce the environmental footprint of polycarbonate production and use. This involves developing more energy-efficient manufacturing processes, increasing the use of recycled content, and improving end-of-life recyclability. Additionally, there is a push to create polycarbonate grades that maintain their high-performance characteristics while being derived from renewable resources.

In the realm of optical applications, researchers are striving to enhance light transmission and reduce haze, particularly for use in automotive lighting and consumer electronics displays. For structural applications, the focus is on improving the strength-to-weight ratio and long-term durability under various environmental conditions.

As polycarbonate continues to evolve, the overarching goal is to achieve optimal performance across a wide range of applications while addressing sustainability concerns. This involves balancing mechanical, thermal, and optical properties with processability, cost-effectiveness, and environmental impact. The future of polycarbonate lies in smart, multifunctional materials that can adapt to changing conditions and meet the complex demands of emerging technologies.

Market Demand Analysis for High-Performance Polycarbonates

The global market for high-performance polycarbonates has been experiencing robust growth, driven by increasing demand across various industries. The automotive sector stands out as a key driver, with manufacturers seeking lightweight materials to improve fuel efficiency and reduce emissions. High-performance polycarbonates offer an excellent strength-to-weight ratio, making them ideal for replacing metal components in vehicles.

In the electronics industry, the demand for high-performance polycarbonates continues to surge. The material's exceptional heat resistance, electrical insulation properties, and durability make it a preferred choice for smartphone casings, laptop bodies, and other consumer electronic devices. As the trend towards thinner, lighter, and more durable electronic products persists, the market for high-performance polycarbonates is expected to expand further.

The construction sector also contributes significantly to the growing demand for high-performance polycarbonates. The material's transparency, impact resistance, and weather durability make it suitable for applications such as skylights, roofing sheets, and safety glazing. With the increasing focus on energy-efficient buildings, polycarbonate sheets are gaining popularity as a sustainable alternative to traditional glass in many architectural applications.

Medical and healthcare industries represent another crucial market segment for high-performance polycarbonates. The material's biocompatibility, sterilizability, and clarity make it ideal for medical devices, surgical instruments, and laboratory equipment. The ongoing COVID-19 pandemic has further accelerated demand in this sector, particularly for personal protective equipment (PPE) and medical device components.

The packaging industry is also witnessing a growing adoption of high-performance polycarbonates. The material's clarity, impact resistance, and ability to withstand high temperatures make it suitable for reusable water bottles, food containers, and industrial packaging applications. As consumers become more environmentally conscious, the demand for durable and recyclable packaging solutions is expected to drive further growth in this segment.

Geographically, Asia-Pacific remains the largest market for high-performance polycarbonates, followed by North America and Europe. The rapid industrialization, urbanization, and growing middle-class population in countries like China and India are fueling demand across various end-use industries. However, environmental concerns and stringent regulations regarding plastic usage in some regions may pose challenges to market growth, emphasizing the need for sustainable and recyclable polycarbonate solutions.

In the electronics industry, the demand for high-performance polycarbonates continues to surge. The material's exceptional heat resistance, electrical insulation properties, and durability make it a preferred choice for smartphone casings, laptop bodies, and other consumer electronic devices. As the trend towards thinner, lighter, and more durable electronic products persists, the market for high-performance polycarbonates is expected to expand further.

The construction sector also contributes significantly to the growing demand for high-performance polycarbonates. The material's transparency, impact resistance, and weather durability make it suitable for applications such as skylights, roofing sheets, and safety glazing. With the increasing focus on energy-efficient buildings, polycarbonate sheets are gaining popularity as a sustainable alternative to traditional glass in many architectural applications.

Medical and healthcare industries represent another crucial market segment for high-performance polycarbonates. The material's biocompatibility, sterilizability, and clarity make it ideal for medical devices, surgical instruments, and laboratory equipment. The ongoing COVID-19 pandemic has further accelerated demand in this sector, particularly for personal protective equipment (PPE) and medical device components.

The packaging industry is also witnessing a growing adoption of high-performance polycarbonates. The material's clarity, impact resistance, and ability to withstand high temperatures make it suitable for reusable water bottles, food containers, and industrial packaging applications. As consumers become more environmentally conscious, the demand for durable and recyclable packaging solutions is expected to drive further growth in this segment.

Geographically, Asia-Pacific remains the largest market for high-performance polycarbonates, followed by North America and Europe. The rapid industrialization, urbanization, and growing middle-class population in countries like China and India are fueling demand across various end-use industries. However, environmental concerns and stringent regulations regarding plastic usage in some regions may pose challenges to market growth, emphasizing the need for sustainable and recyclable polycarbonate solutions.

Current Challenges in Polycarbonate Applications

Despite the widespread use of polycarbonate in various applications, several challenges persist in achieving optimal performance. One of the primary issues is the material's susceptibility to environmental stress cracking (ESC). This phenomenon occurs when polycarbonate is exposed to certain chemicals or subjected to mechanical stress, leading to premature failure. ESC can significantly reduce the lifespan of polycarbonate products and compromise their structural integrity, particularly in demanding environments.

Another challenge lies in the thermal stability of polycarbonate at elevated temperatures. While the material exhibits good heat resistance compared to many other plastics, prolonged exposure to high temperatures can lead to degradation, discoloration, and loss of mechanical properties. This limitation restricts its use in certain high-temperature applications and necessitates careful consideration of thermal management strategies.

The impact resistance of polycarbonate, although generally high, can be compromised under specific conditions. Low-temperature impact strength, for instance, remains a concern in some applications, particularly in outdoor or cold-storage environments. Additionally, the material's tendency to undergo ductile-to-brittle transition under certain loading conditions poses challenges in predicting and preventing failure modes.

Weathering and UV resistance present ongoing challenges for polycarbonate applications exposed to outdoor environments. Prolonged exposure to sunlight and atmospheric conditions can lead to yellowing, loss of transparency, and degradation of mechanical properties. While UV stabilizers and coatings have been developed to mitigate these effects, achieving long-term durability in outdoor applications remains a significant challenge.

The processing of polycarbonate also presents several hurdles in achieving optimal performance. Moisture absorption during processing can lead to hydrolysis and degradation of the polymer chains, affecting the final product's properties. Furthermore, the high melt viscosity of polycarbonate can make processing more challenging, particularly in complex molding operations or when attempting to achieve thin-wall sections.

Optical properties, crucial in many polycarbonate applications, can be difficult to maintain consistently. Issues such as birefringence, haze, and surface defects can compromise the material's clarity and light transmission capabilities. Achieving and maintaining high optical quality, especially in large or complex parts, remains a significant challenge in the industry.

Lastly, the balance between different performance attributes often requires trade-offs. For example, improving flame retardancy may come at the cost of reduced impact strength or increased yellowing. Similarly, enhancing chemical resistance might affect the material's processability or optical properties. Finding the optimal balance among these competing properties continues to be a key challenge in polycarbonate applications.

Another challenge lies in the thermal stability of polycarbonate at elevated temperatures. While the material exhibits good heat resistance compared to many other plastics, prolonged exposure to high temperatures can lead to degradation, discoloration, and loss of mechanical properties. This limitation restricts its use in certain high-temperature applications and necessitates careful consideration of thermal management strategies.

The impact resistance of polycarbonate, although generally high, can be compromised under specific conditions. Low-temperature impact strength, for instance, remains a concern in some applications, particularly in outdoor or cold-storage environments. Additionally, the material's tendency to undergo ductile-to-brittle transition under certain loading conditions poses challenges in predicting and preventing failure modes.

Weathering and UV resistance present ongoing challenges for polycarbonate applications exposed to outdoor environments. Prolonged exposure to sunlight and atmospheric conditions can lead to yellowing, loss of transparency, and degradation of mechanical properties. While UV stabilizers and coatings have been developed to mitigate these effects, achieving long-term durability in outdoor applications remains a significant challenge.

The processing of polycarbonate also presents several hurdles in achieving optimal performance. Moisture absorption during processing can lead to hydrolysis and degradation of the polymer chains, affecting the final product's properties. Furthermore, the high melt viscosity of polycarbonate can make processing more challenging, particularly in complex molding operations or when attempting to achieve thin-wall sections.

Optical properties, crucial in many polycarbonate applications, can be difficult to maintain consistently. Issues such as birefringence, haze, and surface defects can compromise the material's clarity and light transmission capabilities. Achieving and maintaining high optical quality, especially in large or complex parts, remains a significant challenge in the industry.

Lastly, the balance between different performance attributes often requires trade-offs. For example, improving flame retardancy may come at the cost of reduced impact strength or increased yellowing. Similarly, enhancing chemical resistance might affect the material's processability or optical properties. Finding the optimal balance among these competing properties continues to be a key challenge in polycarbonate applications.

Existing Solutions for Enhancing Polycarbonate Performance

01 Improved impact resistance and toughness

Polycarbonate performance can be enhanced by incorporating additives or modifying the polymer structure to improve impact resistance and toughness. This can involve blending with other polymers, adding impact modifiers, or adjusting the molecular weight distribution.- Improved impact resistance and toughness: Polycarbonate performance can be enhanced by incorporating additives or modifying the polymer structure to improve impact resistance and toughness. This can involve blending with other polymers, adding impact modifiers, or adjusting the molecular weight distribution.

- Enhanced thermal stability and flame retardancy: Techniques to improve the thermal stability and flame retardancy of polycarbonates include the addition of flame retardant additives, incorporation of heat-resistant monomers, or surface treatments. These modifications can extend the material's usability in high-temperature applications and improve safety performance.

- Optical and surface property enhancements: Polycarbonate performance in optical applications can be improved by enhancing transparency, reducing haze, and improving scratch resistance. This may involve the use of special additives, surface coatings, or modifications to the polymer structure to achieve desired optical and surface properties.

- Chemical resistance and weatherability improvements: Enhancing the chemical resistance and weatherability of polycarbonates can be achieved through the incorporation of UV stabilizers, antioxidants, or by developing copolymers with improved resistance properties. These modifications can extend the material's lifespan in outdoor or harsh chemical environments.

- Mechanical property optimization: Polycarbonate performance can be optimized by tailoring mechanical properties such as tensile strength, flexural modulus, and creep resistance. This can be achieved through molecular weight control, orientation techniques, or the development of composite materials incorporating polycarbonate.

02 Enhanced thermal stability and flame retardancy

Techniques to improve the thermal stability and flame retardancy of polycarbonates include the addition of flame retardant additives, modification of the polymer backbone, or the use of synergistic combinations of additives to achieve better heat resistance and fire performance.Expand Specific Solutions03 Optical properties and transparency enhancement

Methods to enhance the optical properties and transparency of polycarbonates involve controlling the crystallinity, reducing haze, and improving light transmission. This can be achieved through careful selection of monomers, additives, or processing conditions.Expand Specific Solutions04 Chemical resistance and weatherability improvement

Strategies to enhance the chemical resistance and weatherability of polycarbonates include surface treatments, incorporation of UV stabilizers, and development of copolymers or blends with improved resistance to environmental factors and chemicals.Expand Specific Solutions05 Mechanical strength and dimensional stability

Techniques to improve the mechanical strength and dimensional stability of polycarbonates involve optimizing the molecular structure, incorporating reinforcing agents, or developing new processing methods to enhance the overall structural performance of the material.Expand Specific Solutions

Key Players in Polycarbonate Industry

The polycarbonate applications market is in a mature growth stage, with a global market size expected to reach $25 billion by 2025. The technology's maturity is evident from the involvement of major chemical companies like SABIC, Covestro, and LG Chem, who have established product lines and extensive R&D capabilities. However, there's still room for innovation, particularly in areas like improved impact resistance and optical clarity. Emerging players like Wanhua Chemical and Kingfa Sci. & Tech. are challenging incumbents with new formulations and applications, especially in the Asia-Pacific region. The competitive landscape is characterized by a mix of global giants and specialized regional manufacturers, with a growing focus on sustainable and high-performance polycarbonate solutions.

SABIC Global Technologies BV

Technical Solution: SABIC has implemented a multi-faceted approach to optimize polycarbonate performance. Their LEXAN™ polycarbonate resin portfolio includes grades specifically engineered for various applications, from automotive to electronics. SABIC has developed a proprietary Nano-technology that enhances the impact resistance and flow properties of their polycarbonates[4]. They also utilize advanced polymer blending techniques to create custom formulations that balance properties like heat resistance, durability, and processability. SABIC's LEXAN™ EXL copolymers offer improved low-temperature ductility and higher impact strength compared to standard polycarbonates[5]. Furthermore, they have introduced LEXAN™ CXT, a polycarbonate copolymer that combines high heat resistance with excellent flow properties, enabling thinner-wall designs and complex geometries in automotive and electronics applications[6].

Strengths: Wide range of specialized grades, strong global presence, and continuous innovation in material science. Weaknesses: Some specialized grades may have limited availability or higher costs compared to standard polycarbonates.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a comprehensive strategy to enhance polycarbonate performance. They have invested in advanced polymerization technology that allows for precise control of molecular weight distribution, resulting in improved mechanical properties and processability[7]. Wanhua's polycarbonate grades incorporate proprietary additives that enhance UV stability and flame retardancy without sacrificing optical clarity. They have also developed a unique branching technology that improves melt strength, making their polycarbonates suitable for extrusion applications like sheet and film production[8]. Additionally, Wanhua has introduced eco-friendly polycarbonate grades that incorporate recycled content, addressing the growing demand for sustainable materials in various industries[9].

Strengths: Strong vertical integration in raw material supply, competitive pricing, and growing global presence. Weaknesses: Relatively newer entrant in the global polycarbonate market compared to some established players.

Innovative Approaches in Polycarbonate Formulation

Polycarbonate-based resin composition for extrusion molding using sizing die and molded product

PatentInactiveUS7326467B2

Innovation

- A polycarbonate-based resin composition with specific integral values in 1H-NMR spectra, having a viscosity-average molecular weight of 17000 to 27000, and containing specific proton ratios (Pa, Pb, and Pc) that balance branching and unbranched structures, optimized through a transesterification reaction method, which reduces load on the extruder and improves moldability, impact resistance, and hue.

Polycarbonate composition with high comparative tracking index

PatentWO2022228952A1

Innovation

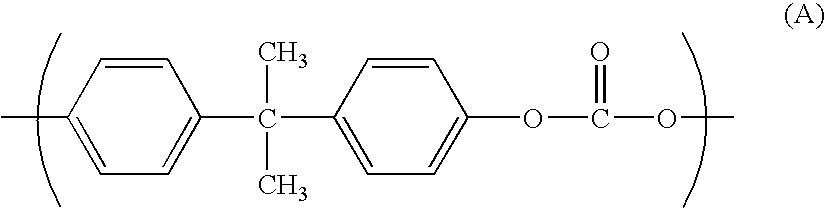

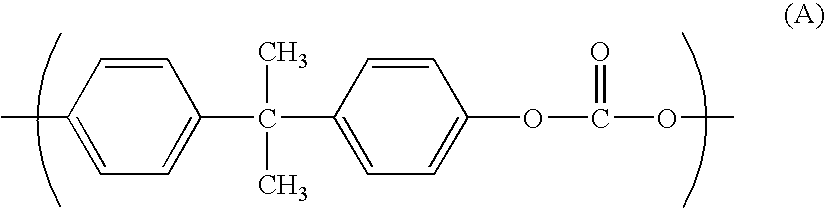

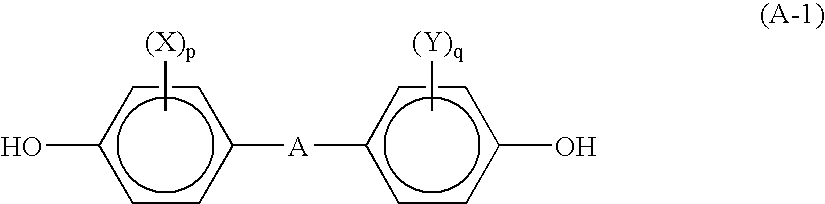

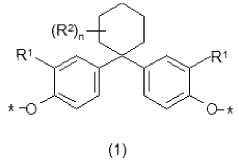

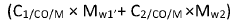

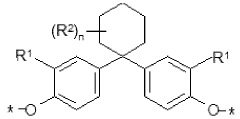

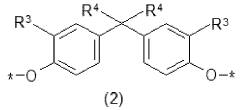

- A polycarbonate composition comprising 60-95 wt.% of a copolycarbonate with specific molecular weight ratios of units derived from bis(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane and bisphenol A, combined with 5-40 wt.% of a homopolycarbonate with a weight-average molecular weight of 24000-28000 g/mol, enhancing CTI to 600 V, transmittance to 86%, and Vicat softening temperature above 175 °C.

Environmental Impact and Sustainability Considerations

In the pursuit of optimal performance in polycarbonate applications, environmental impact and sustainability considerations have become increasingly crucial. Polycarbonate, while offering excellent mechanical properties and versatility, has faced scrutiny due to its potential environmental implications. The production process of polycarbonate involves the use of bisphenol A (BPA), a chemical that has raised concerns regarding its effects on human health and ecosystems.

To address these challenges, the industry has been focusing on developing more sustainable alternatives and improving the environmental footprint of polycarbonate production. One significant area of progress is the development of BPA-free polycarbonates, which utilize alternative monomers to achieve similar performance characteristics without the associated environmental risks. These innovations not only mitigate potential health concerns but also enhance the material's end-of-life recyclability.

Energy efficiency in polycarbonate manufacturing has also seen substantial improvements. Advanced production techniques and equipment have reduced energy consumption, thereby lowering the carbon footprint associated with polycarbonate applications. Additionally, the integration of renewable energy sources in manufacturing facilities has further contributed to reducing the overall environmental impact of polycarbonate production.

Recycling and circular economy principles play a pivotal role in enhancing the sustainability of polycarbonate applications. Improved recycling technologies have made it possible to recover and reprocess polycarbonate materials more efficiently, reducing waste and conserving resources. Closed-loop recycling systems have been implemented in various industries, allowing for the continuous reuse of polycarbonate materials in high-performance applications.

The durability and longevity of polycarbonate products contribute significantly to their sustainability profile. By extending the lifespan of products through improved material formulations and design considerations, the overall environmental impact is reduced. This approach aligns with the principles of sustainable product design, emphasizing the importance of creating long-lasting, high-performance solutions.

Biodegradable additives and bio-based polycarbonate alternatives are emerging as promising avenues for enhancing environmental sustainability. These innovations aim to address the end-of-life challenges associated with traditional polycarbonates while maintaining the desired performance characteristics. However, further research and development are needed to ensure these alternatives can meet the stringent requirements of various applications without compromising on performance or durability.

To address these challenges, the industry has been focusing on developing more sustainable alternatives and improving the environmental footprint of polycarbonate production. One significant area of progress is the development of BPA-free polycarbonates, which utilize alternative monomers to achieve similar performance characteristics without the associated environmental risks. These innovations not only mitigate potential health concerns but also enhance the material's end-of-life recyclability.

Energy efficiency in polycarbonate manufacturing has also seen substantial improvements. Advanced production techniques and equipment have reduced energy consumption, thereby lowering the carbon footprint associated with polycarbonate applications. Additionally, the integration of renewable energy sources in manufacturing facilities has further contributed to reducing the overall environmental impact of polycarbonate production.

Recycling and circular economy principles play a pivotal role in enhancing the sustainability of polycarbonate applications. Improved recycling technologies have made it possible to recover and reprocess polycarbonate materials more efficiently, reducing waste and conserving resources. Closed-loop recycling systems have been implemented in various industries, allowing for the continuous reuse of polycarbonate materials in high-performance applications.

The durability and longevity of polycarbonate products contribute significantly to their sustainability profile. By extending the lifespan of products through improved material formulations and design considerations, the overall environmental impact is reduced. This approach aligns with the principles of sustainable product design, emphasizing the importance of creating long-lasting, high-performance solutions.

Biodegradable additives and bio-based polycarbonate alternatives are emerging as promising avenues for enhancing environmental sustainability. These innovations aim to address the end-of-life challenges associated with traditional polycarbonates while maintaining the desired performance characteristics. However, further research and development are needed to ensure these alternatives can meet the stringent requirements of various applications without compromising on performance or durability.

Regulatory Framework for Polycarbonate Applications

The regulatory framework for polycarbonate applications plays a crucial role in ensuring the safety, quality, and environmental sustainability of products utilizing this versatile material. Globally, various regulatory bodies have established guidelines and standards that manufacturers must adhere to when developing and producing polycarbonate-based products.

In the United States, the Food and Drug Administration (FDA) oversees the use of polycarbonate in food contact applications. The FDA has set specific regulations under the Code of Federal Regulations (CFR) Title 21, which outlines the requirements for food-grade polycarbonate materials. These regulations cover aspects such as chemical composition, manufacturing processes, and migration limits for potential contaminants.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of polycarbonate in various applications. Under REACH, manufacturers must register chemicals used in polycarbonate production and provide safety data to ensure compliance with environmental and health standards.

For automotive applications, polycarbonate products must meet stringent safety standards set by organizations such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe. These standards focus on impact resistance, optical clarity, and durability of polycarbonate components used in vehicle construction.

In the electronics industry, polycarbonate applications are subject to regulations such as the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electrical and electronic equipment. Manufacturers must ensure that their polycarbonate products comply with these restrictions to maintain market access.

The construction sector also has specific regulations governing the use of polycarbonate materials. Building codes and fire safety standards, such as those set by the International Code Council (ICC) and the National Fire Protection Association (NFPA), dictate the performance requirements for polycarbonate products used in construction applications.

Environmental regulations, including those related to recycling and waste management, have a significant impact on polycarbonate applications. Many jurisdictions have implemented extended producer responsibility (EPR) programs, requiring manufacturers to consider the entire lifecycle of their products, including end-of-life disposal or recycling.

To achieve optimal performance in polycarbonate applications, manufacturers must navigate this complex regulatory landscape while continuously innovating to meet evolving standards. Compliance with these regulations not only ensures product safety and quality but also drives technological advancements in polycarbonate formulations and processing techniques.

In the United States, the Food and Drug Administration (FDA) oversees the use of polycarbonate in food contact applications. The FDA has set specific regulations under the Code of Federal Regulations (CFR) Title 21, which outlines the requirements for food-grade polycarbonate materials. These regulations cover aspects such as chemical composition, manufacturing processes, and migration limits for potential contaminants.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of polycarbonate in various applications. Under REACH, manufacturers must register chemicals used in polycarbonate production and provide safety data to ensure compliance with environmental and health standards.

For automotive applications, polycarbonate products must meet stringent safety standards set by organizations such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe. These standards focus on impact resistance, optical clarity, and durability of polycarbonate components used in vehicle construction.

In the electronics industry, polycarbonate applications are subject to regulations such as the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electrical and electronic equipment. Manufacturers must ensure that their polycarbonate products comply with these restrictions to maintain market access.

The construction sector also has specific regulations governing the use of polycarbonate materials. Building codes and fire safety standards, such as those set by the International Code Council (ICC) and the National Fire Protection Association (NFPA), dictate the performance requirements for polycarbonate products used in construction applications.

Environmental regulations, including those related to recycling and waste management, have a significant impact on polycarbonate applications. Many jurisdictions have implemented extended producer responsibility (EPR) programs, requiring manufacturers to consider the entire lifecycle of their products, including end-of-life disposal or recycling.

To achieve optimal performance in polycarbonate applications, manufacturers must navigate this complex regulatory landscape while continuously innovating to meet evolving standards. Compliance with these regulations not only ensures product safety and quality but also drives technological advancements in polycarbonate formulations and processing techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!