How to Cultivate Kevlar's Potential in Eco-Friendly Innovations?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Eco-Innovation Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has long been renowned for its exceptional strength-to-weight ratio and heat-resistant properties. Initially designed for use in tires, Kevlar has since found applications in various industries, including aerospace, automotive, and personal protective equipment. However, as global concerns about environmental sustainability grow, there is an increasing need to explore Kevlar's potential in eco-friendly innovations.

The primary objective of this technical research is to investigate and cultivate Kevlar's potential in environmentally sustainable applications. This involves examining the material's inherent properties, current manufacturing processes, and exploring novel approaches to enhance its eco-friendliness without compromising its performance characteristics.

One key area of focus is the development of more sustainable production methods for Kevlar. Traditional manufacturing processes involve the use of harsh chemicals and energy-intensive procedures, which have significant environmental impacts. By exploring alternative synthesis routes and greener chemical processes, we aim to reduce the carbon footprint associated with Kevlar production while maintaining its superior mechanical properties.

Another crucial aspect of this research is the investigation of Kevlar's potential in renewable energy technologies. The material's high strength and durability make it an excellent candidate for applications in wind turbine blades, solar panel components, and energy storage systems. By leveraging Kevlar's unique properties in these fields, we can contribute to the advancement of clean energy solutions and promote a more sustainable future.

Furthermore, this study aims to explore the integration of Kevlar with biodegradable or recyclable materials. While Kevlar itself is not biodegradable, combining it with eco-friendly materials could lead to the development of hybrid composites that offer both high performance and reduced environmental impact. This approach could potentially revolutionize industries such as automotive and construction, where the demand for lightweight, strong, and sustainable materials is rapidly growing.

Additionally, we will investigate the potential of Kevlar in water treatment and environmental remediation applications. The fiber's chemical resistance and filtration capabilities could be harnessed to develop advanced membranes for water purification or to create innovative solutions for removing pollutants from air and soil.

By pursuing these research directions, we aim to position Kevlar as a key material in the transition towards a more sustainable and environmentally conscious industrial landscape. The ultimate goal is to unlock new applications and manufacturing techniques that not only maintain Kevlar's exceptional performance but also align with global sustainability goals and contribute to a greener future.

The primary objective of this technical research is to investigate and cultivate Kevlar's potential in environmentally sustainable applications. This involves examining the material's inherent properties, current manufacturing processes, and exploring novel approaches to enhance its eco-friendliness without compromising its performance characteristics.

One key area of focus is the development of more sustainable production methods for Kevlar. Traditional manufacturing processes involve the use of harsh chemicals and energy-intensive procedures, which have significant environmental impacts. By exploring alternative synthesis routes and greener chemical processes, we aim to reduce the carbon footprint associated with Kevlar production while maintaining its superior mechanical properties.

Another crucial aspect of this research is the investigation of Kevlar's potential in renewable energy technologies. The material's high strength and durability make it an excellent candidate for applications in wind turbine blades, solar panel components, and energy storage systems. By leveraging Kevlar's unique properties in these fields, we can contribute to the advancement of clean energy solutions and promote a more sustainable future.

Furthermore, this study aims to explore the integration of Kevlar with biodegradable or recyclable materials. While Kevlar itself is not biodegradable, combining it with eco-friendly materials could lead to the development of hybrid composites that offer both high performance and reduced environmental impact. This approach could potentially revolutionize industries such as automotive and construction, where the demand for lightweight, strong, and sustainable materials is rapidly growing.

Additionally, we will investigate the potential of Kevlar in water treatment and environmental remediation applications. The fiber's chemical resistance and filtration capabilities could be harnessed to develop advanced membranes for water purification or to create innovative solutions for removing pollutants from air and soil.

By pursuing these research directions, we aim to position Kevlar as a key material in the transition towards a more sustainable and environmentally conscious industrial landscape. The ultimate goal is to unlock new applications and manufacturing techniques that not only maintain Kevlar's exceptional performance but also align with global sustainability goals and contribute to a greener future.

Market Analysis for Sustainable Kevlar Applications

The market for sustainable Kevlar applications is experiencing significant growth, driven by increasing environmental awareness and the push for eco-friendly innovations across various industries. Kevlar, known for its exceptional strength-to-weight ratio and heat resistance, has traditionally been used in high-performance applications such as body armor, aerospace components, and automotive parts. However, the focus on sustainability has opened new avenues for Kevlar's potential in eco-friendly innovations.

In the construction sector, there is a growing demand for sustainable building materials that offer durability and energy efficiency. Kevlar-reinforced composites are being explored as alternatives to traditional materials, providing enhanced structural integrity while reducing the overall environmental impact of buildings. These composites can contribute to longer-lasting structures, reducing the need for frequent repairs and replacements.

The renewable energy industry presents another promising market for sustainable Kevlar applications. Wind turbine blades reinforced with Kevlar fibers offer improved strength and longevity, potentially increasing the lifespan of wind farms and reducing maintenance costs. Similarly, in the solar energy sector, Kevlar-based materials are being investigated for their potential to enhance the durability and efficiency of solar panels.

The automotive industry is increasingly focusing on lightweight materials to improve fuel efficiency and reduce emissions. Kevlar composites are being utilized in vehicle components to decrease overall weight without compromising safety or performance. This application aligns with the industry's shift towards more sustainable transportation solutions.

In the field of environmental protection, Kevlar-based materials are finding applications in oil spill cleanup and water filtration systems. The material's chemical resistance and durability make it suitable for creating advanced filtration membranes that can effectively remove pollutants from water and air, contributing to cleaner ecosystems.

The textile industry is also exploring Kevlar's potential in creating sustainable, high-performance fabrics. By blending Kevlar with other eco-friendly fibers, manufacturers are developing durable, long-lasting textiles that reduce the need for frequent replacements, thus minimizing waste in the fashion industry.

As the global focus on circular economy principles intensifies, there is growing interest in developing recycling and upcycling processes for Kevlar-based products. This trend is creating new market opportunities for companies specializing in advanced material recovery and repurposing technologies.

The market for sustainable Kevlar applications is expected to expand further as research and development efforts continue to uncover new eco-friendly uses for this versatile material. Companies investing in sustainable Kevlar innovations are likely to gain a competitive edge in their respective industries, as consumers and regulators increasingly prioritize environmentally responsible products and solutions.

In the construction sector, there is a growing demand for sustainable building materials that offer durability and energy efficiency. Kevlar-reinforced composites are being explored as alternatives to traditional materials, providing enhanced structural integrity while reducing the overall environmental impact of buildings. These composites can contribute to longer-lasting structures, reducing the need for frequent repairs and replacements.

The renewable energy industry presents another promising market for sustainable Kevlar applications. Wind turbine blades reinforced with Kevlar fibers offer improved strength and longevity, potentially increasing the lifespan of wind farms and reducing maintenance costs. Similarly, in the solar energy sector, Kevlar-based materials are being investigated for their potential to enhance the durability and efficiency of solar panels.

The automotive industry is increasingly focusing on lightweight materials to improve fuel efficiency and reduce emissions. Kevlar composites are being utilized in vehicle components to decrease overall weight without compromising safety or performance. This application aligns with the industry's shift towards more sustainable transportation solutions.

In the field of environmental protection, Kevlar-based materials are finding applications in oil spill cleanup and water filtration systems. The material's chemical resistance and durability make it suitable for creating advanced filtration membranes that can effectively remove pollutants from water and air, contributing to cleaner ecosystems.

The textile industry is also exploring Kevlar's potential in creating sustainable, high-performance fabrics. By blending Kevlar with other eco-friendly fibers, manufacturers are developing durable, long-lasting textiles that reduce the need for frequent replacements, thus minimizing waste in the fashion industry.

As the global focus on circular economy principles intensifies, there is growing interest in developing recycling and upcycling processes for Kevlar-based products. This trend is creating new market opportunities for companies specializing in advanced material recovery and repurposing technologies.

The market for sustainable Kevlar applications is expected to expand further as research and development efforts continue to uncover new eco-friendly uses for this versatile material. Companies investing in sustainable Kevlar innovations are likely to gain a competitive edge in their respective industries, as consumers and regulators increasingly prioritize environmentally responsible products and solutions.

Current Challenges in Eco-Friendly Kevlar Development

Despite Kevlar's remarkable properties and widespread applications, its development in eco-friendly innovations faces several significant challenges. The primary obstacle lies in the inherent nature of Kevlar production, which traditionally relies on petroleum-based raw materials and energy-intensive processes. This dependency on non-renewable resources contradicts the principles of sustainability and poses a major hurdle in aligning Kevlar with eco-friendly initiatives.

The synthesis of Kevlar involves the use of harsh chemicals and solvents, many of which are toxic and environmentally harmful. The disposal and treatment of these chemical byproducts present ongoing environmental concerns. Moreover, the high-temperature and high-pressure conditions required for Kevlar production contribute to substantial energy consumption and associated carbon emissions, further complicating efforts to make the process more environmentally benign.

Another challenge is the limited biodegradability of Kevlar fibers. While their durability is a prized attribute in many applications, it becomes problematic at the end of the product lifecycle. Kevlar's resistance to degradation means that products containing these fibers can persist in the environment for extended periods, contributing to long-term pollution and waste accumulation.

The recycling of Kevlar-containing products presents its own set of difficulties. The complex composition of many Kevlar-based materials, often involving blends with other fibers or resins, makes separation and recovery of pure Kevlar challenging and economically unfeasible with current technologies. This recycling bottleneck hampers the development of a circular economy model for Kevlar products.

Furthermore, the high cost of eco-friendly alternatives and sustainable production methods poses a significant barrier to widespread adoption. Many potential green innovations in Kevlar production or application require substantial investment in research, development, and infrastructure. The economic viability of these eco-friendly approaches often struggles to compete with established, less environmentally conscious methods.

Regulatory challenges also play a role in impeding eco-friendly Kevlar innovations. The stringent performance standards required for many Kevlar applications, particularly in safety-critical sectors, can limit the adoption of new, potentially more sustainable variants that may not yet match the performance of traditional Kevlar fibers.

Lastly, there is a knowledge gap in understanding the full environmental impact of Kevlar throughout its lifecycle. Comprehensive life cycle assessments are needed to accurately quantify the ecological footprint of Kevlar products and to identify the most effective areas for environmental improvement. This lack of detailed environmental data hinders informed decision-making in developing truly sustainable Kevlar innovations.

The synthesis of Kevlar involves the use of harsh chemicals and solvents, many of which are toxic and environmentally harmful. The disposal and treatment of these chemical byproducts present ongoing environmental concerns. Moreover, the high-temperature and high-pressure conditions required for Kevlar production contribute to substantial energy consumption and associated carbon emissions, further complicating efforts to make the process more environmentally benign.

Another challenge is the limited biodegradability of Kevlar fibers. While their durability is a prized attribute in many applications, it becomes problematic at the end of the product lifecycle. Kevlar's resistance to degradation means that products containing these fibers can persist in the environment for extended periods, contributing to long-term pollution and waste accumulation.

The recycling of Kevlar-containing products presents its own set of difficulties. The complex composition of many Kevlar-based materials, often involving blends with other fibers or resins, makes separation and recovery of pure Kevlar challenging and economically unfeasible with current technologies. This recycling bottleneck hampers the development of a circular economy model for Kevlar products.

Furthermore, the high cost of eco-friendly alternatives and sustainable production methods poses a significant barrier to widespread adoption. Many potential green innovations in Kevlar production or application require substantial investment in research, development, and infrastructure. The economic viability of these eco-friendly approaches often struggles to compete with established, less environmentally conscious methods.

Regulatory challenges also play a role in impeding eco-friendly Kevlar innovations. The stringent performance standards required for many Kevlar applications, particularly in safety-critical sectors, can limit the adoption of new, potentially more sustainable variants that may not yet match the performance of traditional Kevlar fibers.

Lastly, there is a knowledge gap in understanding the full environmental impact of Kevlar throughout its lifecycle. Comprehensive life cycle assessments are needed to accurately quantify the ecological footprint of Kevlar products and to identify the most effective areas for environmental improvement. This lack of detailed environmental data hinders informed decision-making in developing truly sustainable Kevlar innovations.

Existing Eco-Innovations in Kevlar Technology

01 Kevlar-reinforced composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.

- Kevlar in protective gear and clothing: Kevlar is extensively used in the manufacture of protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.

- Kevlar-based fire-resistant materials: Kevlar is utilized in the development of fire-resistant materials and fabrics. These materials are used in firefighting equipment, industrial safety gear, and other applications requiring heat and flame resistance.

- Kevlar in high-performance ropes and cables: Kevlar fibers are incorporated into ropes, cables, and cordage for various applications. These high-strength, low-weight materials are used in marine, industrial, and recreational settings where durability and performance are crucial.

- Kevlar in automotive and aerospace applications: Kevlar is used in automotive and aerospace industries for its lightweight and high-strength properties. It is incorporated into components such as tires, body panels, and structural elements to improve fuel efficiency and overall performance.

02 Kevlar in protective gear and clothing

Kevlar is widely used in the manufacture of protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.Expand Specific Solutions03 Kevlar-based fire-resistant materials

Kevlar is utilized in the development of fire-resistant materials and fabrics. These materials are used in firefighting equipment, industrial safety gear, and other applications requiring heat and flame resistance.Expand Specific Solutions04 Kevlar in automotive applications

Kevlar is employed in various automotive components to reduce weight while maintaining strength. It is used in tires, belts, hoses, and body panels to improve fuel efficiency and overall vehicle performance.Expand Specific Solutions05 Kevlar in sporting goods and equipment

Kevlar is incorporated into sporting goods and equipment to enhance performance and durability. It is used in products such as tennis rackets, bicycle frames, and kayaks to provide strength and lightweight properties.Expand Specific Solutions

Key Players in Eco-Friendly Kevlar Research

The development of eco-friendly innovations using Kevlar is in its early stages, with significant potential for growth. The market size is expanding as industries seek sustainable alternatives, driven by increasing environmental concerns. Technologically, Kevlar's application in eco-friendly solutions is still evolving, with varying levels of maturity across different sectors. Research institutions like Harbin Institute of Technology and Beijing Institute of Technology are at the forefront of exploring Kevlar's eco-friendly applications, while companies such as DSM IP Assets BV and Sharp Corp. are likely focusing on commercial implementations. The competitive landscape is diverse, with both academic and industrial players contributing to advancements in this field.

Indian Institutes of Technology

Technical Solution: The Indian Institutes of Technology (IIT) have been at the forefront of research into eco-friendly applications of Kevlar. One significant project involves the development of Kevlar-based biodegradable composites for packaging materials. By blending Kevlar fibers with biodegradable polymers, researchers have created materials that offer the strength of Kevlar with improved end-of-life characteristics[10]. IIT has also explored the use of Kevlar in sustainable agriculture, developing protective coverings for crops that are both durable and environmentally friendly[11]. Furthermore, their research extends to using Kevlar in advanced water treatment technologies, creating membranes that can effectively remove pollutants while being more durable and energy-efficient than traditional methods[12].

Strengths: Focus on practical, wide-ranging applications, integration with biodegradable materials, addressing critical environmental issues. Weaknesses: Potential high costs for large-scale implementation, need for extensive field testing and validation.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has been exploring eco-friendly applications of Kevlar in aerospace and defense. They have developed a composite material that combines Kevlar with recycled carbon fibers, reducing the overall environmental footprint while maintaining high strength-to-weight ratios[4]. This innovative approach allows for the use of recycled materials in high-performance applications. The company has also invested in research to optimize Kevlar-based structures for improved fuel efficiency in aircraft, indirectly contributing to reduced emissions[5]. Furthermore, Northrop Grumman is investigating the use of Kevlar in advanced energy storage systems for renewable energy applications, leveraging its durability and lightweight properties[6].

Strengths: Integration of recycled materials, application in fuel-efficient designs, potential for energy storage. Weaknesses: Limited to specific industry applications, may face regulatory challenges in defense sector.

Breakthrough Patents in Sustainable Kevlar

Honeycomb core composite article and method and apparatus for making same

PatentInactiveUS7083753B2

Innovation

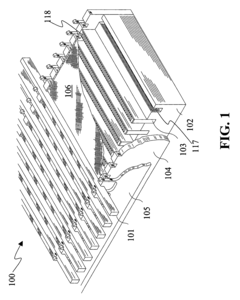

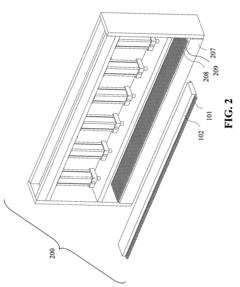

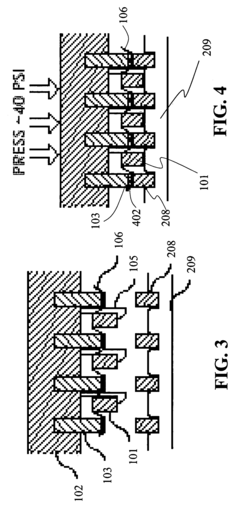

- A process involving the use of thermo-set polymer impregnated fabrics, such as KEVLAR®, where the fabric is aligned and held by bolster plates with heating elements and pins to concentrate pressure and heat, allowing for node-by-node curing and co-curing of plies to form a honeycomb core with controlled orientation for optimal mechanical properties.

Method for preparing layered-structure low-temperature proton exchange membrane based on vacuum-assisted flocculation technology

PatentInactiveCN110556559A

Innovation

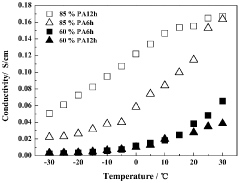

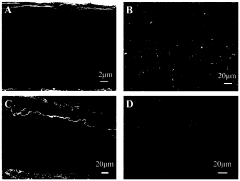

- Vacuum-assisted flocculation technology was used to prepare a low-temperature proton exchange membrane with a layered structure. By using Kevlar fiber, oxidized carbon nanotubes and polyvinyl alcohol as raw materials, vacuum-assisted flocculation technology was used to achieve the orderly assembly of the three components to prepare Non-aqueous proton exchange membrane with high proton conductivity and good mechanical properties.

Environmental Impact Assessment of Kevlar Production

The environmental impact assessment of Kevlar production is a critical aspect of evaluating its potential for eco-friendly innovations. Kevlar, a high-strength synthetic fiber, has been widely used in various applications due to its exceptional properties. However, its production process has significant environmental implications that must be carefully considered.

The manufacturing of Kevlar involves energy-intensive processes and the use of potentially harmful chemicals. The primary raw materials for Kevlar production are petroleum-based, which raises concerns about resource depletion and carbon emissions. The polymerization process requires high temperatures and pressures, consuming substantial amounts of energy and contributing to greenhouse gas emissions.

Water usage is another crucial factor in the environmental impact of Kevlar production. The manufacturing process requires large quantities of water for cooling and washing, potentially leading to water stress in production areas. Additionally, the wastewater generated during production may contain chemical residues that require proper treatment before discharge to prevent water pollution.

Chemical emissions are a significant concern in Kevlar production. The process involves the use of sulfuric acid, which can lead to air and water pollution if not properly managed. Volatile organic compounds (VOCs) may also be released during various stages of production, contributing to air quality issues and potential health risks for workers and surrounding communities.

Waste management is an essential aspect of the environmental impact assessment. The production of Kevlar generates solid waste, including off-spec materials and packaging waste. Proper disposal or recycling of these materials is crucial to minimize landfill impact and resource depletion.

On the positive side, Kevlar's durability and long lifespan can contribute to sustainability by reducing the need for frequent replacements in its applications. This longevity can potentially offset some of the environmental impacts associated with its production.

To mitigate the environmental impact of Kevlar production, several strategies can be implemented. These include optimizing energy efficiency in manufacturing processes, exploring renewable energy sources, improving water recycling and treatment systems, and developing more environmentally friendly chemical alternatives. Additionally, research into bio-based precursors for Kevlar production could potentially reduce its reliance on petroleum-based raw materials.

In conclusion, while Kevlar offers significant benefits in terms of strength and durability, its production process poses several environmental challenges. A comprehensive environmental impact assessment is crucial for identifying areas of improvement and developing strategies to enhance the eco-friendliness of Kevlar production. This assessment forms the foundation for cultivating Kevlar's potential in eco-friendly innovations, balancing its performance benefits with environmental sustainability.

The manufacturing of Kevlar involves energy-intensive processes and the use of potentially harmful chemicals. The primary raw materials for Kevlar production are petroleum-based, which raises concerns about resource depletion and carbon emissions. The polymerization process requires high temperatures and pressures, consuming substantial amounts of energy and contributing to greenhouse gas emissions.

Water usage is another crucial factor in the environmental impact of Kevlar production. The manufacturing process requires large quantities of water for cooling and washing, potentially leading to water stress in production areas. Additionally, the wastewater generated during production may contain chemical residues that require proper treatment before discharge to prevent water pollution.

Chemical emissions are a significant concern in Kevlar production. The process involves the use of sulfuric acid, which can lead to air and water pollution if not properly managed. Volatile organic compounds (VOCs) may also be released during various stages of production, contributing to air quality issues and potential health risks for workers and surrounding communities.

Waste management is an essential aspect of the environmental impact assessment. The production of Kevlar generates solid waste, including off-spec materials and packaging waste. Proper disposal or recycling of these materials is crucial to minimize landfill impact and resource depletion.

On the positive side, Kevlar's durability and long lifespan can contribute to sustainability by reducing the need for frequent replacements in its applications. This longevity can potentially offset some of the environmental impacts associated with its production.

To mitigate the environmental impact of Kevlar production, several strategies can be implemented. These include optimizing energy efficiency in manufacturing processes, exploring renewable energy sources, improving water recycling and treatment systems, and developing more environmentally friendly chemical alternatives. Additionally, research into bio-based precursors for Kevlar production could potentially reduce its reliance on petroleum-based raw materials.

In conclusion, while Kevlar offers significant benefits in terms of strength and durability, its production process poses several environmental challenges. A comprehensive environmental impact assessment is crucial for identifying areas of improvement and developing strategies to enhance the eco-friendliness of Kevlar production. This assessment forms the foundation for cultivating Kevlar's potential in eco-friendly innovations, balancing its performance benefits with environmental sustainability.

Regulatory Framework for Sustainable Materials

The regulatory framework for sustainable materials plays a crucial role in cultivating Kevlar's potential for eco-friendly innovations. As governments and international organizations increasingly prioritize environmental sustainability, the development and implementation of regulations specifically targeting sustainable materials have become more prevalent.

In the context of Kevlar, these regulations often focus on several key areas. Firstly, they address the production process, emphasizing the need for reduced environmental impact during manufacturing. This includes guidelines for minimizing energy consumption, water usage, and chemical emissions. Manufacturers are encouraged to adopt cleaner production techniques and invest in more efficient technologies to meet these standards.

Secondly, the regulatory framework often encompasses the entire lifecycle of Kevlar-based products. This approach considers the environmental impact from raw material extraction to disposal or recycling. Regulations may mandate the use of life cycle assessment (LCA) tools to evaluate and improve the overall sustainability of Kevlar applications.

Product safety and performance standards are another critical component of the regulatory landscape. While Kevlar is known for its exceptional strength and durability, regulations ensure that these properties are maintained when the material is modified for eco-friendly purposes. This balance between performance and sustainability is crucial for the widespread adoption of environmentally conscious Kevlar innovations.

Waste management and recycling regulations also play a significant role. As Kevlar finds applications in various industries, from automotive to aerospace, guidelines for proper disposal and recycling of Kevlar-containing products are essential. These regulations aim to minimize landfill waste and promote the development of efficient recycling technologies specific to Kevlar and similar high-performance materials.

Furthermore, the regulatory framework often includes incentives for research and development in sustainable materials. This may come in the form of tax breaks, grants, or other financial incentives for companies investing in eco-friendly Kevlar innovations. Such measures aim to accelerate the transition towards more sustainable material solutions across industries.

Lastly, international standards and certifications form a crucial part of the regulatory landscape. Organizations like ISO (International Organization for Standardization) have developed specific standards for sustainable materials, which often serve as benchmarks for national regulations. Compliance with these standards not only ensures environmental responsibility but also facilitates global trade and adoption of sustainable Kevlar innovations.

In the context of Kevlar, these regulations often focus on several key areas. Firstly, they address the production process, emphasizing the need for reduced environmental impact during manufacturing. This includes guidelines for minimizing energy consumption, water usage, and chemical emissions. Manufacturers are encouraged to adopt cleaner production techniques and invest in more efficient technologies to meet these standards.

Secondly, the regulatory framework often encompasses the entire lifecycle of Kevlar-based products. This approach considers the environmental impact from raw material extraction to disposal or recycling. Regulations may mandate the use of life cycle assessment (LCA) tools to evaluate and improve the overall sustainability of Kevlar applications.

Product safety and performance standards are another critical component of the regulatory landscape. While Kevlar is known for its exceptional strength and durability, regulations ensure that these properties are maintained when the material is modified for eco-friendly purposes. This balance between performance and sustainability is crucial for the widespread adoption of environmentally conscious Kevlar innovations.

Waste management and recycling regulations also play a significant role. As Kevlar finds applications in various industries, from automotive to aerospace, guidelines for proper disposal and recycling of Kevlar-containing products are essential. These regulations aim to minimize landfill waste and promote the development of efficient recycling technologies specific to Kevlar and similar high-performance materials.

Furthermore, the regulatory framework often includes incentives for research and development in sustainable materials. This may come in the form of tax breaks, grants, or other financial incentives for companies investing in eco-friendly Kevlar innovations. Such measures aim to accelerate the transition towards more sustainable material solutions across industries.

Lastly, international standards and certifications form a crucial part of the regulatory landscape. Organizations like ISO (International Organization for Standardization) have developed specific standards for sustainable materials, which often serve as benchmarks for national regulations. Compliance with these standards not only ensures environmental responsibility but also facilitates global trade and adoption of sustainable Kevlar innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!