How to Customize Hypertonic Solutions for Laboratory Research?

Hypertonic Solutions Background and Objectives

Hypertonic solutions have been a cornerstone in laboratory research for decades, playing a crucial role in various scientific disciplines. These solutions, characterized by their higher solute concentration compared to the surrounding environment, have found applications in fields ranging from cell biology to pharmacology. The evolution of hypertonic solutions in research settings has been marked by continuous refinement and adaptation to meet the diverse needs of modern scientific inquiry.

The primary objective of customizing hypertonic solutions for laboratory research is to create tailored environments that facilitate specific experimental outcomes. This customization process involves careful consideration of factors such as osmolarity, pH, and solute composition to achieve desired cellular responses or biochemical reactions. By fine-tuning these parameters, researchers can manipulate cellular behavior, study membrane transport mechanisms, and investigate osmotic stress responses with unprecedented precision.

The development of hypertonic solutions has been driven by the increasing complexity of research questions and the need for more sophisticated experimental tools. Early applications primarily focused on basic osmotic studies, but as our understanding of cellular physiology deepened, so did the requirements for more specialized hypertonic solutions. This evolution has led to the creation of a wide array of customized solutions, each designed to address specific research needs across various scientific disciplines.

In recent years, the trend towards personalized medicine and advanced cell culture techniques has further emphasized the importance of customizable hypertonic solutions. These solutions now play a critical role in developing organ-on-chip models, 3D cell cultures, and tissue engineering applications. The ability to precisely control the extracellular environment has become essential for mimicking physiological conditions and studying complex biological processes in vitro.

The technological advancements in analytical instruments and high-throughput screening methods have also contributed to the growing demand for customized hypertonic solutions. These tools allow researchers to rapidly assess the effects of various solution compositions on cellular responses, enabling more efficient optimization of experimental conditions. As a result, the field has seen a shift towards more dynamic and adaptable approaches in solution preparation and application.

Looking ahead, the future of hypertonic solutions in laboratory research is poised for further innovation. Emerging areas such as single-cell analysis, nanotechnology-based drug delivery systems, and regenerative medicine are expected to drive new developments in hypertonic solution customization. These advancements will likely focus on enhancing solution stability, improving biocompatibility, and expanding the range of applications in both basic and translational research.

Market Analysis for Lab-Grade Hypertonic Solutions

The market for lab-grade hypertonic solutions is experiencing significant growth, driven by the increasing demand for customized solutions in various research fields. This market segment is closely tied to the broader life sciences and biotechnology industries, which have been expanding rapidly in recent years. The global market for laboratory reagents, including hypertonic solutions, is projected to continue its upward trajectory due to advancements in research methodologies and the growing emphasis on precision medicine.

One of the key factors fueling the demand for customized hypertonic solutions is the rise of personalized medicine and targeted therapies. Researchers require specific osmotic environments to study cellular responses, drug efficacy, and molecular interactions. This has led to a surge in demand for tailored hypertonic solutions that can meet the exact requirements of diverse experimental setups.

The pharmaceutical and biotechnology sectors are major contributors to the market growth of lab-grade hypertonic solutions. These industries rely heavily on precise cellular environments for drug discovery, development, and testing processes. As the number of drug candidates in clinical trials continues to increase, the need for specialized hypertonic solutions is expected to grow proportionally.

Academic and research institutions also play a crucial role in driving the market demand. Universities and research centers are constantly pushing the boundaries of scientific knowledge, necessitating the use of customized hypertonic solutions for a wide range of experiments. This includes studies in cell biology, molecular genetics, and tissue engineering, among others.

The market for lab-grade hypertonic solutions is characterized by a mix of large multinational corporations and specialized suppliers. Major players in the life sciences industry offer a range of standard hypertonic solutions, while smaller, niche companies focus on providing highly customized products to meet specific research needs. This diversity in the supplier landscape ensures that researchers have access to both off-the-shelf and tailor-made solutions.

Geographically, North America and Europe dominate the market for lab-grade hypertonic solutions, owing to their well-established research infrastructure and high R&D spending. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing investments in life sciences research and the expansion of biotechnology industries in countries like China and India.

Looking ahead, the market for customized hypertonic solutions is poised for continued growth. Factors such as the increasing complexity of research projects, the need for reproducibility in experiments, and the growing focus on cell-based therapies are expected to sustain the demand for specialized osmotic environments. Additionally, the integration of automation and high-throughput screening techniques in research laboratories is likely to create new opportunities for innovative hypertonic solution products and delivery systems.

Current Challenges in Hypertonic Solution Customization

The customization of hypertonic solutions for laboratory research faces several significant challenges that hinder the development of precise and effective solutions. One of the primary obstacles is the complexity of maintaining osmotic balance across different cell types and experimental conditions. Researchers often struggle to create solutions that can consistently provide the desired osmotic pressure without causing cellular damage or altering the physiological state of the samples under study.

Another major challenge lies in the variability of solute concentrations required for different experimental protocols. The optimal concentration of solutes can vary widely depending on the specific cell type, tissue, or organism being studied, making it difficult to develop standardized formulations. This variability necessitates extensive trial-and-error processes, which can be time-consuming and resource-intensive.

The stability of hypertonic solutions over time presents an additional hurdle. Many customized solutions may experience changes in their osmotic properties during storage or throughout the course of an experiment, potentially compromising the reliability and reproducibility of research results. Researchers must carefully consider factors such as temperature, pH, and exposure to light when designing and using these solutions.

Furthermore, the interaction between different solutes in complex hypertonic solutions can lead to unexpected effects on cellular function. These interactions may alter membrane permeability, affect intracellular signaling pathways, or influence the activity of certain enzymes, complicating the interpretation of experimental outcomes. Researchers must navigate these potential confounding factors when customizing solutions for their specific needs.

The scalability of hypertonic solution production also poses a challenge, particularly when transitioning from small-scale laboratory preparations to larger volumes required for extensive studies or potential clinical applications. Maintaining consistency in osmolarity and solute concentrations across different batches and scales of production can be technically demanding and may require specialized equipment or expertise.

Lastly, the lack of standardized protocols and guidelines for customizing hypertonic solutions across different research fields contributes to the difficulty in comparing and reproducing results between laboratories. This absence of uniformity can impede collaborative efforts and slow down the overall progress in understanding the effects of osmotic stress on biological systems.

Existing Methods for Customizing Hypertonic Solutions

01 Customization of hypertonic solutions for medical applications

Hypertonic solutions can be customized for various medical applications, including wound healing, osmotic therapy, and treatment of edema. The composition and concentration of solutes can be adjusted to achieve specific therapeutic effects, such as promoting fluid drainage or enhancing tissue hydration.- Customization of hypertonic solutions for medical applications: Hypertonic solutions can be customized for various medical applications, including wound healing, osmotherapy, and treatment of edema. The composition and concentration of solutes can be adjusted to achieve specific therapeutic effects, such as reducing intracranial pressure or promoting fluid drainage from tissues.

- Formulation of hypertonic solutions for cell culture and preservation: Hypertonic solutions can be tailored for cell culture applications and preservation of biological samples. These customized solutions may include specific osmolytes, cryoprotectants, and nutrients to maintain cell viability and function during storage or experimental procedures.

- Development of hypertonic solutions for ophthalmic use: Customized hypertonic solutions can be formulated for ophthalmic applications, such as treating dry eye syndrome or reducing corneal edema. These solutions may incorporate specific electrolytes, osmolytes, and viscosity-enhancing agents to improve ocular surface hydration and comfort.

- Optimization of hypertonic solutions for industrial processes: Hypertonic solutions can be customized for various industrial applications, including desalination, water treatment, and food processing. The composition and concentration of solutes can be optimized to enhance efficiency, reduce energy consumption, or improve product quality in these processes.

- Customization of hypertonic solutions for sports and performance enhancement: Hypertonic solutions can be tailored for use in sports and athletic performance enhancement. These solutions may include specific electrolytes, carbohydrates, and other nutrients to improve hydration, energy delivery, and recovery during intense physical activity.

02 Hypertonic solutions for ophthalmic use

Specialized hypertonic solutions can be formulated for ophthalmic applications, such as treating dry eye syndrome or reducing intraocular pressure. These solutions are designed to be compatible with the eye's delicate tissues while providing the desired osmotic effect.Expand Specific Solutions03 Customization of hypertonic solutions for industrial processes

Hypertonic solutions can be tailored for various industrial applications, including water treatment, food processing, and chemical manufacturing. The composition and concentration of solutes are adjusted to achieve specific process requirements, such as dehydration or separation of materials.Expand Specific Solutions04 Delivery systems for hypertonic solutions

Innovative delivery systems can be developed to administer hypertonic solutions more effectively. These may include specialized containers, applicators, or devices that ensure precise dosing and controlled release of the solution, improving its therapeutic or industrial efficacy.Expand Specific Solutions05 Monitoring and control systems for hypertonic solution applications

Advanced monitoring and control systems can be implemented to optimize the use of hypertonic solutions in various applications. These systems may include sensors, data analysis tools, and automated adjustment mechanisms to ensure the solution maintains its desired properties and effectiveness throughout its use.Expand Specific Solutions

Key Suppliers and Manufacturers in Lab Solutions Industry

The customization of hypertonic solutions for laboratory research is a rapidly evolving field, currently in its growth phase. The market size is expanding due to increasing demand in pharmaceutical and biotechnology sectors. Technologically, the field is moderately mature, with ongoing innovations. Companies like Genentech, Inc., Novartis AG, and Medtronic, Inc. are leading the way in developing advanced hypertonic solutions. Emerging players such as Nanjing Pinsheng Medical Technology Co., Ltd. and Shenyang Xingqi Pharmaceutical Co., Ltd. are also making significant contributions. The competitive landscape is characterized by a mix of established pharmaceutical giants and specialized biotech firms, with a focus on developing tailored solutions for specific research applications.

Novartis AG

Medtronic, Inc.

Innovative Approaches in Hypertonic Solution Formulation

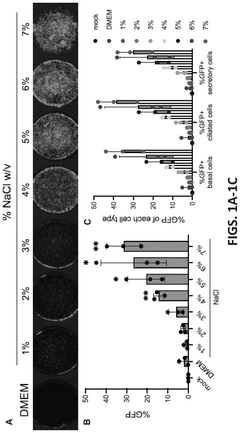

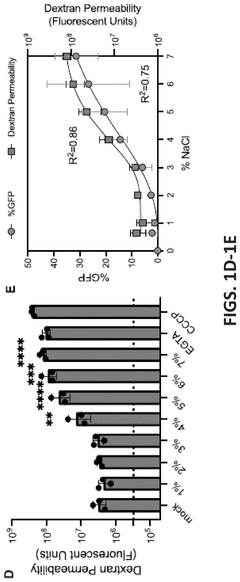

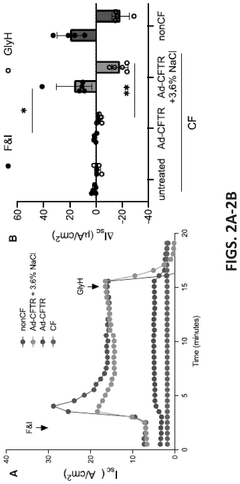

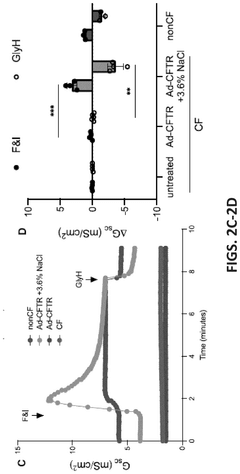

- The use of a hypertonic solution, specifically a hypertonic salt solution with a salt concentration ranging from about 1% to 8%, is introduced to enhance the delivery of gene therapy vectors by contacting cells with it before, after, or simultaneously with the vectors, thereby improving gene transfer efficiency.

- Use of specific polymers at concentrations above their entanglement limit to generate osmotic pressure in hypertonic solutions for cell transfection.

- Precise definition of limiting concentrations for each polymer type to ensure optimal osmotic pressure generation.

- Application of the concept of polymer chain entanglement to optimize hypertonic solutions for cellular uptake of macromolecules.

Quality Control and Safety Standards for Lab Solutions

Quality control and safety standards are paramount in the preparation and use of hypertonic solutions for laboratory research. These standards ensure the reliability, reproducibility, and safety of experiments involving customized hypertonic solutions.

Rigorous quality control measures begin with the sourcing of high-purity chemicals and reagents. Suppliers should be carefully vetted to ensure they meet stringent quality requirements. Each batch of raw materials must undergo thorough testing for purity, composition, and potential contaminants before use in solution preparation.

The preparation process itself requires strict adherence to standardized protocols. This includes using calibrated equipment, maintaining a clean and controlled environment, and following precise mixing and dilution procedures. Regular calibration and maintenance of laboratory equipment, such as balances, pH meters, and osmometers, are essential for accurate solution preparation.

Documentation is a critical aspect of quality control. Detailed records must be kept for each batch of hypertonic solution, including the source of materials, preparation date, exact composition, and any quality control test results. This documentation ensures traceability and allows for the identification of potential issues in case of experimental discrepancies.

Safety standards for hypertonic solutions encompass both personnel safety and environmental considerations. Personal protective equipment (PPE) such as gloves, lab coats, and safety goggles should be mandatory when handling these solutions. Proper training on the potential hazards and safe handling procedures is essential for all laboratory personnel working with hypertonic solutions.

Environmental safety measures include proper disposal protocols for unused solutions and contaminated materials. Many hypertonic solutions may contain components that require special disposal methods to prevent environmental contamination or harm to wastewater treatment systems.

Regular quality checks of prepared solutions are necessary to ensure consistency and stability over time. This may involve periodic testing of osmolality, pH, and chemical composition. Solutions that do not meet the specified criteria should be discarded and replaced to maintain experimental integrity.

Implementing a robust labeling system is crucial for both quality control and safety. Labels should clearly indicate the solution's composition, concentration, preparation date, expiration date, and any relevant hazard warnings. This helps prevent misuse and ensures that researchers are aware of the solution's properties and potential risks.

Adherence to good laboratory practices (GLP) and relevant regulatory guidelines is essential when working with hypertonic solutions in research settings. This may include compliance with ISO standards for laboratory quality management systems or specific industry regulations depending on the nature of the research.

Environmental Impact of Hypertonic Solution Production

The production of hypertonic solutions for laboratory research carries significant environmental implications that warrant careful consideration. The manufacturing process often involves the use of various chemicals and compounds, some of which may pose potential risks to ecosystems if not properly managed. One primary concern is the disposal of waste products generated during production, which can contain high concentrations of salts, sugars, or other solutes. If these waste streams are not adequately treated before release, they may disrupt local aquatic environments, altering pH levels and osmotic balance for native flora and fauna.

Energy consumption is another critical factor in the environmental impact of hypertonic solution production. The process typically requires precise temperature control and sterile conditions, necessitating the use of energy-intensive equipment such as autoclaves, laminar flow hoods, and climate-controlled clean rooms. This increased energy demand contributes to greenhouse gas emissions and places additional strain on power grids, particularly in regions heavily reliant on fossil fuels for electricity generation.

Water usage is a significant consideration, as the production of hypertonic solutions often requires large volumes of purified water. The purification process itself, whether through distillation, reverse osmosis, or other methods, can be resource-intensive and may lead to water stress in areas already facing scarcity issues. Additionally, the discharge of highly concentrated brine from water purification systems can negatively impact local water bodies if not properly managed.

The sourcing of raw materials for hypertonic solutions also plays a role in their environmental footprint. Some compounds used in these solutions may be derived from non-renewable resources or require extensive processing, contributing to resource depletion and pollution. Furthermore, the transportation of both raw materials and finished products adds to the overall carbon footprint of hypertonic solution production.

Packaging and storage of hypertonic solutions present additional environmental challenges. Many solutions require specialized containers to maintain sterility and prevent contamination, often resulting in the use of single-use plastics or other non-biodegradable materials. The disposal or recycling of these containers can contribute to plastic pollution and waste management issues if not handled responsibly.

To mitigate these environmental impacts, researchers and manufacturers are exploring more sustainable production methods. These include implementing closed-loop systems to recycle water and chemicals, adopting renewable energy sources to power production facilities, and developing biodegradable packaging alternatives. Additionally, there is a growing emphasis on green chemistry principles, which aim to design chemical products and processes that reduce or eliminate the use and generation of hazardous substances.