How to Design Hypertonic Solutions for Industrial Processes?

Hypertonic Solutions Background and Objectives

Hypertonic solutions have played a crucial role in various industrial processes for decades, offering unique properties that make them indispensable in many applications. These solutions, characterized by their higher solute concentration compared to the surrounding environment, have evolved from simple salt-based mixtures to complex formulations tailored for specific industrial needs.

The development of hypertonic solutions can be traced back to the early 20th century when scientists began exploring osmotic pressure and its effects on biological systems. As industrial processes became more sophisticated, the demand for specialized hypertonic solutions grew, leading to significant advancements in their design and application.

In recent years, the focus has shifted towards creating more efficient and environmentally friendly hypertonic solutions. This trend is driven by the increasing need for sustainable industrial practices and the growing awareness of the environmental impact of chemical processes. Researchers and engineers are now exploring novel approaches to design hypertonic solutions that not only meet performance requirements but also minimize ecological footprints.

The primary objective in designing hypertonic solutions for industrial processes is to achieve optimal functionality while addressing specific challenges in various sectors. These challenges include improving extraction efficiency in mining operations, enhancing oil recovery in petroleum industries, and optimizing water treatment processes. Additionally, there is a growing emphasis on developing hypertonic solutions that can withstand extreme conditions, such as high temperatures and pressures, to meet the demands of advanced manufacturing processes.

Another key goal is to create versatile hypertonic solutions that can be easily adapted to different industrial applications. This adaptability is crucial in today's fast-paced industrial landscape, where flexibility and quick response to market demands are essential. Researchers are exploring modular design approaches that allow for rapid customization of hypertonic solutions based on specific process requirements.

The future of hypertonic solution design is likely to be influenced by emerging technologies such as nanotechnology and advanced materials science. These fields offer promising avenues for creating highly efficient and precisely controlled hypertonic solutions. For instance, nanoparticle-enhanced hypertonic solutions are being investigated for their potential to dramatically improve performance in various industrial processes.

As we look ahead, the design of hypertonic solutions for industrial processes is expected to become increasingly interdisciplinary. Collaboration between chemists, engineers, and environmental scientists will be crucial in developing innovative solutions that balance performance, cost-effectiveness, and sustainability. This holistic approach will be essential in addressing the complex challenges faced by modern industries while meeting stringent environmental regulations.

Industrial Applications and Market Analysis

Hypertonic solutions have found widespread applications across various industrial processes, driving significant market growth and technological advancements. The global market for hypertonic solutions in industrial applications is experiencing robust expansion, fueled by increasing demand in sectors such as food processing, pharmaceuticals, and water treatment.

In the food processing industry, hypertonic solutions play a crucial role in dehydration and preservation techniques. The market for food-grade hypertonic solutions is projected to grow steadily, driven by the rising demand for extended shelf-life products and the need for efficient food preservation methods. Manufacturers are increasingly adopting hypertonic solution-based processes to improve product quality and reduce energy consumption during processing.

The pharmaceutical sector represents another major market for hypertonic solutions, particularly in the production of intravenous fluids and drug formulations. The growing prevalence of chronic diseases and the expansion of healthcare infrastructure in emerging economies are key factors contributing to the increased demand for pharmaceutical-grade hypertonic solutions. Additionally, the use of hypertonic solutions in cell culture media and bioprocessing applications is gaining traction, further expanding market opportunities.

Water treatment is emerging as a significant application area for hypertonic solutions, especially in desalination processes. As water scarcity becomes a global concern, the demand for efficient desalination technologies is rising, driving the adoption of hypertonic solution-based systems. The market for hypertonic solutions in water treatment is expected to witness substantial growth, particularly in regions facing acute water shortages.

The industrial cleaning sector is also leveraging hypertonic solutions for enhanced cleaning efficiency and reduced water consumption. This application is gaining popularity in industries such as automotive, electronics, and heavy machinery manufacturing, where precision cleaning is essential.

Geographically, North America and Europe currently dominate the market for industrial hypertonic solutions, owing to their well-established industrial base and stringent quality standards. However, the Asia-Pacific region is anticipated to exhibit the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in research and development, and growing awareness of advanced industrial processes.

Key market players are focusing on developing innovative formulations and application-specific hypertonic solutions to gain a competitive edge. Strategic collaborations between solution providers and end-users are becoming increasingly common, aimed at developing tailored solutions for specific industrial processes. The market is also witnessing a trend towards the development of environmentally friendly and sustainable hypertonic solutions, in line with growing environmental concerns and regulatory pressures.

Current Challenges in Hypertonic Solution Design

The design of hypertonic solutions for industrial processes faces several significant challenges that researchers and engineers must address to improve efficiency and effectiveness. One of the primary obstacles is achieving and maintaining the desired osmotic pressure consistently across large-scale industrial applications. The concentration gradient between the hypertonic solution and the surrounding environment can be difficult to control, especially in dynamic industrial settings where temperature fluctuations and other environmental factors come into play.

Another challenge lies in the selection of appropriate solutes for specific industrial processes. Different applications require varying levels of hypertonicity, and finding the right balance of solutes that can provide the necessary osmotic pressure without interfering with the intended process or product quality is crucial. This becomes particularly complex when dealing with sensitive materials or when the hypertonic solution needs to interact with biological systems.

The stability of hypertonic solutions over time presents another significant hurdle. In many industrial processes, solutions need to maintain their hypertonic properties for extended periods. However, factors such as temperature changes, pH shifts, and interactions with other chemicals in the system can lead to degradation or alteration of the solution's properties. Developing formulations that remain stable under diverse conditions while retaining their hypertonic characteristics is an ongoing challenge.

Scalability is a critical issue when designing hypertonic solutions for industrial use. Solutions that work well in laboratory settings may face difficulties when scaled up to industrial volumes. This includes challenges in mixing large quantities uniformly, ensuring consistent quality across batches, and managing the increased costs associated with larger-scale production of specialized solutes.

The environmental impact of hypertonic solutions is an increasingly important consideration. As industries strive for sustainability, there is a growing need to develop eco-friendly hypertonic solutions that minimize waste and reduce the use of potentially harmful chemicals. This challenge involves finding biodegradable or easily recyclable solutes that can still provide the necessary osmotic properties.

Lastly, the economic viability of hypertonic solution design remains a significant challenge. While certain specialized applications may justify higher costs, many industries require cost-effective solutions that can be implemented on a large scale. Balancing the performance requirements with economic constraints often necessitates innovative approaches to formulation and production processes.

Existing Hypertonic Solution Design Approaches

01 Preparation of hypertonic solutions

Hypertonic solutions are prepared by increasing the concentration of solutes beyond physiological levels. This can be achieved by adding various substances such as salts, sugars, or other osmotically active compounds. The concentration is typically expressed in terms of osmolality or tonicity relative to body fluids.- Preparation of hypertonic solutions: Hypertonic solutions are prepared by increasing the concentration of solutes above physiological levels. This can be achieved by adding various substances such as salts, sugars, or other osmotically active compounds. The concentration of these solutions is typically expressed in terms of osmolality or tonicity relative to body fluids.

- Applications in medical treatments: Hypertonic solutions have diverse applications in medical treatments. They are used in intravenous therapy, wound care, and as eye drops. These solutions can help in managing various conditions such as dehydration, edema, and increased intracranial pressure. The concentration of hypertonic solutions is carefully controlled to achieve the desired therapeutic effect while minimizing potential side effects.

- Use in cell culture and biotechnology: Hypertonic solutions play a crucial role in cell culture techniques and biotechnology processes. They are used to create osmotic stress in cells, study cellular responses, and manipulate cell volume. The concentration of these solutions is adjusted based on the specific requirements of the experiment or process, such as cryopreservation or protein extraction.

- Formulation for specific delivery systems: Hypertonic solutions are formulated for specific delivery systems, such as nasal sprays, inhalers, or transdermal patches. The concentration of these solutions is optimized to ensure effective delivery of active ingredients while maintaining the desired osmotic properties. Factors such as pH, viscosity, and stability are considered in the formulation process.

- Measurement and control of concentration: Accurate measurement and control of hypertonic solution concentration are essential for their effectiveness and safety. Various methods are employed, including osmometry, conductivity measurements, and refractive index analysis. Advanced techniques and devices have been developed to ensure precise concentration control in both research and clinical settings.

02 Applications in medical treatments

Hypertonic solutions have diverse medical applications, including treatment of edema, intracranial pressure reduction, and as irrigation solutions in surgical procedures. The high concentration of solutes creates an osmotic gradient that can draw fluid out of tissues or maintain a specific physiological environment.Expand Specific Solutions03 Use in cell culture and biotechnology

In biotechnology and cell culture applications, hypertonic solutions are used for various purposes such as cell preservation, inducing osmotic stress in experiments, and controlling cell volume. The concentration of these solutions is carefully controlled to achieve specific effects on cellular processes.Expand Specific Solutions04 Formulation for ophthalmic use

Hypertonic solutions are formulated for ophthalmic use in treating conditions such as corneal edema or to create a specific osmotic environment in the eye. The concentration of these solutions is critical for ensuring efficacy while maintaining ocular comfort and safety.Expand Specific Solutions05 Methods for measuring and adjusting concentration

Various techniques are employed to measure and adjust the concentration of hypertonic solutions. These may include osmometry, conductivity measurements, or specific gravity determinations. Precise control of concentration is crucial for maintaining the desired osmotic effects in different applications.Expand Specific Solutions

Key Players in Industrial Hypertonic Solutions

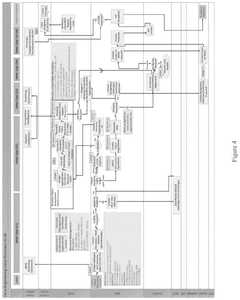

The design of hypertonic solutions for industrial processes is a rapidly evolving field, currently in a growth phase. The market size is expanding, driven by increasing demand across various industries. Technologically, the field is moderately mature, with ongoing innovations. Companies like BASF Corp., Saudi Arabian Oil Co., and China Petroleum & Chemical Corp. are leading players, leveraging their extensive R&D capabilities. Academic institutions such as Zhejiang University and Shanghai Jiao Tong University are contributing significant research. The competitive landscape is diverse, with chemical giants, oil companies, and specialized firms like Kurita Water Industries Ltd. and Solvay SA actively developing advanced solutions, indicating a dynamic and competitive market.

BASF Corp.

Saudi Arabian Oil Co.

Innovative Formulations for Hypertonic Solutions

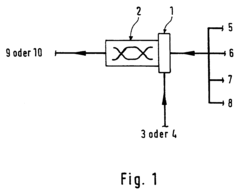

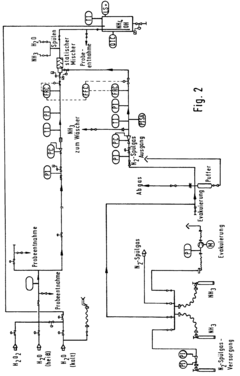

- Producing diluted cleaning solutions directly on-site by mixing gases such as NH3, HCl, or HF with high-purity water and hydrogen peroxide using a static mixer system, avoiding the use of highly concentrated intermediates and employing corrosion-resistant materials for the mixing and supply system.

- A computer-implemented method and system that utilize a solution database and a hierarchical data model to generate a dynamic sequence of questions through a graphical user interface, guiding users to specify their challenges, and subsequently, an automated report builder selects appropriate software solutions from the database based on user inputs.

Environmental Impact of Hypertonic Solutions

The environmental impact of hypertonic solutions in industrial processes is a critical consideration that requires careful assessment and management. These solutions, characterized by their high solute concentration, can have significant effects on ecosystems and natural resources if not properly handled.

One of the primary environmental concerns associated with hypertonic solutions is their potential to disrupt aquatic ecosystems. When discharged into water bodies, these solutions can alter the osmotic balance, leading to stress or mortality in aquatic organisms. Fish, invertebrates, and microorganisms may struggle to maintain their internal water balance, resulting in population declines and ecosystem imbalances.

Soil quality can also be adversely affected by hypertonic solutions. When these solutions seep into the ground, they can increase soil salinity, making it difficult for plants to absorb water and nutrients. This can lead to reduced agricultural productivity and changes in local vegetation patterns, potentially impacting biodiversity.

The production and disposal of hypertonic solutions often involve energy-intensive processes, contributing to greenhouse gas emissions and climate change. Additionally, the extraction of raw materials for these solutions may lead to habitat destruction and resource depletion if not managed sustainably.

Water scarcity is another significant concern, as the preparation and use of hypertonic solutions typically require substantial amounts of water. In regions already facing water stress, this can exacerbate existing shortages and compete with other essential water uses, such as agriculture and domestic consumption.

To mitigate these environmental impacts, industries are increasingly adopting more sustainable practices. These include implementing closed-loop systems to minimize discharge, developing more efficient production methods to reduce resource consumption, and exploring alternative, environmentally friendly solutes.

Advanced treatment technologies are being employed to neutralize or recycle hypertonic solutions before release into the environment. Membrane filtration, reverse osmosis, and chemical precipitation are among the techniques used to remove excess solutes and render the solutions less harmful.

Regulatory frameworks are also evolving to address the environmental challenges posed by hypertonic solutions. Many countries have implemented stricter discharge limits and monitoring requirements to protect water resources and ecosystems. Industries are being encouraged to adopt best practices and invest in cleaner technologies through a combination of incentives and penalties.

Research into bio-based and biodegradable alternatives for traditional hypertonic solutions is gaining momentum. These innovative approaches aim to reduce the environmental footprint of industrial processes while maintaining or improving their effectiveness. As technology advances, it is likely that more sustainable options will become available, further mitigating the environmental impact of hypertonic solutions in industrial applications.

Safety Regulations for Industrial Hypertonic Solutions

Safety regulations for industrial hypertonic solutions are critical to ensure the protection of workers, equipment, and the environment. These regulations typically encompass a wide range of aspects, including handling procedures, storage requirements, personal protective equipment (PPE), and emergency response protocols.

One of the primary concerns in dealing with hypertonic solutions is their potential for causing severe dehydration and tissue damage upon contact with skin or eyes. As such, safety regulations often mandate the use of appropriate PPE, including chemical-resistant gloves, goggles, face shields, and protective clothing. The specific type and level of protection required may vary depending on the concentration and composition of the hypertonic solution.

Storage and handling regulations for hypertonic solutions are designed to prevent accidental spills, leaks, or exposure. These may include requirements for specialized containment systems, such as double-walled tanks or secondary containment areas. Proper labeling and signage are also essential, with clear identification of the solution's contents, hazards, and necessary precautions.

Ventilation requirements are another crucial aspect of safety regulations for hypertonic solutions. Adequate air circulation helps to minimize the risk of inhalation exposure to potentially harmful vapors or aerosols. In some cases, local exhaust ventilation or fume hoods may be required when working with particularly volatile or hazardous hypertonic solutions.

Emergency response procedures form a significant part of safety regulations. These typically include guidelines for spill containment and cleanup, as well as first aid measures in case of accidental exposure. Eyewash stations and safety showers must be readily accessible in areas where hypertonic solutions are handled or stored.

Training and education requirements are often stipulated in safety regulations to ensure that all personnel working with hypertonic solutions are adequately prepared to handle them safely. This may include regular safety briefings, hands-on training sessions, and periodic assessments of competency.

Disposal regulations for hypertonic solutions are also crucial, as improper disposal can lead to environmental contamination and potential harm to ecosystems. These regulations often specify approved disposal methods, which may include neutralization, dilution, or specialized waste treatment processes depending on the specific composition of the solution.

Regular safety audits and inspections are typically mandated to ensure ongoing compliance with safety regulations. These may involve both internal checks and external assessments by regulatory bodies or third-party auditors. Documentation and record-keeping requirements are often specified to demonstrate compliance and track any incidents or near-misses.

In the context of industrial processes involving hypertonic solutions, safety regulations may also address specific operational considerations. These could include guidelines for process control, monitoring systems, and fail-safe mechanisms to prevent uncontrolled releases or reactions involving hypertonic solutions.