How to Develop Hypertonic Solutions for Nanotechnology Uses?

Nanotechnology Hypertonic Solutions Background

Hypertonic solutions have emerged as a critical component in the rapidly evolving field of nanotechnology. These solutions, characterized by their higher solute concentration compared to the surrounding environment, play a pivotal role in various nanotechnological applications. The development of hypertonic solutions for nanotechnology uses stems from the need to manipulate and control nanoscale materials and processes with unprecedented precision.

The concept of hypertonicity in nanotechnology originated from biological sciences, where it was primarily used to study cellular responses to osmotic stress. As nanotechnology advanced, researchers recognized the potential of applying similar principles to nanoscale systems. This cross-disciplinary approach has led to innovative applications in areas such as drug delivery, nanomaterial synthesis, and nanodevice fabrication.

The evolution of hypertonic solutions in nanotechnology has been driven by the unique properties of nanomaterials and the challenges associated with their manipulation. At the nanoscale, surface area to volume ratios increase dramatically, leading to enhanced reactivity and sensitivity to environmental conditions. Hypertonic solutions provide a means to exploit these properties by creating controlled osmotic gradients that can influence the behavior of nanoparticles, nanostructures, and biological entities at the molecular level.

One of the key drivers for developing hypertonic solutions in nanotechnology has been the pharmaceutical industry's quest for more effective drug delivery systems. Hypertonic environments can be used to encapsulate drugs within nanocarriers, control their release, and enhance their penetration through biological barriers. This has opened up new possibilities for targeted therapies and improved treatment efficacy for various diseases.

In materials science, hypertonic solutions have found applications in the synthesis and assembly of nanostructures. By carefully controlling the osmotic environment, researchers can influence the growth, shape, and organization of nanomaterials. This has led to advancements in the production of nanowires, nanotubes, and other complex nanostructures with tailored properties for specific applications.

The development of hypertonic solutions for nanotechnology uses also intersects with the field of microfluidics. Researchers have explored the use of hypertonic gradients to manipulate fluid flow and particle behavior in microfluidic devices, enabling new approaches to particle sorting, concentration, and analysis at the nanoscale.

As nanotechnology continues to advance, the role of hypertonic solutions is expected to expand further. Emerging areas of research include the use of hypertonic environments in nanoscale energy harvesting, environmental remediation, and the development of smart materials that can respond to osmotic stimuli. The ongoing exploration of hypertonic solutions in nanotechnology promises to unlock new capabilities and drive innovation across multiple scientific and technological domains.

Market Analysis for Nanotech Hypertonic Solutions

The market for hypertonic solutions in nanotechnology applications is experiencing significant growth, driven by advancements in nanomedicine, drug delivery systems, and diagnostic technologies. The global nanotechnology market is projected to reach $290.93 billion by 2028, with a compound annual growth rate (CAGR) of 13.3% from 2021 to 2028. Within this broader market, the demand for hypertonic solutions is expected to grow substantially due to their unique properties and versatile applications in nanotech.

One of the primary drivers of market demand is the pharmaceutical industry, where hypertonic solutions are utilized in nanoparticle-based drug delivery systems. These solutions enhance the stability and efficacy of nanocarriers, improving drug targeting and reducing side effects. The global nanomedicine market, a key segment for hypertonic solutions, is anticipated to reach $350.8 billion by 2025, with a CAGR of 12.6% from 2020 to 2025.

In the field of diagnostics, hypertonic solutions play a crucial role in developing advanced biosensors and imaging agents. The increasing prevalence of chronic diseases and the need for early detection are fueling the demand for more sensitive and accurate diagnostic tools. The global nanosensors market, which heavily relies on hypertonic solutions, is expected to grow at a CAGR of 10.5% from 2020 to 2027.

The electronics industry is another significant market for nanotech hypertonic solutions, particularly in the development of advanced semiconductors and energy storage devices. As the demand for smaller, more efficient electronic components grows, the market for hypertonic solutions in this sector is expected to expand rapidly. The global nanoelectronics market is projected to reach $180.67 billion by 2027, with a CAGR of 21.3% from 2020 to 2027.

Environmental applications of nanotechnology, including water purification and pollution control, represent an emerging market for hypertonic solutions. The increasing focus on sustainability and environmental protection is driving research and development in this area. The global market for nanomaterials in environmental applications is expected to grow at a CAGR of 14.2% from 2020 to 2025.

Key market players in the nanotech hypertonic solutions space include established pharmaceutical companies, specialized nanotechnology firms, and research institutions. Collaborations between academia and industry are becoming increasingly common, fostering innovation and accelerating market growth. North America and Europe currently dominate the market, but Asia-Pacific is expected to witness the fastest growth due to increasing investments in nanotechnology research and development.

In conclusion, the market for nanotech hypertonic solutions shows strong growth potential across various industries, driven by technological advancements and increasing applications. As research continues to uncover new uses for these solutions, the market is expected to expand further, offering significant opportunities for innovation and commercialization.

Current Challenges in Hypertonic Solution Development

The development of hypertonic solutions for nanotechnology applications faces several significant challenges. One of the primary obstacles is achieving precise control over osmolarity and solute concentration. Nanotechnology often requires extremely fine-tuned environments, and even minor fluctuations in solution properties can have profound effects on nanoparticle behavior and functionality.

Another major challenge lies in maintaining solution stability over time. Hypertonic solutions used in nanotechnology must remain consistent in their properties throughout the duration of experiments or applications. This is particularly difficult when dealing with complex mixtures of solutes, as interactions between different components can lead to unexpected changes in solution characteristics.

Biocompatibility presents a significant hurdle, especially for applications in nanomedicine and bio-nanotechnology. Developing hypertonic solutions that are both effective for their intended purpose and safe for biological systems is a delicate balancing act. High solute concentrations can be toxic or disruptive to cellular processes, limiting the range of potential applications.

The scalability of hypertonic solution production for nanotechnology uses is another critical challenge. While small-scale laboratory preparations may be straightforward, scaling up to industrial levels while maintaining precise control over solution properties can be technically demanding and cost-prohibitive.

Reproducibility across different batches and laboratories is crucial for scientific and industrial applications. Achieving consistent results with hypertonic solutions in nanotechnology requires standardized protocols and rigorous quality control measures, which are not always easy to implement given the sensitivity of nanoscale systems.

Furthermore, the interaction between hypertonic solutions and nanomaterials is not always well understood. Different nanoparticles may respond unpredictably to changes in osmotic pressure or solute composition, necessitating extensive research to characterize these interactions for each specific application.

Lastly, the development of hypertonic solutions for nanotechnology must also consider environmental and regulatory concerns. As nanotechnology increasingly moves from the laboratory to real-world applications, solutions must be designed with consideration for their potential environmental impact and compliance with evolving regulations in different jurisdictions.

Existing Hypertonic Solution Formulations

01 Preparation of hypertonic solutions

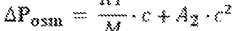

Hypertonic solutions are prepared by increasing the concentration of solutes beyond physiological levels. This can be achieved by adding various substances such as salts, sugars, or other osmotically active compounds. The concentration is typically expressed in terms of osmolality or tonicity relative to body fluids.- Hypertonic solution formulation: Hypertonic solutions are formulated with higher solute concentrations compared to physiological fluids. These solutions are used in various medical applications, including wound cleansing, osmotic therapy, and cell preservation. The concentration of solutes in hypertonic solutions is carefully controlled to achieve desired osmotic effects.

- Osmotic pressure regulation: Hypertonic solutions are designed to regulate osmotic pressure in biological systems. By adjusting the concentration of solutes, these solutions can create an osmotic gradient that facilitates fluid movement across cell membranes. This property is utilized in various therapeutic applications, such as reducing intracranial pressure or treating edema.

- Cell preservation and cryoprotection: Hypertonic solutions play a crucial role in cell preservation and cryoprotection. The high solute concentration helps to dehydrate cells, reducing the formation of intracellular ice crystals during freezing. This application is particularly important in the preservation of biological samples, tissues, and organs for research and transplantation purposes.

- Wound cleansing and debridement: Hypertonic solutions are used in wound care for cleansing and debridement. The high osmotic pressure of these solutions helps to draw out excess fluid from wounds, reduce bacterial load, and promote healing. The concentration of the solution is carefully balanced to maximize efficacy while minimizing tissue damage.

- Drug delivery systems: Hypertonic solutions are employed in drug delivery systems to enhance the absorption and distribution of therapeutic agents. The high concentration gradient created by these solutions can improve drug penetration across biological barriers and increase bioavailability. This approach is particularly useful for topical and transdermal drug delivery applications.

02 Medical applications of hypertonic solutions

Hypertonic solutions have various medical applications, including treatment of edema, intracranial pressure reduction, and fluid resuscitation in trauma patients. The high concentration of solutes creates an osmotic gradient that helps draw excess fluid from tissues or maintain blood volume.Expand Specific Solutions03 Hypertonic solutions in cell culture and biotechnology

In biotechnology and cell culture applications, hypertonic solutions are used to induce osmotic stress, study cellular responses, and optimize growth conditions for various microorganisms. The concentration of these solutions is carefully controlled to achieve desired effects without causing cell damage.Expand Specific Solutions04 Measurement and control of hypertonic solution concentration

Accurate measurement and control of hypertonic solution concentration is crucial for their effectiveness and safety. Various methods, including osmometry, conductivity measurements, and refractive index analysis, are employed to determine and maintain the desired concentration levels.Expand Specific Solutions05 Formulation of hypertonic solutions for specific applications

Hypertonic solutions are formulated with specific concentrations and compositions tailored to their intended use. This may involve combining multiple solutes, adjusting pH, or incorporating additional agents to enhance stability or efficacy. The concentration and composition are optimized based on the particular application and desired physiological effects.Expand Specific Solutions

Key Players in Nanotech Hypertonic Solutions

The development of hypertonic solutions for nanotechnology applications is in a rapidly evolving phase, with significant market potential across various industries. The market size is expanding as nanotechnology finds applications in medicine, electronics, and materials science. Technologically, the field is progressing from early-stage research to more advanced applications. Companies like Nantero, Inc. and Industrial Technology Research Institute are at the forefront, developing innovative solutions. Academic institutions such as Purdue Research Foundation and The Regents of the University of California are contributing fundamental research. Collaborations between industry leaders like BASF Corp. and research institutions are accelerating technological maturity, while specialized entities like the National Institute for Materials Science IAI are pushing boundaries in materials development for hypertonic nanotechnology solutions.

LG Chem Ltd.

National Institute for Materials Science IAI

Innovative Approaches in Hypertonic Nanotech

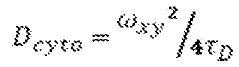

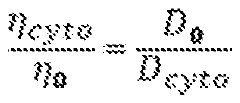

- A hypertonic solution comprising a polymer that forms entangled chains, such as polyethylene glycol, glucose polymer, or sucrose-epichlorohydrin copolymer, is used to generate osmotic pressure, combined with a method involving a hypertonic and hypotonic medium transition to facilitate pinocytic vesicle rupture and release of macromolecules into the cell cytosol, ensuring effective delivery of probes of various sizes.

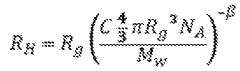

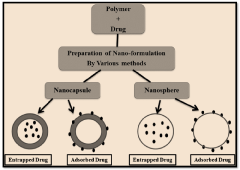

- Nanoparticle engineering using nanosuspensions, where drug microparticles are converted into nanosized particles stabilized by submicron surfactants, enhancing solubility and bioavailability, and allowing for intravenous administration without capillary blockage, with the option to lyophilize suspensions into a solid matrix.

Environmental Impact of Hypertonic Nanosolutions

The environmental impact of hypertonic nanosolutions is a critical consideration in the development and application of nanotechnology. These solutions, characterized by their high solute concentration, can have both positive and negative effects on the environment when used in various nanotechnological applications.

One of the primary environmental concerns associated with hypertonic nanosolutions is their potential to disrupt local ecosystems. When released into aquatic environments, these solutions can alter the osmotic balance, potentially harming aquatic organisms. The high solute concentration may cause dehydration in microorganisms and small aquatic life, leading to population imbalances and ecosystem disturbances.

However, hypertonic nanosolutions also offer potential environmental benefits. In water treatment applications, these solutions can be used to remove contaminants through osmotic processes, potentially providing a more efficient and less chemically intensive method of water purification. This could lead to reduced use of harsh chemicals in water treatment facilities, resulting in a positive environmental impact.

The production and disposal of hypertonic nanosolutions also warrant consideration. Manufacturing processes may require significant energy inputs and potentially harmful chemicals, contributing to carbon emissions and chemical waste. Proper disposal protocols must be established to prevent unintended release into the environment, which could lead to soil and water contamination.

On the other hand, the use of hypertonic nanosolutions in precision agriculture could lead to more efficient use of water and fertilizers, reducing overall agricultural runoff and its associated environmental impacts. By delivering nutrients directly to plants in a controlled manner, these solutions could minimize excess fertilizer use and decrease water pollution from agricultural sources.

The long-term effects of hypertonic nanosolutions on soil microbial communities and plant health are areas that require further research. While these solutions may enhance nutrient delivery, their impact on soil structure and microbial diversity over time is not yet fully understood. Continuous monitoring and assessment of soil health in areas where these solutions are applied will be crucial for sustainable use.

In the realm of environmental remediation, hypertonic nanosolutions show promise for cleaning up contaminated sites. Their ability to selectively extract pollutants from soil and water could lead to more effective and less invasive cleanup methods. However, the fate of the extracted contaminants and the solutions themselves must be carefully managed to prevent secondary contamination.

As research in this field progresses, it is essential to develop comprehensive life cycle assessments for hypertonic nanosolutions. These assessments should consider the environmental impacts from production to disposal, including energy use, resource consumption, and potential for recycling or reuse. Such analyses will be crucial in determining the overall environmental sustainability of these solutions in various nanotechnology applications.

Scalability and Manufacturing Considerations

Scaling up the production of hypertonic solutions for nanotechnology applications presents unique challenges that require careful consideration. The manufacturing process must maintain precise control over solution concentration, purity, and stability while meeting the demands of large-scale production. One key aspect is the selection of appropriate equipment capable of handling the specific requirements of hypertonic solutions. This may include specialized mixing tanks, filtration systems, and packaging lines designed to prevent contamination and maintain solution integrity.

Quality control measures are paramount in ensuring consistency across batches. Implementing robust analytical techniques, such as osmometry and spectroscopy, is essential for verifying solution properties throughout the manufacturing process. Automated monitoring systems can help maintain tight control over critical parameters like temperature, pH, and osmolality, ensuring product uniformity and reliability.

The choice of raw materials and their sourcing also play a crucial role in scalability. Establishing reliable supply chains for high-purity ingredients is vital to maintain consistent quality and meet production demands. Consideration should be given to the storage and handling of these materials, as some components may be sensitive to environmental factors or have limited shelf lives.

Process optimization is another critical factor in scaling up production. This may involve the development of continuous flow processes or the implementation of advanced process analytical technology (PAT) to improve efficiency and reduce waste. Automation of key manufacturing steps can help minimize human error and increase throughput, but must be carefully balanced with the need for flexibility in production.

Regulatory compliance is a significant consideration when scaling up production of hypertonic solutions for nanotechnology uses. Adherence to Good Manufacturing Practices (GMP) and relevant industry standards is essential, particularly if the solutions are intended for biomedical applications. This may necessitate the implementation of rigorous documentation systems, validation protocols, and quality management systems.

Environmental considerations and waste management strategies should also be factored into the scaling process. Developing efficient recycling or treatment methods for waste products can help minimize environmental impact and potentially reduce production costs. Additionally, energy-efficient manufacturing processes and equipment can contribute to sustainability goals and long-term cost-effectiveness.

Lastly, packaging and storage solutions must be carefully evaluated to ensure they maintain the integrity of the hypertonic solutions during transportation and storage. This may involve the use of specialized containers, barrier materials, or controlled atmosphere packaging to prevent degradation or contamination. The scalability of these packaging solutions must also be considered to avoid bottlenecks in the production process.