How to Enhance Kevlar Properties for Industrial Hose Applications?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Enhancement Goals

Kevlar, a high-performance synthetic fiber, has been a cornerstone in industrial applications for decades. In the context of industrial hose applications, enhancing Kevlar properties is crucial for meeting the ever-increasing demands of various sectors. The primary goal is to improve the fiber's strength-to-weight ratio, thermal stability, and chemical resistance while maintaining its flexibility and durability.

One of the key enhancement objectives is to increase Kevlar's tensile strength without compromising its lightweight nature. This would allow for the production of industrial hoses that can withstand higher pressures and more demanding operating conditions. Researchers are exploring various methods, including advanced polymer blending techniques and nanotechnology integration, to achieve this goal.

Another critical aim is to enhance Kevlar's resistance to extreme temperatures. Industrial hoses often operate in environments with significant temperature fluctuations, from cryogenic conditions to high-heat scenarios. Improving Kevlar's thermal stability would extend the operational range of industrial hoses, making them more versatile and reliable across diverse applications.

Chemical resistance is also a paramount concern in industrial settings. Enhancing Kevlar's ability to withstand exposure to a broader range of chemicals, including acids, bases, and organic solvents, would significantly expand its applicability in chemical processing and transportation industries. This goal involves developing new surface treatments or incorporating protective additives into the fiber structure.

Flexibility and fatigue resistance are equally important properties to enhance. Industrial hoses undergo repeated flexing and bending during operation, and improving Kevlar's ability to withstand these stresses without degradation would extend the lifespan of hoses and reduce maintenance costs. Researchers are investigating novel fiber architectures and composite structures to achieve this goal.

Abrasion resistance is another area targeted for improvement. In many industrial applications, hoses are subjected to constant friction and wear. Enhancing Kevlar's abrasion resistance would lead to longer-lasting hoses, reducing downtime and replacement frequency in industrial operations.

Lastly, there is a growing focus on enhancing Kevlar's environmental sustainability. This includes developing more eco-friendly production processes, improving recyclability, and exploring bio-based alternatives that maintain or exceed the performance of traditional Kevlar. These efforts align with the increasing global emphasis on sustainable industrial practices and materials.

One of the key enhancement objectives is to increase Kevlar's tensile strength without compromising its lightweight nature. This would allow for the production of industrial hoses that can withstand higher pressures and more demanding operating conditions. Researchers are exploring various methods, including advanced polymer blending techniques and nanotechnology integration, to achieve this goal.

Another critical aim is to enhance Kevlar's resistance to extreme temperatures. Industrial hoses often operate in environments with significant temperature fluctuations, from cryogenic conditions to high-heat scenarios. Improving Kevlar's thermal stability would extend the operational range of industrial hoses, making them more versatile and reliable across diverse applications.

Chemical resistance is also a paramount concern in industrial settings. Enhancing Kevlar's ability to withstand exposure to a broader range of chemicals, including acids, bases, and organic solvents, would significantly expand its applicability in chemical processing and transportation industries. This goal involves developing new surface treatments or incorporating protective additives into the fiber structure.

Flexibility and fatigue resistance are equally important properties to enhance. Industrial hoses undergo repeated flexing and bending during operation, and improving Kevlar's ability to withstand these stresses without degradation would extend the lifespan of hoses and reduce maintenance costs. Researchers are investigating novel fiber architectures and composite structures to achieve this goal.

Abrasion resistance is another area targeted for improvement. In many industrial applications, hoses are subjected to constant friction and wear. Enhancing Kevlar's abrasion resistance would lead to longer-lasting hoses, reducing downtime and replacement frequency in industrial operations.

Lastly, there is a growing focus on enhancing Kevlar's environmental sustainability. This includes developing more eco-friendly production processes, improving recyclability, and exploring bio-based alternatives that maintain or exceed the performance of traditional Kevlar. These efforts align with the increasing global emphasis on sustainable industrial practices and materials.

Industrial Hose Market Analysis

The industrial hose market has been experiencing steady growth, driven by increasing demand across various sectors such as manufacturing, construction, agriculture, and oil & gas. This market segment is particularly relevant to the application of enhanced Kevlar properties, as industrial hoses require high strength, durability, and resistance to harsh environments.

The global industrial hose market size was valued at approximately $13.5 billion in 2020 and is projected to reach $18.8 billion by 2026, growing at a CAGR of 5.6% during the forecast period. This growth is attributed to the rising industrialization in developing economies, increasing investments in infrastructure development, and the expansion of the manufacturing sector.

Key factors driving the demand for industrial hoses include the need for efficient fluid transfer systems, stringent safety regulations in industrial settings, and the growing emphasis on reducing downtime and maintenance costs. The oil & gas industry remains a significant consumer of industrial hoses, particularly those with enhanced properties to withstand extreme pressures and corrosive materials.

The market for Kevlar-reinforced industrial hoses is witnessing increased traction due to their superior strength-to-weight ratio, excellent abrasion resistance, and ability to maintain flexibility under high-pressure conditions. These properties make Kevlar-enhanced hoses ideal for applications in hydraulic systems, chemical transfer, and high-pressure cleaning equipment.

Regionally, North America and Europe dominate the industrial hose market, owing to their well-established industrial sectors and stringent safety standards. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization in countries like China and India.

The automotive industry represents another significant market for industrial hoses, particularly those reinforced with advanced materials like Kevlar. As vehicle manufacturers strive for lighter and more fuel-efficient designs, the demand for high-performance, lightweight hoses is increasing.

Challenges in the industrial hose market include the volatility of raw material prices, which can impact profit margins, and the growing competition from alternative materials. However, the ongoing research and development in enhancing Kevlar properties present opportunities for manufacturers to differentiate their products and capture a larger market share.

In conclusion, the industrial hose market analysis reveals a growing demand for high-performance materials like Kevlar, driven by the need for durable, lightweight, and efficient fluid transfer solutions across various industries. The market's trajectory suggests that innovations in Kevlar properties for industrial hose applications could significantly impact market dynamics and create new growth opportunities.

The global industrial hose market size was valued at approximately $13.5 billion in 2020 and is projected to reach $18.8 billion by 2026, growing at a CAGR of 5.6% during the forecast period. This growth is attributed to the rising industrialization in developing economies, increasing investments in infrastructure development, and the expansion of the manufacturing sector.

Key factors driving the demand for industrial hoses include the need for efficient fluid transfer systems, stringent safety regulations in industrial settings, and the growing emphasis on reducing downtime and maintenance costs. The oil & gas industry remains a significant consumer of industrial hoses, particularly those with enhanced properties to withstand extreme pressures and corrosive materials.

The market for Kevlar-reinforced industrial hoses is witnessing increased traction due to their superior strength-to-weight ratio, excellent abrasion resistance, and ability to maintain flexibility under high-pressure conditions. These properties make Kevlar-enhanced hoses ideal for applications in hydraulic systems, chemical transfer, and high-pressure cleaning equipment.

Regionally, North America and Europe dominate the industrial hose market, owing to their well-established industrial sectors and stringent safety standards. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization in countries like China and India.

The automotive industry represents another significant market for industrial hoses, particularly those reinforced with advanced materials like Kevlar. As vehicle manufacturers strive for lighter and more fuel-efficient designs, the demand for high-performance, lightweight hoses is increasing.

Challenges in the industrial hose market include the volatility of raw material prices, which can impact profit margins, and the growing competition from alternative materials. However, the ongoing research and development in enhancing Kevlar properties present opportunities for manufacturers to differentiate their products and capture a larger market share.

In conclusion, the industrial hose market analysis reveals a growing demand for high-performance materials like Kevlar, driven by the need for durable, lightweight, and efficient fluid transfer solutions across various industries. The market's trajectory suggests that innovations in Kevlar properties for industrial hose applications could significantly impact market dynamics and create new growth opportunities.

Kevlar Limitations in Hoses

While Kevlar is renowned for its exceptional strength-to-weight ratio and heat resistance, it faces several limitations when applied to industrial hose applications. One primary challenge is its susceptibility to degradation under prolonged exposure to ultraviolet (UV) light. This vulnerability can lead to a reduction in tensile strength and overall durability of hoses used in outdoor environments, potentially compromising their long-term performance and safety.

Another significant limitation is Kevlar's relatively poor resistance to certain chemicals and solvents. Industrial hoses often come into contact with a wide range of substances, including acids, bases, and organic solvents. Kevlar's limited chemical resistance can result in material degradation, affecting the hose's structural integrity and potentially leading to leaks or failures in critical applications.

Kevlar also exhibits challenges in terms of flexibility and fatigue resistance. While it possesses high tensile strength, repeated bending and flexing of Kevlar-reinforced hoses can cause micro-fractures in the fibers over time. This limitation is particularly problematic in applications requiring frequent movement or high-pressure pulsations, potentially reducing the hose's service life and reliability.

The material's inherent hydrophilicity poses another constraint in hose applications. Kevlar tends to absorb moisture, which can lead to dimensional changes and potential weakening of the fiber structure. This characteristic is especially problematic in environments with high humidity or where the hose may be exposed to water, potentially affecting its performance and longevity.

Furthermore, Kevlar's high cost compared to alternative materials like nylon or polyester can limit its widespread adoption in industrial hose manufacturing. The economic considerations often force manufacturers to balance performance requirements with cost-effectiveness, potentially leading to compromises in hose design and material selection.

Kevlar's processing challenges also contribute to its limitations in hose applications. The material's high melting point and low elongation at break can make it difficult to incorporate into complex hose structures or to achieve optimal fiber alignment during the manufacturing process. These processing difficulties can result in inconsistencies in hose quality and performance.

Lastly, Kevlar's limited thermal conductivity can be a drawback in applications where heat dissipation is crucial. In high-temperature industrial environments, this characteristic may lead to heat buildup within the hose structure, potentially affecting the performance of the hose and the fluids or gases it transports.

Another significant limitation is Kevlar's relatively poor resistance to certain chemicals and solvents. Industrial hoses often come into contact with a wide range of substances, including acids, bases, and organic solvents. Kevlar's limited chemical resistance can result in material degradation, affecting the hose's structural integrity and potentially leading to leaks or failures in critical applications.

Kevlar also exhibits challenges in terms of flexibility and fatigue resistance. While it possesses high tensile strength, repeated bending and flexing of Kevlar-reinforced hoses can cause micro-fractures in the fibers over time. This limitation is particularly problematic in applications requiring frequent movement or high-pressure pulsations, potentially reducing the hose's service life and reliability.

The material's inherent hydrophilicity poses another constraint in hose applications. Kevlar tends to absorb moisture, which can lead to dimensional changes and potential weakening of the fiber structure. This characteristic is especially problematic in environments with high humidity or where the hose may be exposed to water, potentially affecting its performance and longevity.

Furthermore, Kevlar's high cost compared to alternative materials like nylon or polyester can limit its widespread adoption in industrial hose manufacturing. The economic considerations often force manufacturers to balance performance requirements with cost-effectiveness, potentially leading to compromises in hose design and material selection.

Kevlar's processing challenges also contribute to its limitations in hose applications. The material's high melting point and low elongation at break can make it difficult to incorporate into complex hose structures or to achieve optimal fiber alignment during the manufacturing process. These processing difficulties can result in inconsistencies in hose quality and performance.

Lastly, Kevlar's limited thermal conductivity can be a drawback in applications where heat dissipation is crucial. In high-temperature industrial environments, this characteristic may lead to heat buildup within the hose structure, potentially affecting the performance of the hose and the fluids or gases it transports.

Current Kevlar Modification Methods

01 High tensile strength and durability

Kevlar is known for its exceptional tensile strength and durability. It exhibits high resistance to wear and tear, making it suitable for applications requiring strong and long-lasting materials. This property makes Kevlar ideal for use in protective gear, aerospace components, and high-performance fabrics.- High tensile strength and durability: Kevlar is known for its exceptional tensile strength and durability. It exhibits high resistance to wear and tear, making it suitable for applications requiring strong and long-lasting materials. This property makes Kevlar ideal for use in protective gear, aerospace components, and high-performance fabrics.

- Heat and flame resistance: Kevlar possesses excellent heat and flame-resistant properties. It maintains its structural integrity at high temperatures and does not easily ignite or melt. This characteristic makes it valuable in firefighting equipment, industrial protective clothing, and automotive applications where heat resistance is crucial.

- Lightweight and flexible nature: Despite its strength, Kevlar is remarkably lightweight and flexible. This combination of properties allows for the creation of thin, pliable materials that offer high protection without compromising mobility or comfort. These attributes make Kevlar suitable for use in body armor, sports equipment, and lightweight composite structures.

- Chemical and corrosion resistance: Kevlar exhibits strong resistance to various chemicals and corrosive substances. It maintains its properties when exposed to many solvents, acids, and alkalis, making it suitable for use in harsh environmental conditions. This characteristic is valuable in industrial applications, chemical processing equipment, and protective gear for hazardous environments.

- Composite reinforcement capabilities: Kevlar is widely used as a reinforcement material in composites. When combined with other materials such as resins or plastics, it enhances the overall strength, stiffness, and impact resistance of the resulting composite. This property is utilized in the production of high-performance sports equipment, automotive components, and aerospace structures.

02 Heat and flame resistance

Kevlar possesses excellent heat and flame-resistant properties. It maintains its structural integrity at high temperatures and does not melt or drip when exposed to flames. This characteristic makes it valuable in firefighting equipment, industrial protective clothing, and automotive applications.Expand Specific Solutions03 Lightweight and flexible nature

Despite its strength, Kevlar is remarkably lightweight and flexible. This combination of properties allows for the creation of thin, pliable materials that offer high levels of protection. It is widely used in body armor, cut-resistant gloves, and high-performance sporting goods.Expand Specific Solutions04 Chemical and corrosion resistance

Kevlar exhibits strong resistance to various chemicals and corrosive substances. This property makes it suitable for use in harsh environments and applications where exposure to aggressive chemicals is common, such as in industrial filters, gaskets, and protective coatings.Expand Specific Solutions05 Composite reinforcement capabilities

Kevlar fibers are extensively used as reinforcement in composite materials. When combined with resins or other matrix materials, Kevlar-reinforced composites offer enhanced strength, stiffness, and impact resistance. These composites find applications in aerospace, automotive, and sporting goods industries.Expand Specific Solutions

Key Kevlar Manufacturers

The market for enhancing Kevlar properties in industrial hose applications is in a growth phase, driven by increasing demand for high-performance materials in various industries. The global market size for advanced materials like Kevlar is expanding, with a projected CAGR of 6-8% over the next five years. Technological maturity varies among key players, with companies like Sumitomo Riko, Bridgestone, and Gates Corp. leading in innovation. These firms are investing heavily in R&D to improve Kevlar's properties, focusing on enhancing tensile strength, heat resistance, and durability for industrial hose applications. Emerging players like Bekaert and Zeon Corp. are also making significant strides in developing novel Kevlar-based solutions, intensifying competition in this specialized market.

Bridgestone Corp.

Technical Solution: Bridgestone has developed an innovative approach to enhance Kevlar properties for industrial hose applications through their proprietary "Nano-Pro-Tech" technology. This method involves the incorporation of nano-scale particles into the Kevlar fiber structure during the manufacturing process. The nanoparticles are carefully selected and engineered to interact with the Kevlar polymer chains, creating additional cross-links and improving the overall molecular structure. This results in enhanced mechanical properties, including increased tensile strength and improved abrasion resistance[3]. Bridgestone also employs a specialized coating process that applies a protective layer to the Kevlar fibers, further improving their resistance to chemicals and environmental factors. The company has reported a 30% increase in hose lifespan when using this enhanced Kevlar technology compared to standard Kevlar reinforcement[4].

Strengths: Significantly improved durability and chemical resistance, extended product lifespan. Weaknesses: Complex manufacturing process, potentially higher cost of production.

Gates Corp.

Technical Solution: Gates Corporation has developed a proprietary technology called Kevlar® Force for industrial hose applications. This technology involves incorporating Kevlar fibers into the hose construction, significantly enhancing its strength and durability. The process includes a unique fiber orientation technique that maximizes the tensile strength of Kevlar in the hose structure. Gates also employs a specialized bonding process to ensure optimal adhesion between the Kevlar reinforcement and the elastomeric materials used in the hose construction[1]. This results in a hose that can withstand higher pressures and more extreme operating conditions compared to traditional reinforced hoses. Additionally, Gates has implemented a surface treatment method for the Kevlar fibers to improve their compatibility with various elastomers, enhancing the overall performance and longevity of the hose[2].

Strengths: Superior strength-to-weight ratio, excellent resistance to abrasion and chemicals, improved flexibility. Weaknesses: Higher production costs, potential challenges in recycling at end-of-life.

Innovative Kevlar Reinforcement Techniques

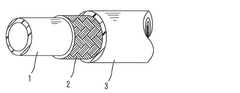

Industrial hose

PatentWO2023120213A1

Innovation

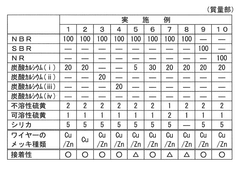

- Incorporating a copper sulfide-containing layer by adding calcium carbonate with a specific BET surface area to the rubber layer to suppress copper ion diffusion and enhance adhesion between the wire reinforcement layer and the rubber layer, without using adhesives.

High-pressure hydraulic hose

PatentWO2014156666A1

Innovation

- A high-pressure hydraulic hose design that uses a rubber composition containing diene rubber, phenolic resin modified with a functional group having a double bond, and at least one vulcanizing agent or accelerator with a morpholine structure to enhance adhesion between the reinforcing wire layer and the rubber layer without the use of adhesives, resulting in improved durability and adhesion.

Environmental Impact Assessment

The environmental impact assessment of enhancing Kevlar properties for industrial hose applications is a critical consideration in the development and implementation of this technology. Kevlar, a high-strength synthetic fiber, has been widely used in various industrial applications due to its exceptional mechanical properties. However, the process of enhancing its properties for specific uses in industrial hoses may have significant environmental implications.

One of the primary environmental concerns is the energy consumption associated with the production and modification of Kevlar fibers. The enhancement process often involves high-temperature treatments and chemical modifications, which can lead to increased energy usage and greenhouse gas emissions. Manufacturers must carefully evaluate and optimize these processes to minimize their carbon footprint and align with sustainability goals.

The use of chemical additives and treatments to enhance Kevlar properties also raises environmental concerns. These substances may include solvents, catalysts, and surface modifiers, some of which could be potentially harmful if released into the environment. Proper handling, disposal, and recycling protocols must be established to prevent contamination of soil and water resources.

Water usage is another important factor to consider in the environmental impact assessment. The production and treatment of Kevlar fibers often require significant amounts of water for processing and cooling. Implementing water recycling systems and adopting water-efficient technologies can help mitigate the strain on local water resources and reduce overall environmental impact.

The durability and longevity of enhanced Kevlar hoses may have positive environmental implications. Improved resistance to wear, chemicals, and extreme conditions can lead to extended product lifespans, reducing the frequency of replacement and ultimately decreasing waste generation. This aspect should be weighed against the potential increased environmental costs of the enhancement process.

End-of-life considerations for enhanced Kevlar hoses are crucial in assessing their overall environmental impact. While Kevlar itself is not biodegradable, research into recycling methods for Kevlar-based products is ongoing. Developing efficient recycling processes for enhanced Kevlar hoses could significantly reduce their environmental footprint and promote a more circular economy approach in the industrial sector.

The potential for reduced material usage in hose manufacturing due to enhanced Kevlar properties should also be evaluated. If stronger and more durable Kevlar allows for the production of thinner or lighter hoses without compromising performance, it could lead to a decrease in raw material consumption and associated environmental impacts throughout the supply chain.

One of the primary environmental concerns is the energy consumption associated with the production and modification of Kevlar fibers. The enhancement process often involves high-temperature treatments and chemical modifications, which can lead to increased energy usage and greenhouse gas emissions. Manufacturers must carefully evaluate and optimize these processes to minimize their carbon footprint and align with sustainability goals.

The use of chemical additives and treatments to enhance Kevlar properties also raises environmental concerns. These substances may include solvents, catalysts, and surface modifiers, some of which could be potentially harmful if released into the environment. Proper handling, disposal, and recycling protocols must be established to prevent contamination of soil and water resources.

Water usage is another important factor to consider in the environmental impact assessment. The production and treatment of Kevlar fibers often require significant amounts of water for processing and cooling. Implementing water recycling systems and adopting water-efficient technologies can help mitigate the strain on local water resources and reduce overall environmental impact.

The durability and longevity of enhanced Kevlar hoses may have positive environmental implications. Improved resistance to wear, chemicals, and extreme conditions can lead to extended product lifespans, reducing the frequency of replacement and ultimately decreasing waste generation. This aspect should be weighed against the potential increased environmental costs of the enhancement process.

End-of-life considerations for enhanced Kevlar hoses are crucial in assessing their overall environmental impact. While Kevlar itself is not biodegradable, research into recycling methods for Kevlar-based products is ongoing. Developing efficient recycling processes for enhanced Kevlar hoses could significantly reduce their environmental footprint and promote a more circular economy approach in the industrial sector.

The potential for reduced material usage in hose manufacturing due to enhanced Kevlar properties should also be evaluated. If stronger and more durable Kevlar allows for the production of thinner or lighter hoses without compromising performance, it could lead to a decrease in raw material consumption and associated environmental impacts throughout the supply chain.

Cost-Benefit Analysis of Enhanced Kevlar

Enhancing Kevlar properties for industrial hose applications presents a significant opportunity for improved performance and durability. However, it is crucial to conduct a thorough cost-benefit analysis to determine the economic viability of such enhancements.

The primary benefits of enhanced Kevlar in industrial hoses include increased tensile strength, improved abrasion resistance, and extended service life. These improvements can lead to reduced maintenance costs, fewer replacements, and enhanced safety in high-pressure or harsh environments. For instance, a 20% increase in tensile strength could potentially extend the hose's lifespan by 30-40%, resulting in substantial long-term savings for industrial users.

On the cost side, the development and implementation of enhanced Kevlar technologies require significant upfront investments. These costs encompass research and development expenses, new manufacturing processes, and potential retooling of production lines. Initial estimates suggest that the cost of producing enhanced Kevlar fibers could be 15-25% higher than standard Kevlar.

However, the increased production costs may be offset by the reduced material usage due to the enhanced properties. For example, a 15% reduction in material thickness while maintaining the same performance characteristics could lead to overall cost savings in raw materials and transportation.

Market analysis indicates that industrial users are willing to pay a premium of 10-15% for hoses with significantly improved durability and performance. This price elasticity suggests that the enhanced Kevlar hoses could command higher profit margins, provided that the performance improvements are clearly demonstrated and marketed effectively.

The long-term economic benefits of enhanced Kevlar hoses extend beyond direct cost savings. Improved reliability can lead to reduced downtime in industrial operations, potentially saving millions in lost productivity. Additionally, the enhanced safety features could result in lower insurance premiums and reduced liability risks for both manufacturers and end-users.

Environmental considerations also play a role in the cost-benefit analysis. The longer lifespan of enhanced Kevlar hoses contributes to waste reduction and aligns with sustainability goals, which can provide intangible benefits in terms of corporate social responsibility and regulatory compliance.

In conclusion, while the initial costs of enhancing Kevlar properties for industrial hose applications are substantial, the long-term benefits in terms of performance, durability, and cost savings appear to outweigh these investments. A phased approach to implementation, coupled with targeted marketing to high-value industrial sectors, could optimize the return on investment and position enhanced Kevlar hoses as a premium product in the industrial market.

The primary benefits of enhanced Kevlar in industrial hoses include increased tensile strength, improved abrasion resistance, and extended service life. These improvements can lead to reduced maintenance costs, fewer replacements, and enhanced safety in high-pressure or harsh environments. For instance, a 20% increase in tensile strength could potentially extend the hose's lifespan by 30-40%, resulting in substantial long-term savings for industrial users.

On the cost side, the development and implementation of enhanced Kevlar technologies require significant upfront investments. These costs encompass research and development expenses, new manufacturing processes, and potential retooling of production lines. Initial estimates suggest that the cost of producing enhanced Kevlar fibers could be 15-25% higher than standard Kevlar.

However, the increased production costs may be offset by the reduced material usage due to the enhanced properties. For example, a 15% reduction in material thickness while maintaining the same performance characteristics could lead to overall cost savings in raw materials and transportation.

Market analysis indicates that industrial users are willing to pay a premium of 10-15% for hoses with significantly improved durability and performance. This price elasticity suggests that the enhanced Kevlar hoses could command higher profit margins, provided that the performance improvements are clearly demonstrated and marketed effectively.

The long-term economic benefits of enhanced Kevlar hoses extend beyond direct cost savings. Improved reliability can lead to reduced downtime in industrial operations, potentially saving millions in lost productivity. Additionally, the enhanced safety features could result in lower insurance premiums and reduced liability risks for both manufacturers and end-users.

Environmental considerations also play a role in the cost-benefit analysis. The longer lifespan of enhanced Kevlar hoses contributes to waste reduction and aligns with sustainability goals, which can provide intangible benefits in terms of corporate social responsibility and regulatory compliance.

In conclusion, while the initial costs of enhancing Kevlar properties for industrial hose applications are substantial, the long-term benefits in terms of performance, durability, and cost savings appear to outweigh these investments. A phased approach to implementation, coupled with targeted marketing to high-value industrial sectors, could optimize the return on investment and position enhanced Kevlar hoses as a premium product in the industrial market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!