How to Implement Kevlar in High-Performance Footwear?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Footwear Evolution

The evolution of Kevlar in high-performance footwear represents a significant advancement in the field of athletic and protective gear. Initially developed by DuPont in the 1960s, Kevlar's journey into footwear began in the late 1980s when manufacturers recognized its potential for enhancing shoe durability and performance.

In the early stages, Kevlar was primarily used in military and law enforcement boots, valued for its exceptional strength-to-weight ratio and resistance to cuts and punctures. The material's integration into civilian footwear started gradually, with outdoor and hiking boots being among the first adopters. These early applications focused on reinforcing high-wear areas such as toe caps and heel counters.

The 1990s saw a surge in Kevlar's use in athletic footwear, particularly in trail running and mountain biking shoes. Manufacturers began incorporating Kevlar fibers into the upper materials, creating lightweight yet highly durable shoes capable of withstanding harsh terrain and extreme conditions. This period also marked the beginning of Kevlar's use in midsole construction, where it provided enhanced stability without adding significant weight.

As material science advanced in the 2000s, so did the applications of Kevlar in footwear. Innovations in fiber blending and weaving techniques allowed for more seamless integration of Kevlar into shoe designs. This era saw the development of Kevlar-reinforced fabrics that maintained flexibility while offering superior tear and abrasion resistance. High-performance running shoes began featuring Kevlar in critical stress points, significantly extending the lifespan of these products.

The 2010s brought about a revolution in Kevlar footwear technology. Manufacturers started experimenting with 3D-printed Kevlar components, allowing for highly customized and optimized shoe structures. This period also saw the emergence of Kevlar-infused foams for midsoles, combining the material's strength with enhanced cushioning properties. Additionally, Kevlar began to be used in shoe laces and closure systems, offering unparalleled durability in these often-overlooked components.

Recent years have witnessed a focus on sustainability in Kevlar footwear applications. Researchers and manufacturers are exploring ways to recycle Kevlar fibers from used products and incorporate them into new footwear designs. This circular approach not only addresses environmental concerns but also opens up new possibilities for material innovation.

Looking ahead, the evolution of Kevlar in high-performance footwear is poised to continue. Emerging trends include the development of smart Kevlar composites that can adapt to different environmental conditions, as well as the integration of Kevlar with other high-tech materials to create hybrid solutions that offer unprecedented levels of protection, comfort, and performance.

In the early stages, Kevlar was primarily used in military and law enforcement boots, valued for its exceptional strength-to-weight ratio and resistance to cuts and punctures. The material's integration into civilian footwear started gradually, with outdoor and hiking boots being among the first adopters. These early applications focused on reinforcing high-wear areas such as toe caps and heel counters.

The 1990s saw a surge in Kevlar's use in athletic footwear, particularly in trail running and mountain biking shoes. Manufacturers began incorporating Kevlar fibers into the upper materials, creating lightweight yet highly durable shoes capable of withstanding harsh terrain and extreme conditions. This period also marked the beginning of Kevlar's use in midsole construction, where it provided enhanced stability without adding significant weight.

As material science advanced in the 2000s, so did the applications of Kevlar in footwear. Innovations in fiber blending and weaving techniques allowed for more seamless integration of Kevlar into shoe designs. This era saw the development of Kevlar-reinforced fabrics that maintained flexibility while offering superior tear and abrasion resistance. High-performance running shoes began featuring Kevlar in critical stress points, significantly extending the lifespan of these products.

The 2010s brought about a revolution in Kevlar footwear technology. Manufacturers started experimenting with 3D-printed Kevlar components, allowing for highly customized and optimized shoe structures. This period also saw the emergence of Kevlar-infused foams for midsoles, combining the material's strength with enhanced cushioning properties. Additionally, Kevlar began to be used in shoe laces and closure systems, offering unparalleled durability in these often-overlooked components.

Recent years have witnessed a focus on sustainability in Kevlar footwear applications. Researchers and manufacturers are exploring ways to recycle Kevlar fibers from used products and incorporate them into new footwear designs. This circular approach not only addresses environmental concerns but also opens up new possibilities for material innovation.

Looking ahead, the evolution of Kevlar in high-performance footwear is poised to continue. Emerging trends include the development of smart Kevlar composites that can adapt to different environmental conditions, as well as the integration of Kevlar with other high-tech materials to create hybrid solutions that offer unprecedented levels of protection, comfort, and performance.

Market Demand Analysis

The market demand for high-performance footwear incorporating Kevlar technology has been steadily growing, driven by the increasing focus on durability, safety, and performance in various sectors. The athletic footwear market, in particular, has shown significant interest in Kevlar-enhanced products, with consumers seeking shoes that offer superior protection and longevity without compromising on comfort or weight.

In the sports and outdoor recreation segment, there is a rising demand for footwear that can withstand extreme conditions and provide enhanced protection against cuts, abrasions, and punctures. Trail running, hiking, and mountaineering enthusiasts are particularly interested in shoes that incorporate Kevlar, as these activities often expose footwear to harsh terrains and potential damage.

The military and law enforcement sectors represent another substantial market for Kevlar-enhanced footwear. These professionals require boots that offer exceptional durability, protection against ballistic threats, and resistance to environmental factors. The integration of Kevlar in tactical footwear has become increasingly important for personnel operating in high-risk environments.

Workwear is another area where the demand for Kevlar-enhanced footwear is growing. Industries such as construction, manufacturing, and oil and gas require safety shoes that can protect against workplace hazards while providing comfort for extended wear. The ability of Kevlar to enhance cut resistance and durability makes it an attractive material for work boots and safety shoes.

The motorsports industry has also shown interest in Kevlar-enhanced footwear, particularly for racing shoes. Drivers and riders seek footwear that offers protection against heat and potential impacts while maintaining sensitivity for precise control operations.

Market analysis indicates that consumers are willing to pay a premium for footwear that incorporates advanced materials like Kevlar, especially when the benefits in terms of durability and protection are clearly demonstrated. This trend is expected to continue as awareness of Kevlar's properties and its applications in footwear increases among consumers.

However, challenges remain in balancing the integration of Kevlar with other desirable footwear characteristics such as breathability, flexibility, and overall comfort. Manufacturers that can successfully address these challenges are likely to gain a significant competitive advantage in the high-performance footwear market.

As sustainability becomes an increasingly important factor for consumers, there is also growing interest in how Kevlar can contribute to the longevity of footwear, potentially reducing the environmental impact associated with frequent shoe replacements. This aspect of Kevlar implementation in footwear aligns with the broader trend towards more sustainable and durable consumer products.

In the sports and outdoor recreation segment, there is a rising demand for footwear that can withstand extreme conditions and provide enhanced protection against cuts, abrasions, and punctures. Trail running, hiking, and mountaineering enthusiasts are particularly interested in shoes that incorporate Kevlar, as these activities often expose footwear to harsh terrains and potential damage.

The military and law enforcement sectors represent another substantial market for Kevlar-enhanced footwear. These professionals require boots that offer exceptional durability, protection against ballistic threats, and resistance to environmental factors. The integration of Kevlar in tactical footwear has become increasingly important for personnel operating in high-risk environments.

Workwear is another area where the demand for Kevlar-enhanced footwear is growing. Industries such as construction, manufacturing, and oil and gas require safety shoes that can protect against workplace hazards while providing comfort for extended wear. The ability of Kevlar to enhance cut resistance and durability makes it an attractive material for work boots and safety shoes.

The motorsports industry has also shown interest in Kevlar-enhanced footwear, particularly for racing shoes. Drivers and riders seek footwear that offers protection against heat and potential impacts while maintaining sensitivity for precise control operations.

Market analysis indicates that consumers are willing to pay a premium for footwear that incorporates advanced materials like Kevlar, especially when the benefits in terms of durability and protection are clearly demonstrated. This trend is expected to continue as awareness of Kevlar's properties and its applications in footwear increases among consumers.

However, challenges remain in balancing the integration of Kevlar with other desirable footwear characteristics such as breathability, flexibility, and overall comfort. Manufacturers that can successfully address these challenges are likely to gain a significant competitive advantage in the high-performance footwear market.

As sustainability becomes an increasingly important factor for consumers, there is also growing interest in how Kevlar can contribute to the longevity of footwear, potentially reducing the environmental impact associated with frequent shoe replacements. This aspect of Kevlar implementation in footwear aligns with the broader trend towards more sustainable and durable consumer products.

Technical Challenges

The implementation of Kevlar in high-performance footwear presents several significant technical challenges that must be addressed to fully leverage its potential. One of the primary obstacles is the integration of Kevlar fibers into existing shoe manufacturing processes without compromising the material's inherent strength and durability. Traditional shoe construction methods may not be suitable for Kevlar, requiring the development of new techniques to effectively incorporate the material into various components of the footwear.

Another challenge lies in balancing the rigidity of Kevlar with the flexibility required for comfortable and functional footwear. While Kevlar's high tensile strength is desirable for durability, it can result in stiffness that may impede natural foot movement. Engineers must find innovative ways to maintain the material's protective qualities while ensuring sufficient flexibility, particularly in high-stress areas such as the toe box and heel counter.

The weight of Kevlar-enhanced footwear is also a critical consideration. High-performance shoes often prioritize lightweight design to enhance athletic performance. However, Kevlar, despite its strength-to-weight ratio, may still add unwanted mass to the shoe. Developing methods to minimize weight while maximizing the protective benefits of Kevlar is a complex engineering task that requires careful material selection and design optimization.

Moisture management presents another significant hurdle in Kevlar implementation. The material's inherent properties may not naturally allow for adequate breathability or moisture-wicking capabilities, which are crucial for athletic footwear. Researchers must explore ways to modify Kevlar or combine it with other materials to improve ventilation and moisture control without sacrificing its protective qualities.

The cost-effectiveness of incorporating Kevlar into mass-produced footwear is also a substantial challenge. The material's high cost and specialized processing requirements may lead to increased production expenses, potentially limiting its widespread adoption in the footwear industry. Manufacturers must develop cost-efficient production methods and explore economies of scale to make Kevlar-enhanced footwear commercially viable.

Lastly, ensuring consistent quality and performance across different shoe models and sizes poses a significant technical challenge. The properties of Kevlar-enhanced components may vary depending on the shoe's design and intended use, requiring extensive testing and quality control measures. Developing standardized manufacturing processes and quality assurance protocols for Kevlar implementation in footwear is essential to maintain product reliability and meet consumer expectations.

Another challenge lies in balancing the rigidity of Kevlar with the flexibility required for comfortable and functional footwear. While Kevlar's high tensile strength is desirable for durability, it can result in stiffness that may impede natural foot movement. Engineers must find innovative ways to maintain the material's protective qualities while ensuring sufficient flexibility, particularly in high-stress areas such as the toe box and heel counter.

The weight of Kevlar-enhanced footwear is also a critical consideration. High-performance shoes often prioritize lightweight design to enhance athletic performance. However, Kevlar, despite its strength-to-weight ratio, may still add unwanted mass to the shoe. Developing methods to minimize weight while maximizing the protective benefits of Kevlar is a complex engineering task that requires careful material selection and design optimization.

Moisture management presents another significant hurdle in Kevlar implementation. The material's inherent properties may not naturally allow for adequate breathability or moisture-wicking capabilities, which are crucial for athletic footwear. Researchers must explore ways to modify Kevlar or combine it with other materials to improve ventilation and moisture control without sacrificing its protective qualities.

The cost-effectiveness of incorporating Kevlar into mass-produced footwear is also a substantial challenge. The material's high cost and specialized processing requirements may lead to increased production expenses, potentially limiting its widespread adoption in the footwear industry. Manufacturers must develop cost-efficient production methods and explore economies of scale to make Kevlar-enhanced footwear commercially viable.

Lastly, ensuring consistent quality and performance across different shoe models and sizes poses a significant technical challenge. The properties of Kevlar-enhanced components may vary depending on the shoe's design and intended use, requiring extensive testing and quality control measures. Developing standardized manufacturing processes and quality assurance protocols for Kevlar implementation in footwear is essential to maintain product reliability and meet consumer expectations.

Current Kevlar Solutions

01 Kevlar-reinforced composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar fibers significantly improves the mechanical properties of the resulting materials.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.

- Kevlar in protective gear and clothing: Kevlar is extensively used in the manufacture of protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.

- Kevlar-based fire-resistant materials: Kevlar is utilized in the development of fire-resistant materials and fabrics. These materials are used in firefighting equipment, industrial safety gear, and other applications requiring high heat resistance.

- Kevlar in automotive applications: Kevlar is employed in various automotive components to reduce weight while maintaining strength. It is used in tires, belts, hoses, and body panels to improve fuel efficiency and overall vehicle performance.

- Kevlar in aerospace and marine industries: Kevlar finds applications in aerospace and marine industries for its high strength-to-weight ratio. It is used in aircraft components, boat hulls, and satellite structures to enhance durability and reduce overall weight.

02 Kevlar-based protective gear

Kevlar is extensively used in the production of personal protective equipment, including bulletproof vests, helmets, and other safety gear. Its high tensile strength and lightweight properties make it ideal for applications requiring impact and ballistic protection. Innovations in this area focus on improving comfort, flexibility, and overall protective performance.Expand Specific Solutions03 Kevlar in textile and clothing applications

Kevlar fibers are incorporated into various textile and clothing products to enhance their durability, cut resistance, and heat resistance. This includes applications in workwear, sports apparel, and high-performance clothing. Innovations in this area focus on improving the integration of Kevlar fibers with other materials and enhancing the overall performance of the resulting fabrics.Expand Specific Solutions04 Kevlar in industrial and automotive applications

Kevlar is utilized in various industrial and automotive applications, such as belts, hoses, and reinforcement materials. Its high strength-to-weight ratio and resistance to heat and chemicals make it suitable for demanding environments. Innovations in this area focus on improving the integration of Kevlar with other materials and enhancing its performance in specific industrial applications.Expand Specific Solutions05 Kevlar in aerospace and marine applications

Kevlar finds applications in aerospace and marine industries, where its lightweight and high-strength properties are particularly valuable. It is used in aircraft components, spacecraft structures, and marine vessels. Innovations in this area focus on developing new composite materials and structures that leverage Kevlar's unique properties to improve performance and reduce weight in these demanding environments.Expand Specific Solutions

Key Industry Players

The implementation of Kevlar in high-performance footwear is in a mature stage of industry development, with a significant market size driven by demand for durable and lightweight athletic shoes. The technology's maturity is evident in its widespread adoption by major players like Reebok, New Balance, and Converse. Companies such as Tecnica Group and ECCO Sko A/S are leveraging Kevlar's properties to enhance their product offerings. Research institutions like Nanjing University of Science & Technology and Beijing Institute of Technology are likely contributing to further advancements in Kevlar applications. The competitive landscape is characterized by a mix of established sportswear giants and specialized footwear manufacturers, all vying to innovate and differentiate their products using this high-performance material.

Decathlon SE

Technical Solution: Decathlon has implemented Kevlar in their high-performance footwear through a technology called K-PROTECT. This system integrates Kevlar fibers into strategic areas of the shoe, particularly in trail running and hiking models. The K-PROTECT technology focuses on reinforcing the toe box, sides, and heel areas of the shoe, providing enhanced protection against rocks, roots, and other trail hazards. Decathlon has also developed a Kevlar-infused midsole compound that offers improved stability and durability without adding significant weight. The company's approach emphasizes affordability, making Kevlar-enhanced footwear more accessible to a broader range of consumers[7][8].

Strengths: Strategic placement of Kevlar for targeted protection, affordable pricing, wide range of applications. Weaknesses: May not offer full Kevlar coverage, potential trade-offs in overall durability for cost-effectiveness.

Tecnica Group SpA

Technical Solution: Tecnica Group, known for their ski boots and outdoor footwear, has incorporated Kevlar into their high-performance footwear through a technology called C.A.S. (Custom Adaptive Shape). This innovative approach uses Kevlar fibers in conjunction with thermo-moldable materials to create a customizable fit that maintains its shape and durability over time. The Kevlar reinforcement is strategically placed in high-stress areas of the boot, such as the ankle support and toe box. Tecnica has also developed a Kevlar-infused lasting board that provides enhanced torsional rigidity and durability in their mountaineering and trekking boots. The company's implementation focuses on combining the strength of Kevlar with the adaptability of heat-moldable materials to create footwear that offers both personalized fit and exceptional durability[9][10].

Strengths: Customizable fit with long-lasting durability, excellent torsional rigidity, targeted reinforcement in critical areas. Weaknesses: Primarily limited to ski boots and specialized outdoor footwear, potentially higher cost due to customization features.

Kevlar Footwear Patents

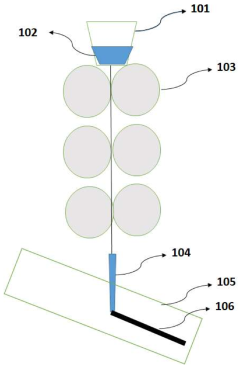

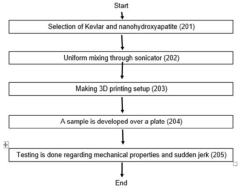

Kevlar and nanohydroxyapatite based bone replacement to counter knee jerk

PatentPendingIN202111041724A

Innovation

- A nanocomposite material composed of Kevlar fiber and nanohydroxyapatite is developed using additive manufacturing techniques like 3D printing, which enhances mechanical properties and biocompatibility, and is tested for impact resistance through a specific manufacturing and testing process.

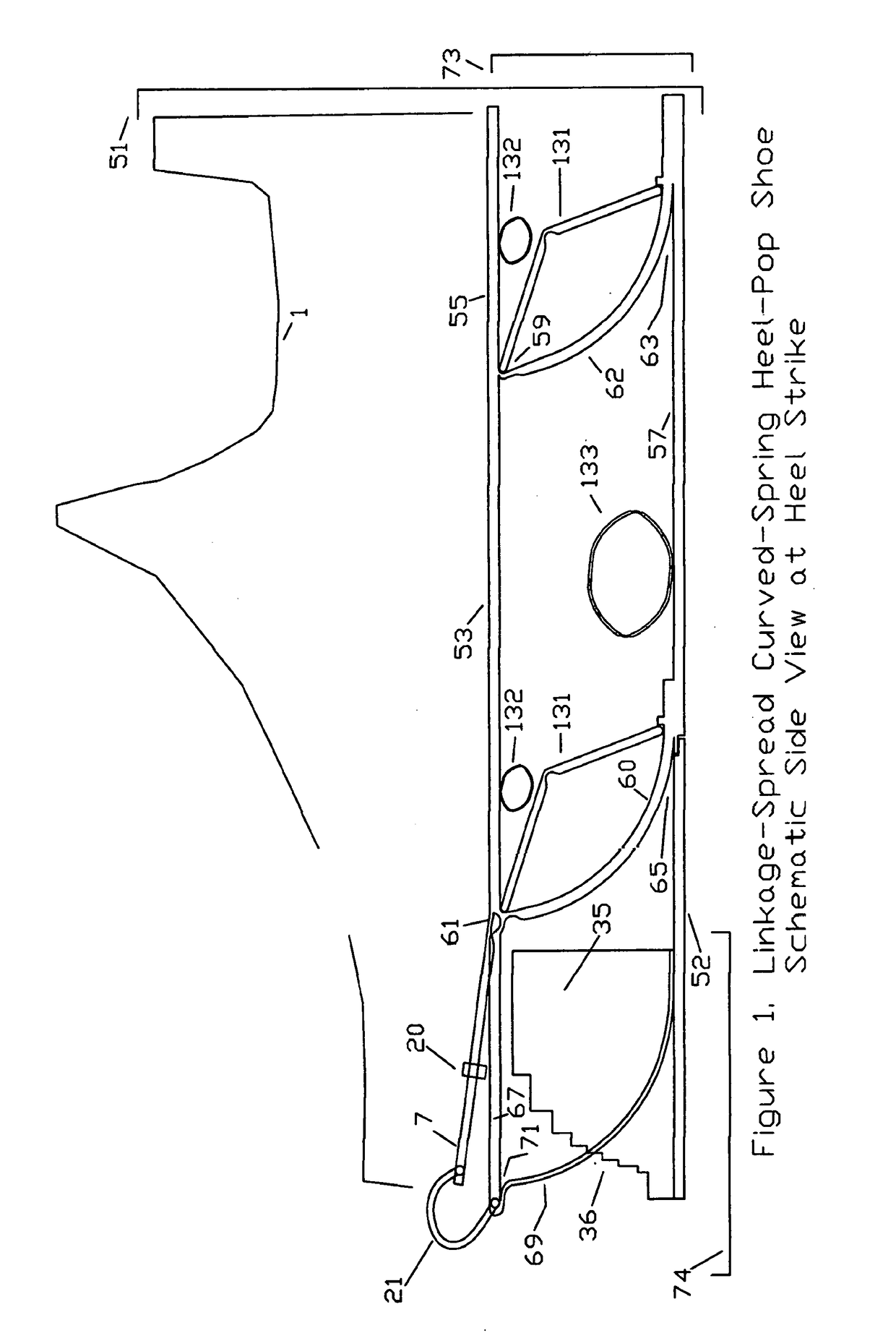

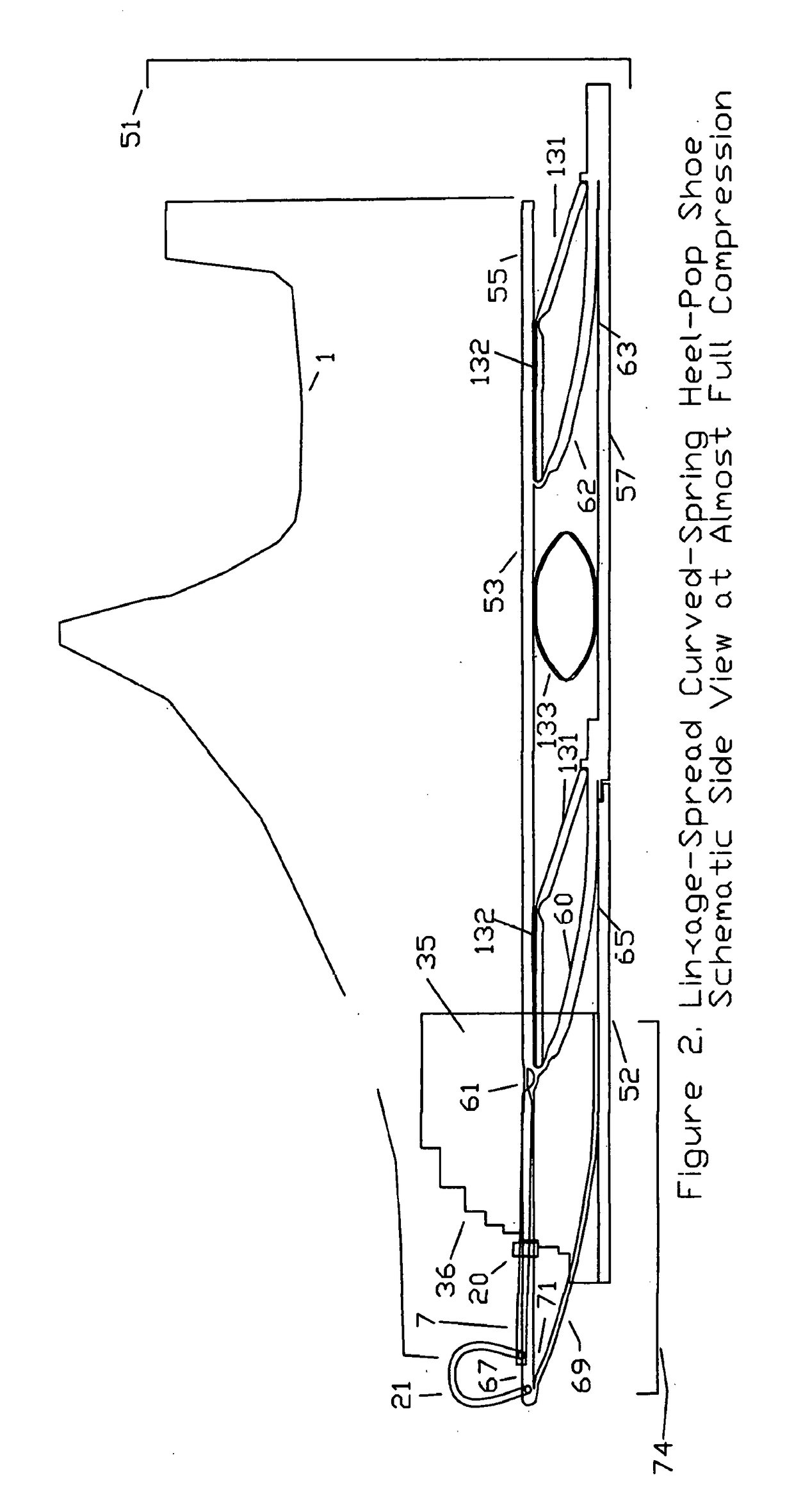

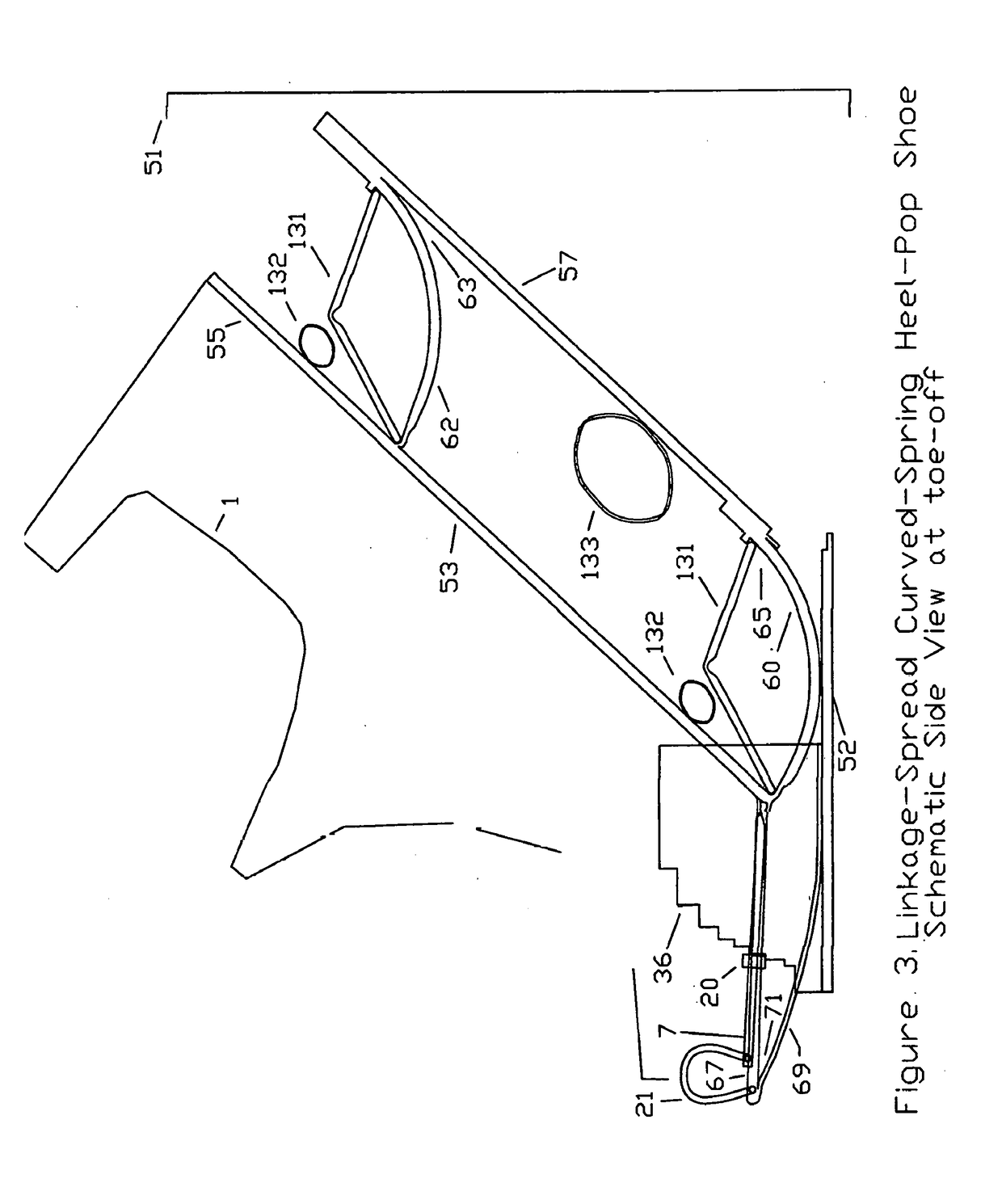

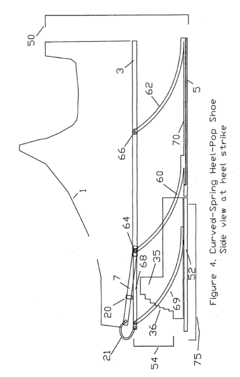

Substantial energy return shoe with optimal low-impact springs, tuned gear change, and smart knee brace

PatentInactiveUS20180220738A1

Innovation

- The design incorporates enhanced heel-lift mechanisms with anti-toe-sink mechanisms and automatic gear changers, utilizing optimized low-impact springs and linkage systems to ensure full sole compression and efficient energy storage and release, reducing the maximum impact force and increasing energy return.

Material Sustainability

The implementation of Kevlar in high-performance footwear presents significant opportunities for enhancing material sustainability in the athletic and outdoor footwear industry. Kevlar, known for its exceptional strength-to-weight ratio and durability, offers a promising alternative to traditional materials that often have shorter lifespans and higher environmental impacts.

One of the primary sustainability benefits of incorporating Kevlar into footwear is its potential to extend product lifespan. The material's high tensile strength and resistance to wear and tear can significantly reduce the frequency of replacements, thereby decreasing overall resource consumption and waste generation. This longevity factor aligns well with the growing consumer demand for durable, long-lasting products that offer better value for money and reduced environmental footprint.

Furthermore, Kevlar's lightweight nature contributes to reduced material usage in footwear production. By replacing heavier materials with Kevlar in key structural components, manufacturers can achieve the same or superior performance while using less raw material overall. This reduction in material input not only conserves resources but also potentially decreases the energy required for production and transportation.

The recyclability of Kevlar presents another avenue for enhancing sustainability in footwear. While not as easily recyclable as some other materials, advancements in recycling technologies are making it increasingly feasible to recover and repurpose Kevlar fibers from end-of-life products. This potential for a circular economy approach could significantly reduce the environmental impact of high-performance footwear over its lifecycle.

However, it is crucial to consider the environmental implications of Kevlar production. The manufacturing process is energy-intensive and involves the use of strong acids, which can have negative environmental impacts if not properly managed. To maximize sustainability benefits, footwear manufacturers must work closely with Kevlar suppliers to ensure responsible production practices and explore ways to minimize the material's environmental footprint throughout its lifecycle.

Integrating Kevlar into footwear design also opens up possibilities for innovative, multi-functional products. By leveraging Kevlar's unique properties, designers can create shoes that serve multiple purposes or adapt to different conditions, potentially reducing the need for consumers to own multiple pairs of specialized footwear. This approach not only enhances product versatility but also contributes to overall resource efficiency in the footwear industry.

In conclusion, while the implementation of Kevlar in high-performance footwear presents some challenges from a sustainability perspective, its potential benefits in terms of product longevity, material efficiency, and innovation make it a compelling option for manufacturers seeking to enhance the environmental performance of their products. As technology advances and sustainable practices evolve, Kevlar could play a significant role in shaping the future of eco-friendly, high-performance footwear.

One of the primary sustainability benefits of incorporating Kevlar into footwear is its potential to extend product lifespan. The material's high tensile strength and resistance to wear and tear can significantly reduce the frequency of replacements, thereby decreasing overall resource consumption and waste generation. This longevity factor aligns well with the growing consumer demand for durable, long-lasting products that offer better value for money and reduced environmental footprint.

Furthermore, Kevlar's lightweight nature contributes to reduced material usage in footwear production. By replacing heavier materials with Kevlar in key structural components, manufacturers can achieve the same or superior performance while using less raw material overall. This reduction in material input not only conserves resources but also potentially decreases the energy required for production and transportation.

The recyclability of Kevlar presents another avenue for enhancing sustainability in footwear. While not as easily recyclable as some other materials, advancements in recycling technologies are making it increasingly feasible to recover and repurpose Kevlar fibers from end-of-life products. This potential for a circular economy approach could significantly reduce the environmental impact of high-performance footwear over its lifecycle.

However, it is crucial to consider the environmental implications of Kevlar production. The manufacturing process is energy-intensive and involves the use of strong acids, which can have negative environmental impacts if not properly managed. To maximize sustainability benefits, footwear manufacturers must work closely with Kevlar suppliers to ensure responsible production practices and explore ways to minimize the material's environmental footprint throughout its lifecycle.

Integrating Kevlar into footwear design also opens up possibilities for innovative, multi-functional products. By leveraging Kevlar's unique properties, designers can create shoes that serve multiple purposes or adapt to different conditions, potentially reducing the need for consumers to own multiple pairs of specialized footwear. This approach not only enhances product versatility but also contributes to overall resource efficiency in the footwear industry.

In conclusion, while the implementation of Kevlar in high-performance footwear presents some challenges from a sustainability perspective, its potential benefits in terms of product longevity, material efficiency, and innovation make it a compelling option for manufacturers seeking to enhance the environmental performance of their products. As technology advances and sustainable practices evolve, Kevlar could play a significant role in shaping the future of eco-friendly, high-performance footwear.

Performance Testing Methods

Performance testing methods for implementing Kevlar in high-performance footwear are crucial to ensure the material's effectiveness and durability in real-world applications. These methods typically involve a series of standardized tests that evaluate various aspects of the footwear's performance, with a particular focus on the Kevlar components.

One of the primary tests is the abrasion resistance test, which assesses the Kevlar-reinforced areas' ability to withstand wear and tear. This test involves subjecting the footwear to repeated cycles of rubbing against abrasive surfaces, simulating the conditions the shoes might encounter during use. The number of cycles the material can withstand before showing signs of significant wear is recorded and compared to industry standards.

Tensile strength testing is another critical method used to evaluate the performance of Kevlar in footwear. This test measures the maximum stress that the Kevlar-reinforced areas can withstand before failure. It involves applying a controlled, gradually increasing force to the material until it breaks or deforms permanently. The results provide valuable insights into the material's ability to resist tearing and maintain structural integrity under stress.

Flexibility and bend testing are essential for assessing how the incorporation of Kevlar affects the overall flexibility of the footwear. This is particularly important for athletic shoes, where freedom of movement is crucial. The test typically involves repeatedly flexing the shoe at specific points, such as the forefoot area, and measuring the force required to bend the material as well as any signs of damage or degradation over time.

Impact resistance testing is conducted to evaluate the Kevlar-reinforced areas' ability to protect against sudden forces or impacts. This can involve dropping weights onto specific areas of the shoe or using specialized equipment to deliver controlled impacts. The energy absorption and distribution properties of the Kevlar-reinforced sections are measured and analyzed.

Moisture management and breathability tests are also crucial, as the addition of Kevlar can potentially affect these properties. These tests measure how well the footwear allows moisture to escape and air to circulate, which is essential for comfort and performance, especially in athletic applications.

Durability testing often involves simulated wear tests, where the footwear is subjected to conditions that mimic extended use. This can include exposure to various environmental factors, repeated stress cycles, and even accelerated aging processes. The performance of the Kevlar components is evaluated throughout these tests to ensure long-term reliability.

Finally, weight analysis is conducted to determine how the inclusion of Kevlar affects the overall weight of the footwear. This is particularly important for high-performance athletic shoes, where every gram can impact an athlete's performance. The weight of the Kevlar-reinforced footwear is compared to standard models to assess the trade-off between enhanced durability and potential weight increase.

One of the primary tests is the abrasion resistance test, which assesses the Kevlar-reinforced areas' ability to withstand wear and tear. This test involves subjecting the footwear to repeated cycles of rubbing against abrasive surfaces, simulating the conditions the shoes might encounter during use. The number of cycles the material can withstand before showing signs of significant wear is recorded and compared to industry standards.

Tensile strength testing is another critical method used to evaluate the performance of Kevlar in footwear. This test measures the maximum stress that the Kevlar-reinforced areas can withstand before failure. It involves applying a controlled, gradually increasing force to the material until it breaks or deforms permanently. The results provide valuable insights into the material's ability to resist tearing and maintain structural integrity under stress.

Flexibility and bend testing are essential for assessing how the incorporation of Kevlar affects the overall flexibility of the footwear. This is particularly important for athletic shoes, where freedom of movement is crucial. The test typically involves repeatedly flexing the shoe at specific points, such as the forefoot area, and measuring the force required to bend the material as well as any signs of damage or degradation over time.

Impact resistance testing is conducted to evaluate the Kevlar-reinforced areas' ability to protect against sudden forces or impacts. This can involve dropping weights onto specific areas of the shoe or using specialized equipment to deliver controlled impacts. The energy absorption and distribution properties of the Kevlar-reinforced sections are measured and analyzed.

Moisture management and breathability tests are also crucial, as the addition of Kevlar can potentially affect these properties. These tests measure how well the footwear allows moisture to escape and air to circulate, which is essential for comfort and performance, especially in athletic applications.

Durability testing often involves simulated wear tests, where the footwear is subjected to conditions that mimic extended use. This can include exposure to various environmental factors, repeated stress cycles, and even accelerated aging processes. The performance of the Kevlar components is evaluated throughout these tests to ensure long-term reliability.

Finally, weight analysis is conducted to determine how the inclusion of Kevlar affects the overall weight of the footwear. This is particularly important for high-performance athletic shoes, where every gram can impact an athlete's performance. The weight of the Kevlar-reinforced footwear is compared to standard models to assess the trade-off between enhanced durability and potential weight increase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!