How to Utilize Kevlar in High-Visibility Safety Gear?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar in Safety Gear: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized the field of personal protective equipment (PPE) and safety gear. Initially designed for use in tires, Kevlar's exceptional strength-to-weight ratio and heat-resistant properties quickly found applications in various industries, including law enforcement, military, and industrial safety.

The evolution of Kevlar in safety gear has been driven by the increasing demand for lightweight, durable, and highly visible protective equipment. As workplace safety regulations have become more stringent and public awareness of occupational hazards has grown, the need for advanced materials in safety gear has intensified. Kevlar's unique properties make it an ideal candidate for integration into high-visibility safety equipment, addressing both protection and visibility requirements.

The primary objective of utilizing Kevlar in high-visibility safety gear is to enhance worker safety in hazardous environments while maintaining comfort and flexibility. By combining Kevlar's strength with high-visibility materials, manufacturers aim to create safety gear that offers superior protection against cuts, abrasions, and impacts while ensuring workers remain visible in low-light conditions or high-traffic areas.

One of the key technological trends in this field is the development of hybrid fabrics that incorporate Kevlar fibers with other materials to achieve optimal performance characteristics. These innovations seek to balance durability, visibility, and comfort, addressing the multifaceted needs of modern safety equipment.

The integration of Kevlar into high-visibility safety gear also aligns with the broader trend of smart PPE development. Researchers and manufacturers are exploring ways to incorporate sensors and other electronic components into Kevlar-based fabrics, potentially enabling real-time monitoring of worker safety and environmental conditions.

As the safety gear industry continues to evolve, the utilization of Kevlar in high-visibility applications faces several challenges and opportunities. These include improving the color retention of high-visibility dyes on Kevlar fibers, enhancing the material's breathability without compromising its protective qualities, and developing more sustainable manufacturing processes for Kevlar-based products.

The future trajectory of Kevlar in safety gear is likely to focus on customization and adaptability. As different industries and work environments present unique safety challenges, there is a growing need for tailored solutions that can leverage Kevlar's properties in combination with other advanced materials and technologies to meet specific safety requirements.

The evolution of Kevlar in safety gear has been driven by the increasing demand for lightweight, durable, and highly visible protective equipment. As workplace safety regulations have become more stringent and public awareness of occupational hazards has grown, the need for advanced materials in safety gear has intensified. Kevlar's unique properties make it an ideal candidate for integration into high-visibility safety equipment, addressing both protection and visibility requirements.

The primary objective of utilizing Kevlar in high-visibility safety gear is to enhance worker safety in hazardous environments while maintaining comfort and flexibility. By combining Kevlar's strength with high-visibility materials, manufacturers aim to create safety gear that offers superior protection against cuts, abrasions, and impacts while ensuring workers remain visible in low-light conditions or high-traffic areas.

One of the key technological trends in this field is the development of hybrid fabrics that incorporate Kevlar fibers with other materials to achieve optimal performance characteristics. These innovations seek to balance durability, visibility, and comfort, addressing the multifaceted needs of modern safety equipment.

The integration of Kevlar into high-visibility safety gear also aligns with the broader trend of smart PPE development. Researchers and manufacturers are exploring ways to incorporate sensors and other electronic components into Kevlar-based fabrics, potentially enabling real-time monitoring of worker safety and environmental conditions.

As the safety gear industry continues to evolve, the utilization of Kevlar in high-visibility applications faces several challenges and opportunities. These include improving the color retention of high-visibility dyes on Kevlar fibers, enhancing the material's breathability without compromising its protective qualities, and developing more sustainable manufacturing processes for Kevlar-based products.

The future trajectory of Kevlar in safety gear is likely to focus on customization and adaptability. As different industries and work environments present unique safety challenges, there is a growing need for tailored solutions that can leverage Kevlar's properties in combination with other advanced materials and technologies to meet specific safety requirements.

Market Analysis for High-Visibility Kevlar Products

The market for high-visibility Kevlar products has shown significant growth potential in recent years, driven by increasing safety regulations across various industries and a growing awareness of workplace safety. The global market for high-visibility safety apparel, including Kevlar-based products, is expected to expand at a steady rate due to stringent occupational safety standards and the rising demand for durable, high-performance safety gear.

Key industries driving the demand for high-visibility Kevlar products include construction, manufacturing, transportation, and emergency services. The construction sector, in particular, has emerged as a major consumer of these products, with workers requiring enhanced visibility and protection in hazardous environments. The transportation industry, including road workers and airport ground staff, also contributes significantly to market growth.

Geographically, North America and Europe lead the market for high-visibility Kevlar products, owing to strict safety regulations and high adoption rates of advanced safety gear. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand, fueled by expanding industrial sectors and increasing focus on worker safety.

The market is characterized by a mix of established players and innovative startups. Major manufacturers of high-visibility safety gear are increasingly incorporating Kevlar into their product lines to offer superior durability and cut resistance. This trend is particularly evident in the production of safety vests, gloves, and protective sleeves.

Consumer preferences in the high-visibility Kevlar product market are shifting towards lightweight, comfortable, and multi-functional gear. Products that combine high visibility with other protective features, such as flame resistance and impact protection, are gaining traction. This trend is driving innovation in product design and material combinations.

Price sensitivity varies across different market segments. While some industries prioritize cost-effectiveness, others are willing to invest in premium high-visibility Kevlar products for their superior performance and longevity. This dynamic creates opportunities for manufacturers to develop diverse product lines catering to different price points and performance requirements.

The market also faces challenges, including the higher cost of Kevlar compared to traditional materials used in high-visibility gear. However, the long-term cost benefits of Kevlar's durability and enhanced protection are gradually overcoming this barrier, especially in high-risk industries where safety is paramount.

Key industries driving the demand for high-visibility Kevlar products include construction, manufacturing, transportation, and emergency services. The construction sector, in particular, has emerged as a major consumer of these products, with workers requiring enhanced visibility and protection in hazardous environments. The transportation industry, including road workers and airport ground staff, also contributes significantly to market growth.

Geographically, North America and Europe lead the market for high-visibility Kevlar products, owing to strict safety regulations and high adoption rates of advanced safety gear. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand, fueled by expanding industrial sectors and increasing focus on worker safety.

The market is characterized by a mix of established players and innovative startups. Major manufacturers of high-visibility safety gear are increasingly incorporating Kevlar into their product lines to offer superior durability and cut resistance. This trend is particularly evident in the production of safety vests, gloves, and protective sleeves.

Consumer preferences in the high-visibility Kevlar product market are shifting towards lightweight, comfortable, and multi-functional gear. Products that combine high visibility with other protective features, such as flame resistance and impact protection, are gaining traction. This trend is driving innovation in product design and material combinations.

Price sensitivity varies across different market segments. While some industries prioritize cost-effectiveness, others are willing to invest in premium high-visibility Kevlar products for their superior performance and longevity. This dynamic creates opportunities for manufacturers to develop diverse product lines catering to different price points and performance requirements.

The market also faces challenges, including the higher cost of Kevlar compared to traditional materials used in high-visibility gear. However, the long-term cost benefits of Kevlar's durability and enhanced protection are gradually overcoming this barrier, especially in high-risk industries where safety is paramount.

Current Challenges in Kevlar-Based Safety Apparel

Despite the numerous advantages of Kevlar in high-visibility safety gear, several challenges persist in its widespread adoption and optimal utilization. One of the primary obstacles is the high cost associated with Kevlar production and integration into safety apparel. The complex manufacturing process and limited availability of raw materials contribute to elevated prices, making Kevlar-based safety gear less accessible for smaller organizations or individual users.

Another significant challenge lies in balancing the inherent strength of Kevlar with the need for flexibility and comfort in safety apparel. While Kevlar offers exceptional tensile strength and cut resistance, it can sometimes result in stiff or rigid garments that may restrict movement or cause discomfort during prolonged wear. This trade-off between protection and wearability remains a key area of concern for manufacturers and end-users alike.

The durability of Kevlar-based safety gear presents both advantages and challenges. While Kevlar is known for its longevity, prolonged exposure to UV radiation can degrade its properties over time. This necessitates the development of effective UV-resistant coatings or treatments to maintain the integrity of Kevlar fibers in outdoor applications, adding complexity to the manufacturing process and potentially increasing costs.

Integration of high-visibility elements with Kevlar-based materials poses another technical hurdle. Achieving the right balance between the protective properties of Kevlar and the reflective or fluorescent characteristics required for high-visibility gear demands innovative design solutions. Ensuring that visibility-enhancing features do not compromise the structural integrity or protective capabilities of Kevlar remains a constant challenge for product developers.

The weight of Kevlar-based safety apparel is another area of concern, particularly in applications requiring extended wear periods. While Kevlar offers a high strength-to-weight ratio compared to many materials, further weight reduction without sacrificing protection levels is an ongoing challenge. This is especially critical in industries where worker fatigue and mobility are significant factors.

Lastly, the environmental impact of Kevlar production and disposal presents growing challenges in an increasingly eco-conscious market. The non-biodegradable nature of Kevlar fibers raises concerns about end-of-life disposal and recycling options. Developing sustainable production methods and exploring biodegradable alternatives or effective recycling processes for Kevlar-based safety gear are becoming increasingly important considerations in the industry.

Another significant challenge lies in balancing the inherent strength of Kevlar with the need for flexibility and comfort in safety apparel. While Kevlar offers exceptional tensile strength and cut resistance, it can sometimes result in stiff or rigid garments that may restrict movement or cause discomfort during prolonged wear. This trade-off between protection and wearability remains a key area of concern for manufacturers and end-users alike.

The durability of Kevlar-based safety gear presents both advantages and challenges. While Kevlar is known for its longevity, prolonged exposure to UV radiation can degrade its properties over time. This necessitates the development of effective UV-resistant coatings or treatments to maintain the integrity of Kevlar fibers in outdoor applications, adding complexity to the manufacturing process and potentially increasing costs.

Integration of high-visibility elements with Kevlar-based materials poses another technical hurdle. Achieving the right balance between the protective properties of Kevlar and the reflective or fluorescent characteristics required for high-visibility gear demands innovative design solutions. Ensuring that visibility-enhancing features do not compromise the structural integrity or protective capabilities of Kevlar remains a constant challenge for product developers.

The weight of Kevlar-based safety apparel is another area of concern, particularly in applications requiring extended wear periods. While Kevlar offers a high strength-to-weight ratio compared to many materials, further weight reduction without sacrificing protection levels is an ongoing challenge. This is especially critical in industries where worker fatigue and mobility are significant factors.

Lastly, the environmental impact of Kevlar production and disposal presents growing challenges in an increasingly eco-conscious market. The non-biodegradable nature of Kevlar fibers raises concerns about end-of-life disposal and recycling options. Developing sustainable production methods and exploring biodegradable alternatives or effective recycling processes for Kevlar-based safety gear are becoming increasingly important considerations in the industry.

Existing Kevlar Integration Methods for Safety Gear

01 Enhancing visibility of Kevlar-based protective gear

Incorporating high-visibility elements into Kevlar-based protective gear to improve the visibility of wearers in low-light conditions. This can include reflective strips, fluorescent materials, or LED lights integrated into the fabric or outer layer of the protective equipment.- Enhancing visibility of Kevlar-based protective gear: Incorporating high-visibility materials or reflective elements into Kevlar-based protective gear to improve visibility in low-light conditions. This can include adding fluorescent colors, reflective strips, or luminescent materials to increase the wearer's visibility and safety.

- Optical properties of Kevlar fibers: Exploring and modifying the optical properties of Kevlar fibers to enhance their visibility. This may involve treatments or coatings that alter the light reflection or absorption characteristics of the fibers, making them more visible in various lighting conditions.

- Integration of Kevlar with smart materials for visibility: Combining Kevlar with smart materials or electronic components to create adaptive visibility solutions. This can include integrating LED lights, photochromic materials, or other responsive elements that change visibility based on environmental conditions.

- Kevlar-based camouflage and concealment: Developing Kevlar-based materials with adjustable visibility properties for camouflage and concealment applications. This involves creating fabrics that can adapt to different environments or switch between high-visibility and low-visibility modes as needed.

- Visibility enhancement in Kevlar composite materials: Improving the visibility of Kevlar composite materials by incorporating visible or fluorescent particles, or by modifying the surface structure to enhance light reflection or scattering. This can be applied to various Kevlar-based products to increase their visibility without compromising their protective properties.

02 Optical properties of Kevlar fibers

Exploring and modifying the optical properties of Kevlar fibers to enhance their visibility. This may involve treatments or additives that alter the light reflection or absorption characteristics of the fibers, making them more visible in various lighting conditions.Expand Specific Solutions03 Kevlar-based camouflage technology

Developing camouflage technologies using Kevlar that can adapt to different environments, potentially including active camouflage systems that can switch between high visibility and concealment modes as needed.Expand Specific Solutions04 Integration of smart materials with Kevlar

Combining Kevlar with smart materials or sensors to create adaptive visibility systems. These could include color-changing properties, temperature-responsive elements, or electronic components that enhance visibility in response to environmental conditions.Expand Specific Solutions05 Kevlar composite materials for improved visibility

Creating composite materials that combine Kevlar with other high-visibility substances or structures. This could involve layering techniques, embedding visible particles, or developing new fiber blends that maintain Kevlar's protective properties while enhancing visibility.Expand Specific Solutions

Key Manufacturers and Suppliers in Kevlar Industry

The market for Kevlar in high-visibility safety gear is in a growth phase, driven by increasing safety regulations and awareness across industries. The global market size for high-visibility clothing is projected to reach $2.3 billion by 2026, with Kevlar-enhanced products gaining traction. Technologically, the integration of Kevlar into safety gear is advancing, with companies like Morning Pride Manufacturing LLC and RMA Armament, Inc. leading innovations in protective clothing and body armor. Thales SA and ABB Group are contributing to the development of advanced materials and smart safety solutions. While the technology is mature for basic applications, ongoing research by institutions like MIT and Beijing Institute of Technology is pushing the boundaries for more sophisticated, multi-functional safety gear incorporating Kevlar.

Morning Pride Manufacturing LLC

Technical Solution: Morning Pride Manufacturing LLC utilizes Kevlar in their high-visibility safety gear by incorporating it into their firefighter turnout gear. They combine Kevlar with other advanced materials to create a multi-layered fabric system that provides both high visibility and superior protection. The company's approach involves weaving Kevlar fibers into the outer shell of the garment, which is then treated with fluorescent dyes and reflective materials. This integration allows for enhanced durability and cut resistance while maintaining the necessary visibility features[1]. The Kevlar-reinforced areas are strategically placed in high-wear zones, such as elbows, knees, and shoulders, to extend the life of the gear without compromising mobility[2].

Strengths: Excellent durability and cut resistance, enhanced visibility in low-light conditions, improved longevity of gear. Weaknesses: Potentially higher cost due to advanced materials, may require specialized care and maintenance.

RMA Armament, Inc.

Technical Solution: RMA Armament, Inc. incorporates Kevlar into high-visibility safety gear by focusing on ballistic protection combined with visibility features. Their approach involves creating multi-layer armor panels that use Kevlar as a key component. These panels are then integrated into high-visibility vests and other protective equipment. The company employs a proprietary manufacturing process that allows for the bonding of high-visibility materials to the Kevlar layers without compromising the protective properties[3]. This technique enables the creation of lightweight, flexible armor that meets both ballistic protection standards and high-visibility requirements for law enforcement and security personnel[4].

Strengths: Superior ballistic protection combined with high visibility, lightweight and flexible design. Weaknesses: May be more specialized and expensive than standard high-visibility gear, potentially limited to specific professional applications.

Innovative Kevlar Applications in High-Visibility Wear

Protective material

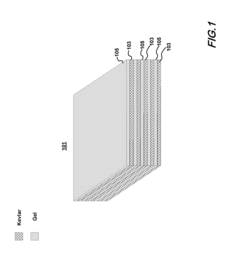

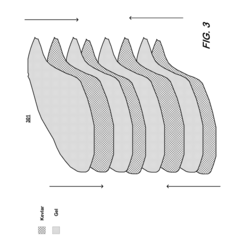

PatentInactiveUS20180292181A1

Innovation

- An enhanced ballistic material is created by interleaving layers of high tensile strength synthetic or polymeric fibers in a mesh weave with a gel matrix material, which remains soft and flexible, allowing for effective projectile stopping while maintaining comfort and flexibility, achieved through the use of heat and pressure to impregnate the gel matrix into the weave layers.

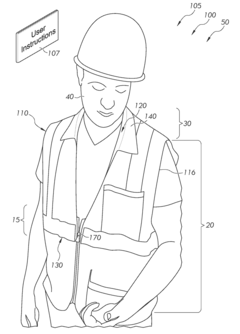

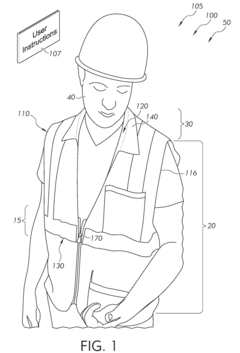

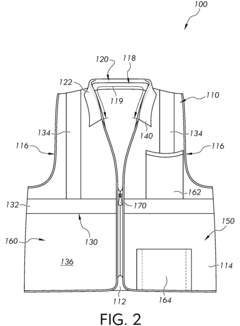

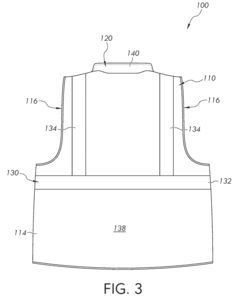

High-visibility vest and method

PatentInactiveUS20180020747A1

Innovation

- A high-visibility vest design featuring a sleeveless garment with reflective torso stripes and a collar stripe, providing enhanced visibility for the torso and neck areas, while maintaining a polished appearance.

Safety Standards and Regulations for Protective Clothing

The utilization of Kevlar in high-visibility safety gear must adhere to strict safety standards and regulations for protective clothing. These standards are designed to ensure the effectiveness and reliability of safety equipment in various hazardous environments.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for high-visibility safety apparel. OSHA references the American National Standards Institute (ANSI) standard ANSI/ISEA 107, which specifies performance requirements for high-visibility safety apparel. This standard categorizes garments into three classes based on the level of visibility required for different work environments.

The European Union employs the EN ISO 20471 standard for high-visibility clothing. This standard defines three classes of garments based on the minimum area of visible material required. It also specifies performance requirements for color, retroreflection, and durability.

For Kevlar-enhanced safety gear, additional standards come into play. The National Fire Protection Association (NFPA) standard 1971 governs protective ensembles for structural firefighting, which often incorporate Kevlar. This standard outlines requirements for thermal protection, flame resistance, and durability.

The International Organization for Standardization (ISO) has developed ISO 11612, which specifies performance requirements for protective clothing against heat and flame. This standard is particularly relevant for Kevlar-based safety gear used in industrial settings with fire hazards.

Compliance with these standards typically involves rigorous testing procedures. For high-visibility aspects, tests include color fastness, retroreflective performance, and photometric performance. For Kevlar components, tests may include tensile strength, tear resistance, and heat and flame resistance.

Manufacturers must also consider the specific regulations of different industries and regions. For instance, the mining industry may have additional requirements for high-visibility gear, as outlined in standards like MSHA (Mine Safety and Health Administration) in the United States.

As technology advances, standards are regularly updated to incorporate new materials and manufacturing techniques. This ongoing evolution ensures that safety gear, including those utilizing Kevlar, continues to provide optimal protection while meeting visibility requirements.

It's crucial for manufacturers and employers to stay informed about these standards and regulations. Compliance not only ensures legal adherence but also demonstrates a commitment to worker safety. Regular audits and certifications are often necessary to maintain compliance and validate the performance of high-visibility Kevlar-enhanced safety gear.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for high-visibility safety apparel. OSHA references the American National Standards Institute (ANSI) standard ANSI/ISEA 107, which specifies performance requirements for high-visibility safety apparel. This standard categorizes garments into three classes based on the level of visibility required for different work environments.

The European Union employs the EN ISO 20471 standard for high-visibility clothing. This standard defines three classes of garments based on the minimum area of visible material required. It also specifies performance requirements for color, retroreflection, and durability.

For Kevlar-enhanced safety gear, additional standards come into play. The National Fire Protection Association (NFPA) standard 1971 governs protective ensembles for structural firefighting, which often incorporate Kevlar. This standard outlines requirements for thermal protection, flame resistance, and durability.

The International Organization for Standardization (ISO) has developed ISO 11612, which specifies performance requirements for protective clothing against heat and flame. This standard is particularly relevant for Kevlar-based safety gear used in industrial settings with fire hazards.

Compliance with these standards typically involves rigorous testing procedures. For high-visibility aspects, tests include color fastness, retroreflective performance, and photometric performance. For Kevlar components, tests may include tensile strength, tear resistance, and heat and flame resistance.

Manufacturers must also consider the specific regulations of different industries and regions. For instance, the mining industry may have additional requirements for high-visibility gear, as outlined in standards like MSHA (Mine Safety and Health Administration) in the United States.

As technology advances, standards are regularly updated to incorporate new materials and manufacturing techniques. This ongoing evolution ensures that safety gear, including those utilizing Kevlar, continues to provide optimal protection while meeting visibility requirements.

It's crucial for manufacturers and employers to stay informed about these standards and regulations. Compliance not only ensures legal adherence but also demonstrates a commitment to worker safety. Regular audits and certifications are often necessary to maintain compliance and validate the performance of high-visibility Kevlar-enhanced safety gear.

Environmental Impact of Kevlar-Based Safety Products

The environmental impact of Kevlar-based safety products is a crucial consideration in the development and utilization of high-visibility safety gear. Kevlar, a synthetic fiber known for its exceptional strength-to-weight ratio, has become increasingly popular in safety applications. However, its production and disposal processes raise important environmental concerns.

The manufacturing of Kevlar involves energy-intensive processes and the use of harmful chemicals, contributing to greenhouse gas emissions and potential pollution. The production requires significant amounts of sulfuric acid and other toxic substances, which can have detrimental effects on local ecosystems if not properly managed. Additionally, the energy consumption during manufacturing contributes to the overall carbon footprint of Kevlar-based products.

Despite these challenges, Kevlar's durability and longevity offer some environmental benefits. The extended lifespan of Kevlar-based safety gear reduces the need for frequent replacements, potentially lowering the overall environmental impact compared to less durable alternatives. This longevity factor is particularly relevant in high-visibility safety applications, where gear is subjected to harsh conditions and frequent use.

End-of-life disposal of Kevlar products presents another environmental challenge. Kevlar is not biodegradable and can persist in the environment for extended periods. Traditional recycling methods are often ineffective due to the fiber's robust chemical structure. However, recent advancements in recycling technologies show promise in addressing this issue. Some innovative approaches involve chemical processes to break down Kevlar fibers, allowing for the recovery and reuse of raw materials.

The use of Kevlar in high-visibility safety gear also intersects with the broader issue of microfiber pollution. As Kevlar-based products wear over time, they may release microscopic fibers into the environment, potentially contributing to the growing problem of microplastic pollution in water bodies and soil.

To mitigate these environmental concerns, manufacturers are exploring more sustainable production methods and materials. This includes the development of bio-based alternatives that mimic Kevlar's properties while offering improved environmental profiles. Additionally, efforts are being made to optimize manufacturing processes to reduce energy consumption and minimize the use of harmful chemicals.

The environmental impact of Kevlar-based safety products extends beyond production and disposal. The enhanced safety provided by these products can indirectly contribute to environmental protection by reducing accidents and their associated environmental consequences. For instance, high-visibility safety gear made with Kevlar can improve worker safety in industries like construction and transportation, potentially preventing incidents that could lead to environmental damage.

The manufacturing of Kevlar involves energy-intensive processes and the use of harmful chemicals, contributing to greenhouse gas emissions and potential pollution. The production requires significant amounts of sulfuric acid and other toxic substances, which can have detrimental effects on local ecosystems if not properly managed. Additionally, the energy consumption during manufacturing contributes to the overall carbon footprint of Kevlar-based products.

Despite these challenges, Kevlar's durability and longevity offer some environmental benefits. The extended lifespan of Kevlar-based safety gear reduces the need for frequent replacements, potentially lowering the overall environmental impact compared to less durable alternatives. This longevity factor is particularly relevant in high-visibility safety applications, where gear is subjected to harsh conditions and frequent use.

End-of-life disposal of Kevlar products presents another environmental challenge. Kevlar is not biodegradable and can persist in the environment for extended periods. Traditional recycling methods are often ineffective due to the fiber's robust chemical structure. However, recent advancements in recycling technologies show promise in addressing this issue. Some innovative approaches involve chemical processes to break down Kevlar fibers, allowing for the recovery and reuse of raw materials.

The use of Kevlar in high-visibility safety gear also intersects with the broader issue of microfiber pollution. As Kevlar-based products wear over time, they may release microscopic fibers into the environment, potentially contributing to the growing problem of microplastic pollution in water bodies and soil.

To mitigate these environmental concerns, manufacturers are exploring more sustainable production methods and materials. This includes the development of bio-based alternatives that mimic Kevlar's properties while offering improved environmental profiles. Additionally, efforts are being made to optimize manufacturing processes to reduce energy consumption and minimize the use of harmful chemicals.

The environmental impact of Kevlar-based safety products extends beyond production and disposal. The enhanced safety provided by these products can indirectly contribute to environmental protection by reducing accidents and their associated environmental consequences. For instance, high-visibility safety gear made with Kevlar can improve worker safety in industries like construction and transportation, potentially preventing incidents that could lead to environmental damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!