Innovations in Regenerative Braking for Hyperloop Transport Systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hyperloop Braking Evolution

The evolution of braking systems for Hyperloop transport has been a critical aspect of its technological development. Initially, the concept relied on traditional friction-based braking methods, which were quickly deemed inadequate for the high-speed, low-pressure environment of Hyperloop tubes. This realization led to the exploration of more advanced braking technologies.

In the early stages of Hyperloop development, magnetic braking systems emerged as a promising alternative. These systems utilized the principle of electromagnetic induction to generate opposing forces, allowing for non-contact deceleration. This approach addressed the limitations of friction-based brakes, which were prone to wear and heat generation at high speeds.

As research progressed, engineers began to focus on regenerative braking techniques. This shift was driven by the need for energy efficiency in Hyperloop systems. Regenerative braking allowed for the conversion of kinetic energy into electrical energy during deceleration, which could then be stored or used to power other components of the transport system.

The integration of linear motors into Hyperloop designs marked another significant milestone in braking evolution. These motors, primarily used for propulsion, could also be reversed to provide braking force. This dual-purpose functionality improved system efficiency and reduced the complexity of separate braking mechanisms.

Recent advancements have seen the development of hybrid braking systems that combine multiple technologies. These systems typically incorporate regenerative braking for primary deceleration, supplemented by magnetic brakes for additional stopping power and emergency situations. This approach offers a balance of efficiency, reliability, and safety.

Current research is focused on enhancing the energy recovery capabilities of regenerative braking systems. Engineers are exploring advanced energy storage solutions, such as high-capacity batteries and supercapacitors, to maximize the utilization of recovered energy. Additionally, efforts are being made to optimize the control algorithms that manage the transition between different braking modes.

The evolution of Hyperloop braking systems has also been influenced by advancements in materials science. The development of lightweight, high-strength materials has enabled the creation of more efficient and compact braking components, contributing to the overall performance of Hyperloop vehicles.

Looking ahead, the future of Hyperloop braking is likely to involve further integration of smart technologies. This may include predictive braking systems that anticipate deceleration needs based on real-time data and AI-driven optimization of braking strategies to maximize energy efficiency and passenger comfort.

In the early stages of Hyperloop development, magnetic braking systems emerged as a promising alternative. These systems utilized the principle of electromagnetic induction to generate opposing forces, allowing for non-contact deceleration. This approach addressed the limitations of friction-based brakes, which were prone to wear and heat generation at high speeds.

As research progressed, engineers began to focus on regenerative braking techniques. This shift was driven by the need for energy efficiency in Hyperloop systems. Regenerative braking allowed for the conversion of kinetic energy into electrical energy during deceleration, which could then be stored or used to power other components of the transport system.

The integration of linear motors into Hyperloop designs marked another significant milestone in braking evolution. These motors, primarily used for propulsion, could also be reversed to provide braking force. This dual-purpose functionality improved system efficiency and reduced the complexity of separate braking mechanisms.

Recent advancements have seen the development of hybrid braking systems that combine multiple technologies. These systems typically incorporate regenerative braking for primary deceleration, supplemented by magnetic brakes for additional stopping power and emergency situations. This approach offers a balance of efficiency, reliability, and safety.

Current research is focused on enhancing the energy recovery capabilities of regenerative braking systems. Engineers are exploring advanced energy storage solutions, such as high-capacity batteries and supercapacitors, to maximize the utilization of recovered energy. Additionally, efforts are being made to optimize the control algorithms that manage the transition between different braking modes.

The evolution of Hyperloop braking systems has also been influenced by advancements in materials science. The development of lightweight, high-strength materials has enabled the creation of more efficient and compact braking components, contributing to the overall performance of Hyperloop vehicles.

Looking ahead, the future of Hyperloop braking is likely to involve further integration of smart technologies. This may include predictive braking systems that anticipate deceleration needs based on real-time data and AI-driven optimization of braking strategies to maximize energy efficiency and passenger comfort.

Market Demand Analysis

The market demand for regenerative braking systems in Hyperloop transport is driven by the increasing focus on energy efficiency and sustainability in the transportation sector. As Hyperloop technology progresses from concept to reality, the need for advanced braking systems that can recover and reuse energy becomes paramount. This demand is further amplified by the high-speed nature of Hyperloop travel, where traditional braking methods would result in significant energy loss.

The potential market for Hyperloop systems is substantial, with projections indicating a compound annual growth rate of over 40% in the coming years. This growth is expected to create a parallel demand for innovative braking technologies, including regenerative systems. The market for these systems is likely to expand as more Hyperloop projects move from testing to commercial implementation.

Regenerative braking in Hyperloop systems addresses several key market needs. Firstly, it significantly enhances energy efficiency, a critical factor in the economic viability of Hyperloop operations. By recapturing kinetic energy during deceleration, these systems can reduce overall energy consumption, potentially lowering operational costs and improving the competitiveness of Hyperloop against other transportation modes.

Secondly, there is a growing demand for sustainable transportation solutions. Regenerative braking aligns with this trend by minimizing energy waste and reducing the carbon footprint of Hyperloop systems. This aspect is particularly appealing to environmentally conscious consumers and aligns with governmental policies promoting green technologies.

The market for regenerative braking in Hyperloop also intersects with the broader trend of electrification in transportation. As more countries and regions set ambitious targets for reducing emissions from the transport sector, technologies that maximize the efficiency of electric propulsion systems, such as regenerative braking, are likely to see increased demand.

Furthermore, the high-speed nature of Hyperloop travel creates unique safety requirements, driving demand for advanced braking systems. Regenerative braking can complement traditional safety systems, providing an additional layer of control and energy management during rapid deceleration events.

The potential applications of regenerative braking technology developed for Hyperloop could extend beyond this specific transport mode. Innovations in this field could find applications in other high-speed rail systems or even in the automotive sector, expanding the potential market size and driving further research and development investments.

In conclusion, the market demand for regenerative braking innovations in Hyperloop systems is robust and multifaceted, driven by needs for energy efficiency, sustainability, safety, and the potential for technology transfer to other sectors. As Hyperloop technology matures and more projects move towards implementation, this demand is expected to grow, creating significant opportunities for technological innovation and market expansion in the field of regenerative braking systems.

The potential market for Hyperloop systems is substantial, with projections indicating a compound annual growth rate of over 40% in the coming years. This growth is expected to create a parallel demand for innovative braking technologies, including regenerative systems. The market for these systems is likely to expand as more Hyperloop projects move from testing to commercial implementation.

Regenerative braking in Hyperloop systems addresses several key market needs. Firstly, it significantly enhances energy efficiency, a critical factor in the economic viability of Hyperloop operations. By recapturing kinetic energy during deceleration, these systems can reduce overall energy consumption, potentially lowering operational costs and improving the competitiveness of Hyperloop against other transportation modes.

Secondly, there is a growing demand for sustainable transportation solutions. Regenerative braking aligns with this trend by minimizing energy waste and reducing the carbon footprint of Hyperloop systems. This aspect is particularly appealing to environmentally conscious consumers and aligns with governmental policies promoting green technologies.

The market for regenerative braking in Hyperloop also intersects with the broader trend of electrification in transportation. As more countries and regions set ambitious targets for reducing emissions from the transport sector, technologies that maximize the efficiency of electric propulsion systems, such as regenerative braking, are likely to see increased demand.

Furthermore, the high-speed nature of Hyperloop travel creates unique safety requirements, driving demand for advanced braking systems. Regenerative braking can complement traditional safety systems, providing an additional layer of control and energy management during rapid deceleration events.

The potential applications of regenerative braking technology developed for Hyperloop could extend beyond this specific transport mode. Innovations in this field could find applications in other high-speed rail systems or even in the automotive sector, expanding the potential market size and driving further research and development investments.

In conclusion, the market demand for regenerative braking innovations in Hyperloop systems is robust and multifaceted, driven by needs for energy efficiency, sustainability, safety, and the potential for technology transfer to other sectors. As Hyperloop technology matures and more projects move towards implementation, this demand is expected to grow, creating significant opportunities for technological innovation and market expansion in the field of regenerative braking systems.

Technical Challenges

The development of regenerative braking systems for Hyperloop transport faces several significant technical challenges. One of the primary obstacles is the high-speed nature of Hyperloop travel, which requires braking systems capable of efficiently dissipating enormous amounts of kinetic energy. Traditional regenerative braking methods used in conventional electric vehicles may not be directly applicable due to the extreme velocities involved.

Another challenge lies in the unique environment of the Hyperloop tube. The near-vacuum conditions inside the tube limit the effectiveness of aerodynamic braking, placing greater emphasis on mechanical and electromagnetic braking systems. This necessitates the development of novel braking technologies that can operate efficiently in low-pressure environments while minimizing heat generation and energy loss.

The integration of regenerative braking with the Hyperloop's propulsion system presents additional complexities. The system must be capable of rapidly switching between acceleration and deceleration modes, requiring sophisticated control algorithms and power management systems. Furthermore, the high-speed linear motors used in Hyperloop propulsion may need to be adapted or redesigned to effectively function as generators during the braking process.

Energy storage and management pose another significant challenge. The large amounts of energy recovered during braking must be efficiently stored and redistributed within the system. This requires the development of high-capacity, fast-charging energy storage solutions that can handle frequent charge-discharge cycles without degradation. Supercapacitors and advanced battery technologies are being explored, but each comes with its own set of technical hurdles.

The material science aspect of regenerative braking for Hyperloop systems is equally challenging. Brake components must withstand extreme temperatures and stresses while maintaining their efficiency and longevity. This necessitates the development of advanced materials with superior thermal and mechanical properties, as well as innovative cooling systems to manage heat dissipation.

Safety considerations add another layer of complexity to the technical challenges. The braking system must be fail-safe and capable of bringing the Hyperloop vehicle to a complete stop even in the event of power failures or other emergencies. This requires redundant systems and fail-safe mechanisms that can operate independently of the primary regenerative braking system.

Lastly, the optimization of energy recovery efficiency presents an ongoing challenge. While regenerative braking offers the potential for significant energy savings, maximizing the percentage of kinetic energy that can be recaptured and reused remains a key area of research and development. This involves minimizing energy losses throughout the braking and energy conversion process, requiring advancements in power electronics, magnetic materials, and system-level optimization techniques.

Another challenge lies in the unique environment of the Hyperloop tube. The near-vacuum conditions inside the tube limit the effectiveness of aerodynamic braking, placing greater emphasis on mechanical and electromagnetic braking systems. This necessitates the development of novel braking technologies that can operate efficiently in low-pressure environments while minimizing heat generation and energy loss.

The integration of regenerative braking with the Hyperloop's propulsion system presents additional complexities. The system must be capable of rapidly switching between acceleration and deceleration modes, requiring sophisticated control algorithms and power management systems. Furthermore, the high-speed linear motors used in Hyperloop propulsion may need to be adapted or redesigned to effectively function as generators during the braking process.

Energy storage and management pose another significant challenge. The large amounts of energy recovered during braking must be efficiently stored and redistributed within the system. This requires the development of high-capacity, fast-charging energy storage solutions that can handle frequent charge-discharge cycles without degradation. Supercapacitors and advanced battery technologies are being explored, but each comes with its own set of technical hurdles.

The material science aspect of regenerative braking for Hyperloop systems is equally challenging. Brake components must withstand extreme temperatures and stresses while maintaining their efficiency and longevity. This necessitates the development of advanced materials with superior thermal and mechanical properties, as well as innovative cooling systems to manage heat dissipation.

Safety considerations add another layer of complexity to the technical challenges. The braking system must be fail-safe and capable of bringing the Hyperloop vehicle to a complete stop even in the event of power failures or other emergencies. This requires redundant systems and fail-safe mechanisms that can operate independently of the primary regenerative braking system.

Lastly, the optimization of energy recovery efficiency presents an ongoing challenge. While regenerative braking offers the potential for significant energy savings, maximizing the percentage of kinetic energy that can be recaptured and reused remains a key area of research and development. This involves minimizing energy losses throughout the braking and energy conversion process, requiring advancements in power electronics, magnetic materials, and system-level optimization techniques.

Current Braking Solutions

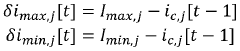

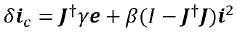

01 Optimization of regenerative braking control systems

Advanced control systems are developed to optimize regenerative braking efficiency. These systems use various parameters such as vehicle speed, battery state of charge, and road conditions to adjust the regenerative braking force dynamically. This approach maximizes energy recovery while maintaining vehicle stability and driver comfort.- Optimization of regenerative braking control systems: Advanced control systems are developed to optimize regenerative braking efficiency. These systems utilize various sensors and algorithms to determine the optimal braking force distribution between regenerative and friction braking, maximizing energy recovery while maintaining vehicle stability and safety.

- Integration of regenerative braking with hybrid and electric powertrains: Regenerative braking systems are integrated with hybrid and electric vehicle powertrains to improve overall energy efficiency. This integration involves coordinating the regenerative braking system with the electric motor, battery management system, and power electronics to maximize energy recovery and extend driving range.

- Enhancement of regenerative braking through energy storage technologies: Advanced energy storage technologies, such as high-capacity batteries and supercapacitors, are utilized to improve the efficiency of regenerative braking systems. These technologies allow for faster energy absorption and storage during braking events, increasing the overall energy recovery potential.

- Improvement of regenerative braking efficiency in heavy-duty vehicles: Specialized regenerative braking systems are developed for heavy-duty vehicles, such as trucks and buses, to improve braking efficiency and energy recovery. These systems often incorporate advanced power electronics and motor designs to handle the higher energy demands of larger vehicles.

- Integration of regenerative braking with intelligent transportation systems: Regenerative braking systems are integrated with intelligent transportation systems and connected vehicle technologies to optimize braking efficiency. This integration allows for predictive braking based on traffic conditions, road topography, and vehicle-to-vehicle communication, further improving energy recovery and overall system efficiency.

02 Integration of regenerative and friction braking

Efficient braking systems combine regenerative and friction braking to maximize energy recovery and ensure optimal braking performance. These systems distribute braking force between regenerative and friction brakes based on various factors, including deceleration rate, vehicle speed, and energy recovery potential.Expand Specific Solutions03 Energy storage system improvements

Advancements in energy storage technologies, such as high-capacity batteries and supercapacitors, enhance the efficiency of regenerative braking systems. These improvements allow for faster energy absorption and storage during braking, increasing the overall energy recovery potential.Expand Specific Solutions04 Adaptive regenerative braking strategies

Intelligent algorithms are developed to adapt regenerative braking strategies based on driving conditions, driver behavior, and vehicle characteristics. These adaptive systems learn from historical data and real-time inputs to optimize braking efficiency and energy recovery in various scenarios.Expand Specific Solutions05 Enhanced motor and generator designs

Improved electric motor and generator designs contribute to increased regenerative braking efficiency. These advancements include optimized magnetic circuits, reduced losses, and enhanced thermal management, allowing for higher power handling capabilities during regenerative braking events.Expand Specific Solutions

Key Industry Players

The competitive landscape for innovations in regenerative braking for Hyperloop transport systems is in an early development stage, with significant potential for growth. The market size is currently limited but expected to expand rapidly as Hyperloop technology advances. Technical maturity varies among key players, with established automotive companies like Ford, Hyundai, and Bosch leveraging their expertise in regenerative braking systems. Academic institutions such as Southwest Jiaotong University and Beijing Jiaotong University are contributing research, while specialized firms like CRRC Qingdao Sifang are developing tailored solutions for high-speed rail applications. The involvement of diverse players indicates a competitive and innovative environment, with opportunities for breakthrough technologies in this emerging field.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has developed an innovative regenerative braking system for Hyperloop transport that focuses on maximizing energy recovery while ensuring passenger comfort and safety. Their system employs a hybrid approach, combining electromagnetic eddy current braking with a high-efficiency flywheel energy storage system[8]. The electromagnetic brakes provide primary deceleration force, while the flywheel system rapidly absorbs and stores kinetic energy for later use[10]. Ford's technology incorporates advanced control algorithms that optimize braking force distribution between the electromagnetic and flywheel systems based on real-time pod speed, energy storage capacity, and track conditions[12]. The system also features an adaptive suspension interface that minimizes vibration and ensures smooth deceleration, even at extremely high speeds[14].

Strengths: High energy recovery efficiency, rapid energy storage capability, and enhanced passenger comfort. Weaknesses: Complexity of the hybrid system and potential challenges in maintaining flywheel stability in the Hyperloop's low-pressure environment.

CRRC Qingdao Sifang Rolling Stock Research Institute Co., Ltd.

Technical Solution: CRRC Qingdao Sifang Rolling Stock Research Institute has developed a regenerative braking system for Hyperloop transport that builds upon their expertise in high-speed rail technology. Their solution integrates a linear eddy current brake system with a novel superconducting magnetic energy storage (SMES) device[15]. The linear eddy current brake provides non-contact braking force, eliminating wear and maintenance issues associated with traditional friction brakes[17]. The SMES system allows for ultra-fast energy absorption and storage, capable of handling the high power demands of Hyperloop deceleration[19]. CRRC's technology also incorporates a sophisticated power management system that optimizes energy flow between the braking system, SMES, and Hyperloop pod propulsion systems, ensuring maximum energy efficiency throughout the journey[21].

Strengths: Non-contact braking for reduced maintenance, ultra-fast energy storage capability, and seamless integration with Hyperloop propulsion systems. Weaknesses: High cost of superconducting technology and potential challenges in scaling up for extensive Hyperloop networks.

Core Innovations

System and method for a hyperloop motion execution controller

PatentWO2023059468A1

Innovation

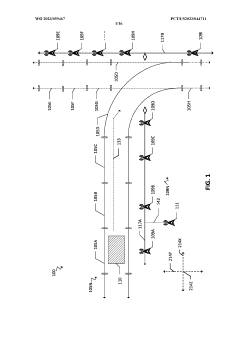

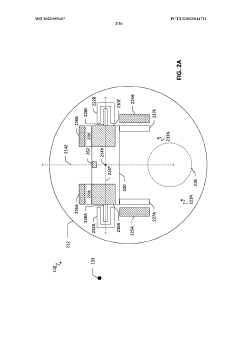

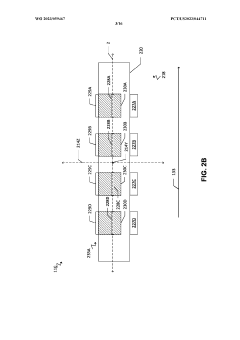

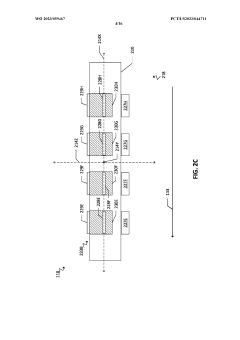

- A system and method utilizing state estimation to command a plurality of electromagnetic assemblies, determining constraints and generating command values to maintain safe and efficient flight by continuously updating commands based on sensor data from inertial measurement units and other sensors, ensuring proper levitation, guidance, and propulsion.

System and method for hyperloop motion control and state estimation

PatentWO2023059467A1

Innovation

- A system and method for hyperloop motion control and state estimation using a processor that receives sensor data to generate state estimations and linearized commands for electromagnetic assemblies, ensuring accurate positioning and orientation, and detecting faults to update commands and maintain safe operation.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of regenerative braking systems for Hyperloop transport. As this innovative technology continues to evolve, it is essential to establish comprehensive safety standards to ensure the protection of passengers, personnel, and infrastructure.

The primary focus of safety regulations for regenerative braking in Hyperloop systems is to address the unique challenges posed by high-speed travel in low-pressure environments. These regulations must cover various aspects, including system design, component reliability, fail-safe mechanisms, and emergency procedures.

One key area of concern is the management of thermal energy generated during the braking process. Safety regulations should mandate the implementation of robust heat dissipation systems to prevent overheating and potential component failure. Additionally, guidelines for the safe storage and distribution of recovered energy must be established to mitigate risks associated with electrical systems operating at high voltages.

Electromagnetic compatibility (EMC) is another critical aspect that safety regulations must address. The regenerative braking system should not interfere with other electronic systems within the Hyperloop infrastructure or nearby facilities. Strict EMC standards and testing protocols should be developed to ensure the safe coexistence of various electronic components.

Safety regulations should also focus on redundancy and fail-safe mechanisms. In the event of a regenerative braking system failure, secondary braking systems must be in place to ensure the safe deceleration of the vehicle. These backup systems should be designed to operate independently and provide sufficient braking force under all operating conditions.

Maintenance and inspection protocols form an integral part of safety regulations for regenerative braking systems. Regular checks and preventive maintenance procedures should be mandated to ensure the continued safe operation of the system. This includes guidelines for component replacement, software updates, and system calibration.

Furthermore, safety regulations must address the human factor in operating and maintaining regenerative braking systems. Comprehensive training programs for operators and maintenance personnel should be required, covering both normal operations and emergency scenarios. Clear communication protocols and decision-making procedures should be established to handle potential system anomalies or failures.

As the Hyperloop technology is still in its early stages, safety regulations for regenerative braking systems should be designed with flexibility in mind. Regular reviews and updates to these regulations will be necessary to accommodate technological advancements and lessons learned from real-world implementations. Collaboration between regulatory bodies, industry experts, and research institutions will be crucial in developing and refining these safety standards.

The primary focus of safety regulations for regenerative braking in Hyperloop systems is to address the unique challenges posed by high-speed travel in low-pressure environments. These regulations must cover various aspects, including system design, component reliability, fail-safe mechanisms, and emergency procedures.

One key area of concern is the management of thermal energy generated during the braking process. Safety regulations should mandate the implementation of robust heat dissipation systems to prevent overheating and potential component failure. Additionally, guidelines for the safe storage and distribution of recovered energy must be established to mitigate risks associated with electrical systems operating at high voltages.

Electromagnetic compatibility (EMC) is another critical aspect that safety regulations must address. The regenerative braking system should not interfere with other electronic systems within the Hyperloop infrastructure or nearby facilities. Strict EMC standards and testing protocols should be developed to ensure the safe coexistence of various electronic components.

Safety regulations should also focus on redundancy and fail-safe mechanisms. In the event of a regenerative braking system failure, secondary braking systems must be in place to ensure the safe deceleration of the vehicle. These backup systems should be designed to operate independently and provide sufficient braking force under all operating conditions.

Maintenance and inspection protocols form an integral part of safety regulations for regenerative braking systems. Regular checks and preventive maintenance procedures should be mandated to ensure the continued safe operation of the system. This includes guidelines for component replacement, software updates, and system calibration.

Furthermore, safety regulations must address the human factor in operating and maintaining regenerative braking systems. Comprehensive training programs for operators and maintenance personnel should be required, covering both normal operations and emergency scenarios. Clear communication protocols and decision-making procedures should be established to handle potential system anomalies or failures.

As the Hyperloop technology is still in its early stages, safety regulations for regenerative braking systems should be designed with flexibility in mind. Regular reviews and updates to these regulations will be necessary to accommodate technological advancements and lessons learned from real-world implementations. Collaboration between regulatory bodies, industry experts, and research institutions will be crucial in developing and refining these safety standards.

Energy Efficiency Impact

The implementation of regenerative braking systems in Hyperloop transport systems has the potential to significantly enhance energy efficiency, making these high-speed transportation solutions more sustainable and cost-effective. By capturing and reusing kinetic energy that would otherwise be lost as heat during deceleration, regenerative braking can substantially reduce the overall energy consumption of Hyperloop systems.

In traditional transportation systems, energy efficiency improvements through regenerative braking have shown promising results. For instance, in electric vehicles, regenerative braking can recover up to 70% of the kinetic energy during deceleration, leading to an increase in overall energy efficiency by 10-25%. When applied to Hyperloop systems, which operate at much higher speeds and with lower friction, the potential for energy recovery and efficiency gains is even greater.

The energy efficiency impact of regenerative braking in Hyperloop systems can be observed in several key areas. Firstly, it reduces the energy required for acceleration by storing and reusing the energy from previous braking events. This is particularly beneficial in Hyperloop systems with frequent stops or speed adjustments, as it minimizes the energy needed to regain high speeds after deceleration.

Secondly, regenerative braking can help optimize the power management of Hyperloop systems. By capturing and storing energy during braking, the system can reduce its reliance on external power sources, potentially lowering operational costs and improving grid stability. This is especially important for Hyperloop routes that traverse areas with limited access to power infrastructure.

Furthermore, the implementation of advanced regenerative braking technologies can contribute to the overall sustainability of Hyperloop systems. By reducing energy waste and improving efficiency, these systems can lower their carbon footprint and align with global efforts to combat climate change. This aspect is crucial for positioning Hyperloop as a green transportation alternative for long-distance travel.

The energy efficiency gains from regenerative braking also have cascading effects on other aspects of Hyperloop system design. For example, improved energy recovery can lead to reduced heat generation during braking, potentially simplifying thermal management systems and further enhancing overall efficiency. Additionally, the ability to recapture energy may allow for the downsizing of onboard energy storage systems, reducing the weight of Hyperloop pods and further improving their energy efficiency.

In traditional transportation systems, energy efficiency improvements through regenerative braking have shown promising results. For instance, in electric vehicles, regenerative braking can recover up to 70% of the kinetic energy during deceleration, leading to an increase in overall energy efficiency by 10-25%. When applied to Hyperloop systems, which operate at much higher speeds and with lower friction, the potential for energy recovery and efficiency gains is even greater.

The energy efficiency impact of regenerative braking in Hyperloop systems can be observed in several key areas. Firstly, it reduces the energy required for acceleration by storing and reusing the energy from previous braking events. This is particularly beneficial in Hyperloop systems with frequent stops or speed adjustments, as it minimizes the energy needed to regain high speeds after deceleration.

Secondly, regenerative braking can help optimize the power management of Hyperloop systems. By capturing and storing energy during braking, the system can reduce its reliance on external power sources, potentially lowering operational costs and improving grid stability. This is especially important for Hyperloop routes that traverse areas with limited access to power infrastructure.

Furthermore, the implementation of advanced regenerative braking technologies can contribute to the overall sustainability of Hyperloop systems. By reducing energy waste and improving efficiency, these systems can lower their carbon footprint and align with global efforts to combat climate change. This aspect is crucial for positioning Hyperloop as a green transportation alternative for long-distance travel.

The energy efficiency gains from regenerative braking also have cascading effects on other aspects of Hyperloop system design. For example, improved energy recovery can lead to reduced heat generation during braking, potentially simplifying thermal management systems and further enhancing overall efficiency. Additionally, the ability to recapture energy may allow for the downsizing of onboard energy storage systems, reducing the weight of Hyperloop pods and further improving their energy efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!