Investigating Regenerative Braking in Electric Vehicle Design Innovations

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Braking Evolution

The evolution of braking systems in electric vehicles (EVs) represents a significant technological advancement in automotive engineering. Traditional friction-based braking systems have been the standard for decades, but the unique characteristics of electric powertrains have paved the way for innovative braking solutions, particularly regenerative braking.

In the early days of EVs, regenerative braking was a novel concept, primarily used to extend the vehicle's range by recapturing energy during deceleration. The first-generation systems were relatively simple, offering limited energy recovery and often working in conjunction with conventional friction brakes. As EV technology progressed, so did the sophistication of regenerative braking systems.

The mid-2000s saw a significant leap in regenerative braking technology with the introduction of more advanced electric motors and power electronics. This allowed for higher efficiency in energy recovery and smoother integration with the vehicle's overall braking system. Manufacturers began to implement blended braking systems, which intelligently combined regenerative and friction braking to optimize energy recovery and maintain consistent pedal feel.

As battery technology improved, allowing for higher power densities and faster charging rates, regenerative braking systems became more capable of handling higher energy loads. This led to the development of one-pedal driving systems in some EVs, where the regenerative braking effect is strong enough to bring the vehicle to a complete stop without using the friction brakes in most driving scenarios.

Recent years have seen further refinements in regenerative braking technology. Advanced control algorithms now allow for more precise modulation of braking force, adapting to various driving conditions and driver preferences. Some systems now incorporate predictive technologies, using data from navigation systems and sensors to optimize energy recovery based on upcoming road conditions and traffic patterns.

The integration of regenerative braking with other vehicle systems has also evolved. Modern EVs often feature adaptive regenerative braking that works in harmony with advanced driver assistance systems (ADAS) and autonomous driving features. This integration enhances both safety and efficiency, allowing for smoother operation in various driving scenarios.

Looking forward, the evolution of EV braking systems is likely to continue with the development of even more efficient energy recovery methods, further integration with AI-driven vehicle control systems, and possibly the incorporation of new materials and technologies to enhance braking performance and energy recapture. As EVs become more prevalent, these advancements in braking technology will play a crucial role in improving overall vehicle efficiency, range, and driving experience.

In the early days of EVs, regenerative braking was a novel concept, primarily used to extend the vehicle's range by recapturing energy during deceleration. The first-generation systems were relatively simple, offering limited energy recovery and often working in conjunction with conventional friction brakes. As EV technology progressed, so did the sophistication of regenerative braking systems.

The mid-2000s saw a significant leap in regenerative braking technology with the introduction of more advanced electric motors and power electronics. This allowed for higher efficiency in energy recovery and smoother integration with the vehicle's overall braking system. Manufacturers began to implement blended braking systems, which intelligently combined regenerative and friction braking to optimize energy recovery and maintain consistent pedal feel.

As battery technology improved, allowing for higher power densities and faster charging rates, regenerative braking systems became more capable of handling higher energy loads. This led to the development of one-pedal driving systems in some EVs, where the regenerative braking effect is strong enough to bring the vehicle to a complete stop without using the friction brakes in most driving scenarios.

Recent years have seen further refinements in regenerative braking technology. Advanced control algorithms now allow for more precise modulation of braking force, adapting to various driving conditions and driver preferences. Some systems now incorporate predictive technologies, using data from navigation systems and sensors to optimize energy recovery based on upcoming road conditions and traffic patterns.

The integration of regenerative braking with other vehicle systems has also evolved. Modern EVs often feature adaptive regenerative braking that works in harmony with advanced driver assistance systems (ADAS) and autonomous driving features. This integration enhances both safety and efficiency, allowing for smoother operation in various driving scenarios.

Looking forward, the evolution of EV braking systems is likely to continue with the development of even more efficient energy recovery methods, further integration with AI-driven vehicle control systems, and possibly the incorporation of new materials and technologies to enhance braking performance and energy recapture. As EVs become more prevalent, these advancements in braking technology will play a crucial role in improving overall vehicle efficiency, range, and driving experience.

Market Demand Analysis

The market demand for regenerative braking systems in electric vehicles (EVs) has been experiencing significant growth, driven by the increasing adoption of EVs worldwide. As governments and consumers alike prioritize sustainability and energy efficiency, regenerative braking technology has become a crucial component in EV design innovations.

The global EV market has been expanding rapidly, with sales projected to reach 10.5 million units in 2022, a 61% increase from 2021. This growth trend is expected to continue, with some analysts predicting that EVs could account for up to 60% of new car sales by 2030. As the EV market expands, so does the demand for advanced regenerative braking systems.

Regenerative braking technology offers several benefits that align with consumer preferences and regulatory requirements. Firstly, it significantly improves the overall energy efficiency of EVs by recovering kinetic energy during deceleration and converting it into electrical energy to recharge the battery. This process can extend the driving range of EVs by up to 25%, addressing one of the primary concerns of potential EV buyers – range anxiety.

Moreover, regenerative braking systems contribute to reduced wear on traditional friction brakes, leading to lower maintenance costs and extended brake life. This aspect is particularly appealing to fleet operators and individual consumers looking to minimize long-term ownership expenses.

The market demand for regenerative braking is further bolstered by stringent emissions regulations and fuel efficiency standards imposed by governments worldwide. For instance, the European Union's CO2 emission targets for new cars have been driving automakers to invest heavily in EV technologies, including advanced regenerative braking systems.

In terms of regional demand, China remains the largest market for EVs and, consequently, for regenerative braking technologies. However, Europe and North America are rapidly catching up, with both regions experiencing substantial growth in EV adoption and related technologies.

The increasing focus on autonomous vehicles and advanced driver assistance systems (ADAS) is also contributing to the demand for more sophisticated regenerative braking systems. These systems need to integrate seamlessly with other vehicle technologies to optimize energy recovery and enhance overall vehicle performance.

As the EV market matures, consumers are becoming more discerning, expecting higher performance and efficiency from their vehicles. This trend is pushing manufacturers to innovate and improve regenerative braking technologies, leading to a growing market for more advanced and efficient systems.

The global EV market has been expanding rapidly, with sales projected to reach 10.5 million units in 2022, a 61% increase from 2021. This growth trend is expected to continue, with some analysts predicting that EVs could account for up to 60% of new car sales by 2030. As the EV market expands, so does the demand for advanced regenerative braking systems.

Regenerative braking technology offers several benefits that align with consumer preferences and regulatory requirements. Firstly, it significantly improves the overall energy efficiency of EVs by recovering kinetic energy during deceleration and converting it into electrical energy to recharge the battery. This process can extend the driving range of EVs by up to 25%, addressing one of the primary concerns of potential EV buyers – range anxiety.

Moreover, regenerative braking systems contribute to reduced wear on traditional friction brakes, leading to lower maintenance costs and extended brake life. This aspect is particularly appealing to fleet operators and individual consumers looking to minimize long-term ownership expenses.

The market demand for regenerative braking is further bolstered by stringent emissions regulations and fuel efficiency standards imposed by governments worldwide. For instance, the European Union's CO2 emission targets for new cars have been driving automakers to invest heavily in EV technologies, including advanced regenerative braking systems.

In terms of regional demand, China remains the largest market for EVs and, consequently, for regenerative braking technologies. However, Europe and North America are rapidly catching up, with both regions experiencing substantial growth in EV adoption and related technologies.

The increasing focus on autonomous vehicles and advanced driver assistance systems (ADAS) is also contributing to the demand for more sophisticated regenerative braking systems. These systems need to integrate seamlessly with other vehicle technologies to optimize energy recovery and enhance overall vehicle performance.

As the EV market matures, consumers are becoming more discerning, expecting higher performance and efficiency from their vehicles. This trend is pushing manufacturers to innovate and improve regenerative braking technologies, leading to a growing market for more advanced and efficient systems.

Tech Challenges

Regenerative braking in electric vehicles (EVs) represents a significant advancement in energy efficiency, yet it faces several technical challenges that require innovative solutions. One of the primary obstacles is the optimization of energy recovery across various driving conditions. The effectiveness of regenerative braking varies greatly depending on factors such as vehicle speed, road gradient, and driver behavior, making it difficult to achieve consistent and optimal energy recapture.

Another significant challenge lies in the integration of regenerative braking with traditional friction braking systems. Achieving a seamless transition between these two braking methods is crucial for both safety and driver comfort. Engineers must develop sophisticated control algorithms that can dynamically adjust the balance between regenerative and friction braking based on real-time driving conditions and vehicle parameters.

The thermal management of the battery and electric motor during regenerative braking poses another technical hurdle. The rapid conversion of kinetic energy to electrical energy can generate substantial heat, potentially impacting the longevity and performance of these components. Developing efficient cooling systems and heat dissipation mechanisms is essential to maintain optimal system performance and prevent premature degradation of critical EV components.

Furthermore, the design of regenerative braking systems must account for the varying power capabilities of different battery technologies. High-power batteries can accept higher regenerative braking currents, allowing for more efficient energy recovery. However, this must be balanced against factors such as battery cost, weight, and overall vehicle range. Engineers face the challenge of optimizing regenerative braking performance within these constraints.

The impact of regenerative braking on vehicle dynamics and stability control systems presents another area of technical complexity. The variable braking force applied during regenerative braking can affect the vehicle's weight distribution and handling characteristics, particularly in low-traction conditions. Developing advanced traction control and stability management systems that can adapt to these dynamic changes is crucial for maintaining vehicle safety and performance.

Lastly, the user experience and driver acceptance of regenerative braking systems remain ongoing challenges. The unique feel of regenerative braking, often described as a strong engine braking effect, can be unfamiliar to drivers accustomed to conventional vehicles. Creating intuitive and customizable regenerative braking profiles that cater to different driving preferences while maximizing energy recovery efficiency is a complex task that requires continuous refinement and user feedback integration.

Another significant challenge lies in the integration of regenerative braking with traditional friction braking systems. Achieving a seamless transition between these two braking methods is crucial for both safety and driver comfort. Engineers must develop sophisticated control algorithms that can dynamically adjust the balance between regenerative and friction braking based on real-time driving conditions and vehicle parameters.

The thermal management of the battery and electric motor during regenerative braking poses another technical hurdle. The rapid conversion of kinetic energy to electrical energy can generate substantial heat, potentially impacting the longevity and performance of these components. Developing efficient cooling systems and heat dissipation mechanisms is essential to maintain optimal system performance and prevent premature degradation of critical EV components.

Furthermore, the design of regenerative braking systems must account for the varying power capabilities of different battery technologies. High-power batteries can accept higher regenerative braking currents, allowing for more efficient energy recovery. However, this must be balanced against factors such as battery cost, weight, and overall vehicle range. Engineers face the challenge of optimizing regenerative braking performance within these constraints.

The impact of regenerative braking on vehicle dynamics and stability control systems presents another area of technical complexity. The variable braking force applied during regenerative braking can affect the vehicle's weight distribution and handling characteristics, particularly in low-traction conditions. Developing advanced traction control and stability management systems that can adapt to these dynamic changes is crucial for maintaining vehicle safety and performance.

Lastly, the user experience and driver acceptance of regenerative braking systems remain ongoing challenges. The unique feel of regenerative braking, often described as a strong engine braking effect, can be unfamiliar to drivers accustomed to conventional vehicles. Creating intuitive and customizable regenerative braking profiles that cater to different driving preferences while maximizing energy recovery efficiency is a complex task that requires continuous refinement and user feedback integration.

Current Regen Systems

01 Energy recovery and storage systems

Regenerative braking systems incorporate energy recovery and storage mechanisms to improve overall energy efficiency. These systems capture kinetic energy during braking and convert it into electrical energy, which is then stored in batteries or other storage devices for later use. This process significantly reduces energy waste and improves the overall efficiency of the vehicle.- Energy recovery systems in regenerative braking: Regenerative braking systems are designed to recover and store energy during deceleration. These systems convert kinetic energy into electrical energy, which can be stored in batteries or capacitors for later use. This process significantly improves the overall energy efficiency of vehicles, particularly in electric and hybrid vehicles.

- Control strategies for optimizing regenerative braking: Advanced control algorithms and strategies are employed to maximize the efficiency of regenerative braking. These systems dynamically adjust the balance between regenerative and friction braking based on various factors such as vehicle speed, battery state of charge, and road conditions. This optimization ensures maximum energy recovery while maintaining vehicle stability and driver comfort.

- Integration with hybrid and electric powertrains: Regenerative braking systems are closely integrated with hybrid and electric vehicle powertrains. This integration allows for seamless energy transfer between the braking system and the electric motor/generator, enhancing overall system efficiency. The recovered energy can be used to power the electric motor or other vehicle systems, reducing the load on the main power source.

- Hydraulic and pneumatic regenerative braking: In addition to electric regenerative braking, some systems utilize hydraulic or pneumatic technologies for energy recovery. These systems store energy in the form of compressed fluid or air, which can be later used to assist in vehicle acceleration or power auxiliary systems. This approach can be particularly effective in heavy-duty vehicles or those with frequent start-stop cycles.

- Thermal management in regenerative braking: Efficient thermal management is crucial for maintaining the performance and longevity of regenerative braking systems. Advanced cooling systems and heat dissipation techniques are employed to manage the heat generated during the energy conversion process. This ensures consistent performance and prevents efficiency losses due to overheating, particularly in high-performance or heavy-duty applications.

02 Control strategies for regenerative braking

Advanced control strategies are implemented to optimize the performance of regenerative braking systems. These strategies involve intelligent algorithms that determine the optimal balance between regenerative and friction braking, considering factors such as vehicle speed, battery state of charge, and road conditions. By fine-tuning the braking process, these control systems maximize energy recovery while maintaining vehicle stability and safety.Expand Specific Solutions03 Integration with hybrid and electric powertrains

Regenerative braking systems are closely integrated with hybrid and electric vehicle powertrains to maximize energy efficiency. This integration allows for seamless coordination between the braking system, electric motors, and power management systems. By optimizing the interaction between these components, vehicles can achieve higher overall energy efficiency and extended driving range.Expand Specific Solutions04 Hydraulic regenerative braking systems

Hydraulic regenerative braking systems offer an alternative approach to energy recovery. These systems use hydraulic accumulators to store energy in the form of pressurized fluid during braking. The stored energy can then be released to assist in vehicle acceleration or power auxiliary systems. Hydraulic systems can provide high power density and rapid energy transfer, making them suitable for certain vehicle applications.Expand Specific Solutions05 Efficiency improvements through material and design innovations

Ongoing research focuses on improving the efficiency of regenerative braking systems through material and design innovations. This includes the development of advanced electric motors with higher power density, more efficient power electronics, and improved energy storage technologies. Additionally, optimized mechanical designs and lightweight materials are employed to reduce energy losses and improve overall system performance.Expand Specific Solutions

EV Industry Players

The regenerative braking technology in electric vehicles is currently in a growth phase, with increasing market adoption and ongoing innovations. The global market for regenerative braking systems is expected to expand significantly in the coming years, driven by the rising demand for electric and hybrid vehicles. Major automotive players like Hyundai, Kia, Ford, Nissan, and BYD are actively developing and implementing this technology, indicating its growing importance in the industry. The technology's maturity is advancing rapidly, with companies like Bosch and NXP Semiconductors contributing to its refinement. Academic institutions such as Jilin University and Beijing University of Technology are also involved in research, suggesting a collaborative effort to enhance the efficiency and effectiveness of regenerative braking systems in electric vehicle design.

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative regenerative braking system for electric vehicles that combines traditional friction brakes with electric motor braking. Their system uses intelligent control algorithms to optimize energy recovery while maintaining smooth deceleration. The system can recover up to 75% of braking energy in urban driving conditions[1]. Bosch's solution integrates seamlessly with their electronic stability control (ESC) systems, allowing for precise torque distribution between regenerative and friction braking. This integration enhances both energy efficiency and vehicle stability during braking maneuvers[2]. Additionally, Bosch has implemented a predictive energy management system that uses navigation data and traffic information to anticipate braking events and maximize energy recuperation opportunities[3].

Strengths: High energy recovery rate, seamless integration with existing safety systems, and predictive capabilities. Weaknesses: Complexity of the system may lead to higher costs and potential reliability issues in the long term.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed an innovative regenerative braking system for their electric vehicles, focusing on efficiency and seamless integration with their e-Powertrain technology. Their system, known as "e-Pedal," allows for one-pedal driving by automatically engaging regenerative braking when the accelerator pedal is released. This system can decelerate the vehicle at up to 0.2g, recovering a significant amount of energy in urban driving conditions[10]. Nissan's regenerative braking technology also incorporates adaptive algorithms that adjust the braking force based on vehicle speed, battery state of charge, and road conditions. The system can recover up to 30% of the vehicle's kinetic energy during normal driving[11]. Additionally, Nissan has implemented a cooperative regenerative braking system that seamlessly blends regenerative and hydraulic braking to maximize energy recovery while maintaining smooth deceleration and stability[12].

Strengths: Intuitive one-pedal driving system, adaptive algorithms for various conditions, and seamless integration with hydraulic brakes. Weaknesses: The one-pedal driving approach may require adaptation for some drivers and could potentially lead to reduced brake pad longevity due to less frequent use of friction brakes.

Key Regen Patents

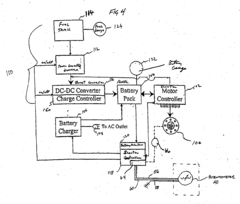

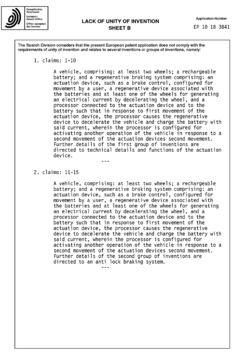

Regenerative braking system for an electric vehicle

PatentInactiveEP2314473A3

Innovation

- A regenerative braking system with a processor-controlled actuating device, such as a twist-grip throttle, that decelerates the vehicle and charges batteries by generating electrical current, and includes a microprocessor-based control circuit to regulate regenerative braking torque, preventing wheel lock-up and adjusting torque based on wheel speed differences.

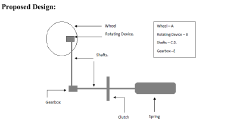

Design and fabrication of regenerative braking

PatentPendingIN202441006973A

Innovation

- The proposed regenerative braking system incorporates a Brake Pedal, Hydraulic Booster Unit, Brake ECU, Pedal Stroke Simulator, and THS ECU, which work in concert to apply braking force and induce regenerative braking, allowing for efficient energy recovery and maintaining a firm braking feel similar to conventional vehicles, while enabling easier component interchangeability and mass production.

Energy Recovery Metrics

Regenerative braking systems in electric vehicles (EVs) have become a crucial component in maximizing energy efficiency and extending driving range. To evaluate the effectiveness of these systems, several key energy recovery metrics have been developed and are widely used in the industry.

One of the primary metrics is the Regenerative Braking Efficiency (RBE), which measures the percentage of kinetic energy that is successfully converted back into electrical energy and stored in the battery during deceleration. Typical RBE values for modern EVs range from 60% to 80%, depending on the vehicle's design and the specific driving conditions.

Another important metric is the Energy Recovery Rate (ERR), which quantifies the amount of energy recovered per unit of time or distance traveled. This metric is particularly useful for comparing the performance of different regenerative braking systems across various driving scenarios, such as urban stop-and-go traffic versus highway cruising.

The Brake Energy Recovery Ratio (BERR) is a metric that compares the energy recovered through regenerative braking to the total energy dissipated during braking events. A higher BERR indicates a more efficient utilization of the vehicle's kinetic energy during deceleration.

To assess the impact of regenerative braking on overall vehicle efficiency, the Extended Range Factor (ERF) is often employed. This metric calculates the percentage increase in driving range attributed to the regenerative braking system, providing a tangible measure of the technology's contribution to vehicle performance.

The Regenerative Braking Power (RBP) is another critical metric, measuring the maximum power that can be captured and converted by the system during deceleration. This metric is particularly relevant for evaluating the system's performance during high-speed braking events or rapid deceleration scenarios.

For a more comprehensive analysis, the Energy Recovery Distribution (ERD) metric is used to map the efficiency of energy recovery across different speed ranges and deceleration rates. This metric helps engineers optimize the regenerative braking system for various driving conditions and user behaviors.

Lastly, the Regenerative Braking Consistency Index (RBCI) measures the system's ability to maintain consistent energy recovery performance over time and under varying environmental conditions. This metric is crucial for assessing the long-term reliability and effectiveness of regenerative braking technologies in real-world applications.

These energy recovery metrics collectively provide a comprehensive framework for evaluating and comparing regenerative braking systems in electric vehicles. By analyzing these metrics, engineers and researchers can continually refine and improve regenerative braking technologies, ultimately contributing to the development of more efficient and sustainable electric vehicles.

One of the primary metrics is the Regenerative Braking Efficiency (RBE), which measures the percentage of kinetic energy that is successfully converted back into electrical energy and stored in the battery during deceleration. Typical RBE values for modern EVs range from 60% to 80%, depending on the vehicle's design and the specific driving conditions.

Another important metric is the Energy Recovery Rate (ERR), which quantifies the amount of energy recovered per unit of time or distance traveled. This metric is particularly useful for comparing the performance of different regenerative braking systems across various driving scenarios, such as urban stop-and-go traffic versus highway cruising.

The Brake Energy Recovery Ratio (BERR) is a metric that compares the energy recovered through regenerative braking to the total energy dissipated during braking events. A higher BERR indicates a more efficient utilization of the vehicle's kinetic energy during deceleration.

To assess the impact of regenerative braking on overall vehicle efficiency, the Extended Range Factor (ERF) is often employed. This metric calculates the percentage increase in driving range attributed to the regenerative braking system, providing a tangible measure of the technology's contribution to vehicle performance.

The Regenerative Braking Power (RBP) is another critical metric, measuring the maximum power that can be captured and converted by the system during deceleration. This metric is particularly relevant for evaluating the system's performance during high-speed braking events or rapid deceleration scenarios.

For a more comprehensive analysis, the Energy Recovery Distribution (ERD) metric is used to map the efficiency of energy recovery across different speed ranges and deceleration rates. This metric helps engineers optimize the regenerative braking system for various driving conditions and user behaviors.

Lastly, the Regenerative Braking Consistency Index (RBCI) measures the system's ability to maintain consistent energy recovery performance over time and under varying environmental conditions. This metric is crucial for assessing the long-term reliability and effectiveness of regenerative braking technologies in real-world applications.

These energy recovery metrics collectively provide a comprehensive framework for evaluating and comparing regenerative braking systems in electric vehicles. By analyzing these metrics, engineers and researchers can continually refine and improve regenerative braking technologies, ultimately contributing to the development of more efficient and sustainable electric vehicles.

Regen Safety Standards

Regenerative braking systems in electric vehicles (EVs) have become a crucial component in enhancing energy efficiency and extending driving range. However, with the increasing adoption of this technology, it is imperative to establish comprehensive safety standards to ensure the reliable and secure operation of these systems. The development of regen safety standards involves a multi-faceted approach, addressing various aspects of vehicle design, performance, and user interaction.

One of the primary concerns in regenerative braking safety is the potential for sudden deceleration, which could lead to loss of vehicle control or unexpected behavior in emergency situations. To mitigate these risks, safety standards typically mandate a smooth and predictable transition between regenerative and friction braking. This often involves sophisticated control algorithms that adjust the regenerative braking force based on factors such as vehicle speed, road conditions, and driver input.

Another critical aspect of regen safety standards is the integration with existing vehicle safety systems, such as anti-lock braking systems (ABS) and electronic stability control (ESC). These standards ensure that regenerative braking does not interfere with the operation of these critical safety features, maintaining optimal vehicle stability and control under all driving conditions.

Electromagnetic compatibility (EMC) is also a key consideration in regen safety standards. The high-power electrical systems involved in regenerative braking can potentially generate electromagnetic interference, which could affect other vehicle systems or nearby electronic devices. Safety standards typically include stringent EMC requirements to prevent such interference and ensure the reliable operation of all vehicle components.

Thermal management is another crucial area addressed by regen safety standards. The energy recovery process in regenerative braking can generate significant heat, particularly during prolonged use or in high-performance scenarios. Safety standards often specify thermal limits and cooling requirements to prevent overheating of the braking system and associated components, ensuring consistent performance and longevity.

User interface and feedback mechanisms are also important elements of regen safety standards. Clear and intuitive indicators of regenerative braking activation and intensity help drivers understand and anticipate vehicle behavior. Standards may specify requirements for visual, auditory, or haptic feedback to enhance driver awareness and control.

Lastly, regen safety standards typically include provisions for fail-safe operation and system redundancy. In the event of a regenerative braking system failure, the vehicle must be able to rely on conventional friction brakes without compromising safety. This often involves backup power systems, redundant control units, and fail-safe mechanisms that ensure a smooth transition to conventional braking in case of system malfunction.

One of the primary concerns in regenerative braking safety is the potential for sudden deceleration, which could lead to loss of vehicle control or unexpected behavior in emergency situations. To mitigate these risks, safety standards typically mandate a smooth and predictable transition between regenerative and friction braking. This often involves sophisticated control algorithms that adjust the regenerative braking force based on factors such as vehicle speed, road conditions, and driver input.

Another critical aspect of regen safety standards is the integration with existing vehicle safety systems, such as anti-lock braking systems (ABS) and electronic stability control (ESC). These standards ensure that regenerative braking does not interfere with the operation of these critical safety features, maintaining optimal vehicle stability and control under all driving conditions.

Electromagnetic compatibility (EMC) is also a key consideration in regen safety standards. The high-power electrical systems involved in regenerative braking can potentially generate electromagnetic interference, which could affect other vehicle systems or nearby electronic devices. Safety standards typically include stringent EMC requirements to prevent such interference and ensure the reliable operation of all vehicle components.

Thermal management is another crucial area addressed by regen safety standards. The energy recovery process in regenerative braking can generate significant heat, particularly during prolonged use or in high-performance scenarios. Safety standards often specify thermal limits and cooling requirements to prevent overheating of the braking system and associated components, ensuring consistent performance and longevity.

User interface and feedback mechanisms are also important elements of regen safety standards. Clear and intuitive indicators of regenerative braking activation and intensity help drivers understand and anticipate vehicle behavior. Standards may specify requirements for visual, auditory, or haptic feedback to enhance driver awareness and control.

Lastly, regen safety standards typically include provisions for fail-safe operation and system redundancy. In the event of a regenerative braking system failure, the vehicle must be able to rely on conventional friction brakes without compromising safety. This often involves backup power systems, redundant control units, and fail-safe mechanisms that ensure a smooth transition to conventional braking in case of system malfunction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!