LS3 Engine: How to Upgrade Exhaust Systems

LS3 Engine Exhaust Technology Background & Objectives

The LS3 engine, a 6.2-liter small-block V8 developed by General Motors, represents a significant milestone in automotive powertrain technology. Introduced in 2008, this engine became renowned for its robust performance characteristics, delivering 430 horsepower and 424 lb-ft of torque in its stock configuration. The exhaust system plays a critical role in the engine's performance envelope, serving not merely as a pathway for spent combustion gases but as an integral component affecting power output, fuel efficiency, and emissions compliance.

The evolution of exhaust technology for high-performance engines has progressed through several distinct phases. Early systems focused primarily on basic functionality, while modern exhaust solutions incorporate advanced materials, precision engineering, and sophisticated flow dynamics. The LS3 platform has benefited from this technological progression, with aftermarket developments consistently pushing the boundaries of performance enhancement through exhaust optimization.

Current exhaust technology for the LS3 engine encompasses various design philosophies, including long-tube headers, high-flow catalytic converters, X-pipe and H-pipe configurations, and performance mufflers with variable flow characteristics. Each component has evolved to address specific performance parameters while navigating increasingly stringent emissions regulations across global markets.

The primary objective of this research is to identify and evaluate potential exhaust system upgrades that can maximize the LS3 engine's performance capabilities while maintaining compliance with relevant emissions standards. Specifically, we aim to investigate how modern materials, manufacturing techniques, and design innovations can be leveraged to enhance exhaust gas scavenging, reduce backpressure, and optimize the engine's volumetric efficiency across its operating range.

Secondary objectives include quantifying the performance gains achievable through various exhaust configurations, analyzing the cost-benefit relationship of different upgrade paths, and assessing the compatibility of advanced exhaust technologies with existing engine management systems. Additionally, this research seeks to explore how emerging technologies such as variable geometry exhaust systems and active noise cancellation might be applied to the LS3 platform.

The technological trajectory suggests several promising avenues for exhaust system enhancement, including computational fluid dynamics-optimized header designs, advanced ceramic coatings for thermal management, and electronically controlled valving systems. By comprehensively examining these technologies, this research aims to establish a clear roadmap for exhaust system upgrades that deliver measurable performance improvements while addressing practical considerations of installation complexity, durability, and regulatory compliance.

Market Demand Analysis for Performance Exhaust Systems

The performance exhaust system market for LS3 engines has experienced significant growth over the past decade, driven by increasing consumer interest in vehicle customization and performance enhancement. Market research indicates that the global automotive aftermarket for performance exhaust systems reached approximately $14.5 billion in 2022, with a compound annual growth rate of 6.8% projected through 2028. The segment specific to GM LS-series engines, particularly the LS3, represents a substantial portion of this market due to the platform's popularity among performance enthusiasts.

Consumer demand analysis reveals distinct market segments seeking LS3 exhaust upgrades. The primary segment consists of sports car owners looking to enhance engine sound and achieve moderate performance gains without significant modifications. This group typically seeks bolt-on solutions with minimal installation complexity. The second major segment includes dedicated performance enthusiasts and racing competitors who prioritize maximum horsepower and torque gains, often as part of comprehensive engine build packages.

Regional market analysis shows North America dominating the LS3 performance exhaust market, accounting for approximately 65% of global sales. This concentration reflects the prevalence of LS3-equipped vehicles in the American market and the strong muscle car culture. Europe represents the second largest market at 18%, followed by Australia at 8%, with growing interest in emerging markets across Asia.

Price sensitivity studies indicate that consumers typically allocate between $800-2,500 for complete LS3 exhaust system upgrades, with premium systems commanding prices up to $3,500. The market demonstrates a clear correlation between price points and material quality, with stainless steel and titanium systems occupying the premium segment.

Industry trends point toward increasing demand for exhaust systems that offer adjustable sound profiles through electronic valve control systems. This technology allows drivers to modify exhaust tone and volume based on driving conditions, addressing noise regulation concerns while maintaining performance capabilities. Additionally, there is growing consumer interest in exhaust systems with integrated emissions compliance features to meet increasingly stringent environmental regulations.

Market forecasts suggest that the LS3 performance exhaust segment will continue to grow despite the automotive industry's shift toward electrification. This resilience is attributed to the large existing vehicle base and the engine platform's continued popularity in specialty vehicle builds and engine swaps. Manufacturers are responding by developing hybrid product lines that combine traditional performance benefits with modern features like digital integration and customization options.

Current Exhaust Technology Challenges

The LS3 engine exhaust system faces several significant technical challenges that limit its performance potential and environmental compliance. Current stock exhaust systems for the LS3 platform demonstrate considerable flow restrictions, particularly at the manifold-to-header junction and catalytic converter sections. These restrictions create excessive backpressure that impedes exhaust gas evacuation, resulting in power losses estimated between 15-25 horsepower across the RPM range.

Material limitations present another critical challenge. Stock exhaust components typically utilize 409 stainless steel which, while cost-effective, exhibits inferior heat resistance and durability compared to premium 304 or 321 stainless steel alternatives. This material choice leads to accelerated thermal degradation, particularly in high-performance applications where exhaust gas temperatures can exceed 1600°F during sustained high-load operation.

Emissions compliance represents an increasingly complex challenge for aftermarket exhaust development. Current CARB (California Air Resources Board) and EPA regulations have established stringent emissions standards that many performance-oriented exhaust modifications struggle to meet. The technical challenge lies in balancing flow improvements with maintaining or improving emissions characteristics, particularly NOx and hydrocarbon outputs that are directly affected by exhaust scavenging efficiency and thermal properties.

Sound management technology in current systems demonstrates significant room for improvement. The stock resonator and muffler designs prioritize noise reduction over flow optimization, utilizing restrictive baffle designs and absorption materials that degrade over time. Modern Helmholtz resonator technology and variable flow path designs remain underutilized in the LS3 platform.

Weight reduction presents another engineering challenge, as stock exhaust systems typically weigh between 45-60 pounds, contributing to unnecessary vehicle mass. The industry has yet to widely implement advanced manufacturing techniques such as hydroforming and thin-wall extrusion that could maintain structural integrity while reducing material usage by up to 30%.

Heat management inefficiencies in current designs lead to performance inconsistencies and increased underhood temperatures. Thermal wrapping solutions offer only partial remediation, while integrated heat shield designs and thermal barrier coatings remain underutilized despite their proven effectiveness in motorsport applications.

Finally, current exhaust valve control systems lack sophistication, with most aftermarket solutions offering only binary open/closed functionality rather than progressive flow control that could optimize performance across various engine loads and RPM ranges. The integration of electronic valve control with engine management systems represents a significant technical gap in current offerings.

Current LS3 Exhaust Upgrade Solutions

01 Exhaust system design for performance optimization

The design of exhaust systems for LS3 engines can significantly impact performance. Key design elements include header configuration, pipe diameter, and overall system layout. Optimized exhaust flow reduces back pressure, allowing the engine to expel exhaust gases more efficiently, resulting in increased horsepower and torque. Advanced designs incorporate computational fluid dynamics to model exhaust gas flow patterns and optimize system geometry for maximum performance.- Exhaust system design for improved performance: The design of exhaust systems for LS3 engines can significantly impact performance. Key design elements include optimized exhaust manifolds, headers, and piping configurations that reduce back pressure and improve exhaust gas flow. Advanced designs incorporate features such as variable geometry, tuned pipe lengths, and optimized bends to enhance engine breathing and power output across different RPM ranges.

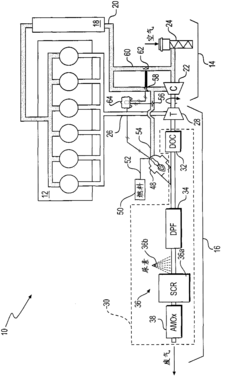

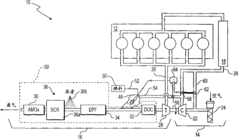

- Catalytic converter and emissions control technologies: Emissions control components in LS3 exhaust systems balance performance with environmental compliance. Advanced catalytic converters, particulate filters, and selective catalytic reduction systems are designed to minimize flow restrictions while effectively reducing harmful emissions. These technologies incorporate high-flow substrates, optimized catalyst formulations, and strategic placement within the exhaust stream to maintain performance while meeting emissions standards.

- Exhaust system monitoring and control systems: Electronic monitoring and control systems enhance LS3 exhaust performance through real-time adjustments. These systems utilize sensors to monitor exhaust gas temperature, pressure, and composition, allowing for adaptive control of exhaust flow characteristics. Advanced control algorithms can adjust exhaust valve timing, bypass systems, or active mufflers to optimize performance across various operating conditions.

- Muffler and sound management technologies: Sound management technologies for LS3 exhaust systems balance noise reduction with performance enhancement. Advanced muffler designs incorporate resonance chambers, perforated tubes, and sound-absorbing materials strategically placed to reduce noise without restricting flow. Some systems feature variable sound control through electronically controlled valves or bypass systems that can alter exhaust flow paths based on driving conditions or driver preferences.

- Heat management and thermal efficiency: Thermal management in LS3 exhaust systems improves overall engine performance and component longevity. Technologies include thermal barriers, heat shields, and insulated exhaust components that control heat dissipation and retention. Some systems incorporate heat recovery mechanisms that capture exhaust thermal energy for use in warming engine components, cabin heating, or conversion to electrical energy, improving overall system efficiency.

02 Catalytic converter and emissions control technology

Emissions control components in LS3 engine exhaust systems balance performance with environmental compliance. Modern catalytic converters are designed to minimize flow restriction while effectively reducing harmful emissions. Advanced materials and catalyst formulations enable efficient conversion of pollutants without significantly impacting engine performance. Strategic placement of these components within the exhaust system helps maintain optimal exhaust gas temperature for catalytic reactions while minimizing performance penalties.Expand Specific Solutions03 Exhaust system monitoring and control methods

Monitoring and control systems for LS3 engine exhaust improve performance through real-time adjustments. Sensors measure parameters such as exhaust gas temperature, pressure, and composition to provide feedback to the engine control unit. This data enables dynamic tuning of engine parameters to optimize performance under varying conditions. Advanced systems incorporate predictive algorithms to anticipate changes in operating conditions and proactively adjust exhaust system behavior for maximum efficiency and power output.Expand Specific Solutions04 Muffler and sound management technology

Sound management in LS3 exhaust systems balances performance with noise control. Advanced muffler designs use resonance chambers, sound-absorbing materials, and flow-optimized paths to reduce noise while minimizing back pressure. Variable geometry mufflers can alter their internal configuration based on engine load and RPM to provide optimal flow characteristics across the operating range. These technologies enable compliance with noise regulations while maintaining or enhancing engine performance characteristics.Expand Specific Solutions05 Turbocharger and forced induction integration

Integration of turbochargers and other forced induction systems with LS3 engine exhaust requires specialized design considerations. Exhaust manifold geometry, wastegate placement, and turbine housing selection significantly impact system efficiency and response. Heat management becomes critical in these applications, with thermal barriers and strategic component placement helping to optimize exhaust gas energy recovery. Advanced systems may incorporate variable geometry turbines or electronic wastegates to provide optimal boost characteristics across the engine's operating range.Expand Specific Solutions

Major Exhaust System Manufacturers Analysis

The LS3 Engine Exhaust System Upgrade market is in a growth phase, with increasing demand driven by stringent emission regulations and performance enhancement requirements. Major automotive manufacturers like Hyundai, Ford, GM, and SAIC Motor are competing alongside specialized component suppliers such as Afton Chemical, BASF, and Infineum International. The market is characterized by a mix of established players and innovative newcomers like Radical Combustion Technologies. Technical maturity varies significantly, with traditional OEMs focusing on incremental improvements while research institutions (Nanjing University of Aeronautics & Astronautics, Zhejiang University) and specialized firms develop more disruptive solutions. The competitive landscape is further shaped by regional regulations, with companies like BYD and BASF China gaining prominence in the rapidly evolving Asian markets.

Ford Global Technologies LLC

GM Global Technology Operations LLC

Key Exhaust Technology Patents & Innovations

- A multi-stage expansion exhaust gas promotion method and device that uses a casing with an annular space, a cooling cylinder, and spiral grooves to accelerate and cool exhaust gases, creating negative pressure for improved flow and thermal energy deprivation, thereby enhancing exhaust efficiency and reducing harmful emissions.

- An exhaust gas treatment device is set up in the exhaust pipe of the engine, and an exhaust gas heater is placed upstream of it. The air inflow is regulated through the air supply channel and the restriction valve to ensure that the exhaust gas treatment device can work effectively under all conditions.

Emissions Compliance & Regulatory Considerations

The regulatory landscape for exhaust system modifications presents significant challenges for LS3 engine upgrades. Current EPA and CARB regulations establish strict emissions standards that aftermarket exhaust systems must meet to maintain legal compliance. These standards include limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM). Any exhaust system upgrade must be certified with an Executive Order (EO) number from CARB to be considered legal for street use in California and states following CARB guidelines.

Federal Tier 3 emissions standards have progressively tightened requirements for vehicle emissions, with implications for performance exhaust systems. These regulations specifically target the reduction of NOx and PM emissions, which are directly affected by exhaust system modifications. Manufacturers seeking to develop compliant LS3 exhaust upgrades must navigate these regulatory frameworks while still delivering performance benefits.

Testing protocols for emissions compliance involve standardized procedures including the Federal Test Procedure (FTP) and Supplemental Federal Test Procedure (SFTP). These tests measure emissions under various driving conditions to ensure real-world compliance. For LS3 engine exhaust upgrades, manufacturers must demonstrate that their systems maintain emissions within acceptable limits across all testing scenarios, which often requires sophisticated catalytic converter technology and precise oxygen sensor placement.

The global regulatory environment adds further complexity, with European Euro 6d standards and upcoming Euro 7 regulations imposing even stricter emissions limits than U.S. standards. This creates challenges for international marketability of exhaust system upgrades and necessitates region-specific product development strategies.

On-Board Diagnostics (OBD-II) compatibility represents another critical regulatory consideration. Modern exhaust systems must integrate with vehicle OBD systems without triggering check engine lights or fault codes. This requires careful engineering of oxygen sensor bungs, heat shields, and electronic components to maintain proper communication with the engine control module.

Recent regulatory trends indicate a continued tightening of emissions standards, with particular focus on real-world driving emissions (RDE) testing. This shift means that exhaust system upgrades must perform consistently across a wider range of operating conditions than previously required. Manufacturers developing LS3 exhaust upgrades must anticipate these regulatory developments and design systems with sufficient headroom to accommodate future standards.

Penalties for non-compliance have also increased substantially, with manufacturers facing potential fines exceeding $37,500 per non-compliant vehicle. This regulatory risk has driven many performance exhaust manufacturers to invest heavily in emissions testing and certification processes to ensure their products remain legally viable in all target markets.

Performance Testing Methodologies & Benchmarks

Comprehensive performance testing is essential for validating exhaust system upgrades on the LS3 engine platform. Standardized methodologies must be established to ensure consistent and reliable data collection across various operating conditions. The primary testing approach involves dynamometer evaluation, which provides controlled measurement of power, torque, and efficiency gains resulting from exhaust modifications.

Chassis dynamometers offer real-world simulation capabilities, measuring wheel horsepower and torque through the entire drivetrain. This testing method accounts for drivetrain losses and provides practical performance metrics that vehicle owners can expect. Engine dynamometers, alternatively, connect directly to the engine, eliminating drivetrain variables and providing more precise measurements of exhaust system effects on engine performance.

Temperature and pressure sensors should be strategically placed throughout the exhaust system to monitor thermal efficiency and backpressure characteristics. Data logging equipment must capture exhaust gas temperatures at multiple points, including pre-catalytic converter, post-catalytic converter, and tailpipe exit. Pressure differential measurements between key points help quantify flow improvements from upgraded components.

Sound level testing represents another critical benchmark, utilizing calibrated decibel meters at standardized distances and engine RPM points. Frequency analysis should document changes across the audible spectrum, particularly focusing on low-frequency resonance that contributes to the characteristic V8 exhaust note. Interior cabin noise measurements provide data on potential drone or resonance issues at cruising speeds.

Emissions testing must verify that upgraded exhaust systems maintain compliance with applicable regulations. Standard five-gas analyzers should measure CO, CO2, HC, NOx, and O2 levels across various engine loads and speeds. Comparative analysis between stock and upgraded systems helps quantify any changes in emissions characteristics.

Acceleration testing provides real-world performance validation, with standardized 0-60 mph, quarter-mile times, and 60-130 mph metrics. These tests should be conducted under identical conditions with the same driver to minimize variables. GPS-based performance measurement tools offer superior accuracy compared to traditional stopwatch methods.

Benchmark comparisons should include direct competitors' exhaust systems tested under identical conditions. Performance data should be normalized for environmental factors such as temperature, humidity, and barometric pressure to ensure valid comparisons. Cost-performance ratio analysis provides valuable context for evaluating the value proposition of various upgrade options.