Membrane reactor integration for methane steam reforming

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Steam Reforming Membrane Reactor Background and Objectives

Methane steam reforming (MSR) has been a cornerstone technology for hydrogen production since the early 20th century, evolving from basic catalytic processes to sophisticated integrated systems. This evolution reflects the growing demand for hydrogen as both an industrial feedstock and a potential clean energy carrier. The integration of membrane technology with traditional reforming processes represents a significant advancement in this field, aiming to overcome thermodynamic limitations and enhance process efficiency.

The historical trajectory of membrane reactor technology began in the 1980s with early conceptual designs, followed by significant breakthroughs in membrane materials during the 1990s. The early 2000s witnessed the first pilot-scale demonstrations, while recent years have seen accelerated development driven by renewed interest in hydrogen economy and carbon emission reduction goals.

Current technical trends in membrane reactor integration focus on several key areas: development of high-temperature, hydrogen-selective membranes with improved stability; process intensification through multifunctional reactor designs; and optimization of catalyst-membrane interfaces to minimize mass transfer limitations. These trends collectively aim to enhance hydrogen yield while reducing energy consumption and carbon footprint.

The primary objectives of membrane reactor integration for methane steam reforming encompass both technical and economic dimensions. From a technical perspective, the goal is to achieve single-step, high-purity hydrogen production by continuously removing hydrogen from the reaction zone, thereby shifting equilibrium toward product formation according to Le Chatelier's principle. This approach aims to overcome the thermodynamic limitations inherent in conventional reforming processes.

Economic objectives include reducing capital and operational costs through process intensification, lowering operating temperatures, and eliminating or simplifying downstream separation units. Environmental goals focus on reducing CO2 emissions through improved efficiency and potential for carbon capture integration.

The long-term vision for this technology extends beyond current applications to enable distributed hydrogen production systems that can support hydrogen infrastructure development. Additionally, membrane reactors may serve as enabling technology for renewable methane utilization pathways, creating synergies with biogas and power-to-gas concepts.

As global energy systems transition toward lower carbon intensity, membrane reactor technology for methane steam reforming represents a critical bridge technology, potentially enabling more efficient utilization of natural gas resources while facilitating the gradual transition to a hydrogen-based economy.

The historical trajectory of membrane reactor technology began in the 1980s with early conceptual designs, followed by significant breakthroughs in membrane materials during the 1990s. The early 2000s witnessed the first pilot-scale demonstrations, while recent years have seen accelerated development driven by renewed interest in hydrogen economy and carbon emission reduction goals.

Current technical trends in membrane reactor integration focus on several key areas: development of high-temperature, hydrogen-selective membranes with improved stability; process intensification through multifunctional reactor designs; and optimization of catalyst-membrane interfaces to minimize mass transfer limitations. These trends collectively aim to enhance hydrogen yield while reducing energy consumption and carbon footprint.

The primary objectives of membrane reactor integration for methane steam reforming encompass both technical and economic dimensions. From a technical perspective, the goal is to achieve single-step, high-purity hydrogen production by continuously removing hydrogen from the reaction zone, thereby shifting equilibrium toward product formation according to Le Chatelier's principle. This approach aims to overcome the thermodynamic limitations inherent in conventional reforming processes.

Economic objectives include reducing capital and operational costs through process intensification, lowering operating temperatures, and eliminating or simplifying downstream separation units. Environmental goals focus on reducing CO2 emissions through improved efficiency and potential for carbon capture integration.

The long-term vision for this technology extends beyond current applications to enable distributed hydrogen production systems that can support hydrogen infrastructure development. Additionally, membrane reactors may serve as enabling technology for renewable methane utilization pathways, creating synergies with biogas and power-to-gas concepts.

As global energy systems transition toward lower carbon intensity, membrane reactor technology for methane steam reforming represents a critical bridge technology, potentially enabling more efficient utilization of natural gas resources while facilitating the gradual transition to a hydrogen-based economy.

Market Analysis for Hydrogen Production Technologies

The global hydrogen market is experiencing significant growth, driven by increasing demand for clean energy solutions and industrial applications. Currently valued at approximately $130 billion, the hydrogen market is projected to reach $220 billion by 2030, with a compound annual growth rate of 9.2% during the forecast period. Hydrogen production technologies are at the center of this expanding market, with methane steam reforming (MSR) dominating current production methods, accounting for over 75% of global hydrogen production.

The integration of membrane reactors with methane steam reforming represents a significant advancement in hydrogen production technology, offering enhanced efficiency and reduced carbon footprint compared to conventional methods. This innovation addresses growing market demands for more sustainable hydrogen production processes as industries worldwide face increasing pressure to decarbonize their operations.

Industrial sectors constitute the largest consumer segment for hydrogen, with petroleum refining and ammonia production collectively accounting for approximately 70% of global hydrogen consumption. However, emerging applications in transportation, power generation, and energy storage are rapidly expanding, creating new market opportunities for advanced hydrogen production technologies like membrane reactor integrated MSR systems.

Regionally, Asia-Pacific dominates the hydrogen production market with approximately 45% market share, followed by Europe and North America. China, Japan, and South Korea are making substantial investments in hydrogen infrastructure, while European countries are focusing on green hydrogen production technologies to meet ambitious climate targets. The United States is increasingly investing in hydrogen technologies through initiatives like the Department of Energy's Hydrogen Program.

Market analysis indicates that membrane reactor technology for methane steam reforming could capture 15-20% of the hydrogen production technology market by 2030, representing a significant commercial opportunity. The technology's ability to produce high-purity hydrogen in a single step while capturing CO2 aligns with market trends toward more efficient and environmentally responsible production methods.

Cost considerations remain a critical factor in market adoption. Current membrane reactor systems face challenges in achieving cost competitiveness with conventional steam reforming, with production costs estimated at $2.50-3.50 per kilogram of hydrogen compared to $1.50-2.00 for conventional methods. However, technological improvements and economies of scale are expected to narrow this gap significantly over the next five years.

Market drivers for membrane reactor technology include increasingly stringent environmental regulations, carbon pricing mechanisms, and growing demand for high-purity hydrogen in fuel cell applications. The technology's potential to reduce carbon emissions by 15-25% compared to conventional steam reforming processes positions it favorably in markets with strong climate policies.

The integration of membrane reactors with methane steam reforming represents a significant advancement in hydrogen production technology, offering enhanced efficiency and reduced carbon footprint compared to conventional methods. This innovation addresses growing market demands for more sustainable hydrogen production processes as industries worldwide face increasing pressure to decarbonize their operations.

Industrial sectors constitute the largest consumer segment for hydrogen, with petroleum refining and ammonia production collectively accounting for approximately 70% of global hydrogen consumption. However, emerging applications in transportation, power generation, and energy storage are rapidly expanding, creating new market opportunities for advanced hydrogen production technologies like membrane reactor integrated MSR systems.

Regionally, Asia-Pacific dominates the hydrogen production market with approximately 45% market share, followed by Europe and North America. China, Japan, and South Korea are making substantial investments in hydrogen infrastructure, while European countries are focusing on green hydrogen production technologies to meet ambitious climate targets. The United States is increasingly investing in hydrogen technologies through initiatives like the Department of Energy's Hydrogen Program.

Market analysis indicates that membrane reactor technology for methane steam reforming could capture 15-20% of the hydrogen production technology market by 2030, representing a significant commercial opportunity. The technology's ability to produce high-purity hydrogen in a single step while capturing CO2 aligns with market trends toward more efficient and environmentally responsible production methods.

Cost considerations remain a critical factor in market adoption. Current membrane reactor systems face challenges in achieving cost competitiveness with conventional steam reforming, with production costs estimated at $2.50-3.50 per kilogram of hydrogen compared to $1.50-2.00 for conventional methods. However, technological improvements and economies of scale are expected to narrow this gap significantly over the next five years.

Market drivers for membrane reactor technology include increasingly stringent environmental regulations, carbon pricing mechanisms, and growing demand for high-purity hydrogen in fuel cell applications. The technology's potential to reduce carbon emissions by 15-25% compared to conventional steam reforming processes positions it favorably in markets with strong climate policies.

Current Challenges in Membrane Reactor Integration

Despite significant advancements in membrane reactor technology for methane steam reforming (MSR), several critical challenges continue to impede widespread industrial implementation. The integration of membrane separation with catalytic reaction processes presents complex engineering hurdles that require innovative solutions.

Material stability remains a primary concern, particularly for hydrogen-selective membranes operating under harsh MSR conditions. Palladium-based membranes, while offering excellent hydrogen selectivity, suffer from embrittlement during thermal cycling and poisoning from sulfur compounds commonly present in natural gas feedstocks. Ceramic and composite membranes show promising thermal stability but often lack the necessary hydrogen permeability or mechanical strength for long-term operation.

Thermal management presents another significant challenge. The endothermic nature of steam reforming requires substantial heat input, while maintaining uniform temperature distribution across the membrane surface is difficult. Temperature gradients can lead to membrane damage through thermal stress and accelerated degradation of both membrane materials and catalysts, ultimately reducing system lifetime and performance reliability.

Catalyst-membrane compatibility issues further complicate reactor design. The proximity of catalyst particles to membrane surfaces can cause physical damage through abrasion or chemical degradation through unwanted side reactions. Additionally, carbon deposition (coking) on both catalyst and membrane surfaces progressively blocks active sites and hydrogen permeation pathways, necessitating frequent regeneration cycles that stress system components.

Scale-up challenges represent a substantial barrier to commercialization. Laboratory-scale successes often fail to translate to industrial-scale operations due to difficulties in manufacturing large-area defect-free membranes and achieving uniform flow distribution in scaled-up reactor configurations. The economic viability of membrane reactors is further compromised by high production costs of specialized membrane materials and complex reactor fabrication requirements.

System integration complexities also present significant hurdles. Membrane reactors must be effectively incorporated into broader process systems, requiring careful consideration of feed pretreatment, product post-processing, and heat integration. The mechanical integrity of sealing systems at high temperatures remains problematic, with thermal expansion mismatches between different materials often leading to gas leakage and safety concerns.

Addressing these multifaceted challenges requires interdisciplinary approaches combining materials science, chemical engineering, and process design. Recent research directions include development of sulfur-tolerant membrane materials, advanced manufacturing techniques for defect-free membrane production, and novel reactor configurations that optimize heat transfer while minimizing mechanical stress on membrane components.

Material stability remains a primary concern, particularly for hydrogen-selective membranes operating under harsh MSR conditions. Palladium-based membranes, while offering excellent hydrogen selectivity, suffer from embrittlement during thermal cycling and poisoning from sulfur compounds commonly present in natural gas feedstocks. Ceramic and composite membranes show promising thermal stability but often lack the necessary hydrogen permeability or mechanical strength for long-term operation.

Thermal management presents another significant challenge. The endothermic nature of steam reforming requires substantial heat input, while maintaining uniform temperature distribution across the membrane surface is difficult. Temperature gradients can lead to membrane damage through thermal stress and accelerated degradation of both membrane materials and catalysts, ultimately reducing system lifetime and performance reliability.

Catalyst-membrane compatibility issues further complicate reactor design. The proximity of catalyst particles to membrane surfaces can cause physical damage through abrasion or chemical degradation through unwanted side reactions. Additionally, carbon deposition (coking) on both catalyst and membrane surfaces progressively blocks active sites and hydrogen permeation pathways, necessitating frequent regeneration cycles that stress system components.

Scale-up challenges represent a substantial barrier to commercialization. Laboratory-scale successes often fail to translate to industrial-scale operations due to difficulties in manufacturing large-area defect-free membranes and achieving uniform flow distribution in scaled-up reactor configurations. The economic viability of membrane reactors is further compromised by high production costs of specialized membrane materials and complex reactor fabrication requirements.

System integration complexities also present significant hurdles. Membrane reactors must be effectively incorporated into broader process systems, requiring careful consideration of feed pretreatment, product post-processing, and heat integration. The mechanical integrity of sealing systems at high temperatures remains problematic, with thermal expansion mismatches between different materials often leading to gas leakage and safety concerns.

Addressing these multifaceted challenges requires interdisciplinary approaches combining materials science, chemical engineering, and process design. Recent research directions include development of sulfur-tolerant membrane materials, advanced manufacturing techniques for defect-free membrane production, and novel reactor configurations that optimize heat transfer while minimizing mechanical stress on membrane components.

Current Membrane Reactor Integration Solutions

01 Membrane reactor design optimization

Optimizing the design of membrane reactors can significantly improve integration efficiency. This includes considerations for reactor geometry, membrane configuration, and material selection. Advanced design approaches focus on maximizing contact area between reactants and catalysts while minimizing transport limitations. Proper design optimization can lead to enhanced mass transfer, reduced pressure drop, and improved overall system performance.- Membrane reactor design optimization: Optimizing the design of membrane reactors can significantly improve integration efficiency. This includes considerations for reactor geometry, membrane configuration, and flow patterns to enhance mass transfer and reaction kinetics. Advanced design approaches incorporate computational fluid dynamics and process intensification principles to minimize energy consumption while maximizing throughput and conversion rates.

- Catalyst integration with membrane systems: The strategic integration of catalysts with membrane systems enhances reaction efficiency in membrane reactors. This approach involves developing specialized catalyst formulations, optimizing catalyst loading methods, and creating novel catalyst-membrane interfaces. These techniques improve reaction selectivity, reduce fouling, and extend operational lifetimes of integrated membrane reactor systems.

- Process control and monitoring systems: Advanced process control and monitoring systems are essential for maintaining optimal membrane reactor efficiency. These systems incorporate real-time sensors, feedback control mechanisms, and predictive algorithms to regulate operating parameters such as temperature, pressure, and flow rates. Intelligent control systems can adapt to changing conditions, prevent membrane fouling, and ensure consistent product quality while minimizing energy consumption.

- Modular and scalable membrane reactor configurations: Modular and scalable membrane reactor designs improve integration efficiency across different production scales. These configurations allow for flexible operation, easier maintenance, and simplified scale-up from laboratory to industrial applications. Standardized modules can be arranged in series or parallel to accommodate varying throughput requirements while maintaining optimal performance characteristics.

- Energy integration and heat management: Effective energy integration and heat management strategies significantly enhance membrane reactor efficiency. These approaches include heat recovery systems, thermal integration with surrounding processes, and innovative heating/cooling designs. Advanced thermal management reduces energy consumption, prevents thermal degradation of membranes, and enables more stable operation across varying process conditions.

02 Process intensification techniques

Process intensification in membrane reactors involves combining multiple unit operations into a single integrated system. This approach reduces equipment footprint, energy consumption, and capital costs while improving efficiency. Techniques include multifunctional reactors, hybrid separation-reaction systems, and modular designs that enable better heat management and mass transfer. These innovations lead to higher conversion rates and selectivity in chemical processes.Expand Specific Solutions03 Catalyst integration and performance enhancement

Effective integration of catalysts within membrane reactors is crucial for efficiency improvement. This involves developing novel catalyst deposition methods, optimizing catalyst distribution, and creating synergistic effects between the membrane and catalyst. Advanced approaches include incorporating nanostructured catalysts, using catalyst-coated membranes, and developing gradient catalyst structures that maximize reaction rates while minimizing deactivation and fouling issues.Expand Specific Solutions04 Control systems and automation for membrane reactors

Implementation of sophisticated control systems and automation technologies enhances membrane reactor integration efficiency. These systems enable real-time monitoring and adjustment of operating parameters, predictive maintenance, and optimization of reaction conditions. Advanced control strategies include model predictive control, artificial intelligence algorithms, and digital twin technologies that can significantly improve process stability, product quality, and energy efficiency.Expand Specific Solutions05 Modular and scalable membrane reactor systems

Modular and scalable membrane reactor designs facilitate efficient integration into existing processes and enable flexible capacity adjustment. These systems feature standardized components, plug-and-play connectivity, and distributed processing capabilities. The modular approach allows for easier maintenance, reduced downtime, and phased implementation, making membrane reactor technology more accessible for various applications from laboratory scale to industrial production.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Membrane reactor integration for methane steam reforming is currently in a growth phase, with the market expanding due to increasing demand for hydrogen production and clean energy solutions. The global market size is estimated to reach $2-3 billion by 2025, driven by industrial applications and energy transition initiatives. Technologically, the field shows varying maturity levels across players. Industry leaders like Air Products & Chemicals, Air Liquide, and Topsoe demonstrate advanced capabilities with commercial-scale implementations, while Shell, Saudi Aramco, and Praxair are making significant R&D investments. Academic institutions including King Fahd University and University of Southern California are contributing fundamental research, while specialized firms like CompactGTL and Media & Process Technology are developing niche applications, creating a competitive landscape balanced between established corporations and innovative technology providers.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced membrane reactor technology for methane steam reforming that integrates hydrogen production and separation in a single unit. Their system utilizes palladium-based membranes that selectively extract hydrogen from the reaction mixture, shifting equilibrium toward higher methane conversion and hydrogen yield. The company's ITM (Ion Transport Membrane) technology operates at temperatures of 800-900°C and incorporates specialized catalysts to enhance reaction kinetics while minimizing carbon formation. Their membrane reactors feature a modular design that can be scaled according to production requirements, with reported hydrogen recovery rates exceeding 95% and methane conversion improvements of 15-25% compared to conventional reforming processes. Air Products has also developed proprietary membrane materials with enhanced thermal stability and resistance to sulfur poisoning, extending operational lifetimes to over 10,000 hours in industrial settings.

Strengths: High hydrogen selectivity and recovery rates; improved process efficiency through equilibrium shift; reduced capital costs through process intensification; modular and scalable design. Weaknesses: Membrane durability challenges in harsh operating conditions; higher operating temperatures required for effective permeation; potential for membrane fouling in industrial environments; relatively high manufacturing costs for specialized membrane materials.

Air Liquide SA

Technical Solution: Air Liquide has pioneered a comprehensive membrane reactor system for methane steam reforming that combines catalytic activity with hydrogen separation functionality. Their technology employs ceramic-supported thin palladium-silver alloy membranes with thickness below 5 μm, achieving hydrogen permeation fluxes of 0.5-1.0 mol/m²·s at operating temperatures of 550-650°C. The company's approach integrates specialized nickel-based catalysts with promoters that enhance activity while minimizing carbon deposition. Air Liquide's membrane reactors feature a unique tube-and-shell configuration that optimizes heat transfer and reaction kinetics, resulting in methane conversion rates exceeding 95% at lower temperatures than conventional reforming. Their system incorporates advanced sealing technologies that maintain integrity under thermal cycling and pressure differentials up to 2.5 MPa. The company has demonstrated successful pilot-scale implementation with capacities of 50-100 Nm³/h of hydrogen production, achieving energy efficiency improvements of approximately 20% compared to conventional steam reforming processes.

Strengths: Significant energy efficiency improvements; operation at lower temperatures than conventional reforming; high hydrogen purity (>99.999%); reduced CO₂ emissions through process intensification. Weaknesses: Higher capital costs compared to conventional technologies; membrane mechanical stability concerns during pressure and temperature fluctuations; sensitivity to feed impurities that can poison catalysts or membranes; complex system integration requirements.

Critical Patents and Technical Literature Review

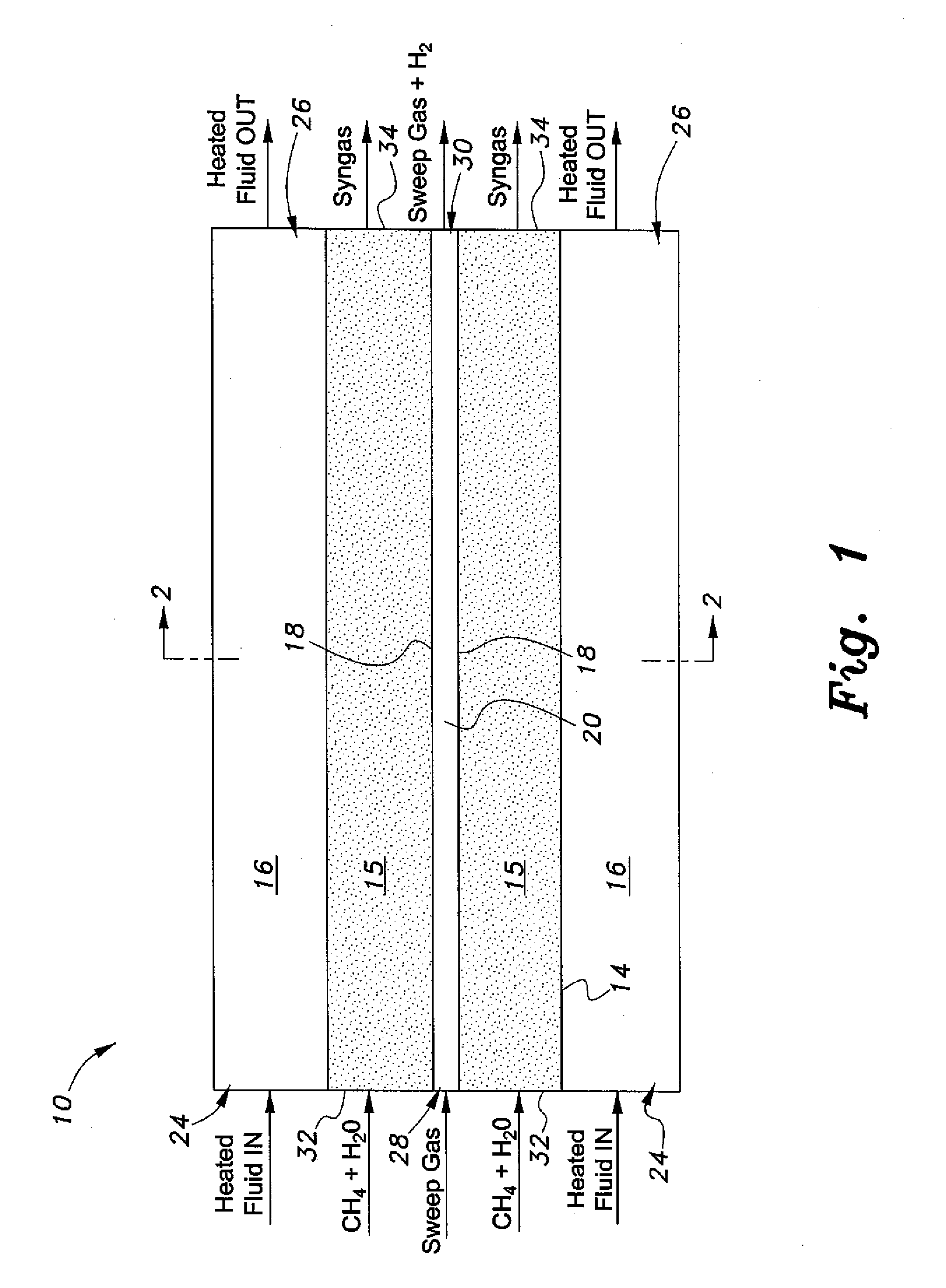

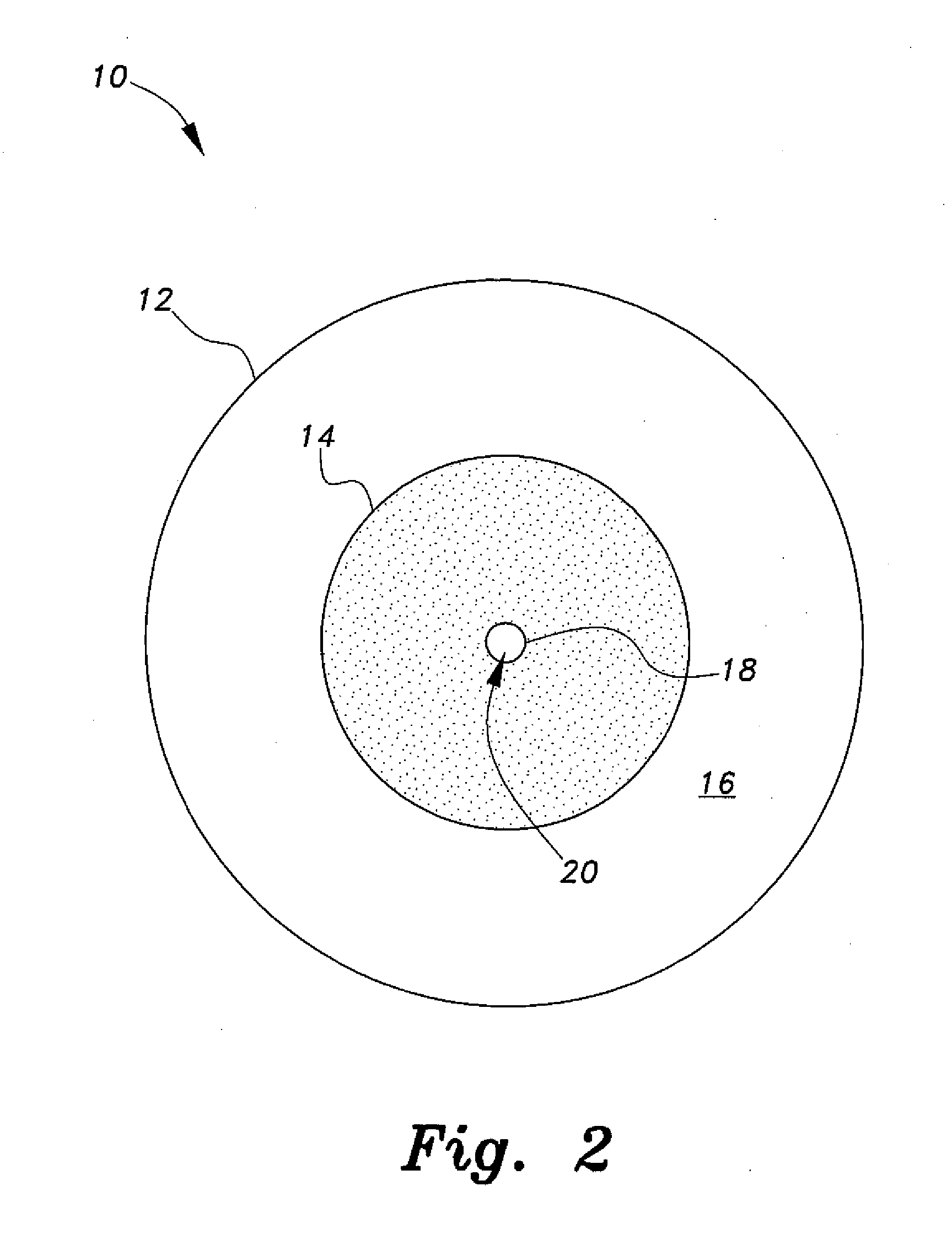

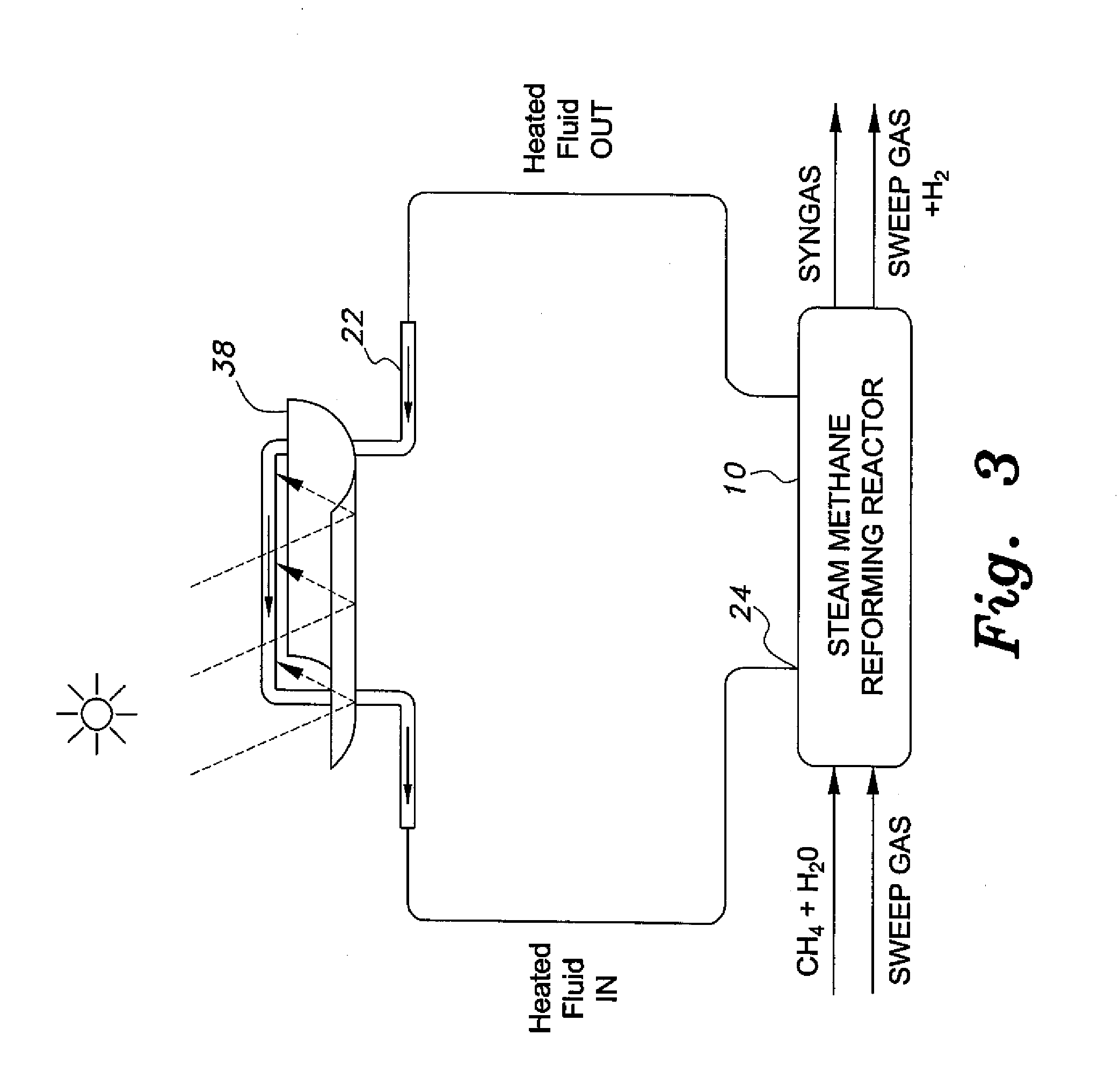

Steam methane reforming reactor with hydrogen selective membrane

PatentInactiveUS20160340187A1

Innovation

- A steam methane reforming reactor equipped with a hydrogen selective membrane, made from materials like palladium alloys, that enhances methane conversion by allowing hydrogen permeation and using a sweep gas and catalysts like nickel or magnesium aluminate, while being heated by a medium such as molten salt or flue gas, shifting the equilibrium towards higher conversion rates.

Integrated membrane and steam reformer for hydrogen production

PatentPendingCA3184162A1

Innovation

- A system integrating a membrane separation unit to remove bulk impurities and utilize the permeate as supplemental fuel for the steam reformer, combined with a water-gas shift and pressure swing adsorption unit to produce a high-purity hydrogen stream, reducing the need for costly multi-stage impurity separation and optimizing fuel usage.

Techno-economic Assessment of Membrane Reactor Systems

The techno-economic assessment of membrane reactor systems for methane steam reforming reveals significant potential for industrial implementation. Economic analyses indicate that membrane reactors can achieve 15-25% lower hydrogen production costs compared to conventional reforming technologies, primarily due to reduced energy consumption and higher conversion efficiencies. Capital expenditure for membrane reactor systems typically ranges from $1,500-2,500 per kW of hydrogen production capacity, with palladium-based membrane systems representing 20-30% of total system costs.

Operational expenditures show favorable trends, with membrane reactors demonstrating 10-15% lower maintenance costs and 20-30% reduced energy requirements compared to conventional systems. The economic sensitivity analysis identifies membrane longevity as the most critical factor affecting long-term viability, with current membrane lifespans ranging from 1,000-5,000 hours requiring extension to 8,000+ hours for optimal economic performance.

Return on investment calculations indicate payback periods of 3-5 years for industrial-scale implementations, contingent upon hydrogen market prices remaining above $2/kg. The levelized cost of hydrogen production using membrane reactor technology currently ranges from $1.60-2.20/kg, approaching cost competitiveness with conventional steam methane reforming ($1.25-1.80/kg).

Scale-up economics demonstrate favorable trends, with cost reductions of approximately 15% achievable when scaling from pilot (50 kg H₂/day) to commercial scale (1,000+ kg H₂/day) operations. However, the economic assessment highlights that membrane manufacturing costs must decrease by at least 30% to achieve widespread commercial viability.

Risk assessment identifies membrane degradation rates and feedstock price volatility as the primary economic uncertainties. Sensitivity analysis shows that a 10% increase in natural gas prices translates to approximately 7% increase in hydrogen production costs, while membrane performance degradation of 1% per 100 hours increases production costs by approximately 3%.

The comparative economic analysis against alternative hydrogen production technologies (electrolysis, coal gasification) positions membrane reactors favorably in scenarios with moderate natural gas prices and carbon taxation policies. Under current market conditions, membrane reactor systems demonstrate a 10-15% cost advantage over alkaline electrolysis and comparable costs to advanced coal gasification with carbon capture.

Operational expenditures show favorable trends, with membrane reactors demonstrating 10-15% lower maintenance costs and 20-30% reduced energy requirements compared to conventional systems. The economic sensitivity analysis identifies membrane longevity as the most critical factor affecting long-term viability, with current membrane lifespans ranging from 1,000-5,000 hours requiring extension to 8,000+ hours for optimal economic performance.

Return on investment calculations indicate payback periods of 3-5 years for industrial-scale implementations, contingent upon hydrogen market prices remaining above $2/kg. The levelized cost of hydrogen production using membrane reactor technology currently ranges from $1.60-2.20/kg, approaching cost competitiveness with conventional steam methane reforming ($1.25-1.80/kg).

Scale-up economics demonstrate favorable trends, with cost reductions of approximately 15% achievable when scaling from pilot (50 kg H₂/day) to commercial scale (1,000+ kg H₂/day) operations. However, the economic assessment highlights that membrane manufacturing costs must decrease by at least 30% to achieve widespread commercial viability.

Risk assessment identifies membrane degradation rates and feedstock price volatility as the primary economic uncertainties. Sensitivity analysis shows that a 10% increase in natural gas prices translates to approximately 7% increase in hydrogen production costs, while membrane performance degradation of 1% per 100 hours increases production costs by approximately 3%.

The comparative economic analysis against alternative hydrogen production technologies (electrolysis, coal gasification) positions membrane reactors favorably in scenarios with moderate natural gas prices and carbon taxation policies. Under current market conditions, membrane reactor systems demonstrate a 10-15% cost advantage over alkaline electrolysis and comparable costs to advanced coal gasification with carbon capture.

Environmental Impact and Carbon Footprint Reduction Potential

Membrane reactor integration for methane steam reforming represents a significant advancement in hydrogen production technology with substantial environmental benefits. The integration of membrane technology into traditional steam reforming processes offers remarkable potential for reducing greenhouse gas emissions, particularly carbon dioxide, which is a major contributor to global warming.

The conventional methane steam reforming process is energy-intensive and generates considerable CO2 emissions, approximately 9-10 kg CO2 per kg of hydrogen produced. By incorporating selective hydrogen permeable membranes, the integrated system can achieve in-situ hydrogen separation, shifting reaction equilibrium favorably and enabling operation at lower temperatures. This temperature reduction translates directly to decreased energy consumption and lower associated carbon emissions.

Studies indicate that membrane reactor integration can reduce the carbon footprint of hydrogen production by 20-30% compared to conventional methods. This reduction stems from both improved process efficiency and the ability to capture concentrated CO2 streams more effectively, facilitating carbon capture and storage (CCS) implementation.

The environmental benefits extend beyond carbon emissions. Membrane reactors typically require smaller plant footprints, reducing land use impact and associated ecosystem disruption. The more efficient conversion of methane also means less natural gas consumption per unit of hydrogen produced, conserving this finite fossil resource.

Water usage represents another environmental dimension where membrane reactors offer advantages. The integrated process demonstrates improved water efficiency, with some configurations showing 15-25% reduction in water consumption compared to conventional steam reforming operations. This aspect becomes increasingly important as water scarcity concerns grow globally.

From a life cycle assessment perspective, membrane reactor technology demonstrates favorable environmental performance across multiple impact categories. Beyond greenhouse gas reduction, these systems show decreased potential for acidification, eutrophication, and photochemical ozone creation when compared to traditional hydrogen production methods.

The technology also creates pathways for renewable integration. As membrane materials advance, opportunities emerge for coupling these systems with renewable energy sources for process heating, potentially creating near-zero emission hydrogen production routes when combined with biogas feedstocks or renewable electricity inputs.

For industrial implementation, membrane reactor integration offers a transitional technology that can significantly reduce the environmental impact of hydrogen production while more radical zero-carbon alternatives continue developing toward commercial viability. This positions the technology as an important stepping stone in the decarbonization journey of industrial hydrogen production.

The conventional methane steam reforming process is energy-intensive and generates considerable CO2 emissions, approximately 9-10 kg CO2 per kg of hydrogen produced. By incorporating selective hydrogen permeable membranes, the integrated system can achieve in-situ hydrogen separation, shifting reaction equilibrium favorably and enabling operation at lower temperatures. This temperature reduction translates directly to decreased energy consumption and lower associated carbon emissions.

Studies indicate that membrane reactor integration can reduce the carbon footprint of hydrogen production by 20-30% compared to conventional methods. This reduction stems from both improved process efficiency and the ability to capture concentrated CO2 streams more effectively, facilitating carbon capture and storage (CCS) implementation.

The environmental benefits extend beyond carbon emissions. Membrane reactors typically require smaller plant footprints, reducing land use impact and associated ecosystem disruption. The more efficient conversion of methane also means less natural gas consumption per unit of hydrogen produced, conserving this finite fossil resource.

Water usage represents another environmental dimension where membrane reactors offer advantages. The integrated process demonstrates improved water efficiency, with some configurations showing 15-25% reduction in water consumption compared to conventional steam reforming operations. This aspect becomes increasingly important as water scarcity concerns grow globally.

From a life cycle assessment perspective, membrane reactor technology demonstrates favorable environmental performance across multiple impact categories. Beyond greenhouse gas reduction, these systems show decreased potential for acidification, eutrophication, and photochemical ozone creation when compared to traditional hydrogen production methods.

The technology also creates pathways for renewable integration. As membrane materials advance, opportunities emerge for coupling these systems with renewable energy sources for process heating, potentially creating near-zero emission hydrogen production routes when combined with biogas feedstocks or renewable electricity inputs.

For industrial implementation, membrane reactor integration offers a transitional technology that can significantly reduce the environmental impact of hydrogen production while more radical zero-carbon alternatives continue developing toward commercial viability. This positions the technology as an important stepping stone in the decarbonization journey of industrial hydrogen production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!