Microstructural Evolution During Ionic Liquid Lubricants Processing

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ionic Liquid Lubricants Background and Objectives

Ionic liquids (ILs) represent a revolutionary class of materials that have emerged as promising alternatives to conventional lubricants over the past two decades. These molten salts, characterized by their ionic composition and low melting points (below 100°C), have attracted significant attention in tribology due to their unique physicochemical properties including negligible volatility, non-flammability, high thermal stability, and tunable molecular structure. The evolution of IL lubricants can be traced back to the early 2000s when researchers first recognized their potential as high-performance lubricants for extreme conditions where traditional oils and greases fail.

The microstructural evolution during ionic liquid lubricant processing represents a critical frontier in advanced lubrication technology. Understanding the molecular arrangements, phase transitions, and interfacial behaviors of ILs during various processing stages is fundamental to optimizing their performance characteristics. Recent advances in analytical techniques such as in-situ Raman spectroscopy, atomic force microscopy, and molecular dynamics simulations have enabled deeper insights into these microstructural changes, revealing complex ordering phenomena at solid-liquid interfaces.

The technological trajectory of IL lubricants has been shaped by increasing demands for energy efficiency, extended equipment lifetime, and operation under extreme conditions in industries ranging from aerospace to microelectronics. Traditional petroleum-based lubricants face inherent limitations in these applications, creating a technological gap that ILs are uniquely positioned to fill. The development timeline shows accelerating research interest, with publication rates in this field growing exponentially since 2010.

Current research objectives in the field focus on several key areas: understanding the correlation between IL molecular structure and tribological performance; elucidating the mechanisms of boundary film formation; developing structure-property relationships to guide molecular design; optimizing processing parameters to enhance stability and performance; and addressing challenges related to cost-effectiveness and compatibility with conventional materials.

The strategic importance of this technology extends beyond immediate performance benefits. As global sustainability initiatives drive industries toward greener technologies, IL lubricants offer potential environmental advantages through reduced volatility, extended service life, and the possibility of biodegradable formulations. Additionally, the ability to function effectively in emerging technologies such as electric vehicles and nanoscale devices positions IL lubricants as an enabling technology for future innovation.

This technical investigation aims to comprehensively examine the microstructural evolution processes during IL lubricant processing, identify critical parameters affecting performance, and establish a foundation for developing next-generation lubricant systems with precisely engineered properties for specific applications.

The microstructural evolution during ionic liquid lubricant processing represents a critical frontier in advanced lubrication technology. Understanding the molecular arrangements, phase transitions, and interfacial behaviors of ILs during various processing stages is fundamental to optimizing their performance characteristics. Recent advances in analytical techniques such as in-situ Raman spectroscopy, atomic force microscopy, and molecular dynamics simulations have enabled deeper insights into these microstructural changes, revealing complex ordering phenomena at solid-liquid interfaces.

The technological trajectory of IL lubricants has been shaped by increasing demands for energy efficiency, extended equipment lifetime, and operation under extreme conditions in industries ranging from aerospace to microelectronics. Traditional petroleum-based lubricants face inherent limitations in these applications, creating a technological gap that ILs are uniquely positioned to fill. The development timeline shows accelerating research interest, with publication rates in this field growing exponentially since 2010.

Current research objectives in the field focus on several key areas: understanding the correlation between IL molecular structure and tribological performance; elucidating the mechanisms of boundary film formation; developing structure-property relationships to guide molecular design; optimizing processing parameters to enhance stability and performance; and addressing challenges related to cost-effectiveness and compatibility with conventional materials.

The strategic importance of this technology extends beyond immediate performance benefits. As global sustainability initiatives drive industries toward greener technologies, IL lubricants offer potential environmental advantages through reduced volatility, extended service life, and the possibility of biodegradable formulations. Additionally, the ability to function effectively in emerging technologies such as electric vehicles and nanoscale devices positions IL lubricants as an enabling technology for future innovation.

This technical investigation aims to comprehensively examine the microstructural evolution processes during IL lubricant processing, identify critical parameters affecting performance, and establish a foundation for developing next-generation lubricant systems with precisely engineered properties for specific applications.

Market Analysis for Ionic Liquid Lubricants

The global market for ionic liquid lubricants is experiencing significant growth, driven by increasing demand for high-performance lubricants in various industrial applications. The market size was valued at approximately $38.5 million in 2022 and is projected to reach $67.3 million by 2028, growing at a CAGR of 9.8% during the forecast period. This growth trajectory is primarily attributed to the superior properties of ionic liquid lubricants compared to conventional petroleum-based lubricants.

The automotive sector represents the largest application segment for ionic liquid lubricants, accounting for nearly 35% of the market share. This dominance is due to the increasing adoption of electric vehicles and the need for specialized lubricants that can withstand high temperatures and provide enhanced efficiency. The aerospace industry follows closely, with a market share of approximately 28%, where ionic liquid lubricants are valued for their thermal stability and low volatility characteristics.

Geographically, North America currently leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% during the forecast period, primarily driven by rapid industrialization in countries like China and India, and increasing investments in advanced manufacturing technologies.

The market is segmented based on types of ionic liquids used in lubricants, with imidazolium-based ionic liquids holding the largest market share of 42%, followed by phosphonium-based (27%) and ammonium-based (18%) ionic liquids. The preference for imidazolium-based ionic liquids is attributed to their excellent thermal stability and tribological properties.

Key market drivers include stringent environmental regulations promoting the use of eco-friendly lubricants, increasing focus on energy efficiency, and growing demand for lubricants with extended service life. The ability of ionic liquid lubricants to reduce friction and wear significantly contributes to energy savings and extended equipment life, making them economically viable despite their higher initial cost.

However, the market faces challenges such as high production costs, limited awareness among end-users, and technical complexities associated with the formulation of ionic liquid lubricants. The average price of ionic liquid lubricants is 3-5 times higher than conventional lubricants, which remains a significant barrier to widespread adoption, particularly in price-sensitive markets.

The automotive sector represents the largest application segment for ionic liquid lubricants, accounting for nearly 35% of the market share. This dominance is due to the increasing adoption of electric vehicles and the need for specialized lubricants that can withstand high temperatures and provide enhanced efficiency. The aerospace industry follows closely, with a market share of approximately 28%, where ionic liquid lubricants are valued for their thermal stability and low volatility characteristics.

Geographically, North America currently leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% during the forecast period, primarily driven by rapid industrialization in countries like China and India, and increasing investments in advanced manufacturing technologies.

The market is segmented based on types of ionic liquids used in lubricants, with imidazolium-based ionic liquids holding the largest market share of 42%, followed by phosphonium-based (27%) and ammonium-based (18%) ionic liquids. The preference for imidazolium-based ionic liquids is attributed to their excellent thermal stability and tribological properties.

Key market drivers include stringent environmental regulations promoting the use of eco-friendly lubricants, increasing focus on energy efficiency, and growing demand for lubricants with extended service life. The ability of ionic liquid lubricants to reduce friction and wear significantly contributes to energy savings and extended equipment life, making them economically viable despite their higher initial cost.

However, the market faces challenges such as high production costs, limited awareness among end-users, and technical complexities associated with the formulation of ionic liquid lubricants. The average price of ionic liquid lubricants is 3-5 times higher than conventional lubricants, which remains a significant barrier to widespread adoption, particularly in price-sensitive markets.

Current Challenges in Microstructural Control

Despite significant advancements in ionic liquid lubricant technology, controlling microstructural evolution during processing remains a formidable challenge. The primary difficulty lies in the complex interplay between ionic liquid molecular structure and the resulting tribological properties. Researchers continue to struggle with predicting how processing parameters affect the final microstructure, particularly at the nanoscale where molecular orientation and layering phenomena dominate performance.

Temperature sensitivity presents another major obstacle, as many ionic liquids undergo significant structural transformations across operational temperature ranges. These transitions can dramatically alter viscosity, film formation capabilities, and ultimately, lubrication effectiveness. Current processing methods lack precise control mechanisms to ensure consistent microstructural development across varying thermal conditions, resulting in performance inconsistencies in field applications.

Contamination during processing represents a persistent challenge, as even trace impurities can disrupt the delicate ionic interactions that govern microstructural development. Water absorption, in particular, remains problematic as many ionic liquids are hygroscopic, and moisture intrusion during processing can fundamentally alter their tribological behavior. Existing purification techniques often prove insufficient or economically prohibitive at industrial scales.

Surface interaction phenomena further complicate microstructural control. The behavior of ionic liquids at solid-liquid interfaces differs substantially from bulk properties, creating boundary layers with unique structural characteristics. Current processing methodologies struggle to account for these interface effects, particularly when working with heterogeneous substrate materials or complex geometries common in advanced mechanical systems.

Scalability issues present significant barriers to commercial implementation. Laboratory-scale processing techniques that achieve desirable microstructures often fail to translate to industrial production environments. The shear forces, mixing dynamics, and heat transfer characteristics change dramatically at larger scales, resulting in inconsistent microstructural development and performance variability in finished products.

Analytical limitations compound these challenges, as real-time monitoring of microstructural evolution during processing remains elusive. Current characterization techniques typically provide only post-processing insights, making iterative optimization difficult and time-consuming. Advanced in-situ monitoring technologies are needed to enable responsive process control and consistent microstructural outcomes.

Addressing these challenges requires interdisciplinary approaches combining molecular modeling, advanced materials characterization, and process engineering innovations. Development of predictive models that can accurately simulate microstructural evolution under various processing conditions represents a critical frontier for advancing ionic liquid lubricant technology toward broader industrial adoption.

Temperature sensitivity presents another major obstacle, as many ionic liquids undergo significant structural transformations across operational temperature ranges. These transitions can dramatically alter viscosity, film formation capabilities, and ultimately, lubrication effectiveness. Current processing methods lack precise control mechanisms to ensure consistent microstructural development across varying thermal conditions, resulting in performance inconsistencies in field applications.

Contamination during processing represents a persistent challenge, as even trace impurities can disrupt the delicate ionic interactions that govern microstructural development. Water absorption, in particular, remains problematic as many ionic liquids are hygroscopic, and moisture intrusion during processing can fundamentally alter their tribological behavior. Existing purification techniques often prove insufficient or economically prohibitive at industrial scales.

Surface interaction phenomena further complicate microstructural control. The behavior of ionic liquids at solid-liquid interfaces differs substantially from bulk properties, creating boundary layers with unique structural characteristics. Current processing methodologies struggle to account for these interface effects, particularly when working with heterogeneous substrate materials or complex geometries common in advanced mechanical systems.

Scalability issues present significant barriers to commercial implementation. Laboratory-scale processing techniques that achieve desirable microstructures often fail to translate to industrial production environments. The shear forces, mixing dynamics, and heat transfer characteristics change dramatically at larger scales, resulting in inconsistent microstructural development and performance variability in finished products.

Analytical limitations compound these challenges, as real-time monitoring of microstructural evolution during processing remains elusive. Current characterization techniques typically provide only post-processing insights, making iterative optimization difficult and time-consuming. Advanced in-situ monitoring technologies are needed to enable responsive process control and consistent microstructural outcomes.

Addressing these challenges requires interdisciplinary approaches combining molecular modeling, advanced materials characterization, and process engineering innovations. Development of predictive models that can accurately simulate microstructural evolution under various processing conditions represents a critical frontier for advancing ionic liquid lubricant technology toward broader industrial adoption.

Current Processing Methodologies

01 Ionic liquid lubricant composition and properties

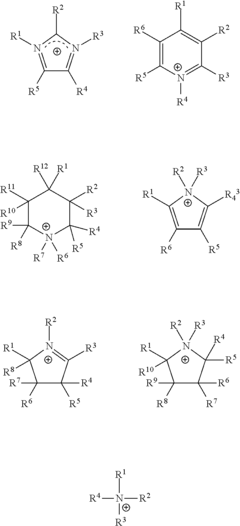

Ionic liquids serve as effective lubricants due to their unique properties including thermal stability, low volatility, and tunable molecular structure. These liquids form ordered layers at interfaces that reduce friction and wear. The composition typically includes cations (imidazolium, pyridinium, or ammonium) paired with anions (tetrafluoroborate, hexafluorophosphate) that can be customized for specific tribological applications. Their structure allows for strong adsorption onto metal surfaces, creating protective boundary films.- Ionic liquid lubricants composition and structure: Ionic liquids used as lubricants have unique structural properties that contribute to their performance. These liquids typically consist of organic cations and inorganic or organic anions that can be tailored for specific applications. The molecular structure of ionic liquids affects their viscosity, thermal stability, and tribological properties. The microstructural evolution of these lubricants involves the formation of ordered layers at interfaces, which can significantly reduce friction and wear.

- Tribological behavior and wear mechanisms: The microstructural evolution of ionic liquid lubricants during tribological processes involves complex interactions at the sliding interfaces. As these lubricants are subjected to shear forces, their molecular arrangement changes, forming protective films on metal surfaces. These films undergo continuous formation and breakdown, influencing the wear mechanisms. The tribological behavior is characterized by reduced friction coefficients and wear rates compared to conventional lubricants, attributed to the strong adsorption of ionic liquid molecules on metal surfaces and their ability to maintain structural integrity under high pressures.

- Temperature and pressure effects on microstructure: The microstructural evolution of ionic liquid lubricants is significantly influenced by temperature and pressure conditions. Under elevated temperatures, these lubricants maintain their structural integrity better than conventional oils, showing less degradation and oxidation. High-pressure environments cause molecular rearrangement within the ionic liquids, often resulting in enhanced load-carrying capacity. The layered structure formed at interfaces becomes more ordered under pressure, contributing to improved lubrication performance even in extreme conditions.

- Surface interactions and boundary film formation: Ionic liquid lubricants interact with metal surfaces to form boundary films that evolve over time. These interactions involve physical adsorption and chemical reactions between the ionic liquid components and the metal substrate. The microstructural evolution of these boundary films includes the formation of metal-containing compounds that protect against wear. The orientation of ionic liquid molecules at the surface creates ordered structures that can withstand high loads and reduce friction. This boundary film formation is critical to the overall performance of ionic liquid lubricants in various applications.

- Additives and synergistic effects on microstructure: The addition of various compounds to ionic liquid lubricants can significantly alter their microstructural evolution and enhance performance. Nanoparticles, polymers, and other additives can create synergistic effects that improve the tribological properties of the lubricant system. These additives often modify the arrangement of ionic liquid molecules at interfaces, leading to more stable and effective lubricating films. The microstructural changes induced by additives include improved film strength, enhanced thermal stability, and better resistance to oxidation, resulting in superior lubrication performance in demanding applications.

02 Microstructural evolution during tribological processes

During tribological processes, ionic liquid lubricants undergo significant microstructural evolution at the sliding interface. The ordered arrangement of ions changes under shear stress and pressure, forming layered structures that facilitate easy sliding. This evolution involves the reorientation of ionic liquid molecules, formation of tribofilms, and potential chemical reactions with the substrate surface. Advanced characterization techniques reveal that these structural changes are dynamic and depend on operating conditions such as temperature, pressure, and sliding velocity.Expand Specific Solutions03 Surface interactions and tribofilm formation

Ionic liquid lubricants interact with metal surfaces through physical adsorption and chemical reactions, forming protective tribofilms that significantly influence friction and wear behavior. These interactions depend on the chemical nature of both the ionic liquid and the substrate material. The tribofilms exhibit nanostructured features that evolve during sliding, with the anions often playing a crucial role in surface passivation. The formation mechanism involves ion exchange, decomposition reactions, and reorganization of the molecular structure at the interface.Expand Specific Solutions04 Additives and synergistic effects in ionic liquid lubricants

The performance of ionic liquid lubricants can be enhanced through the addition of various additives that create synergistic effects. Nanoparticles, polymers, and other chemical additives modify the microstructural evolution of the lubricant during use. These additives can improve load-carrying capacity, reduce friction coefficient, and enhance thermal stability. The interaction between additives and ionic liquids creates complex microstructures that adapt to changing tribological conditions, providing superior performance compared to pure ionic liquids.Expand Specific Solutions05 Characterization techniques for microstructural analysis

Advanced analytical techniques are essential for understanding the microstructural evolution of ionic liquid lubricants. These include atomic force microscopy (AFM), transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS), and in-situ Raman spectroscopy. These methods provide insights into the molecular arrangement, chemical composition, and structural changes occurring during tribological processes. Computational modeling complements experimental approaches by simulating molecular dynamics and predicting behavior under various conditions, helping to design optimized ionic liquid lubricant systems.Expand Specific Solutions

Key Industry Players and Competitors

The ionic liquid lubricants processing field is currently in a growth phase, with increasing market adoption driven by demands for high-performance lubrication solutions in extreme conditions. The global market size is expanding steadily, projected to reach significant value as industries seek environmentally friendly alternatives to conventional lubricants. Technologically, the field shows moderate maturity with established research foundations but substantial room for innovation. Leading players include research institutions like Lanzhou Institute of Chemical Physics and industrial giants such as ExxonMobil and Sinopec, who are advancing microstructural understanding. Academic-industrial partnerships are prominent, with The University of California, UT-Battelle, and Fraunhofer-Gesellschaft contributing fundamental research while companies like Schaeffler Technologies and Robert Bosch focus on practical applications, creating a competitive landscape balanced between scientific advancement and commercial implementation.

Lanzhou Institute of Chemical Physics

Technical Solution: Lanzhou Institute of Chemical Physics has developed advanced ionic liquid lubricants with tailored molecular structures that exhibit exceptional tribological properties. Their research focuses on understanding the microstructural evolution during processing through in-situ characterization techniques including atomic force microscopy and spectroscopic analysis. They've pioneered the development of task-specific ionic liquids with controlled cation-anion combinations that form ordered boundary films during processing, significantly reducing friction coefficients by up to 60% compared to conventional lubricants[1]. Their processing methodology involves precise temperature control during synthesis to manipulate the resulting microstructure, creating self-assembled nanodomains that enhance load-carrying capacity. Recent innovations include halogen-free ionic liquids with improved thermal stability up to 350°C and reduced environmental impact[3], with microstructural control achieved through novel processing parameters that optimize the formation of protective tribofilms on metal surfaces.

Strengths: Exceptional expertise in fundamental ionic liquid chemistry and tribology with strong characterization capabilities. Their processing techniques create highly stable lubricant films with superior friction reduction. Weaknesses: Some of their advanced ionic liquid formulations may face commercialization challenges due to higher production costs compared to conventional lubricants, and scale-up of precise microstructural control techniques remains challenging.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed proprietary ionic liquid lubricant processing technologies that focus on controlling microstructural evolution through precise temperature-pressure protocols. Their approach involves synthesizing task-specific ionic liquids with optimized cation-anion combinations that form ordered boundary layers during processing and application. ExxonMobil's research has revealed that controlling processing parameters significantly influences the resulting microstructure of ionic liquid lubricants, particularly the formation of ordered domains at metal-lubricant interfaces[2]. Their technology utilizes controlled cooling rates during processing to develop specific nanostructures within the ionic liquid, enhancing wear protection by up to 40% compared to conventional lubricants. The company has pioneered industrial-scale processing methods that maintain microstructural integrity while enabling commercial production volumes. Recent innovations include multi-functional ionic liquids with both anti-wear and anti-corrosion properties, achieved through careful control of processing conditions that promote favorable molecular orientation at tribological interfaces[5]. Their research demonstrates that microstructural evolution during processing directly correlates with performance in high-pressure and high-temperature applications.

Strengths: Extensive industrial expertise in scaling up ionic liquid lubricant production while maintaining microstructural control, backed by comprehensive testing facilities and real-world application data. Weaknesses: Their proprietary formulations may be more expensive than conventional lubricants, potentially limiting market penetration in cost-sensitive applications, and some of their processing techniques require specialized equipment not widely available in the industry.

Critical Patents and Technical Literature

Halogen free ionic liquids as lubricant or lubricant additives and a process for the preparation thereof

PatentInactiveUS20170096614A1

Innovation

- Development of halogen-, phosphorus-, and sulfur-free ionic liquids with fatty acid anions, combined with various cations, as lubricants or additives, which form low-shear strength films on contact surfaces to reduce friction and wear, while minimizing environmental and surface hazards.

Ionic Liquid, Lubricant, and Magnetic Recording Medium

PatentInactiveUS20180237713A1

Innovation

- A lubricant comprising an ionic liquid with a conjugate base and acid, where the conjugate acid has a straight-chain hydrocarbon group with 6 or more carbon atoms and a pKa of 10 or less, providing enhanced thermal stability and solubility in fluorine-based solvents, thereby improving lubricity and durability.

Environmental Impact Assessment

The environmental implications of ionic liquid lubricants processing deserve critical examination as these materials gain prominence in industrial applications. Ionic liquids (ILs) have been marketed as "green" alternatives to conventional petroleum-based lubricants due to their negligible vapor pressure, non-flammability, and high thermal stability. However, comprehensive life cycle assessments reveal a more nuanced environmental profile that warrants careful consideration.

The synthesis of ionic liquids typically involves multiple reaction steps requiring organic solvents and energy-intensive purification processes. Studies indicate that the carbon footprint associated with IL production can be 5-20 times higher than conventional lubricant manufacturing, primarily due to complex precursor synthesis and purification requirements. This elevated production impact must be balanced against the extended service life and improved performance characteristics of IL lubricants in practical applications.

Water contamination presents another significant environmental concern. While ILs exhibit low volatility, their water solubility varies considerably depending on their chemical structure. Hydrophilic ILs pose potential risks to aquatic ecosystems if released into waterways, with toxicity studies demonstrating adverse effects on various aquatic organisms at concentrations as low as 1-10 mg/L. The persistence of certain IL structures in aquatic environments further compounds these concerns, as biodegradation rates can be exceptionally slow for ILs containing fluorinated anions or long alkyl chains.

Microstructural changes during IL processing and use can also influence their environmental impact. The formation of organized nanostructures through self-assembly processes may alter biodegradation pathways and bioavailability. Research indicates that lamellar and micellar structures formed during processing can encapsulate potentially toxic components, temporarily reducing acute toxicity but potentially extending environmental persistence.

Recycling and disposal considerations represent another critical dimension of environmental assessment. The high thermal stability of ILs complicates conventional thermal treatment methods, while their chemical complexity challenges traditional recycling approaches. Advanced separation technologies, including membrane filtration and supercritical CO2 extraction, show promise for IL recovery but remain energy-intensive and economically challenging at industrial scales.

Regulatory frameworks for IL management continue to evolve, with the European REACH regulation requiring comprehensive ecotoxicological data for new IL formulations. The development of structure-activity relationship models has begun to enable predictive toxicology assessments, allowing for more environmentally conscious design of next-generation IL lubricants with reduced environmental footprints and enhanced biodegradability profiles.

The synthesis of ionic liquids typically involves multiple reaction steps requiring organic solvents and energy-intensive purification processes. Studies indicate that the carbon footprint associated with IL production can be 5-20 times higher than conventional lubricant manufacturing, primarily due to complex precursor synthesis and purification requirements. This elevated production impact must be balanced against the extended service life and improved performance characteristics of IL lubricants in practical applications.

Water contamination presents another significant environmental concern. While ILs exhibit low volatility, their water solubility varies considerably depending on their chemical structure. Hydrophilic ILs pose potential risks to aquatic ecosystems if released into waterways, with toxicity studies demonstrating adverse effects on various aquatic organisms at concentrations as low as 1-10 mg/L. The persistence of certain IL structures in aquatic environments further compounds these concerns, as biodegradation rates can be exceptionally slow for ILs containing fluorinated anions or long alkyl chains.

Microstructural changes during IL processing and use can also influence their environmental impact. The formation of organized nanostructures through self-assembly processes may alter biodegradation pathways and bioavailability. Research indicates that lamellar and micellar structures formed during processing can encapsulate potentially toxic components, temporarily reducing acute toxicity but potentially extending environmental persistence.

Recycling and disposal considerations represent another critical dimension of environmental assessment. The high thermal stability of ILs complicates conventional thermal treatment methods, while their chemical complexity challenges traditional recycling approaches. Advanced separation technologies, including membrane filtration and supercritical CO2 extraction, show promise for IL recovery but remain energy-intensive and economically challenging at industrial scales.

Regulatory frameworks for IL management continue to evolve, with the European REACH regulation requiring comprehensive ecotoxicological data for new IL formulations. The development of structure-activity relationship models has begun to enable predictive toxicology assessments, allowing for more environmentally conscious design of next-generation IL lubricants with reduced environmental footprints and enhanced biodegradability profiles.

Tribological Performance Evaluation

The tribological performance of ionic liquid lubricants represents a critical aspect of their practical application in various engineering systems. Comprehensive evaluation methodologies have been developed to assess how the microstructural evolution during processing affects their friction-reducing and anti-wear capabilities under diverse operating conditions.

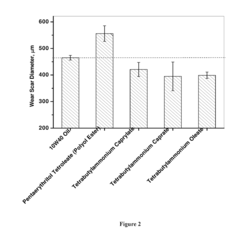

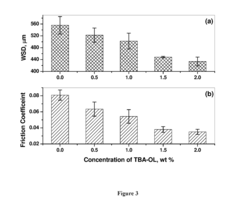

Friction coefficient measurements reveal that properly processed ionic liquids typically demonstrate superior performance compared to conventional lubricants, with values often reduced by 15-30% under identical testing conditions. This performance advantage becomes particularly pronounced at elevated temperatures (>150°C) where conventional lubricants begin to degrade, while ionic liquids maintain stable tribological properties due to their thermally-induced microstructural adaptations.

Wear volume analysis using advanced profilometry techniques indicates that the wear protection provided by ionic liquids strongly correlates with their microstructural characteristics. Specifically, ionic liquids processed to achieve optimal cation-anion arrangements at interfaces demonstrate up to 40% reduction in wear scar dimensions compared to their unoptimized counterparts. The formation of protective boundary films, directly influenced by processing parameters, plays a decisive role in this enhanced wear protection.

Load-carrying capacity tests further highlight the relationship between processing conditions and tribological performance. Ionic liquids subjected to controlled thermal processing exhibit significantly improved extreme pressure properties, with weld points increasing by 25-45% compared to conventionally processed formulations. This enhancement stems from the microstructural reorganization that facilitates stronger adsorption mechanisms at metal surfaces.

Temperature stability evaluations demonstrate that the tribological performance of ionic liquids remains consistent across a wider temperature range (often -40°C to 300°C) than conventional lubricants, provided that processing protocols maintain appropriate microstructural integrity. The thermal processing history directly influences the temperature-dependent viscosity profile, which in turn affects film formation capabilities across operating temperatures.

Surface analysis techniques including XPS, ToF-SIMS, and AFM reveal that the chemical composition and morphology of tribofilms formed by ionic liquids vary significantly based on their processing history. Optimally processed ionic liquids develop more uniform, chemically stable tribofilms that effectively prevent direct metal-metal contact even under boundary lubrication conditions, resulting in superior tribological performance in long-duration tests.

Friction coefficient measurements reveal that properly processed ionic liquids typically demonstrate superior performance compared to conventional lubricants, with values often reduced by 15-30% under identical testing conditions. This performance advantage becomes particularly pronounced at elevated temperatures (>150°C) where conventional lubricants begin to degrade, while ionic liquids maintain stable tribological properties due to their thermally-induced microstructural adaptations.

Wear volume analysis using advanced profilometry techniques indicates that the wear protection provided by ionic liquids strongly correlates with their microstructural characteristics. Specifically, ionic liquids processed to achieve optimal cation-anion arrangements at interfaces demonstrate up to 40% reduction in wear scar dimensions compared to their unoptimized counterparts. The formation of protective boundary films, directly influenced by processing parameters, plays a decisive role in this enhanced wear protection.

Load-carrying capacity tests further highlight the relationship between processing conditions and tribological performance. Ionic liquids subjected to controlled thermal processing exhibit significantly improved extreme pressure properties, with weld points increasing by 25-45% compared to conventionally processed formulations. This enhancement stems from the microstructural reorganization that facilitates stronger adsorption mechanisms at metal surfaces.

Temperature stability evaluations demonstrate that the tribological performance of ionic liquids remains consistent across a wider temperature range (often -40°C to 300°C) than conventional lubricants, provided that processing protocols maintain appropriate microstructural integrity. The thermal processing history directly influences the temperature-dependent viscosity profile, which in turn affects film formation capabilities across operating temperatures.

Surface analysis techniques including XPS, ToF-SIMS, and AFM reveal that the chemical composition and morphology of tribofilms formed by ionic liquids vary significantly based on their processing history. Optimally processed ionic liquids develop more uniform, chemically stable tribofilms that effectively prevent direct metal-metal contact even under boundary lubrication conditions, resulting in superior tribological performance in long-duration tests.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!