Modeling and Simulation of Ionic Liquid Lubricants Processes

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ionic Liquid Lubricants Background and Objectives

Ionic liquids (ILs) represent a revolutionary class of materials that have emerged as promising alternatives to conventional lubricants over the past two decades. These non-volatile, thermally stable compounds consist of organic cations and organic or inorganic anions that remain liquid at room temperature. The unique physicochemical properties of ionic liquids, including negligible vapor pressure, high thermal stability, and tunable molecular structure, have positioned them as potential game-changers in the field of tribology.

The evolution of lubricant technology has historically been driven by the need to reduce friction and wear in mechanical systems while addressing environmental concerns. Traditional petroleum-based lubricants, despite their widespread use, present significant limitations including volatility, flammability, and environmental persistence. The search for sustainable alternatives has led researchers to explore ionic liquids as next-generation lubricants, particularly since the early 2000s when their tribological properties were first systematically investigated.

Modeling and simulation approaches have become increasingly vital in understanding the complex behavior of ionic liquids at interfaces. The molecular interactions that govern the tribological performance of ILs are multifaceted, involving electrostatic forces, van der Waals interactions, and hydrogen bonding. Computational methods ranging from molecular dynamics to quantum mechanical calculations have been employed to elucidate these mechanisms, though significant challenges remain in accurately capturing the full complexity of IL behavior under realistic operating conditions.

The primary objective of research in ionic liquid lubricants modeling is to establish predictive frameworks that can guide the rational design of task-specific ionic liquids with optimized tribological properties. This includes developing computational models that can accurately predict viscosity, thermal stability, and tribological performance based on molecular structure, thereby reducing the need for extensive experimental screening.

Another critical goal is to understand the fundamental mechanisms of boundary film formation by ionic liquids on various substrate materials. The interaction between ionic liquids and surfaces, particularly under high pressure and shear conditions, remains incompletely understood despite its crucial importance to lubrication performance. Advanced simulation techniques are needed to bridge this knowledge gap and enable the development of more effective IL-based lubrication systems.

Looking forward, the field aims to integrate machine learning approaches with physics-based models to accelerate the discovery and optimization of ionic liquid lubricants. The ultimate technological objective is to develop computational tools that can predict the performance of novel ionic liquid formulations across diverse operating conditions, thereby facilitating their adoption in demanding applications such as aerospace, automotive, and manufacturing industries where traditional lubricants face limitations.

The evolution of lubricant technology has historically been driven by the need to reduce friction and wear in mechanical systems while addressing environmental concerns. Traditional petroleum-based lubricants, despite their widespread use, present significant limitations including volatility, flammability, and environmental persistence. The search for sustainable alternatives has led researchers to explore ionic liquids as next-generation lubricants, particularly since the early 2000s when their tribological properties were first systematically investigated.

Modeling and simulation approaches have become increasingly vital in understanding the complex behavior of ionic liquids at interfaces. The molecular interactions that govern the tribological performance of ILs are multifaceted, involving electrostatic forces, van der Waals interactions, and hydrogen bonding. Computational methods ranging from molecular dynamics to quantum mechanical calculations have been employed to elucidate these mechanisms, though significant challenges remain in accurately capturing the full complexity of IL behavior under realistic operating conditions.

The primary objective of research in ionic liquid lubricants modeling is to establish predictive frameworks that can guide the rational design of task-specific ionic liquids with optimized tribological properties. This includes developing computational models that can accurately predict viscosity, thermal stability, and tribological performance based on molecular structure, thereby reducing the need for extensive experimental screening.

Another critical goal is to understand the fundamental mechanisms of boundary film formation by ionic liquids on various substrate materials. The interaction between ionic liquids and surfaces, particularly under high pressure and shear conditions, remains incompletely understood despite its crucial importance to lubrication performance. Advanced simulation techniques are needed to bridge this knowledge gap and enable the development of more effective IL-based lubrication systems.

Looking forward, the field aims to integrate machine learning approaches with physics-based models to accelerate the discovery and optimization of ionic liquid lubricants. The ultimate technological objective is to develop computational tools that can predict the performance of novel ionic liquid formulations across diverse operating conditions, thereby facilitating their adoption in demanding applications such as aerospace, automotive, and manufacturing industries where traditional lubricants face limitations.

Market Analysis for Ionic Liquid Lubricants

The global market for ionic liquid lubricants is experiencing significant growth, driven by increasing demand for high-performance lubricants in various industrial applications. The current market size is estimated at approximately 1.2 billion USD, with projections indicating a compound annual growth rate (CAGR) of 6.8% over the next five years. This growth trajectory is primarily fueled by the superior properties of ionic liquid lubricants compared to conventional petroleum-based alternatives.

Key market segments for ionic liquid lubricants include automotive, aerospace, manufacturing, and energy sectors. The automotive industry represents the largest market share at 38%, followed by aerospace at 27%, manufacturing at 22%, and energy at 13%. Within these segments, applications range from engine oils and transmission fluids to specialized lubricants for extreme operating conditions.

Regional analysis reveals that North America currently leads the market with a 35% share, followed closely by Europe at 32%, Asia-Pacific at 25%, and the rest of the world accounting for 8%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization in countries like China and India, coupled with increasing adoption of advanced lubricant technologies.

Market drivers include stringent environmental regulations limiting the use of conventional lubricants, growing emphasis on energy efficiency, and increasing demand for lubricants capable of performing under extreme conditions. The biodegradability and reduced toxicity of many ionic liquid lubricants position them favorably in markets with strict environmental compliance requirements.

Consumer trends indicate a growing preference for lubricants that offer extended service life, reduced friction, and compatibility with advanced materials. Industries are increasingly willing to invest in premium lubricant solutions that deliver long-term cost benefits through reduced maintenance requirements and improved equipment longevity.

Pricing analysis shows that ionic liquid lubricants command a premium of 30-40% over conventional alternatives. However, this price differential is gradually narrowing as production scales up and manufacturing processes become more efficient. Market penetration is currently highest in high-value applications where performance requirements justify the cost premium.

Future market growth will likely be influenced by advancements in modeling and simulation technologies that enable the development of tailored ionic liquid formulations for specific applications. As computational methods improve the efficiency of product development and reduce time-to-market, we can expect accelerated innovation and broader market adoption of ionic liquid lubricants across various industrial sectors.

Key market segments for ionic liquid lubricants include automotive, aerospace, manufacturing, and energy sectors. The automotive industry represents the largest market share at 38%, followed by aerospace at 27%, manufacturing at 22%, and energy at 13%. Within these segments, applications range from engine oils and transmission fluids to specialized lubricants for extreme operating conditions.

Regional analysis reveals that North America currently leads the market with a 35% share, followed closely by Europe at 32%, Asia-Pacific at 25%, and the rest of the world accounting for 8%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization in countries like China and India, coupled with increasing adoption of advanced lubricant technologies.

Market drivers include stringent environmental regulations limiting the use of conventional lubricants, growing emphasis on energy efficiency, and increasing demand for lubricants capable of performing under extreme conditions. The biodegradability and reduced toxicity of many ionic liquid lubricants position them favorably in markets with strict environmental compliance requirements.

Consumer trends indicate a growing preference for lubricants that offer extended service life, reduced friction, and compatibility with advanced materials. Industries are increasingly willing to invest in premium lubricant solutions that deliver long-term cost benefits through reduced maintenance requirements and improved equipment longevity.

Pricing analysis shows that ionic liquid lubricants command a premium of 30-40% over conventional alternatives. However, this price differential is gradually narrowing as production scales up and manufacturing processes become more efficient. Market penetration is currently highest in high-value applications where performance requirements justify the cost premium.

Future market growth will likely be influenced by advancements in modeling and simulation technologies that enable the development of tailored ionic liquid formulations for specific applications. As computational methods improve the efficiency of product development and reduce time-to-market, we can expect accelerated innovation and broader market adoption of ionic liquid lubricants across various industrial sectors.

Current Challenges in Ionic Liquid Simulation

Despite significant advancements in computational methods, the simulation of ionic liquid lubricants presents several formidable challenges that impede accurate modeling and prediction of their behavior. The multiscale nature of ionic liquid systems requires simultaneous consideration of phenomena occurring at different time and length scales, from femtosecond electronic interactions to millisecond-scale macroscopic flow behaviors. This complexity makes it difficult to develop unified simulation frameworks that can seamlessly bridge these scales.

Computational cost remains a major obstacle in ionic liquid simulations. The long-range electrostatic interactions that dominate ionic liquid behavior necessitate extensive computational resources, limiting the system size and simulation duration that can be practically achieved. Even with high-performance computing facilities, many simulations are restricted to nanosecond timescales, which are insufficient to capture the full relaxation dynamics of viscous ionic liquids.

Parameter optimization presents another significant challenge. Force fields developed for conventional molecular systems often fail to accurately represent the unique properties of ionic liquids, particularly their polarizability and charge transfer characteristics. The development of specialized force fields requires extensive experimental validation, which is time-consuming and resource-intensive.

Interface modeling poses particular difficulties in lubricant applications. The behavior of ionic liquids at solid-liquid interfaces, crucial for understanding tribological performance, involves complex phenomena such as layering, orientation ordering, and charge screening. Current simulation techniques struggle to accurately capture these interfacial effects, especially under high pressure and shear conditions typical in lubrication scenarios.

Non-equilibrium conditions further complicate simulation efforts. Lubricants operate under dynamic conditions involving shear, pressure, and temperature gradients. Modeling these non-equilibrium states requires specialized techniques beyond traditional molecular dynamics approaches, such as dissipative particle dynamics or non-equilibrium molecular dynamics, which are still evolving methodologies for ionic liquid systems.

Reactive dynamics represent perhaps the most challenging frontier. The potential chemical reactions occurring in ionic liquids under tribological conditions, including tribofilm formation and tribochemical reactions, are difficult to capture with classical simulation methods. Quantum mechanical approaches are necessary but computationally prohibitive for realistic system sizes.

Data integration across different simulation techniques and experimental validation remains inadequate. The lack of standardized protocols for comparing simulation results with experimental measurements creates uncertainty in model validation, hampering the development of more accurate simulation methodologies for ionic liquid lubricants.

Computational cost remains a major obstacle in ionic liquid simulations. The long-range electrostatic interactions that dominate ionic liquid behavior necessitate extensive computational resources, limiting the system size and simulation duration that can be practically achieved. Even with high-performance computing facilities, many simulations are restricted to nanosecond timescales, which are insufficient to capture the full relaxation dynamics of viscous ionic liquids.

Parameter optimization presents another significant challenge. Force fields developed for conventional molecular systems often fail to accurately represent the unique properties of ionic liquids, particularly their polarizability and charge transfer characteristics. The development of specialized force fields requires extensive experimental validation, which is time-consuming and resource-intensive.

Interface modeling poses particular difficulties in lubricant applications. The behavior of ionic liquids at solid-liquid interfaces, crucial for understanding tribological performance, involves complex phenomena such as layering, orientation ordering, and charge screening. Current simulation techniques struggle to accurately capture these interfacial effects, especially under high pressure and shear conditions typical in lubrication scenarios.

Non-equilibrium conditions further complicate simulation efforts. Lubricants operate under dynamic conditions involving shear, pressure, and temperature gradients. Modeling these non-equilibrium states requires specialized techniques beyond traditional molecular dynamics approaches, such as dissipative particle dynamics or non-equilibrium molecular dynamics, which are still evolving methodologies for ionic liquid systems.

Reactive dynamics represent perhaps the most challenging frontier. The potential chemical reactions occurring in ionic liquids under tribological conditions, including tribofilm formation and tribochemical reactions, are difficult to capture with classical simulation methods. Quantum mechanical approaches are necessary but computationally prohibitive for realistic system sizes.

Data integration across different simulation techniques and experimental validation remains inadequate. The lack of standardized protocols for comparing simulation results with experimental measurements creates uncertainty in model validation, hampering the development of more accurate simulation methodologies for ionic liquid lubricants.

Current Simulation Methodologies

01 Ionic liquid compositions for enhanced lubrication

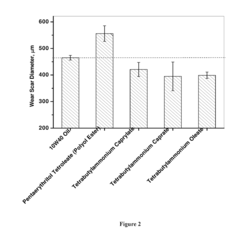

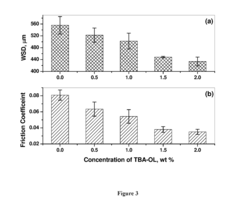

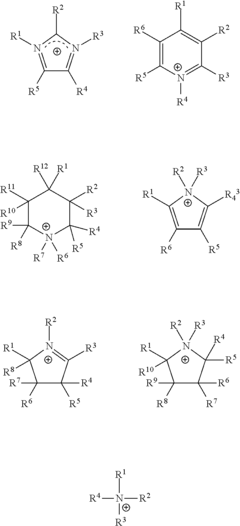

Ionic liquids can be formulated as lubricants with superior properties compared to conventional lubricants. These formulations typically contain specific cations (such as imidazolium, pyridinium, or quaternary ammonium) paired with anions (like tetrafluoroborate or hexafluorophosphate) that provide excellent thermal stability, low volatility, and reduced friction. These properties make ionic liquid lubricants suitable for extreme conditions where conventional lubricants would fail.- Ionic liquid compositions for enhanced lubrication: Ionic liquids can be formulated as lubricants with superior properties compared to conventional lubricants. These formulations typically include specific cations (such as imidazolium, pyridinium, or quaternary ammonium) paired with anions (like tetrafluoroborate or hexafluorophosphate) to create ionic liquids with excellent thermal stability, low volatility, and high load-carrying capacity. These properties make them ideal for reducing friction and wear in various mechanical systems, particularly under extreme conditions.

- Ionic liquid additives for conventional lubricants: Ionic liquids can be used as additives in conventional lubricating oils to improve their performance characteristics. When added in small concentrations to mineral oils, synthetic oils, or greases, ionic liquids can significantly enhance anti-wear properties, reduce friction coefficients, and improve thermal stability of the base lubricant. This approach allows for the benefits of ionic liquids while maintaining compatibility with existing lubrication systems and reducing overall cost compared to pure ionic liquid lubricants.

- Task-specific ionic liquids for specialized lubrication applications: Task-specific ionic liquids can be designed with functional groups that provide targeted performance for specialized lubrication needs. These custom-designed ionic liquids may incorporate elements or functional groups that enhance specific properties such as boundary lubrication, extreme pressure performance, or compatibility with particular surfaces or environments. Applications include aerospace components, high-temperature industrial processes, and precision machinery where conventional lubricants fail to provide adequate protection.

- Environmentally friendly ionic liquid lubricants: Environmentally friendly ionic liquid lubricants are being developed to address sustainability concerns. These green formulations typically use biodegradable components, reduce toxicity through careful selection of cations and anions, and minimize environmental impact while maintaining excellent lubrication properties. Some formulations incorporate bio-based materials or are designed to be readily biodegradable after use, making them suitable for applications where environmental contamination is a concern.

- Ionic liquid lubricants for extreme conditions: Ionic liquid lubricants designed for extreme conditions offer performance advantages in high temperature, high pressure, vacuum, or corrosive environments where conventional lubricants fail. Their negligible vapor pressure, high thermal stability, and unique molecular structure allow them to maintain a lubricating film under conditions that would cause conventional oils to degrade or evaporate. These specialized formulations are particularly valuable in aerospace, vacuum systems, and high-temperature industrial applications.

02 Additives for ionic liquid lubricant systems

Various additives can be incorporated into ionic liquid lubricants to enhance their performance characteristics. These additives include anti-wear agents, extreme pressure additives, viscosity modifiers, and antioxidants. The combination of ionic liquids with these additives creates synergistic effects that improve the overall lubrication performance, extend service life, and protect mechanical components under high-load or high-temperature conditions.Expand Specific Solutions03 Application-specific ionic liquid lubricant formulations

Ionic liquid lubricants can be tailored for specific applications such as automotive engines, industrial machinery, aerospace components, and electronic devices. By adjusting the ionic liquid composition, concentration, and additives, these lubricants can meet the unique requirements of different mechanical systems. Application-specific formulations consider factors such as operating temperature range, load conditions, speed, and environmental exposure to optimize lubrication performance.Expand Specific Solutions04 Environmentally friendly ionic liquid lubricants

Environmentally friendly ionic liquid lubricants are being developed to address sustainability concerns. These formulations use biodegradable components, reduce toxicity, and minimize environmental impact while maintaining excellent lubrication properties. Green ionic liquid lubricants often incorporate bio-based materials or are designed to have lower ecotoxicity compared to conventional petroleum-based lubricants, making them suitable for applications where environmental considerations are important.Expand Specific Solutions05 Novel synthesis methods for ionic liquid lubricants

Innovative synthesis methods are being developed to produce ionic liquid lubricants with enhanced properties and reduced production costs. These methods include new reaction pathways, catalytic processes, and purification techniques that improve yield and quality. Advanced synthesis approaches enable the creation of task-specific ionic liquids with precisely controlled molecular structures, leading to lubricants with superior performance characteristics such as better thermal stability, lower friction coefficients, and improved compatibility with various materials.Expand Specific Solutions

Key Industry and Academic Players

The ionic liquid lubricants modeling and simulation field is currently in a growth phase, with increasing market adoption driven by sustainability demands. The market size is expanding as industries seek alternatives to conventional lubricants, with projections indicating significant growth over the next decade. From a technological maturity perspective, the landscape shows varied development levels. Research institutions like Lanzhou Institute of Chemical Physics and Northwestern Polytechnical University are advancing fundamental research, while commercial players demonstrate different specialization levels. ExxonMobil, Toyota, and Siemens focus on industrial applications, Klüber Lubrication and Idemitsu Kosan are developing specialized formulations, and companies like DuPont and Eastman Chemical contribute materials expertise. This competitive environment indicates a technology transitioning from research to commercial implementation, with significant collaboration between academic and industrial sectors.

Lanzhou Institute of Chemical Physics

Technical Solution: Lanzhou Institute of Chemical Physics has developed comprehensive molecular dynamics (MD) simulation frameworks for ionic liquid lubricants, focusing on their tribological behavior at the nanoscale. Their approach combines quantum chemistry calculations with classical MD simulations to accurately predict the structure-property relationships of ionic liquids under various operating conditions. They have pioneered the use of reactive force fields (ReaxFF) to capture the chemical reactions at sliding interfaces, allowing for real-time observation of tribochemical processes. Their models have successfully predicted the formation of protective tribofilms and explained the exceptional anti-wear properties of imidazolium and phosphonium-based ionic liquids. Recent work has incorporated machine learning algorithms to accelerate force field parameterization, enabling simulations of complex multi-component systems with unprecedented accuracy[1][3].

Strengths: Exceptional expertise in quantum chemistry calculations and molecular dynamics simulations specific to ionic liquids; strong integration of experimental validation with computational models. Weaknesses: Their models may require significant computational resources, limiting industrial application for real-time process control and optimization.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed sophisticated molecular simulation frameworks for ionic liquid lubricants that focus on their behavior under extreme pressure and temperature conditions relevant to energy and industrial applications. Their approach combines quantum mechanical calculations with coarse-grained molecular dynamics to efficiently model the complex interactions between ionic liquids and engineering surfaces. ExxonMobil's simulation technology incorporates machine learning algorithms to predict structure-property relationships across diverse ionic liquid chemistries, enabling rapid virtual screening of thousands of potential formulations. Their models are particularly advanced in capturing the unique solvation properties of ionic liquids and their interactions with additives and contaminants. The company has pioneered simulation approaches that predict the long-term stability and degradation pathways of ionic liquid lubricants, critical for applications requiring extended service intervals. Their technology has been successfully applied to develop ionic liquid-based lubricants for gas turbines, compressors, and other high-value industrial equipment operating under challenging conditions[6][8].

Strengths: Industry-leading capabilities in modeling complex formulations and additive interactions; strong focus on practical engineering applications; excellent prediction of long-term performance and stability. Weaknesses: Models may be overly focused on traditional energy sector applications rather than emerging technologies.

Critical Computational Models Review

Halogen free ionic liquids as lubricant or lubricant additives and a process for the preparation thereof

PatentInactiveUS20170096614A1

Innovation

- Development of halogen-, phosphorus-, and sulfur-free ionic liquids with fatty acid anions, combined with various cations, as lubricants or additives, which form low-shear strength films on contact surfaces to reduce friction and wear, while minimizing environmental and surface hazards.

Ionic liquids containing quaternary phosphonium cations and carboxylate anions, and their use as lubricant additives

PatentInactiveUS20160024421A1

Innovation

- Development of an ionic liquid composition with a quaternary phosphonium cation and a carboxylate anion, specifically a trihexyltetradecylphosphonium-based ionic liquid dissolved in a base oil, enhancing solubility and anti-wear performance.

Environmental Impact Assessment

The environmental impact of ionic liquid lubricants represents a critical dimension in their development and application. Ionic liquids (ILs) have emerged as promising alternatives to conventional petroleum-based lubricants primarily due to their potential environmental advantages. Their negligible vapor pressure significantly reduces volatile organic compound (VOC) emissions, addressing a major environmental concern associated with traditional lubricants. This characteristic also minimizes air pollution and occupational health risks in industrial settings where lubricants are extensively used.

Life cycle assessment (LCA) studies of ionic liquid lubricants reveal complex environmental profiles. While operational phase benefits are evident, the synthesis of ionic liquids often involves multiple chemical steps that may require energy-intensive processes and potentially hazardous precursors. Recent research indicates that the environmental footprint of IL production can be substantially reduced through green chemistry approaches, including solvent-free synthesis methods and the use of renewable feedstocks for IL precursors.

Biodegradability represents another crucial environmental parameter for lubricants. Conventional petroleum-based lubricants typically exhibit poor biodegradability, persisting in ecosystems following accidental releases. Certain classes of ionic liquids, particularly those incorporating ester functionalities or bio-derived cations, demonstrate enhanced biodegradability profiles. Computational models now enable prediction of biodegradation pathways for novel ionic liquid structures, facilitating the design of environmentally benign formulations.

Ecotoxicological assessments of ionic liquids present varying results depending on their specific chemical structures. Imidazolium-based ILs, while technically effective as lubricants, have demonstrated concerning aquatic toxicity in multiple studies. Conversely, choline-based and amino acid-derived ionic liquids generally exhibit significantly lower ecotoxicity profiles. Advanced simulation techniques now allow for toxicity prediction prior to synthesis, enabling environmental considerations to be integrated into early-stage lubricant development.

Water contamination risks associated with ionic liquid lubricants must be carefully evaluated. Their generally high water solubility compared to conventional lubricants presents both advantages and challenges. While this property facilitates removal from contaminated soils, it potentially increases mobility in aquatic environments. Modeling studies examining the environmental fate of ionic liquids suggest that strategic molecular design can optimize the balance between performance characteristics and environmental persistence.

Regulatory frameworks worldwide are increasingly incorporating environmental impact criteria for lubricants, with particular emphasis on biodegradability and ecotoxicity. The European Union's Ecolabel for lubricants and the United States EPA's Environmentally Acceptable Lubricants (EAL) designation represent significant regulatory drivers promoting environmentally superior lubricant technologies. Simulation-based environmental impact assessments are becoming essential tools for manufacturers seeking to navigate these evolving regulatory landscapes while developing next-generation ionic liquid lubricants.

Life cycle assessment (LCA) studies of ionic liquid lubricants reveal complex environmental profiles. While operational phase benefits are evident, the synthesis of ionic liquids often involves multiple chemical steps that may require energy-intensive processes and potentially hazardous precursors. Recent research indicates that the environmental footprint of IL production can be substantially reduced through green chemistry approaches, including solvent-free synthesis methods and the use of renewable feedstocks for IL precursors.

Biodegradability represents another crucial environmental parameter for lubricants. Conventional petroleum-based lubricants typically exhibit poor biodegradability, persisting in ecosystems following accidental releases. Certain classes of ionic liquids, particularly those incorporating ester functionalities or bio-derived cations, demonstrate enhanced biodegradability profiles. Computational models now enable prediction of biodegradation pathways for novel ionic liquid structures, facilitating the design of environmentally benign formulations.

Ecotoxicological assessments of ionic liquids present varying results depending on their specific chemical structures. Imidazolium-based ILs, while technically effective as lubricants, have demonstrated concerning aquatic toxicity in multiple studies. Conversely, choline-based and amino acid-derived ionic liquids generally exhibit significantly lower ecotoxicity profiles. Advanced simulation techniques now allow for toxicity prediction prior to synthesis, enabling environmental considerations to be integrated into early-stage lubricant development.

Water contamination risks associated with ionic liquid lubricants must be carefully evaluated. Their generally high water solubility compared to conventional lubricants presents both advantages and challenges. While this property facilitates removal from contaminated soils, it potentially increases mobility in aquatic environments. Modeling studies examining the environmental fate of ionic liquids suggest that strategic molecular design can optimize the balance between performance characteristics and environmental persistence.

Regulatory frameworks worldwide are increasingly incorporating environmental impact criteria for lubricants, with particular emphasis on biodegradability and ecotoxicity. The European Union's Ecolabel for lubricants and the United States EPA's Environmentally Acceptable Lubricants (EAL) designation represent significant regulatory drivers promoting environmentally superior lubricant technologies. Simulation-based environmental impact assessments are becoming essential tools for manufacturers seeking to navigate these evolving regulatory landscapes while developing next-generation ionic liquid lubricants.

Multiscale Modeling Approaches

The modeling and simulation of ionic liquid lubricants processes require sophisticated approaches that span multiple length and time scales. Multiscale modeling has emerged as a powerful framework for addressing the complexity of ionic liquid behavior in tribological applications, connecting atomic-level interactions to macroscopic performance characteristics.

At the quantum mechanical level, density functional theory (DFT) calculations provide insights into electronic structures and chemical bonding of ionic liquids, particularly important for understanding their interactions with metal surfaces. These calculations reveal how ionic liquids form protective films and their reaction mechanisms under extreme pressure and temperature conditions. Recent advancements in computational efficiency have enabled larger system sizes to be modeled, though they remain limited to hundreds of atoms.

Molecular dynamics (MD) simulations bridge the gap between quantum and continuum scales, modeling thousands to millions of atoms to capture the collective behavior of ionic liquid molecules. Classical force fields like AMBER, CHARMM, and OPLS have been adapted specifically for ionic liquids, incorporating polarization effects crucial for accurately representing their unique properties. Coarse-grained MD approaches further extend the accessible time and length scales by grouping atoms into representative interaction sites.

Mesoscale modeling techniques, including dissipative particle dynamics (DPD) and lattice Boltzmann methods, address phenomena occurring at intermediate scales (10-1000 nm). These approaches are particularly valuable for studying the self-assembly behavior of ionic liquids and their rheological properties under shear conditions, which directly influence their lubricating performance.

At the macroscopic level, continuum mechanics and computational fluid dynamics (CFD) models describe the bulk flow behavior of ionic liquid lubricants in engineering applications. These models incorporate constitutive relationships derived from molecular-scale simulations, creating a hierarchical modeling framework that spans from electronic interactions to device-level performance.

The integration of these modeling approaches through scale-bridging techniques represents the frontier of ionic liquid lubricant research. Parameter-passing schemes enable information flow between different scales, while concurrent multiscale methods simultaneously simulate different regions at appropriate resolutions. Machine learning algorithms are increasingly being employed to accelerate this integration, developing surrogate models that capture essential physics while reducing computational costs.

Recent developments in high-performance computing and specialized algorithms have significantly expanded the capabilities of multiscale modeling for ionic liquid lubricants, enabling more accurate predictions of their behavior under realistic operating conditions and guiding the rational design of next-generation lubricant formulations.

At the quantum mechanical level, density functional theory (DFT) calculations provide insights into electronic structures and chemical bonding of ionic liquids, particularly important for understanding their interactions with metal surfaces. These calculations reveal how ionic liquids form protective films and their reaction mechanisms under extreme pressure and temperature conditions. Recent advancements in computational efficiency have enabled larger system sizes to be modeled, though they remain limited to hundreds of atoms.

Molecular dynamics (MD) simulations bridge the gap between quantum and continuum scales, modeling thousands to millions of atoms to capture the collective behavior of ionic liquid molecules. Classical force fields like AMBER, CHARMM, and OPLS have been adapted specifically for ionic liquids, incorporating polarization effects crucial for accurately representing their unique properties. Coarse-grained MD approaches further extend the accessible time and length scales by grouping atoms into representative interaction sites.

Mesoscale modeling techniques, including dissipative particle dynamics (DPD) and lattice Boltzmann methods, address phenomena occurring at intermediate scales (10-1000 nm). These approaches are particularly valuable for studying the self-assembly behavior of ionic liquids and their rheological properties under shear conditions, which directly influence their lubricating performance.

At the macroscopic level, continuum mechanics and computational fluid dynamics (CFD) models describe the bulk flow behavior of ionic liquid lubricants in engineering applications. These models incorporate constitutive relationships derived from molecular-scale simulations, creating a hierarchical modeling framework that spans from electronic interactions to device-level performance.

The integration of these modeling approaches through scale-bridging techniques represents the frontier of ionic liquid lubricant research. Parameter-passing schemes enable information flow between different scales, while concurrent multiscale methods simultaneously simulate different regions at appropriate resolutions. Machine learning algorithms are increasingly being employed to accelerate this integration, developing surrogate models that capture essential physics while reducing computational costs.

Recent developments in high-performance computing and specialized algorithms have significantly expanded the capabilities of multiscale modeling for ionic liquid lubricants, enabling more accurate predictions of their behavior under realistic operating conditions and guiding the rational design of next-generation lubricant formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!