Perovskite–silicon tandem on PERC, TOPCon, and HJT: architecture comparison

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite-Si Tandem Cell Evolution and Objectives

Perovskite-silicon tandem solar cells have emerged as a promising technology to surpass the theoretical efficiency limits of single-junction silicon solar cells. The evolution of this technology can be traced back to the early 2010s when perovskite materials were first introduced in photovoltaics. Initially, perovskite solar cells were developed as standalone devices, but researchers quickly recognized their potential for tandem applications with silicon.

The journey of perovskite-silicon tandem cells began with proof-of-concept devices that demonstrated the feasibility of combining these two materials. Early tandems faced challenges such as poor stability, low efficiencies, and manufacturing complexities. However, rapid progress in perovskite material engineering and device architecture optimization led to significant improvements.

A key milestone was reached in 2018 when perovskite-silicon tandems first surpassed the 25% efficiency mark, outperforming the best single-junction silicon cells. This achievement sparked intense research and development efforts worldwide, with both academic institutions and industry players investing heavily in the technology.

The evolution of perovskite-silicon tandems has been closely tied to advancements in silicon cell technologies. As the bottom cell in the tandem structure, silicon plays a crucial role in overall performance. The progression from aluminum back surface field (Al-BSF) cells to Passivated Emitter and Rear Cell (PERC), Tunnel Oxide Passivated Contact (TOPCon), and Heterojunction (HJT) technologies has opened new possibilities for tandem architectures.

Each silicon technology presents unique challenges and opportunities for integration with perovskite top cells. PERC, being the most widely adopted technology in commercial production, offers a practical platform for near-term tandem implementation. TOPCon and HJT, with their higher efficiencies and distinct cell structures, provide alternative pathways for pushing tandem performance even further.

The primary objective of perovskite-silicon tandem research is to achieve stable, high-efficiency devices that can be manufactured at scale. Current efforts focus on surpassing the 30% efficiency threshold while ensuring long-term operational stability under real-world conditions. Additionally, researchers aim to develop tandem architectures compatible with existing silicon production lines to facilitate rapid industry adoption.

Looking ahead, the field is moving towards more advanced tandem configurations, including triple-junction cells and novel interconnection schemes. The ultimate goal is to create a technology that not only exceeds the performance of traditional silicon cells but also offers a compelling cost-performance ratio to drive widespread market adoption and accelerate the transition to renewable energy sources.

The journey of perovskite-silicon tandem cells began with proof-of-concept devices that demonstrated the feasibility of combining these two materials. Early tandems faced challenges such as poor stability, low efficiencies, and manufacturing complexities. However, rapid progress in perovskite material engineering and device architecture optimization led to significant improvements.

A key milestone was reached in 2018 when perovskite-silicon tandems first surpassed the 25% efficiency mark, outperforming the best single-junction silicon cells. This achievement sparked intense research and development efforts worldwide, with both academic institutions and industry players investing heavily in the technology.

The evolution of perovskite-silicon tandems has been closely tied to advancements in silicon cell technologies. As the bottom cell in the tandem structure, silicon plays a crucial role in overall performance. The progression from aluminum back surface field (Al-BSF) cells to Passivated Emitter and Rear Cell (PERC), Tunnel Oxide Passivated Contact (TOPCon), and Heterojunction (HJT) technologies has opened new possibilities for tandem architectures.

Each silicon technology presents unique challenges and opportunities for integration with perovskite top cells. PERC, being the most widely adopted technology in commercial production, offers a practical platform for near-term tandem implementation. TOPCon and HJT, with their higher efficiencies and distinct cell structures, provide alternative pathways for pushing tandem performance even further.

The primary objective of perovskite-silicon tandem research is to achieve stable, high-efficiency devices that can be manufactured at scale. Current efforts focus on surpassing the 30% efficiency threshold while ensuring long-term operational stability under real-world conditions. Additionally, researchers aim to develop tandem architectures compatible with existing silicon production lines to facilitate rapid industry adoption.

Looking ahead, the field is moving towards more advanced tandem configurations, including triple-junction cells and novel interconnection schemes. The ultimate goal is to create a technology that not only exceeds the performance of traditional silicon cells but also offers a compelling cost-performance ratio to drive widespread market adoption and accelerate the transition to renewable energy sources.

Market Demand Analysis for High-Efficiency Solar Cells

The global solar energy market has been experiencing significant growth, driven by increasing environmental concerns, government incentives, and the declining costs of solar technology. Within this expanding market, there is a growing demand for high-efficiency solar cells, particularly perovskite-silicon tandem solar cells, which offer the potential for higher conversion efficiencies compared to traditional single-junction silicon cells.

The market for high-efficiency solar cells is primarily driven by the need for improved energy output in space-constrained environments, such as residential rooftops and urban areas. As land availability becomes increasingly limited, there is a strong push for solar technologies that can generate more power from smaller surface areas. Perovskite-silicon tandem cells, with their potential to exceed 30% efficiency, are well-positioned to meet this demand.

In the utility-scale solar sector, there is a growing interest in high-efficiency cells to reduce the overall cost of solar installations. By using more efficient cells, developers can reduce the number of panels required, leading to lower balance-of-system costs and decreased land use. This is particularly important in regions with high land costs or limited suitable areas for solar farms.

The automotive industry is emerging as another significant market for high-efficiency solar cells. As electric vehicles become more prevalent, there is increasing interest in integrating solar panels into vehicle designs to extend range and reduce charging requirements. The high efficiency and potential for flexible form factors make perovskite-silicon tandem cells an attractive option for this application.

Building-integrated photovoltaics (BIPV) represent another growing market segment where high-efficiency cells are in demand. Architects and builders are looking for solar solutions that can be seamlessly integrated into building facades, windows, and roofing materials without compromising aesthetics or structural integrity. The higher efficiency of tandem cells allows for greater power generation from limited surface areas in these applications.

Geographically, the demand for high-efficiency solar cells is strongest in regions with high electricity costs, limited space, and supportive government policies. Countries like Japan, South Korea, and Germany, which face land constraints and have ambitious renewable energy targets, are likely to be early adopters of advanced solar technologies like perovskite-silicon tandem cells.

The market for high-efficiency solar cells is expected to grow significantly in the coming years, driven by technological advancements, cost reductions, and increasing awareness of the need for sustainable energy solutions. As research and development in perovskite-silicon tandem cells continue to progress, addressing challenges related to stability, scalability, and manufacturing costs, the market demand is likely to accelerate further.

The market for high-efficiency solar cells is primarily driven by the need for improved energy output in space-constrained environments, such as residential rooftops and urban areas. As land availability becomes increasingly limited, there is a strong push for solar technologies that can generate more power from smaller surface areas. Perovskite-silicon tandem cells, with their potential to exceed 30% efficiency, are well-positioned to meet this demand.

In the utility-scale solar sector, there is a growing interest in high-efficiency cells to reduce the overall cost of solar installations. By using more efficient cells, developers can reduce the number of panels required, leading to lower balance-of-system costs and decreased land use. This is particularly important in regions with high land costs or limited suitable areas for solar farms.

The automotive industry is emerging as another significant market for high-efficiency solar cells. As electric vehicles become more prevalent, there is increasing interest in integrating solar panels into vehicle designs to extend range and reduce charging requirements. The high efficiency and potential for flexible form factors make perovskite-silicon tandem cells an attractive option for this application.

Building-integrated photovoltaics (BIPV) represent another growing market segment where high-efficiency cells are in demand. Architects and builders are looking for solar solutions that can be seamlessly integrated into building facades, windows, and roofing materials without compromising aesthetics or structural integrity. The higher efficiency of tandem cells allows for greater power generation from limited surface areas in these applications.

Geographically, the demand for high-efficiency solar cells is strongest in regions with high electricity costs, limited space, and supportive government policies. Countries like Japan, South Korea, and Germany, which face land constraints and have ambitious renewable energy targets, are likely to be early adopters of advanced solar technologies like perovskite-silicon tandem cells.

The market for high-efficiency solar cells is expected to grow significantly in the coming years, driven by technological advancements, cost reductions, and increasing awareness of the need for sustainable energy solutions. As research and development in perovskite-silicon tandem cells continue to progress, addressing challenges related to stability, scalability, and manufacturing costs, the market demand is likely to accelerate further.

Current State of PERC, TOPCon, and HJT Technologies

Passivated Emitter and Rear Cell (PERC), Tunnel Oxide Passivated Contact (TOPCon), and Heterojunction (HJT) technologies represent the current state-of-the-art in silicon solar cell manufacturing. Each of these technologies has made significant strides in improving cell efficiency and reducing production costs.

PERC technology has become the industry standard, with a market share of over 80% in 2021. It achieves higher efficiency by adding a dielectric passivation layer on the rear side of the cell, reducing electron recombination. PERC cells have reached efficiencies of up to 23.2% in mass production, with laboratory efficiencies exceeding 24%.

TOPCon technology is an evolution of PERC, incorporating a thin oxide layer and heavily doped polysilicon layer on the rear side. This structure allows for better passivation and reduced recombination, resulting in higher efficiencies. Commercial TOPCon cells have achieved efficiencies of 23.5%, with potential for further improvement.

HJT technology combines crystalline silicon with thin-film amorphous silicon layers, creating a unique cell structure. This design minimizes recombination losses and allows for high open-circuit voltages. HJT cells have demonstrated efficiencies of up to 25% in production, with the potential to reach 26% in the near future.

In terms of production costs, PERC remains the most cost-effective option due to its established manufacturing processes and economies of scale. TOPCon and HJT technologies currently have higher production costs but offer the potential for lower levelized cost of electricity (LCOE) due to their higher efficiencies.

The temperature coefficient, which describes how cell performance changes with temperature, varies among these technologies. HJT cells have the best temperature coefficient, followed by TOPCon and then PERC. This factor is particularly important for real-world performance, especially in hot climates.

Bifaciality, or the ability to generate power from both sides of the cell, is another key differentiator. HJT cells offer the highest bifaciality factor, typically around 90%, followed by TOPCon at 80-85%, and PERC at 70-75%. This characteristic is becoming increasingly important as bifacial modules gain market share.

In terms of long-term stability, all three technologies have shown good results, with degradation rates typically below 0.5% per year. However, HJT cells have demonstrated superior resistance to light-induced degradation (LID) and light and elevated temperature-induced degradation (LeTID), which are more prevalent in PERC and TOPCon cells.

PERC technology has become the industry standard, with a market share of over 80% in 2021. It achieves higher efficiency by adding a dielectric passivation layer on the rear side of the cell, reducing electron recombination. PERC cells have reached efficiencies of up to 23.2% in mass production, with laboratory efficiencies exceeding 24%.

TOPCon technology is an evolution of PERC, incorporating a thin oxide layer and heavily doped polysilicon layer on the rear side. This structure allows for better passivation and reduced recombination, resulting in higher efficiencies. Commercial TOPCon cells have achieved efficiencies of 23.5%, with potential for further improvement.

HJT technology combines crystalline silicon with thin-film amorphous silicon layers, creating a unique cell structure. This design minimizes recombination losses and allows for high open-circuit voltages. HJT cells have demonstrated efficiencies of up to 25% in production, with the potential to reach 26% in the near future.

In terms of production costs, PERC remains the most cost-effective option due to its established manufacturing processes and economies of scale. TOPCon and HJT technologies currently have higher production costs but offer the potential for lower levelized cost of electricity (LCOE) due to their higher efficiencies.

The temperature coefficient, which describes how cell performance changes with temperature, varies among these technologies. HJT cells have the best temperature coefficient, followed by TOPCon and then PERC. This factor is particularly important for real-world performance, especially in hot climates.

Bifaciality, or the ability to generate power from both sides of the cell, is another key differentiator. HJT cells offer the highest bifaciality factor, typically around 90%, followed by TOPCon at 80-85%, and PERC at 70-75%. This characteristic is becoming increasingly important as bifacial modules gain market share.

In terms of long-term stability, all three technologies have shown good results, with degradation rates typically below 0.5% per year. However, HJT cells have demonstrated superior resistance to light-induced degradation (LID) and light and elevated temperature-induced degradation (LeTID), which are more prevalent in PERC and TOPCon cells.

Comparative Analysis of PERC, TOPCon, and HJT Architectures

01 Perovskite-silicon tandem cell structure

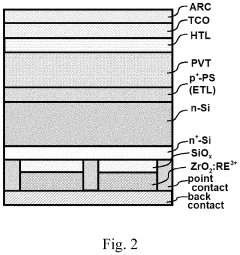

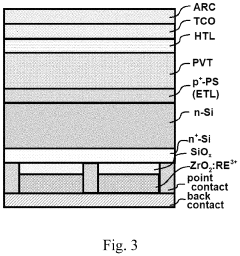

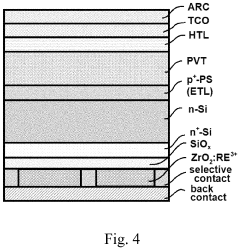

The architecture of perovskite-silicon tandem solar cells typically involves a perovskite top cell and a silicon bottom cell. This structure allows for better light absorption across a wider spectrum, potentially increasing overall efficiency. The perovskite layer is often deposited on top of the silicon cell, with various intermediate layers to optimize performance.- Perovskite-silicon tandem cell structure: The architecture of perovskite-silicon tandem solar cells typically involves stacking a perovskite top cell on a silicon bottom cell. This configuration allows for better light absorption across a wider spectrum, potentially increasing overall efficiency. The structure often includes transparent conductive oxides, electron and hole transport layers, and carefully engineered interfaces between the perovskite and silicon layers.

- Perovskite layer composition and deposition: The composition and deposition method of the perovskite layer are crucial for tandem cell performance. Various perovskite materials and fabrication techniques are explored to optimize light absorption, charge transport, and stability. Solution-based deposition methods, such as spin-coating or slot-die coating, are commonly used, while vapor deposition techniques are also investigated for improved uniformity and scalability.

- Interface engineering and recombination layers: Effective interface engineering between the perovskite and silicon layers is essential for minimizing losses and improving charge collection. Recombination layers or tunnel junctions are often incorporated to facilitate efficient charge transfer between the subcells. Various materials and designs are explored to optimize these interfaces and enhance overall tandem cell performance.

- Light management and texturing: Light management strategies are employed to maximize light absorption and minimize reflection losses in tandem cells. This includes texturing of silicon surfaces, anti-reflection coatings, and light trapping structures. Advanced optical designs are explored to ensure optimal light distribution between the perovskite and silicon subcells, enhancing overall photon utilization and cell efficiency.

- Stability and encapsulation techniques: Improving the long-term stability of perovskite-silicon tandem cells is a key focus area. Various encapsulation techniques and barrier materials are investigated to protect the perovskite layer from moisture and environmental degradation. Additionally, compositional engineering of the perovskite material and interface layers is explored to enhance intrinsic stability and maintain high performance over extended periods.

02 Interface engineering

Interface engineering is crucial in perovskite-silicon tandem cells to reduce recombination losses and improve charge transfer between layers. This may involve the use of buffer layers, passivation techniques, or novel materials at the interfaces between the perovskite and silicon layers, as well as at the electrodes.Expand Specific Solutions03 Light management techniques

Various light management strategies are employed to enhance the performance of perovskite-silicon tandem cells. These may include textured surfaces, anti-reflection coatings, and light trapping structures to maximize light absorption and minimize reflection losses in both the perovskite and silicon layers.Expand Specific Solutions04 Perovskite composition and deposition

The composition and deposition method of the perovskite layer play a critical role in tandem cell performance. Research focuses on developing stable, high-efficiency perovskite materials and scalable deposition techniques compatible with silicon cell manufacturing processes.Expand Specific Solutions05 Interconnection and current matching

Efficient interconnection between the perovskite and silicon subcells is essential for optimal tandem cell performance. This includes strategies for current matching between the two subcells and the development of transparent conductive layers or recombination junctions to facilitate charge transfer.Expand Specific Solutions

Key Players in Perovskite-Silicon Solar Cell Industry

The perovskite-silicon tandem solar cell market is in a growth phase, with increasing research and commercial interest. The global market size for tandem solar cells is projected to expand significantly in the coming years, driven by the potential for higher efficiency compared to traditional silicon cells. Technologically, perovskite-silicon tandems are advancing rapidly but still face challenges in stability and scalability. Key players like Trina Solar, Oxford PV, and JA Solar are making significant strides in R&D and pilot production. Research institutions such as KAUST, MIT, and CEA are also contributing to technological advancements. While not yet fully mature, the technology is progressing towards commercialization, with several companies aiming for market introduction in the near future.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has been actively developing perovskite-silicon tandem solar cells, with a focus on integrating perovskite technology with their existing high-efficiency silicon cell platforms. They have achieved notable success with their n-type TOPCon (Tunnel Oxide Passivated Contact) cells as the bottom cell in tandem structures. In 2022, Trina Solar reported a 24.5% efficiency for a large-area (246 cm²) perovskite-silicon tandem cell[4]. Their approach involves optimizing the interface between the perovskite top cell and the silicon bottom cell to minimize optical and electrical losses. Trina is also exploring industrialization pathways, aiming to scale up tandem cell production while maintaining high efficiency and reliability[5].

Strengths: Strong foundation in silicon cell technology; Large-scale manufacturing capabilities; Progress in large-area tandem cells. Weaknesses: Efficiency still lower than some competitors; Challenges in scaling up perovskite production to match silicon cell output.

HANWHA SOLUTIONS CORP.

Technical Solution: Hanwha Solutions, through its Q CELLS division, is advancing perovskite-silicon tandem solar cell technology. They have developed a unique approach that combines perovskite with their high-efficiency Q.ANTUM silicon cell technology. In 2021, Hanwha Q CELLS achieved a 25.5% efficiency for their tandem cell prototype[6]. Their research focuses on improving the stability and scalability of perovskite materials while leveraging their expertise in silicon HJT (Heterojunction) technology. Hanwha is also exploring innovative encapsulation techniques to enhance the long-term reliability of perovskite layers in real-world conditions[7].

Strengths: Integration with established Q.ANTUM technology; Strong R&D capabilities in both perovskite and silicon; Vertical integration in solar manufacturing. Weaknesses: Efficiency still trails some competitors; Challenges in scaling perovskite production to match their large-scale silicon cell output.

Core Innovations in Perovskite-Silicon Integration

Perovskite-silicon tandem structure and photon upconverters

PatentActiveUS11522096B2

Innovation

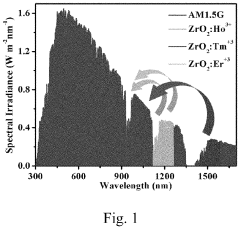

- Incorporating a metal oxide layer doped with Ho3+, Tm3+, and/or Er3+ ions, such as ZrO2, between the back contact and the passivating layer in tandem perovskite-silicon photovoltaic cells to enhance light absorption and conversion efficiency by utilizing up-conversion phenomena.

Rear junction bifacial poly-si/siox passivated contact solar cells and method of manufacturing the same

PatentWO2023235390A3

Innovation

- Highly efficient rear junction TOPCon solar cell with TOPCon on both sides, maximizing the potential of this technology.

- Selective placement of TOPCon on the front side under a metal grid with 5% area coverage, while the remaining 95% area is passivated with Al2O3/SiN dielectric.

- Integration of TOPCon cell as a bottom cell in a tandem solar cell structure.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of perovskite-silicon tandem solar cells are crucial aspects to evaluate when comparing different architectures such as PERC, TOPCon, and HJT. These factors play a significant role in determining the long-term viability and adoption of these technologies in the renewable energy sector.

One of the primary environmental concerns associated with perovskite-silicon tandem solar cells is the use of lead in perovskite materials. While the amount of lead used is relatively small, its potential toxicity and environmental persistence raise questions about the lifecycle impact of these cells. Researchers are actively exploring lead-free alternatives to address this issue, but further development is needed to match the efficiency of lead-based perovskites.

The manufacturing process of tandem solar cells also presents environmental challenges. The production of high-purity silicon for the bottom cell requires significant energy input, contributing to the overall carbon footprint of the technology. However, the increased efficiency of tandem cells compared to traditional silicon cells may offset this impact over the lifetime of the solar panel.

Comparing the three architectures, PERC (Passivated Emitter and Rear Cell) technology has the advantage of being well-established, with optimized manufacturing processes that minimize waste and energy consumption. TOPCon (Tunnel Oxide Passivated Contact) and HJT (Heterojunction) architectures, while potentially more efficient, may require more complex manufacturing steps, potentially increasing their environmental impact in the short term.

The durability and lifespan of perovskite-silicon tandem solar cells are critical factors in their sustainability profile. Perovskite layers are known to be sensitive to environmental factors such as moisture and heat, which can lead to degradation over time. Improving the stability of perovskite materials is a key research focus, with encapsulation techniques and material modifications showing promising results.

Recycling and end-of-life management for tandem solar cells present both challenges and opportunities. The complex structure of these cells, combining different materials and layers, may complicate recycling processes. However, the high value of some components, particularly silver and silicon, provides economic incentives for developing effective recycling methods.

In terms of resource utilization, tandem cells offer advantages by potentially reducing the amount of silicon required per watt of power output. This could alleviate pressure on silicon supply chains and reduce the environmental impact associated with silicon production. However, the introduction of new materials in the perovskite layer may create new supply chain challenges and potential resource constraints.

Overall, while perovskite-silicon tandem solar cells show great promise in improving solar energy efficiency, careful consideration of their environmental impact and sustainability is essential. Continued research and development efforts should focus not only on improving efficiency but also on addressing environmental concerns and enhancing the long-term sustainability of these advanced solar technologies.

One of the primary environmental concerns associated with perovskite-silicon tandem solar cells is the use of lead in perovskite materials. While the amount of lead used is relatively small, its potential toxicity and environmental persistence raise questions about the lifecycle impact of these cells. Researchers are actively exploring lead-free alternatives to address this issue, but further development is needed to match the efficiency of lead-based perovskites.

The manufacturing process of tandem solar cells also presents environmental challenges. The production of high-purity silicon for the bottom cell requires significant energy input, contributing to the overall carbon footprint of the technology. However, the increased efficiency of tandem cells compared to traditional silicon cells may offset this impact over the lifetime of the solar panel.

Comparing the three architectures, PERC (Passivated Emitter and Rear Cell) technology has the advantage of being well-established, with optimized manufacturing processes that minimize waste and energy consumption. TOPCon (Tunnel Oxide Passivated Contact) and HJT (Heterojunction) architectures, while potentially more efficient, may require more complex manufacturing steps, potentially increasing their environmental impact in the short term.

The durability and lifespan of perovskite-silicon tandem solar cells are critical factors in their sustainability profile. Perovskite layers are known to be sensitive to environmental factors such as moisture and heat, which can lead to degradation over time. Improving the stability of perovskite materials is a key research focus, with encapsulation techniques and material modifications showing promising results.

Recycling and end-of-life management for tandem solar cells present both challenges and opportunities. The complex structure of these cells, combining different materials and layers, may complicate recycling processes. However, the high value of some components, particularly silver and silicon, provides economic incentives for developing effective recycling methods.

In terms of resource utilization, tandem cells offer advantages by potentially reducing the amount of silicon required per watt of power output. This could alleviate pressure on silicon supply chains and reduce the environmental impact associated with silicon production. However, the introduction of new materials in the perovskite layer may create new supply chain challenges and potential resource constraints.

Overall, while perovskite-silicon tandem solar cells show great promise in improving solar energy efficiency, careful consideration of their environmental impact and sustainability is essential. Continued research and development efforts should focus not only on improving efficiency but also on addressing environmental concerns and enhancing the long-term sustainability of these advanced solar technologies.

Cost-Performance Trade-offs in Tandem Cell Production

The production of perovskite-silicon tandem solar cells involves a delicate balance between cost and performance. This trade-off is particularly evident when comparing different silicon cell architectures: PERC, TOPCon, and HJT. Each architecture presents unique challenges and opportunities in terms of manufacturing complexity, material costs, and overall efficiency gains.

PERC (Passivated Emitter and Rear Cell) technology, being the most mature and widely adopted, offers a cost-effective base for tandem structures. Its relatively simple manufacturing process and established supply chains contribute to lower production costs. However, the efficiency gains when paired with perovskite may be limited compared to more advanced silicon architectures.

TOPCon (Tunnel Oxide Passivated Contact) cells provide a middle ground in the cost-performance spectrum. They offer higher efficiency potential than PERC while maintaining a reasonable cost structure. The additional processing steps required for TOPCon, such as tunnel oxide formation and poly-silicon deposition, increase manufacturing complexity but can be justified by the improved performance in tandem configurations.

HJT (Heterojunction) technology represents the high-end of silicon cell architectures. Its superior passivation and excellent temperature coefficients make it an ideal candidate for tandem cells. However, the complex manufacturing process, involving specialized equipment and high-purity materials, significantly increases production costs.

When integrating perovskite layers, each architecture faces different challenges. PERC cells may require additional buffer layers to protect against thermal degradation during perovskite deposition. TOPCon cells offer better thermal stability but may need interface optimization to maximize tandem performance. HJT cells, while thermally sensitive, provide an excellent foundation for high-efficiency tandems but at a premium cost.

Material selection also plays a crucial role in the cost-performance equation. High-quality perovskite precursors and advanced deposition techniques can significantly impact both cell efficiency and manufacturing costs. The choice between solution-processed or vapor-deposited perovskites affects scalability and production throughput, further influencing the overall cost structure.

Ultimately, the optimal architecture for perovskite-silicon tandem cells depends on the target market and production scale. For large-scale manufacturing, PERC-based tandems may offer the best balance of cost and performance in the near term. TOPCon-based tandems could emerge as a strong contender as the technology matures and costs decrease. HJT-based tandems, while currently the most expensive, may find applications in high-end markets where maximum efficiency is paramount.

PERC (Passivated Emitter and Rear Cell) technology, being the most mature and widely adopted, offers a cost-effective base for tandem structures. Its relatively simple manufacturing process and established supply chains contribute to lower production costs. However, the efficiency gains when paired with perovskite may be limited compared to more advanced silicon architectures.

TOPCon (Tunnel Oxide Passivated Contact) cells provide a middle ground in the cost-performance spectrum. They offer higher efficiency potential than PERC while maintaining a reasonable cost structure. The additional processing steps required for TOPCon, such as tunnel oxide formation and poly-silicon deposition, increase manufacturing complexity but can be justified by the improved performance in tandem configurations.

HJT (Heterojunction) technology represents the high-end of silicon cell architectures. Its superior passivation and excellent temperature coefficients make it an ideal candidate for tandem cells. However, the complex manufacturing process, involving specialized equipment and high-purity materials, significantly increases production costs.

When integrating perovskite layers, each architecture faces different challenges. PERC cells may require additional buffer layers to protect against thermal degradation during perovskite deposition. TOPCon cells offer better thermal stability but may need interface optimization to maximize tandem performance. HJT cells, while thermally sensitive, provide an excellent foundation for high-efficiency tandems but at a premium cost.

Material selection also plays a crucial role in the cost-performance equation. High-quality perovskite precursors and advanced deposition techniques can significantly impact both cell efficiency and manufacturing costs. The choice between solution-processed or vapor-deposited perovskites affects scalability and production throughput, further influencing the overall cost structure.

Ultimately, the optimal architecture for perovskite-silicon tandem cells depends on the target market and production scale. For large-scale manufacturing, PERC-based tandems may offer the best balance of cost and performance in the near term. TOPCon-based tandems could emerge as a strong contender as the technology matures and costs decrease. HJT-based tandems, while currently the most expensive, may find applications in high-end markets where maximum efficiency is paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!