Perovskite–silicon tandem light management with textured interfaces

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite-Si Tandem Evolution

The evolution of perovskite-silicon tandem solar cells represents a significant milestone in photovoltaic technology. This journey began with the discovery of perovskite materials' photovoltaic properties in 2009, which sparked intense research interest due to their potential for high efficiency and low-cost manufacturing.

Initially, perovskite solar cells were developed as standalone devices, rapidly improving from efficiencies of 3.8% in 2009 to over 20% by 2014. Concurrently, researchers recognized the potential of combining perovskite with silicon to create tandem cells that could surpass the theoretical efficiency limits of single-junction devices.

The first perovskite-silicon tandem cells emerged around 2015, with initial efficiencies around 13-14%. These early designs faced challenges in light management, interface engineering, and stability. However, rapid progress ensued as researchers tackled these issues systematically.

By 2018, tandem cell efficiencies had surpassed 25%, approaching the performance of the best single-junction silicon cells. This progress was driven by improvements in perovskite composition, deposition techniques, and interface engineering. Notably, the development of textured interfaces played a crucial role in enhancing light trapping and reducing reflection losses.

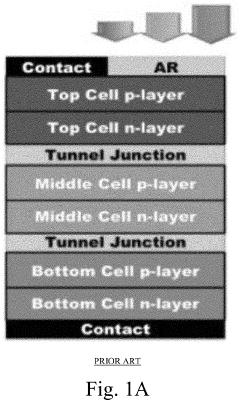

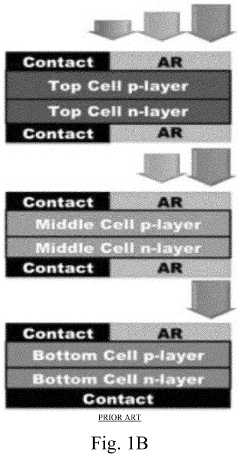

The period from 2019 to 2021 saw further breakthroughs, with efficiencies exceeding 29%. Key advancements included the use of wide-bandgap perovskites for top cells, improved tunnel recombination junctions, and sophisticated light management strategies. The introduction of two-terminal monolithic designs simplified manufacturing processes and reduced potential losses.

Recent years have witnessed a focus on scalability and long-term stability. Researchers have developed larger-area tandem cells and explored encapsulation techniques to protect the perovskite layer from environmental degradation. The use of textured interfaces has become increasingly sophisticated, with nanophotonic structures and advanced surface treatments optimizing light distribution between the perovskite and silicon layers.

As of 2023, perovskite-silicon tandem cells have achieved efficiencies over 31%, surpassing the best single-junction silicon cells by a significant margin. This evolution demonstrates the rapid progress in the field and the potential for further improvements through continued research in light management, material optimization, and interface engineering.

Initially, perovskite solar cells were developed as standalone devices, rapidly improving from efficiencies of 3.8% in 2009 to over 20% by 2014. Concurrently, researchers recognized the potential of combining perovskite with silicon to create tandem cells that could surpass the theoretical efficiency limits of single-junction devices.

The first perovskite-silicon tandem cells emerged around 2015, with initial efficiencies around 13-14%. These early designs faced challenges in light management, interface engineering, and stability. However, rapid progress ensued as researchers tackled these issues systematically.

By 2018, tandem cell efficiencies had surpassed 25%, approaching the performance of the best single-junction silicon cells. This progress was driven by improvements in perovskite composition, deposition techniques, and interface engineering. Notably, the development of textured interfaces played a crucial role in enhancing light trapping and reducing reflection losses.

The period from 2019 to 2021 saw further breakthroughs, with efficiencies exceeding 29%. Key advancements included the use of wide-bandgap perovskites for top cells, improved tunnel recombination junctions, and sophisticated light management strategies. The introduction of two-terminal monolithic designs simplified manufacturing processes and reduced potential losses.

Recent years have witnessed a focus on scalability and long-term stability. Researchers have developed larger-area tandem cells and explored encapsulation techniques to protect the perovskite layer from environmental degradation. The use of textured interfaces has become increasingly sophisticated, with nanophotonic structures and advanced surface treatments optimizing light distribution between the perovskite and silicon layers.

As of 2023, perovskite-silicon tandem cells have achieved efficiencies over 31%, surpassing the best single-junction silicon cells by a significant margin. This evolution demonstrates the rapid progress in the field and the potential for further improvements through continued research in light management, material optimization, and interface engineering.

Market Demand Analysis

The market demand for perovskite-silicon tandem solar cells with textured interfaces is rapidly growing, driven by the increasing global focus on renewable energy and the need for more efficient photovoltaic technologies. This innovative approach combines the high efficiency of perovskite solar cells with the established reliability of silicon-based technology, addressing the limitations of single-junction solar cells.

The global solar energy market is projected to expand significantly in the coming years, with a particular emphasis on high-efficiency solutions. Perovskite-silicon tandem cells are positioned to capture a substantial portion of this growth due to their potential to surpass the theoretical efficiency limits of traditional silicon solar cells.

Industrial and residential sectors are showing keen interest in these advanced solar technologies, as they offer improved power output within the same physical footprint as conventional panels. This is particularly attractive for space-constrained urban environments and large-scale solar farms seeking to maximize energy generation per unit area.

The automotive industry is emerging as a potential major market for perovskite-silicon tandem cells. As electric vehicles become more prevalent, there is growing demand for integrated solar solutions that can extend driving range and reduce the need for grid charging. The high efficiency and potential for flexible form factors make these tandem cells an attractive option for vehicle-integrated photovoltaics.

Government policies and incentives supporting renewable energy adoption are further fueling market demand. Many countries have set ambitious targets for solar energy deployment as part of their climate change mitigation strategies, creating a favorable environment for advanced solar technologies like perovskite-silicon tandems.

The building-integrated photovoltaics (BIPV) sector represents another significant market opportunity. Architects and developers are increasingly looking for solar solutions that can be seamlessly incorporated into building designs, and the potential for semi-transparent perovskite-silicon cells aligns well with this demand.

While the market potential is substantial, challenges remain in scaling up production and ensuring long-term stability of perovskite-silicon tandem cells. Addressing these issues is crucial for meeting the growing market demand and achieving widespread commercial adoption. Research efforts focused on improving light management through textured interfaces are particularly valuable, as they directly contribute to enhancing cell efficiency and performance, key factors driving market interest.

The global solar energy market is projected to expand significantly in the coming years, with a particular emphasis on high-efficiency solutions. Perovskite-silicon tandem cells are positioned to capture a substantial portion of this growth due to their potential to surpass the theoretical efficiency limits of traditional silicon solar cells.

Industrial and residential sectors are showing keen interest in these advanced solar technologies, as they offer improved power output within the same physical footprint as conventional panels. This is particularly attractive for space-constrained urban environments and large-scale solar farms seeking to maximize energy generation per unit area.

The automotive industry is emerging as a potential major market for perovskite-silicon tandem cells. As electric vehicles become more prevalent, there is growing demand for integrated solar solutions that can extend driving range and reduce the need for grid charging. The high efficiency and potential for flexible form factors make these tandem cells an attractive option for vehicle-integrated photovoltaics.

Government policies and incentives supporting renewable energy adoption are further fueling market demand. Many countries have set ambitious targets for solar energy deployment as part of their climate change mitigation strategies, creating a favorable environment for advanced solar technologies like perovskite-silicon tandems.

The building-integrated photovoltaics (BIPV) sector represents another significant market opportunity. Architects and developers are increasingly looking for solar solutions that can be seamlessly incorporated into building designs, and the potential for semi-transparent perovskite-silicon cells aligns well with this demand.

While the market potential is substantial, challenges remain in scaling up production and ensuring long-term stability of perovskite-silicon tandem cells. Addressing these issues is crucial for meeting the growing market demand and achieving widespread commercial adoption. Research efforts focused on improving light management through textured interfaces are particularly valuable, as they directly contribute to enhancing cell efficiency and performance, key factors driving market interest.

Technical Challenges

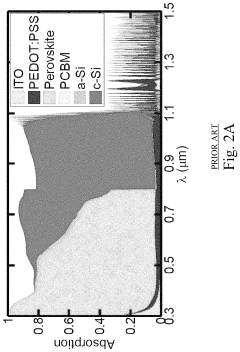

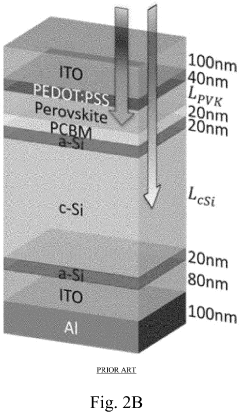

Perovskite-silicon tandem solar cells face several significant technical challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the optimization of light management at the textured interfaces between the perovskite and silicon layers. This challenge arises from the complex interplay of optical and electrical properties at these interfaces, which directly impact the overall efficiency of the tandem cell.

The textured interfaces, while beneficial for light trapping and absorption, introduce complications in maintaining the quality and uniformity of the perovskite layer. The irregular surface topology can lead to non-uniform perovskite crystallization, resulting in defects and reduced performance. Additionally, the textured surface can cause issues with charge transport and recombination at the interface, potentially negating some of the optical benefits gained from texturing.

Another significant challenge lies in the development of suitable transparent conductive oxides (TCOs) that can effectively function as intermediate layers between the perovskite and silicon subcells. These TCOs must possess high transparency to allow maximum light transmission to the bottom silicon cell while maintaining excellent electrical conductivity to facilitate efficient charge collection. Balancing these properties while ensuring compatibility with both perovskite and silicon materials remains a formidable task.

The stability of perovskite materials in tandem configurations presents another major hurdle. Perovskites are known to be sensitive to environmental factors such as moisture, heat, and light exposure. In a tandem structure, the perovskite layer must withstand the processing conditions required for the silicon cell, which can be detrimental to its stability. Developing encapsulation techniques and stable perovskite compositions that can withstand these conditions without compromising performance is crucial.

Furthermore, the challenge of current matching between the perovskite top cell and the silicon bottom cell is critical for maximizing tandem efficiency. The textured interfaces complicate this process by altering the light distribution between the two subcells. Achieving optimal current matching requires precise control over the thickness and composition of both the perovskite and silicon layers, as well as careful engineering of the intermediate layers and texturing patterns.

Lastly, the scalability of perovskite-silicon tandem cells with textured interfaces poses a significant challenge. While laboratory-scale devices have shown promising efficiencies, translating these results to large-area, commercially viable modules is complex. Issues such as uniformity of deposition, consistency of texturing across large areas, and the development of cost-effective manufacturing processes that can maintain high performance at scale need to be addressed.

The textured interfaces, while beneficial for light trapping and absorption, introduce complications in maintaining the quality and uniformity of the perovskite layer. The irregular surface topology can lead to non-uniform perovskite crystallization, resulting in defects and reduced performance. Additionally, the textured surface can cause issues with charge transport and recombination at the interface, potentially negating some of the optical benefits gained from texturing.

Another significant challenge lies in the development of suitable transparent conductive oxides (TCOs) that can effectively function as intermediate layers between the perovskite and silicon subcells. These TCOs must possess high transparency to allow maximum light transmission to the bottom silicon cell while maintaining excellent electrical conductivity to facilitate efficient charge collection. Balancing these properties while ensuring compatibility with both perovskite and silicon materials remains a formidable task.

The stability of perovskite materials in tandem configurations presents another major hurdle. Perovskites are known to be sensitive to environmental factors such as moisture, heat, and light exposure. In a tandem structure, the perovskite layer must withstand the processing conditions required for the silicon cell, which can be detrimental to its stability. Developing encapsulation techniques and stable perovskite compositions that can withstand these conditions without compromising performance is crucial.

Furthermore, the challenge of current matching between the perovskite top cell and the silicon bottom cell is critical for maximizing tandem efficiency. The textured interfaces complicate this process by altering the light distribution between the two subcells. Achieving optimal current matching requires precise control over the thickness and composition of both the perovskite and silicon layers, as well as careful engineering of the intermediate layers and texturing patterns.

Lastly, the scalability of perovskite-silicon tandem cells with textured interfaces poses a significant challenge. While laboratory-scale devices have shown promising efficiencies, translating these results to large-area, commercially viable modules is complex. Issues such as uniformity of deposition, consistency of texturing across large areas, and the development of cost-effective manufacturing processes that can maintain high performance at scale need to be addressed.

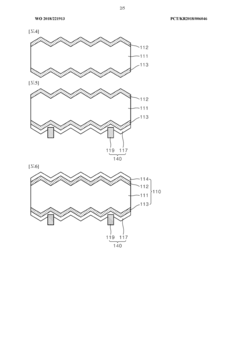

Current Texturing Solutions

01 Textured interfaces for light management

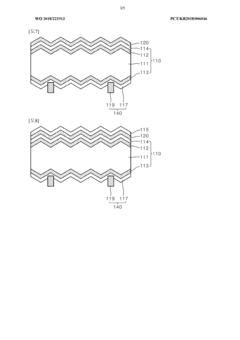

Implementing textured interfaces between the perovskite and silicon layers can enhance light trapping and reduce reflection. This approach improves overall light absorption and increases the efficiency of tandem solar cells by allowing more light to be utilized by both the perovskite top cell and the silicon bottom cell.- Textured interfaces for light trapping: Implementing textured interfaces between the perovskite and silicon layers enhances light trapping and reduces reflection losses. This approach improves the overall efficiency of tandem solar cells by increasing light absorption in both the perovskite and silicon subcells.

- Intermediate reflectors and selective contacts: Utilizing intermediate reflectors and selective contacts between the perovskite and silicon layers helps manage light distribution. These components can reflect specific wavelengths back into the perovskite layer while allowing others to pass through to the silicon layer, optimizing the spectral response of each subcell.

- Nanostructured light management layers: Incorporating nanostructured light management layers, such as photonic crystals or plasmonic nanoparticles, can enhance light absorption and reduce reflection. These structures can be designed to manipulate light at specific wavelengths, improving the overall performance of the tandem cell.

- Antireflective coatings and encapsulation: Applying advanced antireflective coatings and optimizing encapsulation materials can significantly reduce surface reflection and improve light coupling into the device. These techniques enhance the overall light management and protect the sensitive perovskite layer from environmental degradation.

- Transparent conductive oxides optimization: Optimizing transparent conductive oxides (TCOs) used as electrodes in tandem cells is crucial for efficient light management. Developing TCOs with high transparency and low resistivity improves light transmission to the active layers while maintaining good electrical performance.

02 Intermediate reflector layers

Incorporating intermediate reflector layers between the perovskite and silicon subcells can optimize light distribution. These layers selectively reflect certain wavelengths back into the perovskite layer while transmitting others to the silicon layer, improving the spectral utilization and overall efficiency of the tandem structure.Expand Specific Solutions03 Nanostructured light trapping

Utilizing nanostructures such as nanowires, nanoparticles, or photonic crystals in various layers of the tandem cell can enhance light trapping and absorption. These nanostructures can be incorporated into the top electrode, perovskite layer, or silicon layer to manipulate light propagation and increase path length within the active layers.Expand Specific Solutions04 Antireflective coatings

Applying advanced antireflective coatings on the top surface of the tandem cell can significantly reduce surface reflection and increase light coupling into the device. These coatings can be designed to work effectively across a broad spectrum of wavelengths relevant to both perovskite and silicon absorption ranges.Expand Specific Solutions05 Transparent conductive oxides optimization

Optimizing the properties of transparent conductive oxides (TCOs) used as electrodes in tandem cells can improve light management. This includes tuning the thickness, composition, and deposition conditions of TCO layers to achieve high transparency and conductivity, minimizing parasitic absorption while maintaining good electrical performance.Expand Specific Solutions

Key Industry Players

The research on perovskite-silicon tandem light management with textured interfaces is in a rapidly evolving phase, with significant market potential and growing technological maturity. The global photovoltaic industry is experiencing a transition towards higher efficiency solar cells, driving interest in tandem technologies. Key players like Trina Solar, JinkoSolar, and Hanwha Solutions are investing heavily in R&D to commercialize this technology. Academic institutions such as King Abdullah University of Science & Technology and The University of North Carolina at Chapel Hill are contributing fundamental research. Companies like Microquanta (Hangzhou Xianna Ophotoelectrics Technology) are pioneering in perovskite commercialization, while established firms like LG Electronics and BYD are exploring integration into their existing solar product lines.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has developed a commercial approach to light management in perovskite-silicon tandem solar cells, focusing on industrially viable techniques. Their strategy involves adapting existing texturing processes used in silicon solar cell production to create optimized interfaces for tandem devices. The company has implemented a modified random pyramid texturing process for the silicon bottom cell, which enhances light trapping while maintaining compatibility with perovskite top cell deposition[13]. They have also explored the use of anti-reflection coatings with tailored refractive indices to minimize reflection losses at the perovskite-silicon interface. Trina Solar has reported tandem cell efficiencies exceeding 26% using their light management techniques in pilot production lines[14], demonstrating the potential for large-scale manufacturing of high-efficiency tandem devices.

Strengths: Strong industrial expertise, established manufacturing capabilities, and focus on scalable technologies. Weaknesses: Potentially less advanced in cutting-edge nanostructured interfaces compared to academic institutions, need for further optimization to reach highest reported efficiencies.

Oxford University Innovation Ltd.

Technical Solution: Oxford University Innovation has developed advanced light management techniques for perovskite-silicon tandem solar cells. Their approach involves using textured interfaces to enhance light trapping and reduce reflection losses. The team has implemented nanophotonic structures at the perovskite-silicon interface, which have been shown to increase light absorption in both the perovskite top cell and the silicon bottom cell[1]. They have also explored the use of periodic and quasi-random textures to optimize light distribution between the two sub-cells[2]. Their research has demonstrated that carefully designed textured interfaces can lead to a significant boost in the overall power conversion efficiency of tandem devices, with reported improvements of up to 2-3% absolute compared to planar interfaces[3].

Strengths: Cutting-edge nanophotonic design expertise, access to advanced fabrication facilities, and strong academic research background. Weaknesses: Potential challenges in scaling up to industrial production and higher costs associated with complex nanostructures.

Innovative Interface Designs

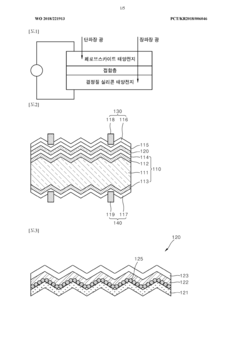

Perovskite-silicon tandem solar cell

PatentActiveUS11437537B2

Innovation

- The implementation of a tandem photovoltaic cell structure incorporating a porous silicon layer as an electron transport layer, directly contacting the perovskite layer, and optionally doped with n-type or p-type silicon, which enhances light absorption and reduces parasitic absorption losses by eliminating the need for interfacial layers.

Method for manufacturing perovskite silicon tandem solar cell

PatentWO2018221913A1

Innovation

- A method involving a sputtering process to form a microporous perovskite absorption layer on a textured substrate with a concavo-convex structure, followed by a halide thin film formation and post-heat treatment, to create a conformal perovskite layer that reduces light reflectance and enhances light absorption.

Efficiency Improvement Potential

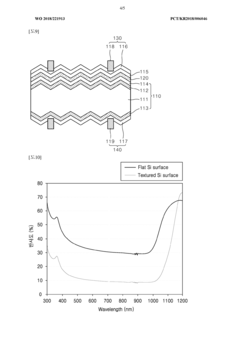

Perovskite-silicon tandem solar cells have shown remarkable potential for improving photovoltaic efficiency beyond the theoretical limit of single-junction silicon cells. The efficiency improvement potential of these tandem structures is primarily attributed to their ability to harness a broader spectrum of sunlight and reduce thermalization losses. By combining the high bandgap perovskite top cell with the lower bandgap silicon bottom cell, these tandems can theoretically achieve efficiencies exceeding 30%.

The textured interfaces between the perovskite and silicon layers play a crucial role in enhancing light management and, consequently, the overall efficiency of the tandem structure. These textured interfaces can significantly reduce reflection losses and increase light trapping, particularly for longer wavelengths that are poorly absorbed by the perovskite layer. By optimizing the texture morphology, researchers have demonstrated improved current matching between the top and bottom cells, leading to higher overall efficiencies.

Recent studies have shown that carefully designed textured interfaces can potentially increase the short-circuit current density by up to 2 mA/cm² compared to planar interfaces. This improvement translates to an efficiency gain of approximately 1-2% absolute, pushing the practical efficiency limits of perovskite-silicon tandems closer to their theoretical maximum.

Furthermore, advanced light management strategies, such as incorporating photonic structures or nanopatterned interlayers, have shown promise in further enhancing the efficiency of these tandem devices. These approaches can selectively redirect light of specific wavelengths to the appropriate subcell, maximizing absorption and current generation in both the perovskite and silicon layers.

The efficiency improvement potential is not limited to optical enhancements alone. Advances in perovskite material engineering, such as compositional tuning and defect passivation, can lead to higher open-circuit voltages and fill factors. Combined with optimized light management, these improvements could potentially push perovskite-silicon tandem efficiencies beyond 35% in the coming years.

However, it is important to note that realizing the full efficiency potential of perovskite-silicon tandems with textured interfaces requires overcoming several challenges. These include developing scalable and cost-effective fabrication methods for textured interfaces, ensuring long-term stability of the perovskite layer on textured surfaces, and maintaining high-quality interfaces between the subcells. Addressing these challenges will be crucial in translating the promising laboratory results into commercially viable high-efficiency tandem solar cells.

The textured interfaces between the perovskite and silicon layers play a crucial role in enhancing light management and, consequently, the overall efficiency of the tandem structure. These textured interfaces can significantly reduce reflection losses and increase light trapping, particularly for longer wavelengths that are poorly absorbed by the perovskite layer. By optimizing the texture morphology, researchers have demonstrated improved current matching between the top and bottom cells, leading to higher overall efficiencies.

Recent studies have shown that carefully designed textured interfaces can potentially increase the short-circuit current density by up to 2 mA/cm² compared to planar interfaces. This improvement translates to an efficiency gain of approximately 1-2% absolute, pushing the practical efficiency limits of perovskite-silicon tandems closer to their theoretical maximum.

Furthermore, advanced light management strategies, such as incorporating photonic structures or nanopatterned interlayers, have shown promise in further enhancing the efficiency of these tandem devices. These approaches can selectively redirect light of specific wavelengths to the appropriate subcell, maximizing absorption and current generation in both the perovskite and silicon layers.

The efficiency improvement potential is not limited to optical enhancements alone. Advances in perovskite material engineering, such as compositional tuning and defect passivation, can lead to higher open-circuit voltages and fill factors. Combined with optimized light management, these improvements could potentially push perovskite-silicon tandem efficiencies beyond 35% in the coming years.

However, it is important to note that realizing the full efficiency potential of perovskite-silicon tandems with textured interfaces requires overcoming several challenges. These include developing scalable and cost-effective fabrication methods for textured interfaces, ensuring long-term stability of the perovskite layer on textured surfaces, and maintaining high-quality interfaces between the subcells. Addressing these challenges will be crucial in translating the promising laboratory results into commercially viable high-efficiency tandem solar cells.

Scalability and Commercialization

The scalability and commercialization of perovskite-silicon tandem solar cells with textured interfaces present both significant opportunities and challenges. As the technology advances, the potential for large-scale production and market adoption becomes increasingly feasible. However, several key factors must be addressed to ensure successful commercialization.

One of the primary considerations is the development of cost-effective manufacturing processes that can maintain the high efficiency of laboratory-scale devices when scaled up to industrial production. This includes optimizing deposition techniques for perovskite layers on textured silicon surfaces, ensuring uniform coverage and minimizing defects across large areas. Additionally, the integration of textured interfaces into existing silicon solar cell production lines requires careful engineering to maintain compatibility with current manufacturing equipment and processes.

The stability and longevity of perovskite-silicon tandem cells with textured interfaces are crucial for commercial viability. While textured interfaces can enhance light management and improve overall efficiency, they may also introduce additional complexity in terms of long-term durability. Addressing issues such as perovskite degradation, interface stability, and encapsulation techniques that can withstand various environmental conditions is essential for meeting industry standards and consumer expectations.

Material availability and supply chain considerations play a significant role in scalability. The perovskite layer typically contains lead, which raises environmental concerns and may face regulatory challenges in some markets. Developing lead-free alternatives or implementing robust recycling and disposal processes will be critical for widespread adoption. Furthermore, ensuring a stable supply of high-quality precursor materials for both the perovskite and silicon components is necessary to support large-scale production.

The economic viability of perovskite-silicon tandem cells with textured interfaces depends on achieving a balance between increased efficiency and production costs. While the potential for higher power conversion efficiencies is promising, the additional manufacturing steps and materials required for textured interfaces must not significantly increase the overall cost per watt of the final product. Conducting thorough cost-benefit analyses and identifying opportunities for process optimization will be crucial in making these tandem cells competitive with existing solar technologies.

Market acceptance and integration into existing solar energy systems are key factors for successful commercialization. This includes addressing potential concerns from installers, utilities, and end-users regarding the reliability and performance of this new technology. Demonstrating long-term field performance, developing appropriate warranty structures, and ensuring compatibility with existing balance-of-system components will be essential for gaining market trust and accelerating adoption.

One of the primary considerations is the development of cost-effective manufacturing processes that can maintain the high efficiency of laboratory-scale devices when scaled up to industrial production. This includes optimizing deposition techniques for perovskite layers on textured silicon surfaces, ensuring uniform coverage and minimizing defects across large areas. Additionally, the integration of textured interfaces into existing silicon solar cell production lines requires careful engineering to maintain compatibility with current manufacturing equipment and processes.

The stability and longevity of perovskite-silicon tandem cells with textured interfaces are crucial for commercial viability. While textured interfaces can enhance light management and improve overall efficiency, they may also introduce additional complexity in terms of long-term durability. Addressing issues such as perovskite degradation, interface stability, and encapsulation techniques that can withstand various environmental conditions is essential for meeting industry standards and consumer expectations.

Material availability and supply chain considerations play a significant role in scalability. The perovskite layer typically contains lead, which raises environmental concerns and may face regulatory challenges in some markets. Developing lead-free alternatives or implementing robust recycling and disposal processes will be critical for widespread adoption. Furthermore, ensuring a stable supply of high-quality precursor materials for both the perovskite and silicon components is necessary to support large-scale production.

The economic viability of perovskite-silicon tandem cells with textured interfaces depends on achieving a balance between increased efficiency and production costs. While the potential for higher power conversion efficiencies is promising, the additional manufacturing steps and materials required for textured interfaces must not significantly increase the overall cost per watt of the final product. Conducting thorough cost-benefit analyses and identifying opportunities for process optimization will be crucial in making these tandem cells competitive with existing solar technologies.

Market acceptance and integration into existing solar energy systems are key factors for successful commercialization. This includes addressing potential concerns from installers, utilities, and end-users regarding the reliability and performance of this new technology. Demonstrating long-term field performance, developing appropriate warranty structures, and ensuring compatibility with existing balance-of-system components will be essential for gaining market trust and accelerating adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!