Advanced Lubricant Formulations For Improved Performance - Eureka

JUN 17, 20253 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Advanced Lubricant Formulation Goals and Background

The primary objective is to provide an in-depth analysis of the current state and future prospects of advanced lubricant formulations for improved performance. This includes a comprehensive review of the technological advancements, market trends, and key players in this field.

The report will delve into the challenges and limitations faced by existing lubricant formulations, highlighting the need for innovative solutions. It will also explore the potential avenues for technological breakthroughs and novel approaches that could lead to enhanced performance and efficiency in various applications.

The report will delve into the challenges and limitations faced by existing lubricant formulations, highlighting the need for innovative solutions. It will also explore the potential avenues for technological breakthroughs and novel approaches that could lead to enhanced performance and efficiency in various applications.

Market Demand for High-Performance Lubricants

- Growing Demand for High-Performance Lubricants The market for high-performance lubricants is expanding rapidly due to the increasing demand for improved efficiency, extended equipment life, and reduced maintenance costs across various industries.

- Automotive and Transportation Sector The automotive and transportation sectors are major drivers of the high-performance lubricant market, driven by the need for improved fuel efficiency, reduced emissions, and longer service intervals.

- Industrial Machinery and Equipment The industrial sector, including manufacturing, construction, and mining, requires high-performance lubricants to ensure reliable operation, reduce downtime, and extend the lifespan of machinery and equipment.

- Aerospace and Defense The aerospace and defense industries have stringent requirements for lubricants that can withstand extreme temperatures, pressures, and operating conditions, driving the demand for advanced formulations.

- Renewable Energy and Power Generation The growing adoption of renewable energy technologies, such as wind turbines and solar power systems, has created a demand for specialized lubricants that can operate efficiently in harsh environments.

Current State and Challenges in Lubricant Technology

- Technological Limitations

Current lubricant formulations face challenges in extreme conditions, such as high temperatures, heavy loads, and corrosive environments, leading to reduced performance and shorter lifespan. - Environmental Concerns

Many conventional lubricants contain hazardous compounds that pose risks to the environment and human health, driving the need for eco-friendly alternatives. - Compatibility Issues

Compatibility between lubricants and various materials used in machinery can be problematic, resulting in degradation, wear, and potential system failures. - Energy Efficiency

Improving energy efficiency through reduced friction and wear is a significant challenge, as it directly impacts operational costs and sustainability. - Additive Depletion

Lubricant additives that enhance performance can deplete over time, necessitating frequent replacements or replenishments, increasing maintenance costs.

Existing Solutions in Lubricant Formulations

01 Oxidation and Deposit Control Lubricants

Formulated with additives or components that enhance resistance to oxidation and prevent deposit formation, improving overall performance and extending service life.- Oxidation and Deposit Control Lubricants: Formulated with additives or components that enhance resistance to oxidation and prevent deposit formation, improving overall performance and extending service life.

- Low-Temperature Performance Lubricants: Designed to maintain fluidity and lubrication properties at low temperatures, ensuring optimal performance in cold environments or during cold starts.

- Synthetic Lubricants with Improved Performance: Made from synthetic base oils or compounds, offering enhanced performance characteristics compared to conventional mineral-based lubricants, such as better thermal stability, oxidation resistance, and low-temperature fluidity.

- Extreme Pressure and Anti-Wear Lubricants: Formulated with additives or components that provide enhanced protection against extreme pressure and wear conditions, suitable for heavy-duty applications or severe operating environments.

- Lubricant Performance Improvement Processes: Various techniques, processes, or methods aimed at enhancing the performance characteristics of lubricants, such as improving oxidation stability, reducing friction, or extending service life.

02 Synthetic Lubricants with Improved Properties

Synthetically produced lubricants offering superior performance compared to conventional mineral-based ones, such as improved thermal stability, low-temperature fluidity, and resistance to degradation.Expand Specific Solutions03 Fuel Economy Lubricants

Formulated to reduce friction and energy losses, resulting in improved fuel efficiency and reduced emissions when used in engines or machinery.Expand Specific Solutions04 Extreme Pressure and Anti-Wear Lubricants

Containing additives or components that enhance their ability to withstand extreme pressure conditions and reduce wear on metal surfaces, suitable for heavy-duty applications.Expand Specific Solutions05 Improved Lubricant Manufacturing Processes

Advancements in the production or regeneration of lubricants, such as hydrogenation, distillation, or incorporation of specific additives, to improve their quality and performance characteristics.Expand Specific Solutions

Key Players in Lubricant Industry

The competitive landscape for advanced lubricant formulations is characterized by established industry giants and specialized research entities. The industry is mature, driven by automotive, industrial, and marine sectors. Key players include China Petroleum & Chemical Corp., Exxon Research & Engineering Co., BASF SE, Shell Internationale Research Maatschappij BV, and The Lubrizol Corp., with advanced R&D capabilities and market reach. Ongoing innovations focus on enhancing lubricant efficiency and sustainability.

Exxon Research & Engineering Co.

Technical Solution: Exxon Research & Engineering Co. develops advanced lubricant formulations with synthetic base oils and proprietary additives for enhanced thermal stability, reduced friction, and extreme condition performance.

Strength: High thermal stability. Weakness: Higher cost.

BASF SE

Technical Solution: BASF SE offers innovative lubricant solutions with high-performance additives for improved wear protection and extended machinery life.

Strength: Excellent wear protection. Weakness: Limited availability in some regions.

Core Innovations in Lubricant Chemistry

Enhanced Lubricant Formulation

PatentInactiveUS20150252280A1

Innovation

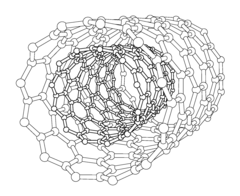

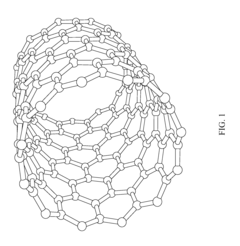

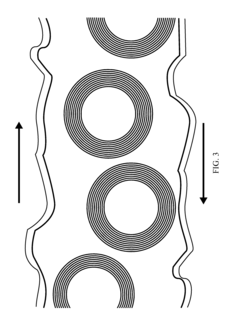

- Combination of icl nanoparticles with an existing lubricant: the formulation combines the lubricating properties of an existing lubricant with the tribological enhancement properties of icl nanoparticles. this combination allows for improved performance and extended life of mechanical systems.

- Reduction of friction and surface roughness: the use of icl nanoparticles in the formulation provides a rolling effect and exfoliates the lamellar exterior, resulting in reduced friction and surface roughness. this leads to improved tribological properties and reduced wear and tear on moving parts.

- Improved performance under extreme conditions: the formulation also provides improved performance under conditions of extreme temperature and pressure. this is a significant advantage as it allows the lubricant to maintain its effectiveness in demanding operating conditions.

Environmental Impact of Lubricant Formulations

Advanced lubricant formulations aim to enhance the performance and efficiency of mechanical systems by reducing friction, wear, and energy losses. The market demand for these formulations is driven by the need for improved fuel economy, extended equipment life, and reduced maintenance costs across various industries. Key challenges include developing environmentally friendly and biodegradable lubricants, improving thermal and oxidative stability, and enhancing load-carrying capacity. Potential innovation directions involve exploring novel additive packages, bio-based lubricants, and nanotechnology-enabled formulations for enhanced tribological properties and performance under extreme conditions.

Regulatory Standards for Lubricant Performance

Lubricants play a crucial role in enhancing the performance and longevity of mechanical systems. Advanced lubricant formulations aim to improve properties such as wear resistance, oxidation stability, and low-temperature fluidity. Key areas of research include developing synthetic base oils, optimizing additive packages, and exploring novel nanoparticle-based lubricants. Potential innovations involve bio-based lubricants, ionic liquids, and self-healing coatings. Collaborations between academia, industry, and government agencies drive progress in this field, fostering sustainable and high-performance lubricant solutions for various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!