Strategies To Mitigate Wear In Check Valves

NOV 8, 20244 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mitigating Wear In Check Valve: Technology Background And Goals

The primary objective is to investigate and analyze the current state, challenges, and potential solutions for reducing wear in check valves, which are crucial components in various industrial applications. This research aims to provide a comprehensive understanding of the wear mechanisms, identify key factors contributing to valve degradation, and explore innovative approaches to enhance valve durability and extend service life.

Wear in check valves can lead to leakage, reduced flow efficiency, and premature failure, resulting in significant operational and maintenance costs. By addressing this issue, industries can improve system reliability, reduce downtime, and achieve cost savings. The research will delve into the latest advancements in materials, coatings, valve designs, and monitoring techniques to mitigate wear and prolong valve performance.

Ultimately, the findings from this study will guide the development of more robust and wear-resistant check valve solutions, benefiting a wide range of industries and contributing to improved operational efficiency and sustainability.

Ultimately, the findings from this study will guide the development of more robust and wear-resistant check valve solutions, benefiting a wide range of industries and contributing to improved operational efficiency and sustainability.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valve products and services, including the breakdown by industry sectors and geographical regions. Estimate the potential market growth rate based on factors like industrial expansion, infrastructure development, and regulatory changes. - Key Demand Drivers

Identify the primary drivers fueling the demand for check valves, such as the need for reliable fluid control, prevention of backflow, and compliance with safety standards. Examine how these drivers vary across different applications and industries. - Emerging Applications

Explore emerging applications or industries that may create new demand for check valves, such as renewable energy systems, desalination plants, or advanced manufacturing processes. Assess the potential impact of these applications on market growth. - Customer Preferences

Analyze customer preferences and requirements regarding check valve performance, durability, maintenance, and cost-effectiveness. Identify any shifts in preferences driven by factors like sustainability concerns or technological advancements. - Competitive Landscape

Evaluate the competitive landscape, including the market share and positioning of major check valve manufacturers. Assess the impact of new entrants, disruptive technologies, or alternative solutions on the market dynamics.

Mitigating Wear In Check Valve: Technology Status And Challenges

- Valve Wear Mechanisms

Erosion, corrosion, cavitation, and mechanical wear are the primary causes of valve degradation. - Challenges in Severe Environments

High temperatures, pressures, and corrosive media pose significant challenges for valve materials and designs. - Material Limitations

Conventional materials like metals and elastomers have limited durability in harsh conditions, necessitating advanced materials. - Design Constraints

Valve geometries and flow patterns can contribute to wear, requiring optimized designs for specific applications. - Monitoring and Maintenance

Effective wear monitoring and timely maintenance are crucial for ensuring valve reliability and safety.

Mitigating Wear In Check Valve: Current Technical Solutions

01 Erosion and Corrosion Wear

Check valves can experience wear due to erosion from fluid flow and corrosion from exposure to certain chemicals or environments, leading to leakage, reduced efficiency, and potential failure.- Particulate Matter Wear: Check valves can experience wear due to particulate matter in the fluid flow, causing abrasion and erosion of components, leading to leakage and reduced performance over time. Mitigating measures include wear-resistant materials, filters, and regular maintenance.

- Fluid Property Wear: Fluid properties like corrosiveness, temperature, and viscosity can contribute to check valve wear, affecting materials and sealing surfaces, leading to degradation and leakage. Compatible materials, coatings, and fluid property control can mitigate this issue.

- Cyclic Loading Wear: Check valves undergo cyclic loading during operation, causing fatigue and wear of components over time. Using high fatigue strength materials, optimizing design, and preventive maintenance can address this issue.

- Installation and Operation Wear: Improper installation or operation of check valves can lead to premature wear and failure, including misalignment, excessive vibration, or exposure beyond design limits. Proper practices are crucial for mitigation.

- Wear Monitoring and Detection: Monitoring and detecting wear in check valves is essential for timely maintenance and replacement. Techniques like acoustic emission monitoring, vibration analysis, and pressure drop measurements can detect and quantify valve wear, enabling proactive maintenance strategies.

02 Mechanical Wear

Mechanical factors like friction, impact, and cyclic loading can contribute to wear of check valve components, affecting their ability to seal properly and requiring replacement or maintenance.Expand Specific Solutions03 Wear-Resistant Materials

Using wear-resistant materials like ceramics, hard coatings, or specialized alloys can help reduce wear in check valves and extend their service life, particularly in harsh environments or with abrasive fluids.Expand Specific Solutions04 Wear-Reducing Design

Specific design features like optimized flow paths, reduced turbulence, and improved sealing surfaces can help minimize wear in check valves by reducing erosion, cavitation, and other wear-inducing factors.Expand Specific Solutions05 Monitoring and Maintenance

Regular monitoring and maintenance of check valves can help detect and address wear issues before they lead to more significant problems, involving techniques like visual inspection, leak testing, and predictive maintenance strategies.Expand Specific Solutions

Mitigating Wear In Check Valve: Main Player Analysis

The competitive landscape for reducing wear of check valves is characterized by established industry leaders and specialized companies. The market is mature, driven by demand across various sectors. Key players like Robert Bosch GmbH, Honeywell International Technologies Ltd., and Siemens AG leverage extensive R&D to innovate in this space.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced materials and coatings, including high-performance ceramics and diamond-like carbon (DLC), to enhance check valve durability and lifespan.

Strength: High durability and lifespan. Weakness: High cost of materials and coatings.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has introduced a proprietary surface treatment technology involving specialized lubricants that form a protective layer, reducing friction and extending valve operational life.

Strength: Effective in reducing friction. Weakness: May require frequent reapplication of lubricant.

Mitigating Wear In Check Valve: Key Technology Interpretation

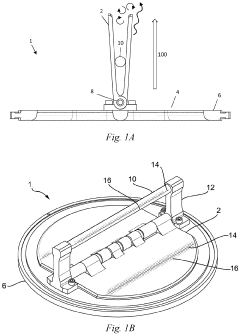

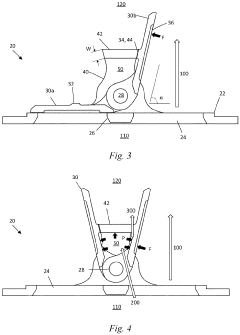

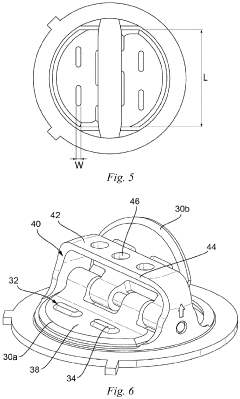

Flapper check valve

PatentActiveEP4083478A1

Innovation

- Conformal contact surfaces: the provision of relatively large contact areas due to the conformal contact surfaces allows for the even distribution of stress between the flappers and stop elements. this reduces wear and tear on the components, especially during percussive opening of the valve. the use of conformal contact surfaces ensures that the stress is evenly distributed, preventing localized wear.

- Bumpers and adjacent openings: the inclusion of bumpers and adjacent openings in the valve design facilitates smooth opening and closing of the valve. these elements help reduce fluttering and percussive opening events, which can cause wear and damage to the contact surfaces. by minimizing these events, the valve can have a longer lifespan and reduced maintenance requirements.

- Static stop element: the provision of a static stop element with contact surfaces configured to be stationary (e.g. non-resilient) further prevents positional fluctuations of the flapper when in the open position. this additional stationary stop element further reduces wear on the contact surfaces and the pin of the hinge. the use of a static stop element ensures that the flapper remains in a fixed position, preventing any unwanted movement that could cause wear.

- Synergistic effect: the combination of conformal contact surfaces, bumpers, and static stop elements that are configured to remain stationary (rather than bend or flex in use) provides a synergistic effect. this ensures that wear on the contact surfaces is minimized, preventing wear on the pin of the hinge and reducing wear on the contact surfaces themselves. by preventing wear, the valve can have a longer lifespan and require less maintenance, resulting in cost savings for the organization.

Check Valve Wear Reduction Economic Analysis

Check valve wear is a significant issue that can lead to reduced efficiency, increased maintenance costs, and potential safety hazards. An economic analysis of check valve wear reduction strategies is crucial for identifying cost-effective solutions and optimizing operational expenses. This analysis should encompass factors such as the cost of valve replacement, downtime expenses, energy losses due to leakage, and the potential savings from implementing wear reduction measures. By quantifying these elements, organizations can make informed decisions regarding the implementation of wear mitigation techniques, ultimately enhancing operational reliability, minimizing unplanned shutdowns, and maximizing profitability.

Check Valve Wear Reduction Policy And Regulatory Impact

The regulatory landscape surrounding check valve wear reduction is complex and multifaceted. Various government agencies and industry bodies have implemented guidelines and standards to mitigate valve wear and ensure safe operation. Environmental regulations aim to minimize emissions and leakage, while safety protocols prioritize the integrity of critical infrastructure. Compliance with these regulations is essential for manufacturers and operators, as violations can result in hefty fines and legal consequences. Additionally, the impact of regulations extends beyond the immediate industry, influencing supply chains, material sourcing, and disposal practices. Staying abreast of evolving regulations and proactively addressing compliance requirements is crucial for maintaining operational efficiency and minimizing risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!