Advanced Sealing Materials For Improving Sealing Performance Of Check Valves

NOV 7, 20244 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Check Valve Sealing Materials Background And Goals

The primary objective is to comprehensively investigate the development history of advanced sealing materials for improving the sealing performance of check valves, and explore the technological evolution trends in this field. This includes examining the key milestones and breakthroughs that have shaped the progress of sealing materials, as well as identifying the anticipated technological goals and advancements expected to be achieved in the future.

The analysis will delve into the driving forces behind the advancements in sealing materials, such as the need for improved reliability, durability, and performance in various industrial applications. It will also shed light on the potential challenges and limitations that may hinder the widespread adoption of these advanced materials, and outline strategies to overcome these obstacles.

The analysis will delve into the driving forces behind the advancements in sealing materials, such as the need for improved reliability, durability, and performance in various industrial applications. It will also shed light on the potential challenges and limitations that may hinder the widespread adoption of these advanced materials, and outline strategies to overcome these obstacles.

Check Valve Market Demand Analysis

- Growing Demand for Check Valves

Check valves are essential components in various industries, including oil and gas, chemical processing, water treatment, and power generation. The demand for check valves is driven by the need for reliable and efficient fluid control systems. - Expansion of End-Use Industries

The growth of end-use industries, such as oil and gas exploration and production, petrochemical plants, and power generation facilities, is fueling the demand for check valves. As these industries expand and upgrade their infrastructure, the need for high-performance check valves increases. - Stringent Regulations and Safety Standards

Stringent regulations and safety standards imposed by governing bodies are driving the demand for advanced sealing materials in check valves. These regulations aim to ensure the safe and efficient operation of fluid systems, minimizing the risk of leaks and environmental hazards. - Replacement and Maintenance Needs

Existing check valves in aging infrastructure require periodic replacement and maintenance. The demand for advanced sealing materials is driven by the need to extend the service life and improve the reliability of check valves in these applications. - Emerging Markets and Industrialization

The rapid industrialization and infrastructure development in emerging markets, such as Asia-Pacific and the Middle East, are creating new opportunities for check valve manufacturers. These regions are witnessing significant investments in various industries, driving the demand for advanced sealing materials.

Check Valve Sealing Technology Status And Challenges

- Sealing Performance Challenges

Check valves face issues like leakage, erosion, and premature failure due to harsh operating conditions and aggressive media. Advanced sealing materials are needed to enhance sealing integrity and extend service life. - Material Requirements

Desired properties include high temperature and pressure resistance, chemical inertness, wear and abrasion resistance, and compatibility with various fluids and gases. - Current Material Limitations

Conventional elastomers and polymers have limited performance in extreme environments. Metallic seals offer better durability but lack flexibility and sealing efficiency. - Emerging Material Solutions

Promising options include engineered polymer composites, advanced ceramics, and surface-modified metals for improved tribological properties and chemical resistance.

Check Valve Current Sealing Solutions

01 Sealing Structure

The sealing performance of check valves is influenced by their sealing structure, which can include features like sealing surfaces, sealing members (e.g., gaskets, O-rings), and sealing mechanisms. Optimizing the design of these components can improve sealing performance.- Sealing Structure: The sealing performance of check valves is influenced by the design of the valve seat, valve disc, and sealing surfaces. Optimizing their geometry and materials can improve sealing effectiveness and prevent leakage.

- Sealing Materials: Selecting appropriate materials with suitable properties like wear resistance, chemical compatibility, and temperature resistance for valve components like the seat, disc, and sealing surfaces can enhance sealing performance.

- Sealing Mechanisms: Various sealing mechanisms, such as spring-loaded sealing, metal-to-metal sealing, or specialized sealing elements like O-rings or gaskets, can be employed to improve sealing performance based on application requirements.

- Surface Treatments: Surface treatments like polishing, coating, or texturing applied to sealing surfaces can enhance sealing performance by improving surface finish, reducing friction, or increasing sealing contact area.

- Sealing Force Optimization: Optimizing the sealing force applied between the valve disc and valve seat through design modifications like adjusting spring preload or incorporating sealing force amplification mechanisms can improve sealing performance.

02 Materials

Selecting suitable materials with desirable properties like chemical resistance, temperature resistance, and compatibility with the fluid being handled for sealing components can enhance sealing performance.Expand Specific Solutions03 Design and Configuration

The overall design and configuration of check valves, including factors like valve geometry, flow path, and sealing force, can influence their sealing performance. Optimizing these design aspects can help minimize leakage and improve sealing effectiveness.Expand Specific Solutions04 Sealing Mechanisms

Check valves can employ various sealing mechanisms, such as spring-loaded sealing, gravity-assisted sealing, or pressure-assisted sealing, to ensure effective sealing performance. Selecting and optimizing the appropriate sealing mechanism can enhance sealing capabilities.Expand Specific Solutions05 Maintenance and Operation

Proper maintenance and operation practices, such as regular inspections, cleaning, and replacement of worn components, can help maintain the sealing performance of check valves over time. Following recommended maintenance procedures can prevent leakage and ensure optimal sealing.Expand Specific Solutions

Check Valve Main Player Analysis

The competitive landscape for advanced sealing materials to improve the sealing performance of check valves is characterized by a diverse range of players at different stages of industry development. The market size for such materials is expanding due to increasing demand for high-performance sealing solutions in various sectors.

Fisher Controls International LLC

Technical Solution: Fisher Controls develops high-performance elastomers and composites for enhanced sealing, wear resistance, and durability in check valves.

Strength: High resistance to wear and chemical degradation. Weakness: Higher cost compared to conventional materials.

NOK Corp.

Technical Solution: NOK Corp. specializes in rubber compounds and manufacturing techniques for durable, fluid-compatible sealing materials that reduce leakage in check valves.

Strength: Excellent durability and fluid compatibility. Weakness: Limited availability in some regions.

Check Valve Key Sealing Technology Interpretation

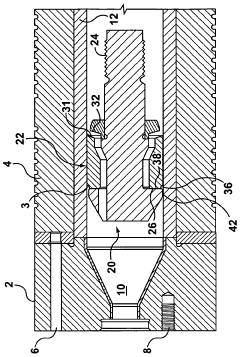

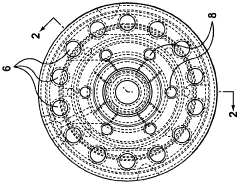

Check valve lip seal for an injection molding machine

PatentWO2006000075A1

Innovation

- A lip seal for a check ring of a check valve for a metal injection machine, with a groove interior of a circumferential surface of the ring that engages with a surface of the valve to block flow of injection material into a melt passageway.

- A check valve with a groove formed in a forward face of the ring portion that receives melt to force an outer circumferential portion of the ring in a radial direction to provide a seal between the ring portion and a wall in the machine.

- The use of a lip seal design with a groove and circumferential sealing surface, specifically tailored for metal injection molding and die casting applications.

Check Valve Sealing Materials Environmental Impact

The sealing materials used in check valves can have a significant environmental impact throughout their lifecycle. During the manufacturing process, the production of certain sealing materials may involve the use of hazardous chemicals or generate harmful emissions, contributing to environmental pollution. Additionally, the extraction and processing of raw materials for these sealing components can lead to resource depletion and habitat destruction. Once installed in check valves, the potential leakage or degradation of sealing materials could result in the release of toxic substances into the surrounding environment, contaminating water sources or soil. Furthermore, the disposal of worn-out sealing materials may pose challenges if not properly managed, as some materials are non-biodegradable and can persist in landfills or the environment for extended periods.

Check Valve Sealing Materials Regulatory Considerations

The regulatory considerations for sealing materials used in check valves are crucial to ensure safety, reliability, and compliance with industry standards. These materials must meet stringent requirements regarding chemical compatibility, temperature resistance, and durability under various operating conditions. Regulatory bodies, such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), have established guidelines and specifications for the selection and testing of sealing materials. Compliance with these regulations is essential to mitigate risks associated with leakage, contamination, and premature failure of check valves in critical applications. Manufacturers must conduct rigorous testing and obtain certifications to demonstrate the suitability of their sealing materials for specific applications and operating environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!