Improving The Sealing Performance Of Check Valves

Check Valve Technology Background And Goals

Key areas of focus include evaluating the materials and designs employed in check valve sealing components, examining the factors that contribute to leakage or premature wear, and investigating emerging technologies or novel approaches that could address these issues. The goal is to provide a thorough understanding of the technical landscape and propose viable strategies for developing more reliable and efficient sealing systems for check valves.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valves and related products, highlighting key application areas. Provide projections for market growth over the next 5-10 years, considering factors like industrial expansion and infrastructure development. - Regional Demand Trends

Examine regional variations in demand for check valves, identifying regions with high growth potential. Discuss factors driving demand, such as regulatory changes, industry-specific requirements, or technological advancements. - Application-Specific Needs

Assess the unique sealing performance requirements across different applications, such as oil and gas, chemical processing, water treatment, and power generation. Highlight any emerging applications that may drive future demand. - Customer Preferences

Analyze customer preferences regarding sealing performance, material selection, durability, and maintenance requirements. Identify any unmet needs or pain points that could influence product development. - Competitive Landscape

Provide an overview of major players in the check valve market, their market share, and their strengths and weaknesses in terms of sealing performance. Discuss any disruptive technologies or innovations that could impact the competitive dynamics.

Check Valve Technology Status And Challenges

- Sealing Challenges

Check valves face sealing issues due to wear, corrosion, and high-pressure environments, leading to leakage and reduced efficiency. - Material Limitations

Conventional materials like metals and elastomers have limitations in terms of durability, chemical resistance, and temperature tolerance. - Design Constraints

Complex valve geometries and tight clearances pose challenges in achieving effective sealing while maintaining smooth operation. - Maintenance Requirements

Regular maintenance and replacement of sealing components are often necessary, increasing operational costs and downtime.

Check Valve Current Technical Solutions

01 Sealing Structure

The sealing structure, including sealing surfaces, members (gaskets, O-rings), and mechanisms, can be optimized to enhance sealing capability and prevent leakage.- Check Valve Sealing Structure: Optimizing the sealing structure between the valve body and valve element can improve sealing performance. This may involve specialized sealing materials, unique geometries, or additional components to enhance sealing capability and prevent leakage.

- Sealing Materials: Specialized sealing materials with desirable properties like high temperature resistance, chemical compatibility, and low friction can be used to improve sealing capability and extend valve service life.

- Sealing Mechanisms: Various sealing mechanisms, such as spring-loaded sealing elements, pressure-assisted sealing, or specialized geometries, can be incorporated to enhance sealing performance under different operating conditions.

- Surface Treatments: Surface treatments like coatings, texturing, or modifications applied to sealing surfaces can improve sealing properties, reduce friction, or increase wear resistance.

- Sealing Assembly Designs: Optimizing the overall design of the sealing assembly, including configuration, additional components, or specialized mechanisms, can ensure reliable and effective sealing under various operating conditions.

02 Materials and Coatings

Selecting suitable materials and coatings with desirable properties like corrosion resistance, wear resistance, and fluid compatibility can improve sealing and extend valve service life.Expand Specific Solutions03 Design and Configuration

Optimizing the overall design and configuration, such as valve type, flow path, and orientation, can minimize turbulence, reduce wear, and ensure proper sealing under various operating conditions.Expand Specific Solutions04 Sealing Mechanisms

Incorporating sealing mechanisms like spring-loaded seals, metal-to-metal sealing, or specialized geometries can enhance sealing performance and prevent backflow or leakage.Expand Specific Solutions05 Maintenance and Testing

Regular maintenance, inspection, and testing procedures like cleaning, component replacement, and leak tests can ensure optimal sealing performance and prevent failures.Expand Specific Solutions

Check Valve Main Player Analysis

Neway Valve (Suzhou) Co., Ltd.

Fisher Controls International LLC

Check Valve Key Technology Interpretation

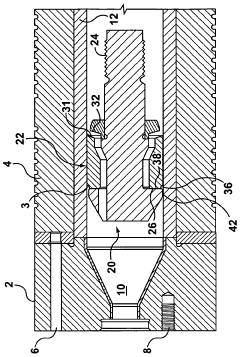

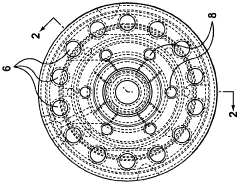

- A lip seal for a check ring of a check valve for a metal injection machine, with a groove interior of a circumferential surface of the ring that engages with a surface of the valve to block flow of injection material.

- A check valve with a groove formed in the forward face of the ring portion that receives melt to force an outer circumferential portion of the ring in a radial direction to provide a seal between the ring portion and the wall in the machine.

- The use of a lip seal design with a groove and circumferential sealing surface, specifically tailored for metal injection molding and die casting environments.

Check Valve Sealing Performance Improvement Economic Analysis

The sealing performance of check valves is crucial for ensuring efficient and reliable fluid flow control in various industrial applications. An economic analysis of improving check valve sealing performance should consider the potential cost savings and operational benefits. Improved sealing can reduce leakage, minimize downtime, and extend equipment lifespan, leading to significant cost reductions over the long term. Additionally, enhanced sealing performance can improve process efficiency, product quality, and environmental compliance, contributing to increased revenue and competitiveness. However, the implementation costs, including research and development, material upgrades, and installation expenses, must be carefully evaluated against the projected benefits to determine the overall economic feasibility and return on investment.