Check Valves With Active Flow Control For Improved Efficiency And Reliability

Technology Background And Goals

By incorporating active flow control mechanisms, these advanced check valves can dynamically adjust their operation based on real-time flow conditions, optimizing fluid flow and minimizing energy losses. This innovation promises improved energy efficiency, reduced maintenance requirements, and extended service life for critical infrastructure and industrial applications.

Check Valves Market Demand Analysis

- Market Size and Growth

The global market for check valves with active flow control is expected to witness significant growth, driven by the increasing demand for efficient and reliable fluid handling systems across various industries. - Key Application Areas

Major application areas include oil and gas, power generation, chemical processing, water and wastewater treatment, and HVAC systems, where precise flow control and prevention of backflow are crucial. - Industry Trends

- Rising emphasis on energy efficiency and emission reduction

- Adoption of advanced automation and control systems

- Increasing focus on asset reliability and maintenance optimization

- Regional Demand Dynamics

The demand for these valves is particularly high in regions with well-established industrial sectors, such as North America, Europe, and Asia-Pacific, driven by stringent regulations and the need for process optimization.

Technology Status And Challenges

- Valve Design Evolution

Tracing the development of check valve designs, from traditional swing and lift check valves to advanced active flow control valves with integrated sensors and actuators. - Key Technical Challenges

Identifying major challenges in achieving reliable and efficient active flow control, such as precise flow monitoring, rapid actuation response, and robust valve sealing. - Geographical Distribution

Highlighting regions with significant research activities and industrial capabilities in active flow control valve technologies, including major academic and industrial research centers.

Current Technical Solutions

01 Fluid Flow Control

Check valves allow fluid flow in one direction while preventing backflow, controlling flow direction and preventing reverse flow that can cause damage or malfunction in fluid systems like pipelines, pumps, and fluid handling equipment.- Fluid Flow Control: Check valves are designed to allow fluid flow in one direction while preventing backflow in the opposite direction, controlling the direction of flow and preventing reverse flow that can cause damage or malfunction in fluid systems.

- Valve Designs and Configurations: Check valves come in various designs and configurations, such as swing, lift, ball, and diaphragm types, made from different materials like metals, plastics, or composites, to suit specific applications and operating conditions.

- Industrial Applications: Check valves find applications in industries like water and wastewater treatment, oil and gas, chemical processing, power generation, and HVAC systems, preventing backflow, maintaining system pressure, and protecting equipment.

- Maintenance and Troubleshooting: Proper maintenance, including inspection, cleaning, and replacement of worn parts, and troubleshooting of issues like valve sticking, leakage, and component wear, are essential for reliable operation and preventing system failures.

- Testing and Performance Evaluation: Testing methods like flow, leak, and cycle testing are crucial for evaluating check valve performance under different operating conditions, ensuring they meet specifications, and identifying areas for improvement.

02 Valve Designs and Materials

Check valves come in different designs like swing, lift, ball, and diaphragm types, incorporating various materials, sealing mechanisms, and flow paths to optimize performance and reliability for specific applications and conditions.Expand Specific Solutions03 Fluid System Applications

Check valves are used in various fluid systems, such as water supply, hydraulic, pneumatic, and process piping systems, preventing backflow, maintaining pressure, and protecting equipment from reverse flow damage.Expand Specific Solutions04 Maintenance and Testing

Regular maintenance, including inspections, cleaning, component replacement, and performance testing under various flow conditions, is essential for proper functioning, preventing failures, and extending the service life of check valves.Expand Specific Solutions05 Technological Advancements

Research and development efforts aim to improve check valve performance, reliability, and efficiency through advanced materials, innovative designs, and integration of monitoring and control systems, enhancing flow control and reducing maintenance requirements.Expand Specific Solutions

Check Valves Main Player Analysis

Honeywell International Technologies Ltd.

Ford Global Technologies LLC

Key Technology Interpretation

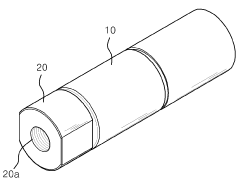

- 1. The check valve uses a seal ring equipped with an expandable wing that can improve the blocking ability using high-pressure fluid, ensuring reliable sealing and control capabilities.

- 2. The check valve simplifies the configuration by utilizing the high-pressure fluid to improve sealing ability, preventing deterioration in durability even under high pressure.

- 3. The check valve utilizes the backflow of high-pressure fluid to enhance the sealing ability of the seal ring, improving the overall sealing performance.

Regulatory Landscape for Flow Control Devices

The regulatory landscape for flow control devices is a complex and evolving area, with various national and international standards and guidelines governing their design, manufacturing, and application. These regulations aim to ensure the safety, reliability, and environmental compliance of flow control systems across different industries.

In the United States, the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) have established comprehensive codes and standards for the design, construction, and operation of flow control devices, particularly in the oil and gas industry. These standards cover aspects such as material selection, pressure ratings, testing procedures, and installation requirements.

The European Union has implemented the Pressure Equipment Directive (PED) and the Machinery Directive, which set essential safety requirements for pressure equipment and machinery, including flow control devices. These directives ensure the free movement of products within the European Economic Area while maintaining high safety standards.

International organizations, such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), have also developed widely recognized standards for flow control devices. These standards provide guidelines for performance, testing, and quality assurance, facilitating global trade and ensuring consistent product quality.

In addition to these general regulations, specific industries may have their own regulatory frameworks and guidelines for flow control devices. For example, the nuclear industry has stringent regulations regarding the design and operation of flow control systems to ensure the safe and reliable operation of nuclear facilities.

Environmental regulations also play a crucial role in the regulatory landscape for flow control devices. Agencies such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) have established guidelines and standards to minimize the environmental impact of industrial processes, including the use of flow control devices.

Compliance with these regulations is essential for manufacturers and end-users of flow control devices to ensure product safety, reliability, and environmental responsibility. Failure to adhere to these regulations can result in legal consequences, product recalls, and reputational damage.

Environmental Impact of Flow Control Technologies

Environmental impact is a crucial consideration when evaluating flow control technologies. Active flow control using check valves can have both positive and negative effects on the environment, depending on the specific implementation and application.

On the positive side, active flow control systems can potentially improve energy efficiency by optimizing fluid flow patterns and reducing turbulence. This can lead to reduced energy consumption and lower greenhouse gas emissions in various industrial processes, transportation systems, and building ventilation systems. Additionally, effective flow control can minimize fluid losses and leakages, contributing to resource conservation and waste reduction.

However, the manufacturing and installation of check valves and associated control systems may involve the use of materials and processes that have an environmental footprint. The production of metals, plastics, and electronic components can contribute to resource depletion, energy consumption, and emissions. Proper material selection, recycling, and end-of-life management strategies should be considered to mitigate these impacts.

The operation of active flow control systems may also have environmental implications. Depending on the power source and control mechanisms employed, there could be energy consumption and associated emissions during operation. Noise pollution from valve actuation and fluid flow should also be evaluated, particularly in sensitive environments or urban areas.

Furthermore, the potential for leakage or failure of check valves could lead to uncontrolled fluid releases, posing risks to water bodies, soil, and air quality. Robust design, maintenance, and monitoring protocols are essential to minimize these risks.

It is crucial to conduct comprehensive life cycle assessments and environmental impact studies to quantify the environmental footprint of active flow control technologies using check valves. These assessments should consider the entire life cycle, from raw material extraction to manufacturing, transportation, installation, operation, and eventual decommissioning or recycling. By identifying and addressing potential environmental concerns, appropriate mitigation strategies can be developed to ensure the sustainable implementation of these technologies.