Increasing The Flow Rate Of Check Valves

Increasing The Flow Rate Of Check Valves: Background And Goals

Check valves are essential components in piping systems, designed to allow flow in one direction while preventing backflow. However, their flow rate can be limited by factors such as valve design, fluid properties, and system conditions. Enhancing the flow rate of check valves can lead to improved system efficiency, reduced energy consumption, and cost savings. This report aims to provide a comprehensive overview of the current landscape, identify key challenges, and explore potential innovative solutions to address this technological problem.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valves and projected growth rates across various industries and regions. Identify key drivers fueling market expansion. - Application Landscape

Examine the diverse applications of check valves, such as water and wastewater treatment, oil and gas, chemical processing, and power generation. Highlight industries with high demand for increased flow rates. - Regional Demand Patterns

Assess regional variations in check valve demand, considering factors like infrastructure development, regulatory standards, and industry concentration. Pinpoint regions with significant growth potential. - Competitive Landscape

Evaluate the competitive dynamics within the check valve market, including major players, market shares, and product offerings. Identify opportunities for differentiation through improved flow rates. - Emerging Trends and Challenges

Discuss emerging trends shaping the check valve market, such as the adoption of advanced materials, energy efficiency initiatives, and the need for higher flow rates. Address challenges that may impact market growth.

Technology Status And Challenges

- Valve Design Limitations

Current check valve designs have inherent limitations that restrict flow rates, such as narrow flow paths, abrupt directional changes, and turbulence-inducing geometries. - Material Constraints

The materials used in valve construction, like metals and polymers, can introduce friction and resistance, reducing flow efficiency. - Scaling Challenges

Increasing valve size to accommodate higher flow rates often leads to disproportionate increases in pressure drop and turbulence. - Installation Constraints

Existing piping systems and infrastructure may impose spatial and geometric constraints, limiting the ability to optimize valve designs for improved flow. - Maintenance Issues

Fouling, corrosion, and wear can degrade valve performance over time, reducing flow rates and requiring frequent maintenance or replacement.

Current Technical Solutions

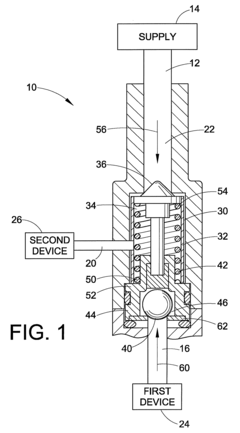

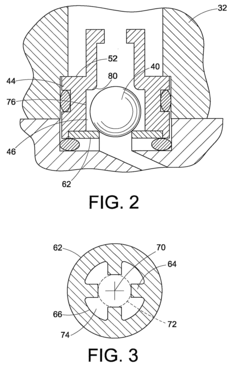

01 Check Valve Structure and Design

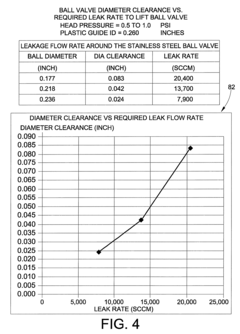

Valve configurations like swing, lift, ball, and diaphragm check valves allow one-way flow and prevent backflow. Valve geometry, sealing mechanisms, and materials impact flow rate and pressure drop.- Check Valve Structure and Design: Valve body shape, valve seat geometry, and valve disc/poppet design impact flow rate and pressure drop. Optimizing these elements can improve flow efficiency and reduce pressure losses.

- Check Valve Materials and Coatings: Low-friction materials and smooth surfaces reduce turbulence and improve flow characteristics. Corrosion-resistant materials/coatings prevent buildup and maintain optimal flow rates.

- Check Valve Sizing and Flow Path Optimization: Proper valve sizing, inlet/outlet configurations, and flow path geometry impact flow rate and pressure drop. Optimization ensures efficient flow and minimizes pressure losses.

- Check Valve Applications and Flow Rate Requirements: Understanding flow rate requirements for different applications and industries allows selecting appropriate check valve designs and configurations for optimal performance.

- Check Valve Monitoring and Flow Rate Control: Incorporating flow sensors, pressure sensors, or control valves enables monitoring and controlling flow rates through check valves to maintain desired flow conditions.

02 Flow Rate Control and Regulation

Check valves can incorporate adjustable flow control components, variable orifice sizes, or integrated flow regulators to enable precise flow rate management tailored to application requirements.Expand Specific Solutions03 Check Valve Applications and Systems

Check valves are used in fluid handling, hydraulic, process piping, and HVAC systems where flow control and backflow prevention are essential. Application requirements influence valve type and design for optimal flow rate performance.Expand Specific Solutions04 Check Valve Materials and Coatings

Low-friction, corrosion-resistant, and fluid-compatible materials and coatings improve flow rates and reduce pressure drops across the valve.Expand Specific Solutions05 Check Valve Testing and Performance Evaluation

Flow loop testing, computational fluid dynamics simulations, and standardized testing procedures are used to assess check valve flow rates, pressure drops, and leakage rates under different operating conditions.Expand Specific Solutions

Technology Main Player Analysis

Bendix Commercial Vehicle Systems LLC

TLV Co. Ltd.

Key Technology Interpretation

- The check valve has dual threshold volumetric flow rates, allowing fluid flow in one direction when the upstream volumetric flow rate exceeds the first threshold, and preventing fluid flow in the opposite direction unless the upstream volumetric flow rate exceeds the second higher threshold.

- The valve structure incorporates features to enable different threshold flow rates in opposite directions, providing improved control over fluid flow.

- The valve design is specifically tailored for use in heavy vehicles, addressing the unique requirements of this application.

Regulatory Landscape for Check Valve Manufacturing

The regulatory landscape for check valve manufacturing encompasses a comprehensive set of guidelines, standards, and regulations aimed at ensuring the safety, reliability, and quality of these critical components. Compliance with these regulations is essential for manufacturers to operate legally and maintain a competitive edge in the market.

One of the primary regulatory bodies governing check valve manufacturing is the American Society of Mechanical Engineers (ASME). The ASME Boiler and Pressure Vessel Code (BPVC) provides detailed requirements for the design, fabrication, inspection, and testing of check valves used in various industries, including power generation, oil and gas, and chemical processing. Adherence to the BPVC is often mandated by local and national authorities, ensuring consistent safety standards across different regions.

In addition to the ASME codes, check valve manufacturers must comply with industry-specific regulations. For instance, the American Petroleum Institute (API) has established standards for check valves used in the oil and gas industry, such as API 594 for check valves used in petroleum and natural gas industries, and API 598 for valve inspection and testing. These standards cover aspects like material selection, design criteria, performance testing, and quality control measures.

The International Organization for Standardization (ISO) also plays a crucial role in the regulatory landscape for check valve manufacturing. The ISO 16137 standard provides guidelines for the design, manufacturing, and testing of check valves used in various applications, including water supply systems, industrial processes, and fire protection systems. Compliance with ISO standards is often required for manufacturers seeking to export their products globally.

Environmental regulations are another important aspect of the regulatory landscape. Manufacturers must ensure that their production processes and materials comply with relevant environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union.

Furthermore, local and national authorities may impose additional regulations or certification requirements specific to their regions or industries. For example, the Nuclear Regulatory Commission (NRC) in the United States has stringent regulations for check valves used in nuclear power plants, while the Food and Drug Administration (FDA) regulates check valves used in the pharmaceutical and food industries.

Navigating the complex regulatory landscape for check valve manufacturing requires manufacturers to stay up-to-date with the latest standards, regulations, and industry best practices. Failure to comply with these regulations can result in severe consequences, including product recalls, fines, and legal liabilities. Manufacturers must implement robust quality management systems, maintain comprehensive documentation, and undergo regular audits and inspections to ensure compliance and maintain their competitive edge in the market.

Environmental Impact of Check Valve Technologies

Environmental impact is a crucial consideration when evaluating check valve technologies. These valves play a vital role in various industrial processes, and their design and operation can significantly influence their environmental footprint. This section aims to analyze the potential environmental impacts associated with check valve technologies, highlighting areas of concern and potential mitigation strategies.

One of the primary environmental concerns related to check valves is the risk of leakage. Valve leakage can lead to the release of hazardous substances, pollutants, or process fluids into the surrounding environment, posing risks to air, water, and soil quality. Proper valve maintenance, regular inspections, and timely replacement of worn components are essential to minimize leakage and prevent environmental contamination.

Another aspect to consider is the energy consumption associated with check valve operation. Inefficient valve designs or improper sizing can result in increased pressure drops, leading to higher energy requirements for pumping systems. This increased energy demand translates into higher greenhouse gas emissions and a larger carbon footprint. Optimizing valve design and selection can contribute to energy efficiency and reduce the environmental impact of industrial processes.

The materials used in check valve construction also have environmental implications. Certain materials may contain hazardous substances or be difficult to recycle or dispose of at the end of their service life. Selecting environmentally friendly materials, such as those that are recyclable or biodegradable, can help mitigate the environmental impact of check valve technologies.

Furthermore, the manufacturing processes involved in producing check valves can have environmental consequences. Energy-intensive processes, the use of harmful chemicals, and the generation of waste products can contribute to environmental degradation. Adopting sustainable manufacturing practices, such as implementing energy-efficient processes, minimizing waste, and promoting the use of renewable resources, can help reduce the environmental impact of check valve production.

To address these environmental concerns, it is essential to adopt a life cycle approach when evaluating check valve technologies. This involves considering the environmental impact at every stage, from material sourcing and manufacturing to operation, maintenance, and eventual disposal or recycling. Collaboration between valve manufacturers, end-users, and regulatory bodies is crucial to develop and implement environmentally responsible practices and technologies.