Enhancing The Tensile Strength Of Epoxy Resins

Epoxy Resin Strengthening Goals

Epoxy resins are thermoset polymers formed by cross-linking reactions between epoxide groups and curing agents. The tensile strength of epoxy resins is influenced by factors such as the chemical structure of the resin and curing agent, the degree of cross-linking, and the presence of reinforcing fillers or additives. Enhancing the tensile strength may involve modifying the resin formulation, incorporating advanced reinforcements, or exploring novel curing techniques.

Market Demand for High-Strength Epoxy Resins

- Growing Demand for High-Performance Materials

Epoxy resins with enhanced tensile strength are in high demand across various industries, including aerospace, automotive, construction, and wind energy. These sectors require lightweight yet robust materials to improve product performance and durability. - Lightweight and Durable Structures

High-strength epoxy resins enable the creation of lightweight yet durable structures, leading to improved fuel efficiency in transportation applications and reduced material costs in construction projects. - Expanding Applications

The market demand for high-strength epoxy resins is driven by their expanding applications in composite materials, adhesives, coatings, and electrical insulation, among others. - Sustainability and Environmental Considerations

The demand for environmentally friendly and sustainable materials is increasing, creating opportunities for high-strength epoxy resins that can be produced using bio-based or recycled materials.

Current State and Challenges in Epoxy Resin Strengthening

- Epoxy Resins' Tensile Strength Limitations

Epoxy resins have relatively low tensile strength compared to other engineering materials, limiting their applications in load-bearing structures. - Challenges in Enhancing Tensile Strength

Increasing crosslink density can improve tensile strength but may compromise other properties like flexibility and impact resistance. Incorporating reinforcements like fibers or nanoparticles can be effective but uniform dispersion is challenging. - Geographical Distribution of Research

Research on enhancing epoxy resin tensile strength is globally distributed, with major contributions from the USA, Europe, and Asia, particularly China and Japan.

Existing Solutions for Enhancing Epoxy Resin Strength

01 Chemical Modification for High Tensile Strength

Certain chemical modifications, such as incorporating specific functional groups or modifying the molecular structure, can be made to epoxy resins to enhance their mechanical properties, including increased tensile strength.- Chemical Modification for High Tensile Strength: Epoxy resins can be chemically modified to incorporate specific functional groups or additives that improve crosslinking density and intermolecular interactions, leading to increased tensile strength.

- Reinforcement with High-Strength Fibers or Fillers: Incorporating high-strength reinforcing fibers or fillers like carbon fibers, glass fibers, aramid fibers, carbon nanotubes, or graphene into the epoxy resin matrix enhances the load-bearing capacity and mechanical properties, resulting in improved tensile strength.

- High Crosslink Density Formulations: Formulating epoxy resin systems with a high crosslink density, achieved by using multifunctional epoxy resins, hardeners, or curing agents that promote extensive crosslinking, results in a more rigid and stronger polymer network with improved tensile strength.

- High-Performance Additives for Tensile Strength Enhancement: Incorporating high-performance additives like toughening agents, impact modifiers, or nanoparticles into the epoxy resin formulation improves mechanical properties, resistance to crack propagation, and ultimately enhances tensile strength.

- Tailored Molecular Architecture for High Tensile Strength: Designing and synthesizing epoxy resins with specific molecular architectures, such as branched or hyperbranched structures, or incorporating rigid or semi-rigid segments into the polymer backbone, can optimize the mechanical properties and tensile strength of the cured resin.

02 Reinforcement for High Tensile Strength

Adding reinforcing materials like fibers or nanoparticles to the epoxy resin matrix creates a composite material with improved mechanical properties, including higher tensile strength.Expand Specific Solutions03 Curing Conditions for High Tensile Strength

Optimizing curing conditions, such as temperature, pressure, and curing agent, can lead to improved cross-linking and molecular packing, resulting in epoxy resins with higher tensile strength.Expand Specific Solutions04 Blending for High Tensile Strength

Blending epoxy resins with other polymers or additives, such as thermoplastics or elastomers, can improve the toughness and tensile properties of the resulting epoxy resin blend.Expand Specific Solutions05 Molecular Design for High Tensile Strength

Tailoring the molecular structure and composition of epoxy resins, including specific molecular weights, functional groups, or architectures, can contribute to improved mechanical properties and enhanced tensile strength.Expand Specific Solutions

Key Players in Epoxy Resin Industry

Toray Industries, Inc.

Dow Global Technologies LLC

Core Innovations in Epoxy Resin Strengthening

- Utilization of epoxy resins with functionality greater than two to increase toughness and stiffness of the composite material

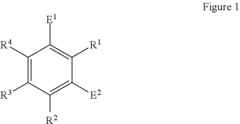

- Incorporation of epoxy resins with at least one meta-substituted phenyl ring in the backbone to enhance tensile strength and damage tolerance

- Maintaining high levels of matrix-fiber bonding and damage tolerance while improving tensile strength

Environmental Impact of Epoxy Resin Production

Epoxy resin production poses significant environmental challenges due to the emission of volatile organic compounds (VOCs), hazardous waste generation, and reliance on non-renewable resources. VOCs like epichlorohydrin and bisphenol A, emitted during manufacturing, contribute to air pollution, impacting both worker health and nearby communities.

Additionally, epoxy resin production creates hazardous waste byproducts that require careful treatment and disposal to prevent soil and water contamination, which can harm ecosystems and human health. The industry’s dependence on petroleum-based raw materials and fossil fuels also raises sustainability concerns due to the depletion of finite resources.

To address these impacts, manufacturers are adopting cleaner technologies, using alternative, lower-impact materials, and enhancing waste management. Research into bio-based epoxy resins from renewable sources offers promising potential for reducing reliance on non-renewables. Ongoing innovation and adherence to environmental regulations are key to minimizing these environmental impacts and promoting sustainability in epoxy resin production.

Regulatory Standards for Epoxy Resins

The regulatory framework for epoxy resins is complex, involving various national and international guidelines to ensure safe production, handling, and use while reducing environmental impact. In the United States, the Environmental Protection Agency (EPA) regulates epoxy resins under the Toxic Substances Control Act (TSCA), requiring manufacturers to disclose chemical compositions and hazards, while OSHA sets workplace safety standards.

In the European Union, the REACH regulation mandates that manufacturers and importers register and assess chemical risks, restricting hazardous substances and encouraging safer alternatives. Asian countries like China, Japan, and South Korea also have regulatory frameworks, with China's IECSC managing new and existing chemical substances.

International bodies like the United Nations and OECD work to harmonize global standards for safe epoxy resin management. Compliance with these regulations is vital for manufacturers, as non-compliance can lead to fines, recalls, and market restrictions. Staying informed on regulatory updates helps companies remain competitive and compliant.