Research on flexible substrates for wearable biosensing patches

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Biosensing Substrate Technology Evolution and Objectives

Flexible substrates for wearable biosensing patches have evolved significantly over the past two decades, transitioning from rigid electronic components to highly conformable materials that can seamlessly integrate with the human body. The journey began with conventional flexible printed circuit boards (PCBs) in the early 2000s, which offered limited flexibility but provided a foundation for subsequent innovations.

By the mid-2000s, polymer-based substrates such as polyimide (PI) and polyethylene terephthalate (PET) emerged as viable alternatives, offering improved flexibility while maintaining adequate mechanical stability. These materials enabled the first generation of wearable health monitors, though they still presented limitations in terms of biocompatibility and conformability to complex body contours.

The 2010s witnessed a paradigm shift with the introduction of ultra-thin elastomeric substrates, particularly polydimethylsiloxane (PDMS) and thermoplastic polyurethanes (TPUs), which dramatically enhanced the mechanical compatibility with human skin. This advancement facilitated the development of "electronic skin" concepts and enabled long-term, comfortable wear of biosensing devices.

Recent years have seen the emergence of biodegradable and biocompatible substrates, including natural polymers like cellulose derivatives and silk fibroin, addressing growing concerns about electronic waste and biocompatibility. These materials support environmentally sustainable approaches while maintaining the functional requirements of biosensing applications.

The current technological frontier focuses on "imperceptible electronics" utilizing substrates with thickness below 5 μm and elastic moduli closely matching human skin (approximately 130-180 kPa). These advanced materials aim to eliminate the mechanical and perceptual boundary between electronic devices and biological tissues.

The primary objectives of flexible substrate technology development include achieving enhanced conformability to complex anatomical surfaces, improved biocompatibility for extended skin contact, optimized breathability to prevent skin irritation, and sufficient durability to withstand repeated mechanical deformation during daily activities.

Additionally, researchers are pursuing multifunctional substrates that can simultaneously serve as sensing platforms, energy storage components, and drug delivery systems. The integration of self-healing properties represents another critical objective, aiming to extend device lifespan and reliability in real-world applications.

The ultimate goal remains the development of substrates that can seamlessly integrate with biological tissues while supporting comprehensive biosensing capabilities, thereby enabling continuous health monitoring without compromising user comfort or natural movement.

By the mid-2000s, polymer-based substrates such as polyimide (PI) and polyethylene terephthalate (PET) emerged as viable alternatives, offering improved flexibility while maintaining adequate mechanical stability. These materials enabled the first generation of wearable health monitors, though they still presented limitations in terms of biocompatibility and conformability to complex body contours.

The 2010s witnessed a paradigm shift with the introduction of ultra-thin elastomeric substrates, particularly polydimethylsiloxane (PDMS) and thermoplastic polyurethanes (TPUs), which dramatically enhanced the mechanical compatibility with human skin. This advancement facilitated the development of "electronic skin" concepts and enabled long-term, comfortable wear of biosensing devices.

Recent years have seen the emergence of biodegradable and biocompatible substrates, including natural polymers like cellulose derivatives and silk fibroin, addressing growing concerns about electronic waste and biocompatibility. These materials support environmentally sustainable approaches while maintaining the functional requirements of biosensing applications.

The current technological frontier focuses on "imperceptible electronics" utilizing substrates with thickness below 5 μm and elastic moduli closely matching human skin (approximately 130-180 kPa). These advanced materials aim to eliminate the mechanical and perceptual boundary between electronic devices and biological tissues.

The primary objectives of flexible substrate technology development include achieving enhanced conformability to complex anatomical surfaces, improved biocompatibility for extended skin contact, optimized breathability to prevent skin irritation, and sufficient durability to withstand repeated mechanical deformation during daily activities.

Additionally, researchers are pursuing multifunctional substrates that can simultaneously serve as sensing platforms, energy storage components, and drug delivery systems. The integration of self-healing properties represents another critical objective, aiming to extend device lifespan and reliability in real-world applications.

The ultimate goal remains the development of substrates that can seamlessly integrate with biological tissues while supporting comprehensive biosensing capabilities, thereby enabling continuous health monitoring without compromising user comfort or natural movement.

Market Analysis for Wearable Biosensing Patch Applications

The wearable biosensing patch market is experiencing significant growth, driven by increasing health consciousness and the rising prevalence of chronic diseases requiring continuous monitoring. The global market for wearable biosensors was valued at approximately $12 billion in 2022 and is projected to reach $33 billion by 2027, representing a compound annual growth rate of 22.4%. This remarkable growth trajectory underscores the expanding demand for non-invasive, continuous health monitoring solutions.

Healthcare applications currently dominate the market, accounting for nearly 65% of total revenue. Within this segment, continuous glucose monitoring represents the largest application, followed by cardiac monitoring and physical activity tracking. The consumer fitness and wellness sector is the second-largest market segment, driven by growing interest in personalized health management and preventive care approaches.

Geographically, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 25.3% through 2027, primarily due to increasing healthcare expenditure, growing awareness about preventive healthcare, and rapid technological adoption in countries like China, Japan, and South Korea.

Key market drivers include the aging global population, increasing prevalence of chronic diseases, growing consumer preference for home healthcare, and technological advancements in flexible electronics and miniaturization. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of remote patient monitoring and reducing hospital visits.

Despite promising growth prospects, several challenges persist in the market. These include concerns regarding data privacy and security, regulatory hurdles for medical-grade devices, reimbursement issues, and technical limitations related to sensor accuracy and battery life. Additionally, high development and production costs remain significant barriers to market entry for smaller companies.

The competitive landscape is characterized by both established medical device manufacturers and technology startups. Major players include Medtronic, Abbott Laboratories, Dexcom, Philips Healthcare, and Samsung Electronics. Recent years have witnessed increasing strategic partnerships between technology companies and healthcare providers to develop integrated biosensing solutions.

Future market trends indicate growing demand for multi-parameter sensing capabilities, improved data analytics through artificial intelligence, enhanced wireless connectivity (particularly with 5G implementation), and development of biodegradable or environmentally friendly sensor materials. The integration of biosensing patches with telehealth platforms represents another significant growth opportunity as healthcare systems increasingly adopt digital transformation initiatives.

Healthcare applications currently dominate the market, accounting for nearly 65% of total revenue. Within this segment, continuous glucose monitoring represents the largest application, followed by cardiac monitoring and physical activity tracking. The consumer fitness and wellness sector is the second-largest market segment, driven by growing interest in personalized health management and preventive care approaches.

Geographically, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 25.3% through 2027, primarily due to increasing healthcare expenditure, growing awareness about preventive healthcare, and rapid technological adoption in countries like China, Japan, and South Korea.

Key market drivers include the aging global population, increasing prevalence of chronic diseases, growing consumer preference for home healthcare, and technological advancements in flexible electronics and miniaturization. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of remote patient monitoring and reducing hospital visits.

Despite promising growth prospects, several challenges persist in the market. These include concerns regarding data privacy and security, regulatory hurdles for medical-grade devices, reimbursement issues, and technical limitations related to sensor accuracy and battery life. Additionally, high development and production costs remain significant barriers to market entry for smaller companies.

The competitive landscape is characterized by both established medical device manufacturers and technology startups. Major players include Medtronic, Abbott Laboratories, Dexcom, Philips Healthcare, and Samsung Electronics. Recent years have witnessed increasing strategic partnerships between technology companies and healthcare providers to develop integrated biosensing solutions.

Future market trends indicate growing demand for multi-parameter sensing capabilities, improved data analytics through artificial intelligence, enhanced wireless connectivity (particularly with 5G implementation), and development of biodegradable or environmentally friendly sensor materials. The integration of biosensing patches with telehealth platforms represents another significant growth opportunity as healthcare systems increasingly adopt digital transformation initiatives.

Current Flexible Substrate Technologies and Limitations

Flexible substrates serve as the foundation for wearable biosensing patches, providing mechanical support while enabling conformability to the human body. Currently, several materials dominate the flexible substrate landscape, each with distinct advantages and limitations. Polymeric materials such as polyimide (PI), polyethylene terephthalate (PET), and polydimethylsiloxane (PDMS) represent the most widely adopted substrates due to their excellent flexibility, chemical stability, and relatively low cost. PI offers superior thermal stability (up to 400°C) and chemical resistance but exhibits limited stretchability (typically <5%). PET provides good optical transparency and moderate flexibility at lower cost, though its thermal stability is inferior to PI (maximum ~150°C).

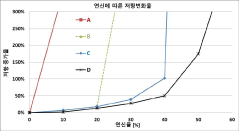

PDMS has emerged as a particularly promising substrate material, offering exceptional stretchability (up to 1000% strain), biocompatibility, and oxygen permeability. However, PDMS presents significant challenges in terms of surface modification and metallization processes, often requiring complex plasma treatments to improve adhesion with sensing elements. Additionally, its hydrophobic nature can limit integration with aqueous biological samples without surface treatment.

Paper-based substrates have gained attention for their biodegradability, cost-effectiveness, and capillary wicking properties. While advantageous for disposable applications, paper substrates suffer from limited mechanical durability, especially in moist environments, and typically demonstrate inferior electrical performance compared to polymeric alternatives.

Textile-integrated substrates represent another emerging category, offering breathability and natural integration with clothing. However, they face challenges related to washing durability, consistent electrical performance, and manufacturing scalability. The irregular surface topology of textiles also complicates the deposition of uniform sensing elements.

A critical limitation across most flexible substrates is the trade-off between flexibility and durability. Highly flexible materials often demonstrate accelerated mechanical degradation under repeated deformation cycles. For instance, PDMS-based sensors typically show performance deterioration after 1000-2000 bending cycles, while PI maintains better electrical stability but offers less conformability to complex body contours.

Biocompatibility remains another significant challenge, particularly for long-term wear applications. While materials like PDMS and certain medical-grade polymers demonstrate good short-term biocompatibility, extended skin contact can lead to irritation, inflammation, or allergic responses in some users. Furthermore, gas permeability limitations in many polymeric substrates can cause skin maceration during prolonged wear, potentially compromising both user comfort and sensor performance.

Manufacturing scalability presents additional barriers, as many laboratory-demonstrated flexible substrates rely on processes incompatible with high-volume production. The integration of sensing elements onto flexible substrates often requires specialized deposition techniques that maintain functionality during bending and stretching, further complicating mass production efforts.

PDMS has emerged as a particularly promising substrate material, offering exceptional stretchability (up to 1000% strain), biocompatibility, and oxygen permeability. However, PDMS presents significant challenges in terms of surface modification and metallization processes, often requiring complex plasma treatments to improve adhesion with sensing elements. Additionally, its hydrophobic nature can limit integration with aqueous biological samples without surface treatment.

Paper-based substrates have gained attention for their biodegradability, cost-effectiveness, and capillary wicking properties. While advantageous for disposable applications, paper substrates suffer from limited mechanical durability, especially in moist environments, and typically demonstrate inferior electrical performance compared to polymeric alternatives.

Textile-integrated substrates represent another emerging category, offering breathability and natural integration with clothing. However, they face challenges related to washing durability, consistent electrical performance, and manufacturing scalability. The irregular surface topology of textiles also complicates the deposition of uniform sensing elements.

A critical limitation across most flexible substrates is the trade-off between flexibility and durability. Highly flexible materials often demonstrate accelerated mechanical degradation under repeated deformation cycles. For instance, PDMS-based sensors typically show performance deterioration after 1000-2000 bending cycles, while PI maintains better electrical stability but offers less conformability to complex body contours.

Biocompatibility remains another significant challenge, particularly for long-term wear applications. While materials like PDMS and certain medical-grade polymers demonstrate good short-term biocompatibility, extended skin contact can lead to irritation, inflammation, or allergic responses in some users. Furthermore, gas permeability limitations in many polymeric substrates can cause skin maceration during prolonged wear, potentially compromising both user comfort and sensor performance.

Manufacturing scalability presents additional barriers, as many laboratory-demonstrated flexible substrates rely on processes incompatible with high-volume production. The integration of sensing elements onto flexible substrates often requires specialized deposition techniques that maintain functionality during bending and stretching, further complicating mass production efforts.

Current Flexible Substrate Solutions for Wearable Patches

01 Flexible display technologies

Flexible display technologies incorporate substrates that can bend, fold, or roll without damage. These displays use materials like polyimide or thin glass that maintain functionality while being deformed. The flexibility allows for curved screens, foldable devices, and rollable displays that can be compacted for storage and expanded for use. These technologies enable new form factors for electronic devices while maintaining display quality and durability.- Flexible substrate materials for electronic devices: Various materials can be used as flexible substrates in electronic devices to provide the necessary flexibility while maintaining structural integrity. These materials include polymers, thin metal foils, and composite materials that can bend without breaking. The flexibility of these substrates enables the development of foldable, rollable, and stretchable electronic devices that can conform to curved surfaces or withstand mechanical deformation.

- Manufacturing techniques for flexible substrates: Specialized manufacturing techniques are employed to create flexible substrates with consistent properties. These techniques include roll-to-roll processing, thin film deposition on flexible carriers, and laser patterning methods that maintain substrate integrity while creating necessary features. Advanced lamination processes and surface treatments are also used to enhance the adhesion of functional layers to the flexible base materials.

- Flexible display technologies: Flexible display technologies incorporate specialized substrate designs that allow for bending and folding while maintaining display functionality. These displays use thin-film transistor arrays on flexible substrates, with protective layers that prevent damage during flexing. The integration of organic light-emitting diodes (OLEDs) with flexible substrates enables the creation of bendable and foldable screens for mobile devices and other applications.

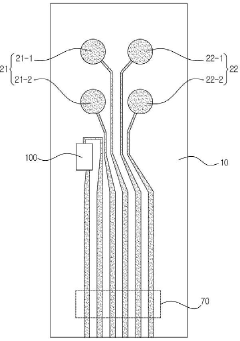

- Flexible circuit boards and interconnects: Flexible circuit boards and interconnects are designed to maintain electrical connectivity while undergoing bending and flexing. These components use specialized substrate materials with conductive traces that can withstand repeated mechanical stress. Various connection technologies, including anisotropic conductive films and stretchable conductive inks, are employed to ensure reliable electrical connections between rigid and flexible components in hybrid electronic systems.

- Enhancing substrate flexibility through structural design: Structural design innovations can enhance the flexibility of substrates beyond what material properties alone would allow. These designs include the incorporation of engineered patterns, such as serpentine structures, mesh configurations, and origami-inspired folding patterns. Micro-perforations and strategic thinning in specific areas can create preferential bending zones, while maintaining rigidity where needed for component mounting and protection.

02 Materials for flexible substrates

Various materials are used to create flexible substrates, including polymers like polyimide, polyethylene terephthalate (PET), and polydimethylsiloxane (PDMS). These materials offer different degrees of flexibility, transparency, and thermal stability. Some flexible substrates incorporate composite structures or thin metal foils to enhance conductivity while maintaining bendability. The choice of material depends on the specific application requirements, including bend radius, operating temperature, and environmental exposure.Expand Specific Solutions03 Flexible electronic components and circuits

Flexible electronic components are designed to maintain functionality while being bent or flexed. These include thin-film transistors, flexible batteries, stretchable interconnects, and bendable sensors. Manufacturing techniques like transfer printing and direct deposition enable the creation of electronic circuits on flexible substrates. These components can conform to non-planar surfaces and withstand repeated bending cycles, making them suitable for wearable devices, medical implants, and curved displays.Expand Specific Solutions04 Fabrication methods for flexible devices

Specialized fabrication methods are employed to create flexible devices, including roll-to-roll processing, laser patterning, and solution-based deposition techniques. These methods allow for high-throughput production while maintaining the flexibility of the substrate. Low-temperature processes are often used to prevent damage to temperature-sensitive flexible materials. Techniques like transfer printing enable the integration of rigid components onto flexible substrates while preserving overall flexibility.Expand Specific Solutions05 Applications of flexible substrate technology

Flexible substrate technology enables numerous applications across various industries. In consumer electronics, it allows for foldable smartphones, rollable displays, and curved televisions. In healthcare, flexible substrates are used for wearable health monitors, electronic skin, and implantable medical devices. Other applications include flexible solar cells, conformable lighting panels, and smart textiles. The ability to conform to irregular surfaces makes these technologies particularly valuable for applications where rigid substrates would be impractical.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Biosensors

The flexible substrates for wearable biosensing patches market is currently in a growth phase, with increasing demand driven by healthcare monitoring applications. The global market size for wearable biosensors is projected to reach $25 billion by 2025, expanding at a CAGR of approximately 15%. Technology maturity varies across different substrate materials, with academic institutions leading fundamental research while companies focus on commercialization. Universities like MIT, Zhejiang University, and Fudan University are pioneering novel flexible materials, while companies such as Xerox, Amorepacific, and Boao Biology are developing market-ready applications. The competitive landscape shows strong collaboration between academia and industry, with Chinese institutions particularly active in publishing research on flexible polymer and textile-based substrates for next-generation wearable health monitoring devices.

Fudan University

Technical Solution: Fudan University has developed a breakthrough flexible substrate platform for wearable biosensing patches based on silk fibroin derivatives. Their technology utilizes regenerated silk proteins modified with functional groups to create ultrathin (sub-10μm) substrates with programmable biodegradability and mechanical properties. The university's research team has engineered a proprietary process for controlling the crystallinity of silk films, allowing precise tuning of flexibility, strength, and oxygen permeability to match specific biosensing applications[1]. Their substrates incorporate micropatterned adhesive regions that enable strong skin attachment while maintaining breathability through engineered micropores (5-20μm diameter). Fudan researchers have also developed a novel water-soluble sacrificial layer technique that allows complex electronic components to be transferred to the silk substrates without exposure to harsh chemicals or high temperatures, preserving sensor functionality[3]. Recent innovations include photocrosslinkable silk derivatives that can be precisely patterned using standard photolithography, enabling high-resolution integration of multiple sensing elements on a single flexible substrate[7].

Strengths: Exceptional biocompatibility as a natural protein-based material; programmable biodegradability for environmentally friendly applications; excellent optical transparency for optical sensing modalities. Weaknesses: Higher production costs compared to synthetic polymers; potential batch-to-batch variability in natural material properties; limited long-term stability in high-humidity environments.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative flexible substrate technologies for wearable biosensing patches based on nanofiber-reinforced hydrogel composites. Their proprietary approach combines electrospun nanofibers with biocompatible hydrogels to create substrates with exceptional mechanical properties and breathability. The university's research team has engineered substrates with controlled porosity (40-70%) that facilitate oxygen and moisture transmission while maintaining structural integrity under deformation[2]. Their technology incorporates temperature-responsive polymers that allow the substrate to maintain adhesion at body temperature while enabling easy removal without skin damage. Zhejiang University has also pioneered conductive hydrogel substrates doped with graphene derivatives that serve dual purposes as both the supporting material and as conductive pathways for sensor signals, reducing the overall complexity of device fabrication[4]. Recent innovations include self-healing substrates that can recover from mechanical damage through dynamic hydrogen bonding networks, extending the operational lifetime of wearable biosensors by up to 300% compared to conventional flexible substrates[6].

Strengths: Excellent biocompatibility with minimal skin irritation; superior moisture management properties ideal for long-term wear; innovative self-healing capabilities extending device lifespan. Weaknesses: Manufacturing scalability challenges for complex composite structures; potential stability issues in varying environmental conditions; higher material costs compared to traditional medical-grade polymers.

Key Patents and Innovations in Flexible Biosensing Materials

Flexible biosensor for wearable device and Preparation method therof

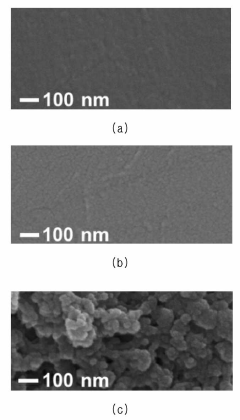

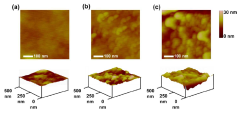

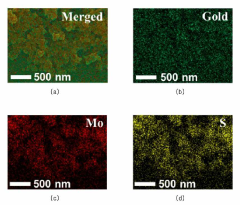

PatentActiveKR1020200104091A

Innovation

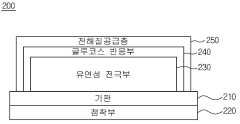

- A flexible biosensor is developed with a conductive layer formed by sequentially laminating gold, molybdenum disulfide, and gold on a polymer film, using sputtering deposition and spin coating to enhance electron transfer, and enzymes are bound through chemical functional groups for improved sensitivity.

Bio Sensor

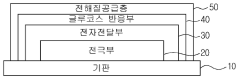

PatentPendingKR1020210097444A

Innovation

- A wearable biosensor with a flexible electrode part made of conductive polymer and an adhesive substrate, enhancing stretchability and reducing process complexity.

Biocompatibility and Skin Interface Considerations

Biocompatibility represents a critical consideration in the development of flexible substrates for wearable biosensing patches. The direct and prolonged contact between these devices and human skin necessitates materials that minimize adverse biological reactions while maintaining sensor functionality. Current research focuses on materials that demonstrate low cytotoxicity, reduced inflammatory responses, and minimal skin irritation, with silicones, polyurethanes, and certain biopolymers showing promising results in clinical evaluations.

The skin-substrate interface presents unique challenges due to the dynamic nature of human skin. Perspiration, sebum production, skin shedding, and movement can all compromise sensor adhesion and data quality. Advanced substrate designs now incorporate microstructured surfaces that enhance conformability while allowing appropriate moisture permeability, preventing maceration and irritation during extended wear periods. These microstructures also help maintain stable electrical connections despite skin movement and environmental factors.

Mechanical properties of flexible substrates must balance conformability with durability. Optimal substrates demonstrate elastic moduli similar to human skin (approximately 0.1-1 MPa) while resisting mechanical fatigue during repeated stretching and bending cycles. Recent innovations include strain-isolating designs that protect sensing elements from mechanical deformation, and self-healing materials that can recover from minor damage during wear.

Allergenic potential remains a significant concern, with studies indicating approximately 5-10% of users experience some form of contact dermatitis from medical adhesives. Research has advanced toward hypoallergenic formulations utilizing medical-grade silicones and acrylate-free adhesives. Additionally, antimicrobial properties are being integrated into substrate materials through incorporation of silver nanoparticles, zinc oxide, or chitosan derivatives to prevent bacterial colonization during extended wear periods.

The gas and moisture permeability characteristics of substrate materials significantly impact both user comfort and sensor performance. Optimal materials maintain a balance between occlusion and breathability, with water vapor transmission rates between 500-2000 g/m²/day showing the best results for extended wear applications. This prevents excessive moisture accumulation while maintaining sufficient adhesion and sensor contact.

Regulatory considerations for skin-contacting materials have become increasingly stringent, with ISO 10993 standards providing the framework for biocompatibility evaluation. Manufacturers must now conduct comprehensive testing including cytotoxicity, sensitization, and irritation assessments before market approval. This regulatory landscape continues to evolve as wearable technology advances, with particular attention to novel materials and extended-wear applications.

The skin-substrate interface presents unique challenges due to the dynamic nature of human skin. Perspiration, sebum production, skin shedding, and movement can all compromise sensor adhesion and data quality. Advanced substrate designs now incorporate microstructured surfaces that enhance conformability while allowing appropriate moisture permeability, preventing maceration and irritation during extended wear periods. These microstructures also help maintain stable electrical connections despite skin movement and environmental factors.

Mechanical properties of flexible substrates must balance conformability with durability. Optimal substrates demonstrate elastic moduli similar to human skin (approximately 0.1-1 MPa) while resisting mechanical fatigue during repeated stretching and bending cycles. Recent innovations include strain-isolating designs that protect sensing elements from mechanical deformation, and self-healing materials that can recover from minor damage during wear.

Allergenic potential remains a significant concern, with studies indicating approximately 5-10% of users experience some form of contact dermatitis from medical adhesives. Research has advanced toward hypoallergenic formulations utilizing medical-grade silicones and acrylate-free adhesives. Additionally, antimicrobial properties are being integrated into substrate materials through incorporation of silver nanoparticles, zinc oxide, or chitosan derivatives to prevent bacterial colonization during extended wear periods.

The gas and moisture permeability characteristics of substrate materials significantly impact both user comfort and sensor performance. Optimal materials maintain a balance between occlusion and breathability, with water vapor transmission rates between 500-2000 g/m²/day showing the best results for extended wear applications. This prevents excessive moisture accumulation while maintaining sufficient adhesion and sensor contact.

Regulatory considerations for skin-contacting materials have become increasingly stringent, with ISO 10993 standards providing the framework for biocompatibility evaluation. Manufacturers must now conduct comprehensive testing including cytotoxicity, sensitization, and irritation assessments before market approval. This regulatory landscape continues to evolve as wearable technology advances, with particular attention to novel materials and extended-wear applications.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for flexible substrates in wearable biosensing patches represents a critical factor in their commercial viability. Current production methods vary significantly in their readiness for mass production, with roll-to-roll (R2R) processing emerging as the most promising approach for high-volume manufacturing. This continuous production method allows for efficient deposition of materials onto flexible substrates at speeds reaching 100 meters per minute, dramatically reducing per-unit costs compared to batch processing techniques.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Polymeric substrates like polyimide (PI) and polyethylene terephthalate (PET) offer cost advantages at $3-15 per square meter compared to specialized biocompatible materials that can exceed $50 per square meter. The trade-off between material performance and cost presents a key challenge for manufacturers targeting consumer markets versus medical-grade applications.

Equipment investment represents another substantial cost factor, with industrial-scale R2R systems requiring capital expenditures of $500,000 to $5 million. This creates significant barriers to entry for startups and smaller enterprises, though shared manufacturing facilities and contract manufacturing options are emerging to address this challenge. Yield rates in flexible substrate production currently range from 70-90%, with defect rates increasing proportionally with substrate thinness.

Labor costs vary by manufacturing location, with significant differences between regions. While Asian manufacturing hubs offer lower labor costs, intellectual property protection concerns and quality control issues must be carefully weighed against these savings. Automated production lines can reduce labor requirements by up to 80% but require substantial initial investment.

Economies of scale demonstrate that production volumes exceeding 100,000 units annually can reduce per-unit costs by 40-60% compared to small-batch production. This creates a challenging transition phase for technologies moving from research to commercialization. Several companies have successfully navigated this transition, including MC10's BioStamp and Dexcom's continuous glucose monitoring systems, providing valuable case studies in manufacturing scale-up.

Regulatory compliance adds another layer of complexity and cost, particularly for medical-grade wearable biosensors. FDA approval processes can add 12-36 months to development timelines and $1-5 million in additional costs, necessitating careful planning and resource allocation during manufacturing scale-up.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Polymeric substrates like polyimide (PI) and polyethylene terephthalate (PET) offer cost advantages at $3-15 per square meter compared to specialized biocompatible materials that can exceed $50 per square meter. The trade-off between material performance and cost presents a key challenge for manufacturers targeting consumer markets versus medical-grade applications.

Equipment investment represents another substantial cost factor, with industrial-scale R2R systems requiring capital expenditures of $500,000 to $5 million. This creates significant barriers to entry for startups and smaller enterprises, though shared manufacturing facilities and contract manufacturing options are emerging to address this challenge. Yield rates in flexible substrate production currently range from 70-90%, with defect rates increasing proportionally with substrate thinness.

Labor costs vary by manufacturing location, with significant differences between regions. While Asian manufacturing hubs offer lower labor costs, intellectual property protection concerns and quality control issues must be carefully weighed against these savings. Automated production lines can reduce labor requirements by up to 80% but require substantial initial investment.

Economies of scale demonstrate that production volumes exceeding 100,000 units annually can reduce per-unit costs by 40-60% compared to small-batch production. This creates a challenging transition phase for technologies moving from research to commercialization. Several companies have successfully navigated this transition, including MC10's BioStamp and Dexcom's continuous glucose monitoring systems, providing valuable case studies in manufacturing scale-up.

Regulatory compliance adds another layer of complexity and cost, particularly for medical-grade wearable biosensors. FDA approval processes can add 12-36 months to development timelines and $1-5 million in additional costs, necessitating careful planning and resource allocation during manufacturing scale-up.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!