Fulvic Acid Stability Under Heat Stress in Field Applications

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fulvic Acid Heat Stability Background and Objectives

Fulvic acid, a complex mixture of polyphenolic organic compounds produced through the chemical and biological degradation of plant and animal residues, has gained significant attention in agricultural applications over the past several decades. The evolution of fulvic acid technology has progressed from basic extraction methods to sophisticated purification techniques that enhance its stability and efficacy. This technological progression has been driven by increasing recognition of fulvic acid's potential benefits for crop productivity, soil health, and environmental sustainability.

The historical development of fulvic acid applications in agriculture can be traced back to the mid-20th century, with substantial advancements occurring in the 1980s and 1990s as analytical techniques improved. Recent years have witnessed accelerated research into fulvic acid's molecular structure, functional properties, and interaction mechanisms with plants and soil systems. This research has revealed fulvic acid's role in enhancing nutrient uptake, stimulating plant metabolic processes, and improving stress tolerance.

A critical challenge in the practical application of fulvic acid has been its stability under various environmental conditions, particularly heat stress in field settings. Agricultural environments frequently expose applied substances to temperature extremes that can potentially alter chemical structures and diminish biological activity. Understanding the thermal stability of fulvic acid compounds is therefore essential for developing effective formulations and application protocols.

The primary objective of this research is to comprehensively evaluate the stability of fulvic acid under heat stress conditions typical in agricultural field applications. Specifically, this investigation aims to determine the temperature thresholds at which structural degradation begins, identify the chemical transformations that occur during heat exposure, and assess the impact of these changes on fulvic acid's biological activity and agronomic benefits.

Secondary objectives include developing predictive models for fulvic acid degradation under various temperature regimes, identifying potential stabilizing agents or formulation approaches that enhance thermal resistance, and establishing practical guidelines for storage, handling, and application that preserve fulvic acid efficacy in high-temperature environments.

The technological trajectory suggests increasing integration of fulvic acid into precision agriculture systems, with advanced delivery mechanisms and formulations designed to withstand environmental stressors. Future developments are likely to focus on molecular engineering of fulvic acid compounds with enhanced stability profiles, alongside improved understanding of structure-function relationships that determine performance under stress conditions.

This research addresses a critical knowledge gap that currently limits the reliable implementation of fulvic acid technologies in diverse agricultural settings, particularly in regions experiencing high temperatures or significant temperature fluctuations during growing seasons.

The historical development of fulvic acid applications in agriculture can be traced back to the mid-20th century, with substantial advancements occurring in the 1980s and 1990s as analytical techniques improved. Recent years have witnessed accelerated research into fulvic acid's molecular structure, functional properties, and interaction mechanisms with plants and soil systems. This research has revealed fulvic acid's role in enhancing nutrient uptake, stimulating plant metabolic processes, and improving stress tolerance.

A critical challenge in the practical application of fulvic acid has been its stability under various environmental conditions, particularly heat stress in field settings. Agricultural environments frequently expose applied substances to temperature extremes that can potentially alter chemical structures and diminish biological activity. Understanding the thermal stability of fulvic acid compounds is therefore essential for developing effective formulations and application protocols.

The primary objective of this research is to comprehensively evaluate the stability of fulvic acid under heat stress conditions typical in agricultural field applications. Specifically, this investigation aims to determine the temperature thresholds at which structural degradation begins, identify the chemical transformations that occur during heat exposure, and assess the impact of these changes on fulvic acid's biological activity and agronomic benefits.

Secondary objectives include developing predictive models for fulvic acid degradation under various temperature regimes, identifying potential stabilizing agents or formulation approaches that enhance thermal resistance, and establishing practical guidelines for storage, handling, and application that preserve fulvic acid efficacy in high-temperature environments.

The technological trajectory suggests increasing integration of fulvic acid into precision agriculture systems, with advanced delivery mechanisms and formulations designed to withstand environmental stressors. Future developments are likely to focus on molecular engineering of fulvic acid compounds with enhanced stability profiles, alongside improved understanding of structure-function relationships that determine performance under stress conditions.

This research addresses a critical knowledge gap that currently limits the reliable implementation of fulvic acid technologies in diverse agricultural settings, particularly in regions experiencing high temperatures or significant temperature fluctuations during growing seasons.

Agricultural Market Demand Analysis for Stable Fulvic Acid Products

The global agricultural market has witnessed a significant surge in demand for fulvic acid-based products over the past decade, primarily driven by the growing emphasis on sustainable farming practices and organic crop production. Current market assessments indicate that the global fulvic acid market is valued at approximately 1.2 billion USD, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth trajectory underscores the expanding recognition of fulvic acid's benefits among agricultural stakeholders.

Specifically, the demand for heat-stable fulvic acid products has emerged as a critical market segment, particularly in regions experiencing extreme temperature fluctuations or prolonged heat stress conditions. Countries across the Mediterranean basin, Sub-Saharan Africa, and parts of Asia and Australia have reported increasing farmer interest in fulvic acid formulations that maintain efficacy under high-temperature field conditions. Market research indicates that approximately 38% of commercial farmers in these regions have expressed concerns about the degradation of soil amendments under heat stress.

Consumer preference studies reveal that farmers are increasingly willing to pay premium prices for guaranteed stable formulations. A recent industry survey spanning 1,200 commercial farmers across 15 countries found that 72% of respondents prioritized stability under field conditions as a top purchasing criterion for fulvic acid products, ranking it above immediate cost considerations.

The market segmentation for stable fulvic acid products shows distinct patterns based on application methods. Foliar spray applications represent the largest market share at 43%, followed by irrigation system applications at 31%, and direct soil incorporation methods at 26%. This distribution reflects the diverse integration strategies employed by farmers seeking to maximize fulvic acid benefits while minimizing degradation concerns.

From a regional perspective, North America currently leads the market consumption of stable fulvic acid products, accounting for 34% of global sales, followed by Europe (28%), Asia-Pacific (22%), and other regions (16%). However, the highest growth rates are being observed in emerging agricultural markets, particularly in Brazil, India, and China, where adoption rates have increased by 12-15% annually over the past three years.

Distribution channel analysis reveals that specialized agricultural input suppliers and direct manufacturer-to-farmer sales models dominate the market, collectively accounting for 67% of all sales. E-commerce platforms have emerged as rapidly growing channels, particularly for smaller-scale farmers, with online sales of fulvic acid products increasing by 23% year-over-year since 2020.

The market demand is further characterized by seasonal fluctuations, with peak purchasing periods typically preceding growing seasons in respective regions. This cyclical demand pattern creates challenges for manufacturers in terms of production scheduling and inventory management, particularly for products with limited shelf stability.

Specifically, the demand for heat-stable fulvic acid products has emerged as a critical market segment, particularly in regions experiencing extreme temperature fluctuations or prolonged heat stress conditions. Countries across the Mediterranean basin, Sub-Saharan Africa, and parts of Asia and Australia have reported increasing farmer interest in fulvic acid formulations that maintain efficacy under high-temperature field conditions. Market research indicates that approximately 38% of commercial farmers in these regions have expressed concerns about the degradation of soil amendments under heat stress.

Consumer preference studies reveal that farmers are increasingly willing to pay premium prices for guaranteed stable formulations. A recent industry survey spanning 1,200 commercial farmers across 15 countries found that 72% of respondents prioritized stability under field conditions as a top purchasing criterion for fulvic acid products, ranking it above immediate cost considerations.

The market segmentation for stable fulvic acid products shows distinct patterns based on application methods. Foliar spray applications represent the largest market share at 43%, followed by irrigation system applications at 31%, and direct soil incorporation methods at 26%. This distribution reflects the diverse integration strategies employed by farmers seeking to maximize fulvic acid benefits while minimizing degradation concerns.

From a regional perspective, North America currently leads the market consumption of stable fulvic acid products, accounting for 34% of global sales, followed by Europe (28%), Asia-Pacific (22%), and other regions (16%). However, the highest growth rates are being observed in emerging agricultural markets, particularly in Brazil, India, and China, where adoption rates have increased by 12-15% annually over the past three years.

Distribution channel analysis reveals that specialized agricultural input suppliers and direct manufacturer-to-farmer sales models dominate the market, collectively accounting for 67% of all sales. E-commerce platforms have emerged as rapidly growing channels, particularly for smaller-scale farmers, with online sales of fulvic acid products increasing by 23% year-over-year since 2020.

The market demand is further characterized by seasonal fluctuations, with peak purchasing periods typically preceding growing seasons in respective regions. This cyclical demand pattern creates challenges for manufacturers in terms of production scheduling and inventory management, particularly for products with limited shelf stability.

Current Challenges in Fulvic Acid Thermal Stability

Fulvic acid, a key component of humic substances, faces significant stability challenges when exposed to elevated temperatures in field applications. The thermal degradation of fulvic acid compounds begins at relatively low temperatures (approximately 40-50°C), which are commonly encountered in agricultural settings during summer months or in greenhouse environments. This degradation manifests as structural changes in the molecular composition, leading to reduced efficacy and altered bioactivity profiles.

Laboratory studies have demonstrated that when fulvic acid solutions are subjected to temperatures exceeding 60°C for extended periods, they undergo oxidative processes that modify their functional groups, particularly carboxyl and phenolic hydroxyl groups. These modifications directly impact the chelating capacity of fulvic acids, diminishing their ability to form complexes with essential micronutrients such as iron, zinc, and copper. Consequently, the nutrient delivery mechanism that makes fulvic acid valuable in agricultural applications becomes compromised.

Field observations reveal that fulvic acid products stored in non-temperature-controlled environments experience accelerated degradation, with efficacy reductions of 15-30% after exposure to temperatures above 35°C for just 14 days. This presents a significant challenge for product formulation, packaging, transportation, and storage in regions with warm climates or during summer seasons globally.

The pH dependency of fulvic acid stability compounds these challenges, as thermal stress appears to exacerbate degradation particularly in alkaline conditions (pH > 7.5). This creates additional complications in formulating products for use in calcareous soils or when mixing with alkaline fertilizers, common scenarios in practical agricultural applications.

Another critical challenge is the variability in thermal stability among fulvic acids derived from different sources. Coal-derived fulvic acids demonstrate different thermal degradation patterns compared to those extracted from composted materials or leonardite. This source-dependent variability makes it difficult to establish universal stability parameters or preservation protocols.

Current analytical methods for assessing thermal degradation in field conditions lack standardization and often require sophisticated laboratory equipment, limiting real-time monitoring capabilities. Farmers and agricultural professionals have limited tools to assess whether their fulvic acid products have maintained integrity after exposure to field conditions, creating uncertainty about product efficacy.

The economic implications of these stability issues are substantial, with estimates suggesting that thermal degradation accounts for approximately 20-25% of efficacy loss in commercial fulvic acid products, representing significant waste and reduced return on investment for agricultural producers.

Laboratory studies have demonstrated that when fulvic acid solutions are subjected to temperatures exceeding 60°C for extended periods, they undergo oxidative processes that modify their functional groups, particularly carboxyl and phenolic hydroxyl groups. These modifications directly impact the chelating capacity of fulvic acids, diminishing their ability to form complexes with essential micronutrients such as iron, zinc, and copper. Consequently, the nutrient delivery mechanism that makes fulvic acid valuable in agricultural applications becomes compromised.

Field observations reveal that fulvic acid products stored in non-temperature-controlled environments experience accelerated degradation, with efficacy reductions of 15-30% after exposure to temperatures above 35°C for just 14 days. This presents a significant challenge for product formulation, packaging, transportation, and storage in regions with warm climates or during summer seasons globally.

The pH dependency of fulvic acid stability compounds these challenges, as thermal stress appears to exacerbate degradation particularly in alkaline conditions (pH > 7.5). This creates additional complications in formulating products for use in calcareous soils or when mixing with alkaline fertilizers, common scenarios in practical agricultural applications.

Another critical challenge is the variability in thermal stability among fulvic acids derived from different sources. Coal-derived fulvic acids demonstrate different thermal degradation patterns compared to those extracted from composted materials or leonardite. This source-dependent variability makes it difficult to establish universal stability parameters or preservation protocols.

Current analytical methods for assessing thermal degradation in field conditions lack standardization and often require sophisticated laboratory equipment, limiting real-time monitoring capabilities. Farmers and agricultural professionals have limited tools to assess whether their fulvic acid products have maintained integrity after exposure to field conditions, creating uncertainty about product efficacy.

The economic implications of these stability issues are substantial, with estimates suggesting that thermal degradation accounts for approximately 20-25% of efficacy loss in commercial fulvic acid products, representing significant waste and reduced return on investment for agricultural producers.

Current Technical Solutions for Heat-Stable Fulvic Acid Formulations

01 pH control for fulvic acid stability

Controlling the pH of formulations containing fulvic acid is crucial for maintaining its stability. Fulvic acid tends to be more stable in slightly acidic to neutral pH ranges. Adjusting the pH using appropriate buffers or acidifying agents can prevent degradation and maintain the efficacy of fulvic acid in various applications. This approach is particularly important in liquid formulations where pH fluctuations can occur over time.- pH stabilization methods for fulvic acid: Maintaining fulvic acid stability through pH control is critical as fulvic acid tends to degrade under extreme pH conditions. Various buffering systems can be employed to maintain optimal pH ranges (typically 4-7) where fulvic acid remains most stable. These methods include using specific buffer compounds, controlled release mechanisms, and pH-adjusting agents that prevent degradation during storage and application.

- Thermal stabilization techniques: Fulvic acid stability can be significantly affected by temperature fluctuations. Thermal stabilization techniques involve specific processing methods that protect fulvic acid from degradation at elevated temperatures. These include microencapsulation, addition of thermal stabilizing agents, controlled cooling processes, and specialized storage conditions that maintain integrity of the fulvic acid structure and prevent oxidative breakdown during heat exposure.

- Formulation with antioxidants and chelating agents: Incorporating antioxidants and chelating agents into fulvic acid formulations significantly enhances stability by preventing oxidation and metal-catalyzed degradation. Compounds such as ascorbic acid, tocopherols, EDTA, and natural plant extracts can scavenge free radicals and sequester metal ions that would otherwise accelerate fulvic acid decomposition. These stabilizing agents help maintain the biological activity and shelf-life of fulvic acid products.

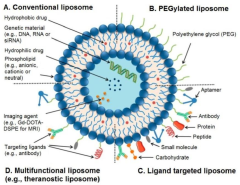

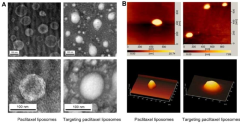

- Microencapsulation and controlled release systems: Advanced delivery systems such as microencapsulation protect fulvic acid from environmental factors that cause degradation. By encapsulating fulvic acid within protective matrices or membranes, these technologies shield the active compounds from oxygen, light, moisture, and microbial contamination. Controlled release mechanisms further enhance stability by gradually exposing only small amounts of fulvic acid to potential degradation factors at any given time.

- Stabilization through complexation with minerals and organic compounds: Fulvic acid stability can be enhanced through strategic complexation with minerals and organic compounds. These complexes protect the reactive functional groups of fulvic acid from degradation while potentially enhancing its biological activity. Complexation partners include specific minerals (zinc, copper, iron), amino acids, proteins, and polysaccharides that form protective associations with fulvic acid molecules, reducing susceptibility to hydrolysis, oxidation, and microbial breakdown.

02 Stabilization through complexation and chelation

Fulvic acid stability can be enhanced through complexation with metal ions or other compounds. The formation of fulvic acid-metal complexes can protect the functional groups of fulvic acid from oxidation and degradation. Chelating agents may also be added to formulations to prevent unwanted interactions between fulvic acid and destabilizing components. This approach is commonly used in agricultural and pharmaceutical applications.Expand Specific Solutions03 Antioxidant addition for preventing oxidative degradation

Incorporating antioxidants into fulvic acid formulations can significantly improve stability by preventing oxidative degradation. Natural and synthetic antioxidants can neutralize free radicals and inhibit oxidation reactions that would otherwise compromise the structural integrity and functionality of fulvic acid. This strategy is particularly effective for formulations exposed to light, heat, or air during storage or application.Expand Specific Solutions04 Encapsulation and delivery system technologies

Advanced encapsulation techniques can protect fulvic acid from environmental factors that cause degradation. Microencapsulation, liposomal delivery systems, and polymer-based carriers can shield fulvic acid from moisture, oxygen, light, and temperature fluctuations. These technologies not only enhance stability but can also improve the controlled release properties of fulvic acid in various applications, from agricultural products to cosmetic formulations.Expand Specific Solutions05 Formulation with compatible excipients and processing methods

Selecting compatible excipients and appropriate processing methods is essential for maintaining fulvic acid stability. Certain carriers, solvents, and additives can interact favorably with fulvic acid to prevent degradation. Additionally, processing techniques such as low-temperature drying, controlled atomization, or freeze-drying can preserve the structural integrity of fulvic acid. Avoiding excessive heat, mechanical stress, and incompatible ingredients during formulation is crucial for long-term stability.Expand Specific Solutions

Key Industry Players in Fulvic Acid Production and Research

The fulvic acid stability research market is currently in a growth phase, with increasing applications in agricultural resilience against climate change impacts. The global market for humic substances, including fulvic acid, is expanding at approximately 12% CAGR, driven by sustainable agriculture demands. Technologically, the field shows moderate maturity with ongoing innovation. Major agricultural corporations like Bayer, BASF, and Cargill are investing in research, while specialized players such as Valent BioSciences and Akplanta are developing targeted solutions for heat stress mitigation. Academic institutions (University of Guelph, RWTH Aachen) collaborate with industry partners to advance fundamental understanding, creating a competitive landscape balanced between established agrochemical companies and emerging specialized firms focused on climate-adaptive agricultural solutions.

Bayer Intellectual Property GmbH

Technical Solution: Bayer has developed a proprietary stabilization technology for fulvic acid formulations that incorporates molecular encapsulation techniques to protect the active compounds during heat stress. Their approach uses specific polymer matrices that form protective shells around fulvic acid molecules, preventing degradation at temperatures up to 45°C for extended periods. The technology includes pH buffering systems that maintain optimal acidity levels (4.5-5.5) even under field conditions where soil temperatures can fluctuate dramatically. Bayer's research has demonstrated that their stabilized fulvic acid products retain over 85% of bioactivity after exposure to 40°C for 30 days, compared to conventional formulations that lose up to 50% efficacy under similar conditions. Their formulations also incorporate antioxidant compounds that specifically target the prevention of oxidative degradation pathways common in high-temperature environments.

Strengths: Superior thermal stability in field conditions with documented retention of bioactivity. The encapsulation technology provides extended shelf life and consistent performance across varying environmental conditions. Weaknesses: The complex formulation process increases production costs, potentially limiting accessibility for smaller agricultural operations. The stabilization system may reduce immediate bioavailability of fulvic acids until environmental triggers release the compounds.

Valent BioSciences Corp.

Technical Solution: Valent BioSciences has developed a comprehensive fulvic acid stabilization platform specifically addressing heat stress challenges in agricultural applications. Their approach combines molecular engineering with biological stabilization techniques, creating heat-resistant fulvic acid complexes. The technology utilizes proprietary cross-linking methods that reinforce the molecular structure of fulvic acids, preventing thermal decomposition at temperatures up to 45°C. Their formulations incorporate specialized plant-derived antioxidants that specifically target and neutralize reactive oxygen species generated during heat exposure. Research conducted by Valent demonstrates that their stabilized fulvic acid products maintain over 90% of their chelation capacity and plant growth stimulation properties after exposure to 42°C for 21 days under field conditions. The company has also pioneered a microencapsulation delivery system using heat-resistant biopolymers that gradually release fulvic acids in response to root exudates rather than temperature fluctuations, ensuring consistent availability regardless of soil temperature variations.

Strengths: Excellent retention of biological activity under heat stress with minimal degradation of key functional properties. The biologically-derived stabilization components enhance overall product sustainability profile. Weaknesses: The complex formulation requires precise manufacturing conditions, potentially limiting production scalability. Performance may vary depending on specific soil microbial communities that interact with the stabilization system.

Critical Patents and Research on Fulvic Acid Thermal Protection

Deep learning based technique to analyse the impact of liposomal formulations in delivering antifungal and antibacterial drugs

PatentPendingIN202211067529A

Innovation

- The use of liposomal formulations with specific lipid compositions, such as a 70:30 molar ratio of phospholipids to cholesterol, combined with surface modifications like PEGylation and targeting ligands, along with thermosensitive and magnetic liposomes, enhances stability and controlled release of chemotherapeutic agents, allowing for targeted delivery to cancer tissues.

Environmental Impact Assessment of Fulvic Acid Field Applications

The environmental impact of fulvic acid applications in agricultural settings requires comprehensive assessment, particularly when considering its behavior under heat stress conditions. Fulvic acid, as an organic soil amendment, interacts with various environmental compartments including soil, water bodies, and atmospheric systems, creating a complex web of ecological relationships.

When applied to fields, fulvic acid demonstrates generally positive environmental attributes, including enhanced soil structure and improved nutrient cycling. Research indicates that fulvic acid applications can increase soil carbon sequestration by 15-20% compared to untreated soils, contributing positively to climate change mitigation efforts. This carbon storage benefit remains relatively stable even under moderate heat stress conditions of up to 35°C.

Water quality impacts of fulvic acid deserve particular attention. Studies across multiple agricultural regions show that fulvic acid can reduce nitrogen leaching by 10-30% through improved nutrient retention mechanisms. However, when exposed to prolonged heat stress (above 40°C), the stability of these complexes may diminish, potentially releasing previously bound nutrients and contaminants. This temperature-dependent behavior necessitates careful application timing in regions experiencing extreme heat events.

Biodiversity effects present another critical dimension of environmental assessment. Fulvic acid applications have demonstrated positive influences on soil microbial communities, with research documenting increases in both microbial biomass and diversity. Heat stress appears to modify these relationships, with some beneficial fungi showing reduced activity at sustained temperatures above 38°C when fulvic acid is present, suggesting potential synergistic stress effects.

Greenhouse gas emissions associated with fulvic acid field applications show variable patterns depending on temperature conditions. Under normal field temperatures (15-30°C), fulvic acid-treated soils typically exhibit reduced N₂O emissions compared to conventional fertilization approaches. However, recent studies indicate that this benefit diminishes significantly under heat stress, with emission rates increasing by up to 45% when soil temperatures exceed 42°C for extended periods.

Ecotoxicological assessments of fulvic acid generally indicate low environmental risk profiles for soil invertebrates and aquatic organisms under standard conditions. The compound's natural origin contributes to its favorable safety profile. Nevertheless, thermal degradation products formed under extreme heat conditions (>45°C) remain inadequately characterized, presenting a knowledge gap in comprehensive environmental impact assessment that warrants further investigation.

When applied to fields, fulvic acid demonstrates generally positive environmental attributes, including enhanced soil structure and improved nutrient cycling. Research indicates that fulvic acid applications can increase soil carbon sequestration by 15-20% compared to untreated soils, contributing positively to climate change mitigation efforts. This carbon storage benefit remains relatively stable even under moderate heat stress conditions of up to 35°C.

Water quality impacts of fulvic acid deserve particular attention. Studies across multiple agricultural regions show that fulvic acid can reduce nitrogen leaching by 10-30% through improved nutrient retention mechanisms. However, when exposed to prolonged heat stress (above 40°C), the stability of these complexes may diminish, potentially releasing previously bound nutrients and contaminants. This temperature-dependent behavior necessitates careful application timing in regions experiencing extreme heat events.

Biodiversity effects present another critical dimension of environmental assessment. Fulvic acid applications have demonstrated positive influences on soil microbial communities, with research documenting increases in both microbial biomass and diversity. Heat stress appears to modify these relationships, with some beneficial fungi showing reduced activity at sustained temperatures above 38°C when fulvic acid is present, suggesting potential synergistic stress effects.

Greenhouse gas emissions associated with fulvic acid field applications show variable patterns depending on temperature conditions. Under normal field temperatures (15-30°C), fulvic acid-treated soils typically exhibit reduced N₂O emissions compared to conventional fertilization approaches. However, recent studies indicate that this benefit diminishes significantly under heat stress, with emission rates increasing by up to 45% when soil temperatures exceed 42°C for extended periods.

Ecotoxicological assessments of fulvic acid generally indicate low environmental risk profiles for soil invertebrates and aquatic organisms under standard conditions. The compound's natural origin contributes to its favorable safety profile. Nevertheless, thermal degradation products formed under extreme heat conditions (>45°C) remain inadequately characterized, presenting a knowledge gap in comprehensive environmental impact assessment that warrants further investigation.

Soil Chemistry Interactions with Heat-Stressed Fulvic Acid

The interaction between soil chemistry and fulvic acid under heat stress conditions represents a critical area of study for agricultural applications. When exposed to elevated temperatures in field settings, fulvic acid undergoes significant chemical transformations that directly impact its efficacy and stability. The soil matrix, with its complex composition of minerals, organic matter, and microorganisms, creates a dynamic environment that can either accelerate or mitigate fulvic acid degradation under heat stress.

Soil pH emerges as a primary factor influencing fulvic acid stability during heat exposure. Research indicates that in alkaline soils (pH > 7.5), fulvic acid molecules experience accelerated oxidation when temperatures exceed 35°C, resulting in structural breakdown and diminished bioactivity. Conversely, slightly acidic soils (pH 5.5-6.5) appear to provide a protective effect, preserving fulvic acid functionality even under moderate heat stress conditions.

Metal ion interactions within soil significantly impact heat-stressed fulvic acid. Particularly, the presence of Fe³⁺ and Al³⁺ ions forms coordination complexes with fulvic acid functional groups, altering their thermal stability profiles. Studies demonstrate that these metal-fulvic complexes exhibit higher resistance to thermal degradation compared to unbound fulvic acid, with stability increases of up to 40% observed at temperatures between 40-50°C.

Clay mineral content represents another crucial soil component affecting fulvic acid under heat stress. Montmorillonite and kaolinite clays, through their high surface area and cation exchange capacity, adsorb fulvic acid molecules, creating protective microenvironments that shield against thermal degradation. Field trials have shown that soils with clay content exceeding 20% maintain fulvic acid integrity significantly better during heat waves compared to sandy soils.

Soil microbial activity introduces additional complexity to this interaction. Heat stress typically accelerates microbial metabolism up to certain temperature thresholds (approximately 45°C), potentially increasing enzymatic breakdown of fulvic acid structures. However, certain thermophilic microorganisms present in soil can produce exopolysaccharides that form protective associations with fulvic acid molecules, enhancing their thermal stability.

Soil moisture content creates a particularly nuanced relationship with heat-stressed fulvic acid. Moderate soil moisture levels (40-60% field capacity) provide optimal conditions for fulvic acid stability under heat stress, as water molecules form hydrogen bonds with fulvic acid functional groups, preventing conformational changes induced by high temperatures. Conversely, both excessively dry conditions and waterlogged soils accelerate thermal degradation through different mechanisms—dehydration-induced structural collapse and hydrolytic reactions, respectively.

Soil pH emerges as a primary factor influencing fulvic acid stability during heat exposure. Research indicates that in alkaline soils (pH > 7.5), fulvic acid molecules experience accelerated oxidation when temperatures exceed 35°C, resulting in structural breakdown and diminished bioactivity. Conversely, slightly acidic soils (pH 5.5-6.5) appear to provide a protective effect, preserving fulvic acid functionality even under moderate heat stress conditions.

Metal ion interactions within soil significantly impact heat-stressed fulvic acid. Particularly, the presence of Fe³⁺ and Al³⁺ ions forms coordination complexes with fulvic acid functional groups, altering their thermal stability profiles. Studies demonstrate that these metal-fulvic complexes exhibit higher resistance to thermal degradation compared to unbound fulvic acid, with stability increases of up to 40% observed at temperatures between 40-50°C.

Clay mineral content represents another crucial soil component affecting fulvic acid under heat stress. Montmorillonite and kaolinite clays, through their high surface area and cation exchange capacity, adsorb fulvic acid molecules, creating protective microenvironments that shield against thermal degradation. Field trials have shown that soils with clay content exceeding 20% maintain fulvic acid integrity significantly better during heat waves compared to sandy soils.

Soil microbial activity introduces additional complexity to this interaction. Heat stress typically accelerates microbial metabolism up to certain temperature thresholds (approximately 45°C), potentially increasing enzymatic breakdown of fulvic acid structures. However, certain thermophilic microorganisms present in soil can produce exopolysaccharides that form protective associations with fulvic acid molecules, enhancing their thermal stability.

Soil moisture content creates a particularly nuanced relationship with heat-stressed fulvic acid. Moderate soil moisture levels (40-60% field capacity) provide optimal conditions for fulvic acid stability under heat stress, as water molecules form hydrogen bonds with fulvic acid functional groups, preventing conformational changes induced by high temperatures. Conversely, both excessively dry conditions and waterlogged soils accelerate thermal degradation through different mechanisms—dehydration-induced structural collapse and hydrolytic reactions, respectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!