Improving The Pressure Resistance Of Check Valves

Technology Background And Goals

Achieving this goal requires a comprehensive understanding of the underlying principles governing fluid dynamics, material science, and valve design. It involves exploring innovative materials, optimizing valve geometries, and implementing advanced manufacturing techniques to create robust and durable check valve solutions. Ultimately, the successful development of this technology would contribute to increased system reliability, reduced maintenance costs, and enhanced safety in critical fluid handling operations across various industries.

Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, and water treatment. Factors such as infrastructure development, urbanization, and the need for efficient fluid control systems contribute to market expansion. - Industry Trends

Key trends shaping the check valve market include the demand for high-performance and durable valves, the adoption of advanced materials for improved corrosion resistance, and the integration of smart technologies for remote monitoring and predictive maintenance. - Application Sectors

Check valves find widespread applications across various sectors, including:- Oil and gas: Upstream, midstream, and downstream operations

- Chemical processing: Handling corrosive and hazardous fluids

- Power generation: Thermal and nuclear power plants

- Water and wastewater treatment: Preventing backflow and regulating flow

- Regional Dynamics

The Asia-Pacific region is expected to be a significant market for check valves, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold substantial market shares due to stringent regulations and the presence of established industries.

Technology Status And Challenges

- Valve Design Limitations

Current check valve designs have inherent limitations in withstanding high pressures, leading to potential failures and safety concerns. - Material Constraints

Traditional materials used in valve construction, such as metals and polymers, have limited strength and durability under extreme pressure conditions. - Sealing Challenges

Maintaining an effective seal at high pressures is a significant challenge, as leakage can occur due to deformation or wear of sealing components. - Fatigue and Erosion

Repeated exposure to high pressures can cause fatigue and erosion of valve components, compromising their structural integrity and performance. - Extreme Environment Compatibility

Certain applications, such as deep-sea or high-temperature environments, impose additional challenges on valve materials and designs.

Current Technical Solutions

01 High-Pressure Resistant Structure

The check valve structure is designed to withstand high pressure conditions, involving robust materials, reinforced components, and optimized valve geometry for reliable operation under elevated pressure levels.- High-Pressure Resistant Structure: The check valve structure is designed to withstand high pressure conditions, using robust materials, reinforced components, and optimized geometry to enhance pressure resistance and prevent leakage or failure.

- Pressure Relief Mechanism: Some check valves incorporate a pressure relief mechanism to prevent excessive pressure buildup, allowing the release of excess pressure and protecting the valve and system components from damage.

- Pressure-Responsive Sealing: These check valves feature sealing mechanisms that respond to pressure changes, enhancing the sealing force or contact area between components to improve high-pressure resistance and prevent leakage.

- Pressure-Balanced Design: Pressure-balanced check valve designs aim to minimize the effects of pressure on the valve components, using counterbalancing forces or pressure-equalizing chambers to reduce the net force acting on the valve.

- Pressure-Assisted Operation: In these check valves, the pressure differential across the valve is utilized to assist in the opening or closing of the valve, ensuring reliable operation under varying pressure conditions.

02 Pressure-Resistant Sealing Mechanisms

The sealing mechanisms employed in check valves play a crucial role in ensuring pressure resistance, including specialized sealing materials, geometries, and surface treatments to prevent leakage under high pressure.Expand Specific Solutions03 High-Pressure Materials

The selection of high-strength metals, alloys, or composite materials used in check valve construction is critical for achieving pressure resistance and withstanding stresses in high-pressure environments.Expand Specific Solutions04 Pressure Surge Protection

Check valves can be designed to protect against pressure surges or water hammer effects, incorporating pressure relief mechanisms, dampening systems, or specialized valve configurations to mitigate stress on components.Expand Specific Solutions05 Pressure Resistance Testing and Validation

Rigorous testing and validation procedures are employed to ensure the pressure resistance of check valves, including simulated high-pressure conditions, burst pressure tests, and accelerated life cycle testing.Expand Specific Solutions

Technology Main Player Analysis

Hitachi Ltd.

Robert Bosch GmbH

Key Technology Interpretation

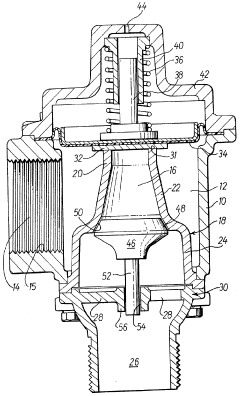

- The check valve assembly comprises two individual pressure responsive valves in series, where one valve closes firmly at high back pressures and the other valve closes firmly at low back pressures, preventing reverse flow in both high and low back pressure conditions.

- The two individual pressure responsive valves are integrated into a common housing, providing a compact and efficient design for the check valve assembly.

- The check valve assembly allows forward flow of the pressure medium from the source to the reservoir while preventing reverse flow in both high and low back pressure conditions.

Check Valve Pressure Resistance Improvement Economic Impact

Evaluating the economic impact of improving the pressure resistance of check valves reveals several key insights. Enhancing the durability and efficiency of these valves can lead to significant cost savings, particularly in industries reliant on fluid control systems such as oil and gas, water treatment, and chemical processing. Improved pressure resistance can extend the service life of the valves, reducing maintenance costs and downtime. This directly translates to enhanced operational efficiency and productivity.

Moreover, by increasing the reliability of check valves, companies can avoid potential catastrophic failures that may lead to environmental damages and regulatory penalties. This not only saves costs but also protects brand reputation and stakeholder trust. In a competitive market, the ability to provide more robust and efficient valves could also strengthen market positioning and increase market share.

Innovations in this domain may also spur demand for these advanced valves, thereby fostering growth within the industry. This could lead to increased revenue opportunities for both existing players and new entrants who capitalize on these technological advancements. As a result, investments in research and development aimed at improving the pressure resistance of check valves could yield substantial economic benefits across various sectors.