Optimizing Fluid Flow Design For Check Valves

Check Valve Technology Background And Goals

By establishing a solid understanding of the technological background and objectives, this section lays the foundation for further analysis and strategic planning in subsequent sections of the report. It sets the context and highlights the significance of optimizing fluid flow design for check valves, paving the way for a more in-depth exploration of market demands, technological challenges, and potential solutions.

Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, chemical processing, and water treatment. Key factors fueling this demand include the need for efficient fluid control, prevention of backflow, and compliance with safety regulations. - Industry Trends

Emerging trends shaping the check valve market include the adoption of advanced materials for improved durability and corrosion resistance, the integration of smart monitoring systems for predictive maintenance, and the development of compact and lightweight designs for space-constrained applications. - Regional Dynamics

The Asia-Pacific region is anticipated to be a major contributor to the check valve market growth, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe are also expected to witness steady demand due to stringent regulations and the need for equipment upgrades.

Technology Status And Challenges

- Valve Design Challenges

Intricate flow patterns and high-velocity fluid streams pose significant design hurdles for optimizing check valve performance. - Material Limitations

Existing valve materials may not withstand extreme pressures, temperatures, or corrosive environments, necessitating advanced material research. - Sealing Effectiveness

Ensuring reliable sealing under varying conditions is crucial to prevent leakage and maintain system integrity. - Noise and Vibration

Turbulent flow and valve operation can generate excessive noise and vibration, requiring mitigation strategies. - Maintenance and Reliability

Frequent maintenance or premature failure can lead to costly downtime, highlighting the need for robust and reliable designs.

Current Technical Solutions

01 Fluid Flow Direction Control

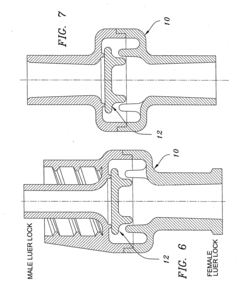

Check valves allow fluid flow in one direction while preventing backflow, commonly used in pumping systems, pipelines, and hydraulic systems, with movable components like balls, discs, or swings.- Fluid Flow Direction Control: Check valves allow fluid flow in one direction while preventing backflow, maintaining proper flow direction and preventing reverse flow that can cause damage or malfunction.

- Improved Sealing and Flow Characteristics: Various designs enhance sealing performance and optimize fluid flow, incorporating features like improved sealing surfaces, reduced turbulence, and minimized pressure drop for increased efficiency and reliability.

- Application-Specific Check Valves: Check valves can be designed for specific applications or environments, such as high-temperature, high-pressure, corrosive fluids, or specialized industries like oil and gas, chemical processing, or aerospace.

- Materials and Construction: Check valves can be constructed from various materials like metals, plastics, or composites to withstand different operating conditions, fluid compatibility, and durability requirements, impacting performance and service life.

- Installation, Maintenance, and Testing: Proper installation, maintenance, and testing procedures are crucial for reliable operation, including guidelines for valve orientation, accessibility for inspection and maintenance, and testing methods to verify functionality and leak-tightness.

02 Improved Sealing and Flow Characteristics

Various designs enhance sealing performance and optimize fluid flow, incorporating improved sealing surfaces, specialized valve seat geometries, additional sealing components, and reduced pressure drop and turbulence.Expand Specific Solutions03 Application-Specific Check Valves

Check valves can be designed for specific applications or environments, such as high-temperature, cryogenic, corrosive or abrasive fluids, subsea or extreme pressure, with tailored materials, coatings, and construction.Expand Specific Solutions04 Check Valve Assemblies and Integration

Check valves can be integrated into larger valve assemblies or combined with other components like relief or isolation valves, arranged in series or parallel for specific flow control requirements or redundancy and fail-safe operation.Expand Specific Solutions05 Maintenance, Testing, and Monitoring

Techniques and methods related to maintenance, testing, and monitoring of check valves, including inspection, servicing, testing procedures, and systems for monitoring and diagnosing performance during operation.Expand Specific Solutions

Main Player Analysis

Schlumberger Technologies, Inc.

Bendix Commercial Vehicle Systems LLC

Key Technology Interpretation

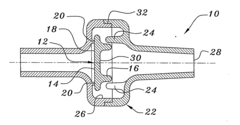

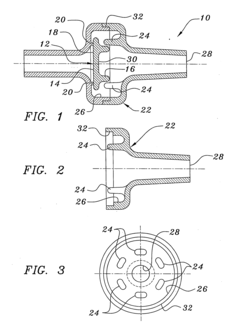

- The valve features a free-floating disc-shaped check valve that is held in the center by finger-shaped projections, allowing for maximized fluid flow rate and minimized failure due to the valve member becoming stuck.

- The valve body is made of a single piece of elastomeric material coated with a non-stick material, minimizing friction between the valve member and valve body.

- The valve member is enclosed inside the valve body and can be visually inspected, allowing for easy monitoring of the valve's operation.

Check Valve Fluid Flow Optimization Economic Impact

The deployment of check valves with optimized fluid flow design can have substantial economic impacts across multiple industries. By enhancing fluid dynamics and reducing flow resistance, these valves contribute to increased operational efficiency in systems such as pipelines and HVAC installations. This efficiency leads to cost savings through lower energy consumption and reduced wear and tear on system components, which in turn extends equipment lifespans and minimizes maintenance expenses.

Furthermore, improved valve design may lead to competitive advantages for businesses by enabling them to offer more reliable and durable products, thus capturing larger market shares and potentially commanding higher price points. The optimization of these valves supports sustainable practices by lowering the overall carbon footprint, aligning with global energy efficiency standards and potentially qualifying industries for tax incentives related to environmental compliance.

The cumulative economic impact of adopting advanced check valve designs includes reduced utility costs, decreased environmental penalties, and enhanced market positioning. These factors collectively can significantly influence bottom-line profitability and foster competitive resilience in an increasingly environmentally-conscious market landscape.

Check Valve Fluid Flow Optimization Environmental Impact

Check valves with optimized fluid flow design are a pivotal innovation in the field of industrial mechanics with substantial environmental implications. By enhancing fluid flow efficiency, these valves reduce energy consumption across various systems, minimizing the carbon footprint associated with pumping and fluid transportation. The design optimization leads to less turbulence and friction losses, meaning that systems operate more effectively with less energy required to achieve the same level of performance. Additionally, the improved efficiency prolongs the operational lifespan of the systems, thereby reducing material waste and the frequency of replacements, which in turn lessens the environmental burden of manufacturing new components.

Moreover, these valves can be instrumental in the efficient management of water resources, an increasingly critical global issue. By facilitating smoother fluid flow, they help in reducing leakage and maintaining optimal water usage levels. The sustainable impact is further underscored by the potential reduction in chemical treatments needed for maintenance, promoting a cleaner operational environment. As industries worldwide seek solutions to comply with stringent environmental regulations, these valves offer an innovative pathway to achieving better eco-performance without compromising on functional efficacy. Consequently, the environmental benefits of check valves with optimized fluid flow design make them a crucial component in advancing sustainable industrial practices.